Professional Documents

Culture Documents

Katalog Steel

Uploaded by

Muhammad YusufCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Katalog Steel

Uploaded by

Muhammad YusufCopyright:

Available Formats

NORSOK STANDARD

COMMON REQUIREMENTS

MATERIAL DATA SHEETS FOR STRUCTURAL STEEL

M-CR-120

Rev. 1, December 1994

Please note that whilst every effort has been made to ensure the accuracy of the NORSOK standards neither OLF nor

TBL or any of their members will assume liability for any use thereof.

1 FOREWORD

This standard has been developed by the NORSOK standardisation work group and agreed by the

Norwegian industry for the widest possible national and international application.

2 SCOPE

This Standard is a collection of the Material Data Sheets (MDS) applicable to selected material

standards and grades for use in steel structures. The scope for the MDSes is as follows:

The materials shall be delivered in accordance with the standard referred to. In addition the MDS

specifies the selected options in the referred standard and modified requirements which shall

supersede the corresponding requirements in the referred standard.

3 NORMATIVE REFERENCES

As stated in the individual data sheets.

4 DEFINITIONS

MDS Material data sheet

M-CR-120, Rev. 1, December 1994 page 1

5 COLLECTION OF MATERIAL DATA SHEETS

5.1 General

The material selection menu for the actual strength levels and grades is shown in table 1.

All listed MDS' are enclosed.

The grades 235 and 275 (MDS Y01 and Y02) shall not be used for thicknesses above 25 mm.

5.2 Selection Criteria

The number of steel grades used in a project should be limited to the practical minimum (preferably

one). An evaluation should be carried out to determined the optimum grade.

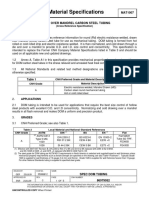

Table 1: Material Data Sheets for Structural Steel

NORSOK Standard Product Type Steel MDS

Steel Grade Quality number

Level

S 235 JR G2 EN 10 025 Plates, Sections and Seamless IV Y01

tubulars

S 275 JR EN 10 025 Plates, Sections and Seamless IV Y02

tubulars

S 355 J2 G3NO 1 EN 10 025prEN Plates, Sections and Seamless III Y03

10225 tubulars

S 355 NLO 5 prEN 10225 Plates I Y20

S 355 NLO 5 prEN 10225 Rolled Sections I Y21

S 355 NLO 5 prEN 10225 Seamless Tubulars I Y22

S 355 NLO 3 prEN 10225 Plates II Y25

S 355 NLO 3 prEN 10225 Rolled Sections II Y26

S 355 NLO 3 prEN 10225 Seamless Tubulars II Y27

M-CR-120, Rev. 1, December 1994 page 2

S 420 QLO 4 prEN 10225 Plates I Y30

S 420 QLO 4 prEN 10225 Rolled Sections I Y31

S 420 QLO 2 (mod) prEN 10225 Seamless Tubulars I Y32

S 420 QLO 2 prEN 10225 Plates II Y35

S 420 QLO 2 prEN 10225 Rolled Sections II Y36

S 420 QLO 2 prEN 10225 Seamless Tubulars II Y37

S 460 QLO 4 prEN 10225 Plates I Y40

S 460 QLO 4 prEN 10225 Rolled Sections I Y41

S 460 QLO 2 (mod) prEN 10225 Seamless Tubulars I Y42

S 460 QLO 2 prEN 10225 Plates II Y45

S 460 QLO 2 prEN 10225 Rolled Sections II Y46

S 460 QLO 2 prEN 10225 Seamless Tubulars II Y47

S 500 QLO 4 1) prEN 10225 Plates I Y50

S 500 QLO 4 1) prEN 10225 Rolled Sections I Y51

S 500 QLO 4 1) prEN 10225 Seamless Tubulars I Y52

S 500 QLO 2 1) prEN 10225 Plates II Y55

S 500 QLO 2 1) prEN 10225 Rolled Sections II Y56

S 500 QLO 2 1) prEN 10225 Seamless Tubulars II Y57

Note 1): This steel grade designation is not included in prEN 10225.

M-CR-120, Rev. 1, December 1994 page 3

MATERIAL DATA SHEET MDS - Y01 Rev. 1

TYPE OF MATERIAL: Structural Steel, Grade 235

PRODUCT STANDARD GRADE

Plates, sections and EN 10 025 S 235 JR G2

seamless tubulars

SCOPE This MDS specifies the selected options in the referred standard and modified

requirements which shall supersede the corresponding requirements in the referred

standard. This grade shall not be used for thicknesses above 25mm.

STEEL GRADE Grades S 235 J0, S 235 J2 G3, S 235 J2 G4 are acceptable as substitutes.

QUALIFICATIONS

HEAT The steel shall comply with deoxidisation type ‘'FN'', ref. option 3.

TREATMENT/DELIVERY

CONDITION

CHEMICAL

COMPOSITION

TENSILE TESTING

EXTENT OF TESTING

DIMENSIONS /

TOLERANCES

NON DESTRUCTIVE

EXAMINATION (NDE)

SURFACE PROTECTION The surface of the material shall comply to Rustgrade A or B or better according to ISO

8501-1.

MARKING

CERTIFICATION EN 10 204 Type 2.2.

M-CR-120, Rev. 1, December 1994 page 4

MATERIAL DATA SHEET MDS - Y02 Rev. 1

TYPE OF MATERIAL:

Structural Steel, Grade 275

PRODUCT STANDARD GRADE

Plates, sections and EN 10 025 S 275 JR

seamless tubulars

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard. This grade shall

not be used for thicknesses above 25mm.

STEEL GRADE Grades S 275 JO, S 275 J2 G3 and S 275 J2 G4 are acceptable as substitutes.

QUALIFICATIONS

HEAT

TREATMENT/

DELIVERY

CONDITION

CHEMICAL

COMPOSITION

TENSILE TESTING

EXTENT OF

TESTING

DIMENSIONS /

TOLERANCES

NON

DESTRUCTIVE

EXAMINATION

(NDE)

SURFACE The surface of the material shall comply to Rustgrade A or B or better according to ISO 8501-1.

PROTECTION

MARKING

CERTIFICATION EN 10 204 Type 2.2.

M-CR-120, Rev. 1, December 1994 page 5

MATERIAL DATA SHEET MDS - Y03 Rev. 1

TYPE OF MATERIAL:

Structural Steel, Grade 355

PRODUCT STANDARD GRADE

Plates and sections EN 10 025 S 355 J2 G3

Seamless tubulars prEN 10225 NO 1

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

STEEL GRADE For plates and sections, EN 10025 Grade S 355 K2 G3 is acceptable as substitute.

QUALIFICATIONS

HEAT

TREATMENT/

DELIVERY

CONDITION

CHEMICAL

COMPOSITION

TENSILE TESTING

EXTENT OF

TESTING

DIMENSIONS /

TOLERANCES

NON

DESTRUCTIVE

EXAMINATION

(NDE)

SURFACE The surface of the material shall comply to Rustgrade A or B or better according to ISO 8501-1.

PROTECTION

MARKING

CERTIFICATION EN 10 204 Type 3.1.B.

M-CR-120, Rev. 1, December 1994 page 6

MATERIAL DATA SHEET MDS - Y20 Rev. 1

TYPE OF MATERIAL:

Structural Steel with documented through thickness properties, Grade S 355 NLO 5

PRODUCT STANDARD GRADE

Plates prEN 10225 S 355 NLO 5

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid/ be established prior to delivery:The documentation of base material shall include

strain ageing tests (ref. option 11), Charpy V-notch transition curves and typical tensile test

results for plates within each of the following thickness ranges that are relevant for the order:

25<t < 40mm

40<t < 63mm

63<t < 100mm

100<t < 150mm

Documentation of base material and weldability tests shall cover both as-delivered and PWHT

condition and the material shall comply with the specified requirements in PWHT condition.

Weldability tests in accordance with Annex F shall be carried out within each of these thickness

ranges (option 17). CTOD testing shall be included and shall meet a requirement of min. 0.25 mm

(as-welded)/min. 0.20 mm (PWHT condition), unless a lower value has been accepted by the

purchaser.

HEAT Quenched and Tempered , Normalized, TMCR (Option 5).

TREATMENT/

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in the standard and any other elements intentionally added, and both CEV and Pcm values

(option 6,7,8). The chemical composition shall be modified as follows: Nmax : 0.012%,

CEVmax: 0.41, Pcm max 0.21%.

TENSILE

TESTING

EXTENT OF Through thickness testing shall be carried out for t> 25 mm (option 12).

TESTING

DIMENSIONS /

TOLERANCES

NON

DESTRUCTIVE

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 7

MATERIAL DATA SHEET MDS - Y21 Rev. 1

TYPE OF MATERIAL:

Structural Steel with documented through thickness properties, grade S 355 NLO 5

PRODUCT STANDARD GRADE

Rolled Sections prEN 10225 S 355 NLO 5

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid/ be established prior to delivery:The documentation of base material shall include

Charpy V-notch transition curves and typical tensile test results for rolled sections with thickness

approximately 20mm or the greatest section thickness required in the Purchase Order.Weldability

tests in accordance with Annex F shall be carried out for thicknesses above 25 mm (option 17).

HEAT Quenched and Tempered , Normalized, TMCR (Option 5)

TREATMENT/

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in the Standard and any other elements intentionally added, and both Pcm and CEV values.

(Option 6, 7, 8). The chemical composition shall be modified as follows: Nmax : 0.012%, Pcm

max 0.22%

TENSILE TESTING

EXTENT OF Through thickness testing shall be carried out in for t > 25 mm (option 12).

TESTING

DIMENSIONS /

TOLERANCES

NON Ultrasonic examination of webs and flanges are required for web thicknesses above 12 mm

DESTRUCTIVE (option para 7.7.2.3)

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 8

MATERIAL DATA SHEET MDS - Y22 Rev. 1

TYPE OF MATERIAL:

Structural Steel with documented through thickness properties, Grade S 355 NLO5

PRODUCT STANDARD GRADE

Seamless prEN 10225 S 355 NLO 5

tubulars(Seamless

hollow sections)

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid/ be established prior to delivery:The documentation of base material shall include

Charpy V-notch transition curves and typical tensile test results for tubulars with thickness

approximately 20 mm or the greatest wall thickness required in the Purchase Order.Weldability

tests in accordance with Annex F shall be carried out for tubular thicknesses above 25 mm

(option 17).

HEAT Quenched and Tempered , Normalised (Option 5).

TREATMENT/

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in the Standard and any other elements intentionally added, and both Pcm and CEV values

(option 6, 7, 8). The chemical composition in Table 9 shall be modified as follows: Cmax :

0.16%, Nb+Vmax: 0.07, Pcm max 0.22%

TENSILE

TESTING

EXTENT OF Through thickness testing shall be carried out for t > 25 mm (option 12).

TESTING

DIMENSIONS /

TOLERANCES

NON Ultrasonic examination to prEN 10246-14 (option 24).

DESTRUCTIVE

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 9

MATERIAL DATA SHEET MDS - Y25 Rev. 1

TYPE OF MATERIAL:

Structural Steel, Grade S 355 NLO 3

PRODUCT STANDARD GRADE

Plates prEN 10225 S 355 NLO 3

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid / be established prior to delivery:The documentation of base material shall include

strain ageing tests (ref. option 11), Charpy V-notch transition curves and typical tensile test

results for plates within each of the following thickness ranges that are relevant for the order:

25 <t < 40 mm

40 <t < 63 mm

63 <t < 100 mm

100 <t < 150 mm

Documentation of base material and weldability tests shall cover both as-delivered and PWHT

condition and the material shall comply with the specified requirements in PWHT

condition.Weldability tests in accordance with Annex F shall be carried out within each of these

thickness ranges (option 17). CTOD testing shall be included and shall meet a requirement of

min. 0.25 mm (as-welded)/min. 0.20 mm (PWHT condition), unless a lower value has been

accepted by the purchaser.

HEAT Quenched and Tempered , Normalised, TMCR (Option 5).

TREATMENT/

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in the Standard and any other elements intentionally added, and both Pcm and CEV value

(option 6, 7, 8). The chemical composition shall be modified as follows: Nmax: 0.012%,

CEVmax: 0.41, Pcm max 0.21%.

TENSILE

TESTING

EXTENT OF

TESTING

DIMENSIONS /

TOLERANCES

NON

DESTRUCTIVE

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 10

MATERIAL DATA SHEET MDS - Y26 Rev. 1

TYPE OF MATERIAL:

Structural Steel, Grade S 355 NLO 3

PRODUCT STANDARD GRADE

Rolled Sections prEN 10225 S355 NLO 3

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid/ be established prior to delivery:The documentation of base material shall include

Charpy V-notch transition curves and typical tensile test results for rolled sections with thickness

approximately 20 mm or the greatest section thickness required in the Purchase

Order.Weldability tests in accordance with Annex F shall be carried out for thicknesses above 25

mm (option 17).

HEAT Quenched and Tempered , Normalised, TMCR (Option 5).

TREATMENT/

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in the Standard and any other elements intentionally added, and both Pcm and CEV values.

(option 6, 7, 8). The chemical composition shall be modified as follows: Nmax : 0.012%, Pcm

max 0.22%

TENSILE TESTING

EXTENT OF

TESTING

DIMENSIONS /

TOLERANCES

NON

DESTRUCTIVE

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 11

MATERIAL DATA SHEET MDS - Y27 Rev. 1

TYPE OF MATERIAL:

Structural Steel, Grade S 355 NLO 3

PRODUCT STANDARD GRADE

Seamless prEN 10225 S355 NLO 3

tubulars(Seamless

hollow sections)

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid/ be established prior to delivery:The documentation of base material shall include

Charpy V-notch transition curves and typical tensile test results for tubular with thickness

approximately 20 mm or the greatest wall thickness required in the Purchase Order.Weldability

tests in accordance with Annex F shall be carried out for tubular thicknesses above 25 mm

(option 17).

HEAT Quenched and Tempered , Normalised (Option 5).

TREATMENT/

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in table 9 and any other elements intentionally added, and both Pcm and CEV values

(option 6, 7, 8). The chemical composition shall be modified as follows: Cmax : 0.16%, Pcm max

0.22%

TENSILE

TESTING

EXTENT OF

TESTING

DIMENSIONS /

TOLERANCES

NON

DESTRUCTIVE

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 12

MATERIAL DATA SHEET MDS - Y30 Rev. 1

TYPE OF MATERIAL:

Structural Steel, with documented through thickness properties, Grade S 420 QLO4

PRODUCT STANDARD GRADE

Plates prEN 10225 S 420 QLO 4

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid/ be established prior to delivery:The documentation of base material shall include

strain ageing tests (ref. option 11), Charpy V-notch transition curves and typical tensile test

results for plates within each of the following thickness ranges that are relevant for the order:

25<t < 40 mm

40<t < 63 mm

63<t < 80 mm

80<t < 100 mm

Documentation of base material and weldability tests shall cover both as-delivered and PWHT

condition and the material shall comply with the specified requirements in PWHT

condition.Weldability tests in accordance with Annex F shall be carried out within each of these

thickness ranges (option 17). CTOD testing shall be included and shall meet a requirement of

min. 0.25 mm (as-welded)/min. 0.20 mm (PWHT condition), unless a lower value has been

accepted by the purchaser.

HEAT Quenched and Tempered , Normalised, TMCR (Option 5)

TREATMENT/

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in the Standard and any other elements intentionally added, and both Pcm and CEV values.

(option 6, 7, 8). The chemical composition shall be modified as follows: Smax: 0.005%,

Nb+Vmax: 0.07%, CEVmax: 0.41, Pcm max 0.21%.

TENSILE Mechanical properties given in Table 4b shall be modified as follows:

TESTING Yield Strength (min.) : 420 MPa (all thicknesses)

Tensile Strength : 500-660 MPa (all thicknesses)

EXTENT OF Through thickness testing shall be carried out for t > 25 mm (option 12).

TESTING

DIMENSIONS /

TOLERANCES

NON

DESTRUCTIVE

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 13

MATERIAL DATA SHEET MDS - Y31 Rev. 1

TYPE OF MATERIAL:

Structural Steel with documented through thickness properties, Grade S 420 QLO4

PRODUCT STANDARD GRADE

Rolled Sections prEN 10225 S 420 QLO4

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid/ be established prior to delivery:The documentation of base material shall include

Charpy V-notch transition curves and typical tensile test results for rolled sections with thickness

approximately 20 mm or the greatest section thickness required in the Purchase

Order.Weldability tests in accordance with Annex F shall be carried out for the largest thickness

of the delivery, within ± 5 mm. (Ref. option 17)

HEAT Quenched and Tempered , Normalised, TMCR (option 5)

TREATMENT/

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in the Standard and any other elements intentionally added, and both Pcm and CEV values

(option 6, 7 and 8). The chemical composition shall be modified as follows: Pcm max 0.22%

TENSILE TESTING Mechanical properties given in Table 6 shall be modified as follows:

Yield Strength (min.) : 420 MPa (all thicknesses)

Tensile Strength : 500-660 MPa (all thicknesses)

EXTENT OF Through thickness testing shall be carried out for t >= 25 mm (option 12).

TESTING

DIMENSIONS /

TOLERANCES

NON Ultrasonic examination of webs and flanges are required for web thicknesses above 12 mm

DESTRUCTIVE (option para 7.7.2.3)

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 14

MATERIAL DATA SHEET MDS - Y32 Rev. 1

TYPE OF MATERIAL:

Structural Steel with documented through thickness properties, Grade S 420 QLO2 (mod).

PRODUCT STANDARD GRADE

Seamless prEN 10225 S 420 QLO2(mod).

tubulars(Seamless

hollow sections)

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid/ be established prior to delivery:The documentation of base material shall include

Charpy V-notch transition curves and typical tensile test results for tubulars with thickness

approximately 20 mm or the greatest wall thickness required in the Purchase Order.Weldability

tests in accordance with Annex F shall be carried out for the largest tubular thickness of the

delivery, within ± 5 mm (option 17).

HEAT Quenched and Tempered , Normalised (option 5).

TREATMENT/

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in the Standard and any other elements intentionally added, and both Pcm and CEV values

(option 6, 7, 8). The chemical composition in Table 9 shall be modified as follows: Nb+Vmax:

0.07%, Pcm max 0.22%

TENSILE Mechanical properties given in Table 10 shall be modified as follows:

TESTING Yield Strength (min.) : 420 MPa (all thicknesses)

Tensile Strength : 500-660 MPa (all thicknesses)

EXTENT OF Through thickness testing shall be carried out for t >= 25 mm (option 12).

TESTING

DIMENSIONS /

TOLERANCES

NON

DESTRUCTIVE

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 15

MATERIAL DATA SHEET MDS - Y35 Rev. 1

TYPE OF MATERIAL:

Structural Steel, Grade S 420 QLO2

PRODUCT STANDARD GRADE

Plates prEN 10225 S 420 QLO 2

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid/ be established prior to delivery:The documentation of base material shall include

strain ageing tests (ref. option 11), Charpy V-notch transition curves and typical tensile test

results for plates within each of the following thickness ranges that are relevant for the order:

25<t < 40 mm

40<t < 63 mm

63<t < 80 mm

80<t < 100 mm

Documentation of base material and weldability tests shall cover both as-delivered and PWHT

condition and the material shall comply with the specified requirements in PWHT

condition.Weldability tests in accordance with Annex F shall be carried out within each of these

thickness ranges (option 17). CTOD testing shall be included and shall meet a requirement of

min. 0.25 mm (as-welded)/min. 0.20 mm (PWHT condition), unless a lower value has been

accepted by the purchaser.

HEAT Quenched and Tempered , Normalised, TMCR (Option 5)

TREATMENT/

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in the Standard and any other elements intentionally added, and both Pcm and CEV values.

(option 6, 7, 8). The chemical composition shall be modified as follows: Nb+Vmax: 0.07 %,

CEVmax: 0.41, Pcm max 0.21%.

TENSILE Mechanical properties given in Table 4b shall be modified as follows:

TESTING Yield Strength (min.) : 420 MPa (all thicknesses)

Tensile Strength : 500-660 MPa (all thicknesses)

EXTENT OF

TESTING

DIMENSIONS /

TOLERANCES

NON

DESTRUCTIVE

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 16

MATERIAL DATA SHEET MDS - Y36 Rev. 1

TYPE OF MATERIAL:

Structural Steel, Grade S420 QLO2

PRODUCT STANDARD GRADE

Rolled Sections prEN 10225 S 420 QLO2

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid/ be established prior to delivery:The documentation of base material shall include

Charpy V-notch transition curves and typical tensile test results for rolled sections with thickness

approximately 20 mm or the greatest section thickness required in the Purchase

Order.Weldability tests in accordance with Annex F shall be carried out for the largest thickness

of the delivery, within ± 5 mm (ref. option 17).

HEAT Quenched and Tempered , Normalised, TMCR (option 5)

TREATMENT/

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in the Standard and any other elements intentionally added, and both Pcm and CEV values

(option 6, 7 and 8). The chemical composition shall be modified as follows: Nb+Vmax: 0.007%,

Pcm max 0.22%

TENSILE TESTING Mechanical properties given in Table 6 shall be modified as follows:

Yield Strength (min.) : 420 MPa (all thicknesses)

Tensile Strength : 500-660 MPa (all thicknesses)

EXTENT OF

TESTING

DIMENSIONS /

TOLERANCES

NON

DESTRUCTIVE

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 17

MATERIAL DATA SHEET MDS - Y37 Rev. 1

TYPE OF MATERIAL:

Structural Steel, Grade S 420 QLO2

PRODUCT STANDARD GRADE

Seamless prEN 10225 S 420 QLO2

tubulars(Seamless

hollow sections)

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid/ be established prior to delivery:The documentation of base material shall include

Charpy V-notch transition curves and typical tensile test results for tubulars with thickness

approximately 20 mm or the greatest wall thickness required in the Purchase Order.Weldability

tests in accordance with Annex F shall be carried out for the largest tubular thickness of the

delivery, within ± 5 mm (ref. option 17).

HEAT Quenched and Tempered , Normalised (option 5).

TREATMENT/

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in the Standard and any other elements intentionally added, and both Pcm and CEV values

(option 6, 7, 8). The chemical composition in Table 9 shall be modified as follows: Pcm max

0.22%

TENSILE Mechanical properties given in Table 10 shall be modified as follows:

TESTING Yield Strength (min.) : 420 MPa (all thicknesses)

Tensile Strength : 500-660 MPa (all thicknesses)

EXTENT OF

TESTING

DIMENSIONS /

TOLERANCES

NON

DESTRUCTIVE

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 18

MATERIAL DATA SHEET MDS - Y40 Rev. 1

TYPE OF MATERIAL:

Structural Steel, with documented through thickness properties, Grade S 460 QLO4

PRODUCT STANDARD GRADE

Plates prEN 10225 S 460 QLO 4

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid/ be established prior to delivery:The documentation of base material shall include

strain ageing tests (ref. option 11), Charpy V-notch transition curves and typical tensile test

results for plates within each of the following thickness ranges that are relevant for the order:

25<t < 40 mm

40<t < 63 mm

63<t < 80 mm

80<t < 100 mm

Documentation of base material and weldability tests shall cover both as-delivered and PWHT

condition and the material shall comply with the specified requirements in PWHT

condition.Weldability tests in accordance with Annex F shall be carried out within each of these

thickness ranges (option 17). CTOD testing shall be included and shall meet a requirement of

min. 0.25 mm (as-welded)/min. 0.20 mm (PWHT condition), unless a lower value has been

accepted by the purchaser.

HEAT TREATMENT/ Quenched and Tempered , Normalised, TMCR (Option 5)

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in the Standard and any other elements intentionally added, and both Pcm and CEV

values. (option 6, 7, 8). The chemical composition shall be modified as follows: Smax: 0.005%,

Pmax: 0.015%, Pcm max 0.22%.

TENSILE TESTING Mechanical properties shall be modified as follows:

Yield Strength (min.) : 460 MPa (thicknesses < 40 mm)

Yield Strength (min): 420 MPa (thicknesses > 40 mm)

Tensile Strength : 550-700 MPa (thicknesses < 40 mm)

Tensile Strength: 500-660MPa (thicknesses > 40 mm)

EXTENT OF Through thickness testing shall be carried out for t >= 25 mm (option 12).

TESTING

DIMENSIONS /

TOLERANCES

NON

DESTRUCTIVE

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 19

MATERIAL DATA SHEET MDS - Y41 Rev. 1

TYPE OF MATERIAL:

Structural Steel with documented through thickness properties, Grade S 460 QLO4

PRODUCT STANDARD GRADE

Rolled Sections prEN 10225 S 460 QLO4

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid/ be established prior to delivery:The documentation of base material shall include

Charpy V-notch transition curves and typical tensile test results for rolled sections with thickness

approximately 20 mm or the greatest section thickness required in the Purchase

Order.Weldability tests in accordance with Annex F shall be carried out for the largest thickness

of the delivery, within ± 5 mm (ref. option 17).

HEAT Quenched and Tempered , Normalised, TMCR (option 5)

TREATMENT/

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in the Standard and any other elements intentionally added, and both Pcm and CEV values

(option 6, 7 and 8). The chemical composition shall be modified as follows: CEV max: 0.45, Pcm

max 0.24%

TENSILE TESTING Mechanical properties shall be modified as follows:

Yield Strength (min.) : 460 MPa (thicknesses < 40 mm)

Yield Strength (min): 420 MPa (thicknesses > 40 mm)

Tensile Strength : 550-700 MPa (thicknesses < 40 mm)

Tensile Strength: 500-660MPa (thicknesses > 40 mm)

EXTENT OF Through thickness testing shall be carried out for t >= 25 mm (option 12).

TESTING

DIMENSIONS /

TOLERANCES

NON Ultrasonic examination of webs and flanges are required for web thicknesses above 12 mm

DESTRUCTIVE (option para 7.7.2.3)

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 20

MATERIAL DATA SHEET MDS - Y42 Rev. 1

TYPE OF MATERIAL:

Structural Steel with documented through thickness properties, Grade S 460 QLO2 (mod).

PRODUCT STANDARD GRADE

Seamless prEN 10225 S 460 QLO2(mod).

tubulars(Seamless

hollow sections)

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid/ be established prior to delivery:The documentation of base material shall include

Charpy V-notch transition curves and typical tensile test results for tubulars with thickness

approximately 20 mm or the greatest wall thickness required in the Purchase Order.Weldability

tests in accordance with Annex F shall be carried out for the largest tubular thickness of the

delivery, within ± 5 mm (ref. option 17).

HEAT Quenched and Tempered (option 5).

TREATMENT/

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in the Standard and any other elements intentionally added, and both Pcm and CEV values

(option 6, 7, 8). The chemical composition in Table 9 shall be modified as follows: CEVmax:

0.45, Pcm max 0.24%

TENSILE Mechanical properties shall be modified as follows:

TESTING Yield Strength (min.) : 460 MPa (thicknesses < 40 mm)

Yield Strength (min): 420 MPa (thicknesses > 40 mm)

Tensile Strength : 550-700 MPa (thicknesses < 40 mm)

Tensile Strength: 500-660MPa (thicknesses > 40 mm)

EXTENT OF Through thickness testing shall be carried out for t >= 25 mm (option 12).

TESTING

DIMENSIONS /

TOLERANCES

NON

DESTRUCTIVE

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 21

MATERIAL DATA SHEET MDS - Y45 Rev. 1

TYPE OF MATERIAL:

Structural Steel, Grade S 460 QLO2

PRODUCT STANDARD GRADE

Plates prEN 10225 S 460 QLO 2

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid/ be established prior to delivery:The documentation of base material shall include

strain ageing tests (ref. option 11), Charpy V-notch transition curves and typical tensile test

results for plates within each of the following thickness ranges that are relevant for the order:

25<t < 40 mm

40<t < 63 mm

63<t < 80 mm

80<t < 100 mm

Documentation of base material and weldability tests shall cover both as-delivered and PWHT

condition and the material shall comply with the specified requirements in PWHT

condition.Weldability tests in accordance with Annex F shall be carried out within each of these

thickness ranges (option 17). CTOD testing shall be included and shall meet a requirement of

min. 0.25 mm (as-welded)/min. 0.20 mm (PWHT condition), unless a lower value has been

accepted by the purchaser.

HEAT Quenched and Tempered , Normalised, TMCR (Option 5)

TREATMENT/

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in the Standard and any other elements intentionally added, and both Pcm and CEV values.

(option 6, 7, 8). The chemical composition shall be modified as follows: Pcm max 0.22%.

TENSILE TESTING Mechanical properties shall be modified as follows:

Yield Strength (min.) : 460 MPa (thicknesses < 40 mm)

Yield Strength (min): 420 MPa (thicknesses > 40 mm)

Tensile Strength : 550-700 MPa (thicknesses < 40 mm)

Tensile Strength: 500-660MPa (thicknesses > 40 mm)

EXTENT OF

TESTING

DIMENSIONS /

TOLERANCES

NON

DESTRUCTIVE

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 22

MATERIAL DATA SHEET MDS - Y46 Rev. 1

TYPE OF MATERIAL:

Structural Steel, S 460 QLO 2

PRODUCT STANDARD GRADE

Rolled Sections prEN 10225 S 460 QLO2

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid/ be established prior to delivery:The documentation of base material shall include

Charpy V-notch transition curves and typical tensile test results for rolled sections with thickness

approximately 20 mm or the greatest section thickness required in the Purchase

Order.Weldability tests in accordance with Annex F shall be carried out for the largest thickness

of the delivery, within ± 5 mm (ref. option 17).

HEAT Quenched and Tempered , Normalised, TMCR (option 5)

TREATMENT/

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in the Standard and any other elements intentionally added, and both Pcm and CEV values

(option 6, 7 and 8). The chemical composition shall be modified as follows: CEV max: 0.45, Pcm

max 0.24%

TENSILE TESTING Mechanical properties shall be modified as follows:

Yield Strength (min.) : 460 MPa (thicknesses < 40 mm)

Yield Strength (min): 420 MPa (thicknesses > 40 mm)

Tensile Strength : 550-700 MPa (thicknesses < 40 mm)

Tensile Strength: 500-660MPa (thicknesses > 40 mm)

EXTENT OF

TESTING

DIMENSIONS /

TOLERANCES

NON

DESTRUCTIVE

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 23

MATERIAL DATA SHEET MDS - Y47 Rev. 1

TYPE OF MATERIAL:

Structural Steel, Grade S 460 QLO 2

PRODUCT STANDARD GRADE

Seamless prEN 10225 S 460 QLO 2.

tubulars(Seamless

hollow sections)

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid/ be established prior to delivery:The documentation of base material shall include

Charpy V-notch transition curves and typical tensile test results for tubulars with thickness

approximately 20 mm or the greatest wall thickness required in the Purchase Order.Weldability

tests in accordance with Annex F shall be carried out for the largest tubular thickness of the

delivery, within ± 5 mm (ref. option 17).

HEAT Quenched and Tempered (option 5).

TREATMENT/

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in the Standard and any other elements intentionally added, and both Pcm and CEV values

(option 6, 7, 8). The chemical composition in Table 9 shall be modified as follows: CEVmax:

0.45, Pcm max 0.24%

TENSILE Mechanical properties shall be modified as follows:

TESTING Yield Strength (min.) : 460 MPa (thicknesses < 40 mm)

Yield Strength (min): 420 MPa (thicknesses > 40 mm)

Tensile Strength : 550-700 MPa (thicknesses < 40 mm)

Tensile Strength: 500-660MPa (thicknesses > 40 mm)

EXTENT OF

TESTING

DIMENSIONS /

TOLERANCES

NON

DESTRUCTIVE

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 24

MATERIAL DATA SHEET MDS - Y50 Rev. 1

TYPE OF MATERIAL:

Structural Steel with documented through thickness properties, Grade S 500 QLO4

PRODUCT STANDARD GRADE

Plates prEN 10225 S 500 QLO 4

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

STEEL GRADE Grade S 460 QLO 4 shall be modified to Grade S 500 QLO 4 as specified by this MDS.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid/ be established prior to delivery:The documentation of base material shall include

strain ageing tests (ref. option 11), Charpy V-notch transition curves and typical tensile test

results for plates within each of the following thickness ranges that are relevant for the order:

25<t < 40 mm

40<t < 63 mm

63<t < 80 mm

80<t < 100 mmDocumentation of base material and weldability tests shall cover both as-

delivered and PWHT condition and the material shall comply with the specified requirements in

PWHT condition.Weldability tests in accordance with Annex F shall be carried out within each

of these thickness ranges (option 17). CTOD testing shall be included and shall meet a

requirement of min. 0.25 mm (as-welded)/min. 0.20 mm (PWHT condition), unless a lower

value has been accepted by the purchaser.

HEAT TREATMENT/ Quenched and Tempered , Normalised, TMCR (Option 5)

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in the Standard and any other elements intentionally added, and both Pcm and CEV

values. (option 6, 7, 8). The chemical composition shall be modified as follows: Smax: 0.005%,

Pmax: 0.015% Pcm max 0.22%.

TENSILE TESTING Mechanical properties given in Table 4c for Grade S 460 QLO 4 shall be modified as follows:

Yield Strength (min.) : 500 MPa (thicknesses < 40 mm)

Yield Strength (min): 460 MPa (thicknesses > 40 mm)

Tensile Strength : 600-750 MPa (thicknesses < 40 mm)

Tensile Strength: 550-700 MPa (thicknesses > 40 mm)

EXTENT OF Through thickness testing shall be carried out for t > 25 mm (option 12).

TESTING

DIMENSIONS /

TOLERANCES

NON

DESTRUCTIVE

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 25

MATERIAL DATA SHEET MDS - Y51 Rev. 1

TYPE OF MATERIAL:

Structural Steel with documented through thickness properties, Grade S 500 QLO 4

PRODUCT STANDARD GRADE

Rolled Sections prEN 10225 S 500 QLO 4

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

STEEL GRADE Grade S 460 QLO 4 shall be modified to Grade S 500 QLO 4 as specified by this MDS.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid/ be established prior to delivery:The documentation of base material shall include

Charpy V-notch transition curves and typical tensile test results for rolled sections with thickness

approximately 20 mm or the greatest section thickness required in the Purchase

Order.Weldability tests in accordance with Annex F shall be carried out for the largest thickness

of the delivery, within ± 5 mm (ref. option 17).

HEAT Quenched and Tempered (Option 5)

TREATMENT/

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in the Standard and any other elements intentionally added, and both Pcm and CEV values.

(option 6, 7, 8). The chemical composition shall be modified as follows: CEVmax: 0.45, Pcm

max 0.24%.

TENSILE TESTING Mechanical properties given in Table 6 for Grade S 460 QLO 4 shall be modified as follows:

Yield Strength (min.) : 500 MPa (thicknesses < 40 mm)

Yield Strength (min): 460 MPa (thicknesses > 40 mm)

Tensile Strength : 600-750 MPa (thicknesses < 40 mm)

Tensile Strength: 550-700 MPa (thicknesses > 40 mm)

EXTENT OF Through thickness testing shall be carried out for t >= 25 mm (option 12).

TESTING

DIMENSIONS /

TOLERANCES

NON Ultrasonic examination of webs and flanges are required for web thicknesses above 12 mm

DESTRUCTIVE (option para 7.7.2.3).

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 26

MATERIAL DATA SHEET MDS - Y52 Rev. 1

TYPE OF MATERIAL:

Structural Steel, with documented through thickness properties, Grade S 500 QLO4

PRODUCT STANDARD GRADE

Seamless prEN 10225 S 500 QLO 4

tubulars(Seamless

hollow sections)

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

STEEL GRADE Grade S 460 QLO 2 shall be modified to Grade S 500 QLO 4 as specified by this MDS.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid/ be established prior to delivery:The documentation of base material shall include

Charpy V-notch transition curves and typical tensile test results for tubulars with thickness

approximately 20 mm or the greatest wall thickness required in the Purchase Order.Weldability

tests in accordance with Annex F shall be carried out for the largest tubular thickness of the

delivery, within ± 5 mm (ref. option 17).

HEAT Quenched and Tempered (Option 5)

TREATMENT/

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in the Standard and any other elements intentionally added, and both Pcm and CEV values.

(option 6, 7, 8). The chemical composition shall be modified as follows: Smax: 0.007%,

CEVmax: 0.45, Pcm max 0.24%.

TENSILE TESTING Mechanical properties given in Table 10 for Grade S 460 QLO 2 shall be modified as follows:

Yield Strength (min.) : 500 MPa (thicknesses < 40 mm)

Yield Strength (min): 460 MPa (thicknesses > 40 mm)

Tensile Strength : 600-750 MPa (thicknesses < 40 mm)

Tensile Strength: 550-700 MPa (thicknesses > 40 mm)

EXTENT OF Through thickness testing shall be carried out for t > 25 mm (option 12).

TESTING

DIMENSIONS /

TOLERANCES

NON

DESTRUCTIVE

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 27

MATERIAL DATA SHEET MDS - Y55 Rev. 1

TYPE OF MATERIAL:

Structural Steel, Grade S 500 QLO 2

PRODUCT STANDARD GRADE

Plates prEN 10225 S 500 QLO 2

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

STEEL GRADE Grade S 460 QLO 2 shall be modified to Grade S 500 QLO 2 as specified by this MDS.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid/ be established prior to delivery:The documentation of base material shall include

strain ageing tests (ref. option 11), Charpy V-notch transition curves and typical tensile test

results for plates within each of the following thickness ranges that are relevant for the order:

25<t < 40 mm

40<t < 63 mm

63<t < 80 mm

80<t < 100 mmDocumentation of base material and weldability tests shall cover both as-

delivered and PWHT condition and the material shall comply with the specified requirements in

PWHT condition.Weldability tests in accordance with Annex F shall be carried out within each

of these thickness ranges (option 17). CTOD testing shall be included and shall meet a

requirement of min. 0.25 mm (as-welded)/min. 0.20 mm (PWHT condition), unless a lower value

has been accepted by the purchaser.

HEAT Quenched and Tempered , Normalised, TMCR (Option 5)

TREATMENT/

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in the Standard and any other elements intentionally added, and both Pcm and CEV values.

(option 6, 7, 8). The chemical composition shall be modified as follows: Pcm max 0.22%.

TENSILE TESTING Mechanical properties given in Table 4c for Grade S 460 QLO 2 shall be modified as follows:

Yield Strength (min.) : 500 MPa (thicknesses < 40 mm)

Yield Strength (min): 460 MPa (thicknesses > 40 mm)

Tensile Strength : 600-750 MPa (thicknesses < 40 mm)

Tensile Strength: 550-700 MPa (thicknesses > 40 mm)

EXTENT OF

TESTING

DIMENSIONS /

TOLERANCES

NON

DESTRUCTIVE

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 28

MATERIAL DATA SHEET MDS - Y56 Rev. 1

TYPE OF MATERIAL:

Structural Steel, Grade S 500 QLO 2

PRODUCT STANDARD GRADE

Rolled Sections prEN 10225 S 500 QLO 2

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

STEEL GRADE Grade S 460 QLO 2 shall be modified to Grade S 500 QLO 2 as specified by this MDS.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid/ be established prior to delivery:The documentation of base material shall include

Charpy V-notch transition curves and typical tensile test results for rolled sections with thickness

approximately 20 mm or the greatest section thickness required in the Purchase

Order.Weldability tests in accordance with Annex F shall be carried out for the target thickness

of the delivery, within ± 5 mm (ref. option 17).

HEAT Quenched and Tempered (Option 5)

TREATMENT/

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in the Standard and any other elements intentionally added, and both Pcm and CEV values.

(option 6, 7, 8). The chemical composition shall be modified as follows: CEVmax: 0.45, Pcm

max 0.24%.

TENSILE TESTING Mechanical properties given in Table 6 for Grade S 460 QLO 2 shall be modified as follows:

Yield Strength (min.) : 500 MPa (thicknesses < 40 mm)

Yield Strength (min): 460 MPa (thicknesses > 40 mm)

Tensile Strength : 600-750 MPa (thicknesses < 40 mm)

Tensile Strength: 550-700 MPa (thicknesses > 40 mm)

EXTENT OF

TESTING

DIMENSIONS /

TOLERANCES

NON

DESTRUCTIVE

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 29

MATERIAL DATA SHEET MDS - Y57 Rev. 1

TYPE OF MATERIAL:

Structural Steel, Grade S 500 QLO 2

PRODUCT STANDARD GRADE

Seamless prEN 10225 S 500 QLO 2

tubulars(Seamless

hollow sections)

SCOPE This MDS specifies the selected options in the referred standard and modified requirements

which shall supersede the corresponding requirements in the referred standard.

STEEL GRADE Grade S 460 QLO 2 shall be modified to Grade S 500 QLO 2 as specified by this MDS.

QUALIFICATIONS Base material information and documentation and results of weldability tests shall be submitted

with the bid/ be established prior to delivery:The documentation of base material shall include

Charpy V-notch transition curves and typical tensile test results for tubulars with thickness

approximately 20 mm or the greatest wall thickness required in the Purchase Order.Weldability

tests in accordance with Annex F shall be carried out for the target tubular thickness of the

delivery, within ± 5 mm (ref. option 17).

HEAT Quenched and Tempered (Option 5)

TREATMENT/

DELIVERY

CONDITION

CHEMICAL The Manufacturer shall state the guaranteed minimum and maximum values for all elements

COMPOSITION listed in the Standard and any other elements intentionally added, and both Pcm and CEV values.

(option 6, 7, 8). The chemical composition shall be modified as follows: CEVmax: 0.045, Pcm

max 0.24%.

TENSILE TESTING Mechanical properties given in Table 10 for Grade S 460 QLO 2 shall be modified as follows:

Yield Strength (min.) : 500 MPa (thicknesses < 40 mm)

Yield Strength (min): 460 MPa (thicknesses > 40 mm)

Tensile Strength : 600-750 MPa (thicknesses < 40 mm)

Tensile Strength: 550-700 MPa (thicknesses > 40 mm)

EXTENT OF

TESTING

DIMENSIONS /

TOLERANCES

NON

DESTRUCTIVE

EXAMINATION

(NDE)

SURFACE All surfaces shall receive a preliminary protective primer coat. Blast cleaning shall comply with

PROTECTION ISO 8501-1 Sa 2 1/2 and the surface shall remain at Sa 2 1/2 until application of the primer. The

primer shall consist of 1 coat zinc ethyl silicate primer with 15 microns. Measured on a plane

polished steel or glass test plate the maximum DFT shall be maximum 25 microns.

MARKING Unique marking as defined in the purchase order.

CERTIFICATION EN 10 204 Type 3.1B

M-CR-120, Rev. 1, December 1994 page 30

You might also like

- M 120Document40 pagesM 120ilkinNo ratings yet

- Norsok Standard M-120Document42 pagesNorsok Standard M-120marz_dacuteNo ratings yet

- Norsok Material Data Sheet (M-630r2)Document77 pagesNorsok Material Data Sheet (M-630r2)karuna346No ratings yet

- En 10025Document4 pagesEn 10025Jayesh83% (6)

- NORSOK Data Sheets For PipingDocument6 pagesNORSOK Data Sheets For PipingWalid LabidiNo ratings yet

- Structural Steel Plates and Sections MDSDocument1 pageStructural Steel Plates and Sections MDSvon18No ratings yet

- Norsok M 630Document77 pagesNorsok M 630Hal SkoglundNo ratings yet

- En 10025 - 2004Document11 pagesEn 10025 - 2004Abhishek GoelNo ratings yet

- Structural Steel Standard SANS 50025 / EN 10025:2004: Macsteel Trading Macsteel VRN Tel: 011-871-4600 Tel: 011-861-5200Document11 pagesStructural Steel Standard SANS 50025 / EN 10025:2004: Macsteel Trading Macsteel VRN Tel: 011-871-4600 Tel: 011-861-5200JakesNo ratings yet

- Structural Steel Specification for Offshore PlatformsDocument38 pagesStructural Steel Specification for Offshore Platforms'Izzad AfifNo ratings yet

- EN 10025: 2004 Is The New European Standard For Structural Steel.Document6 pagesEN 10025: 2004 Is The New European Standard For Structural Steel.Alin DavidNo ratings yet

- COMMON REQUIREMENTS FOR STRUCTURAL STEEL FABRICATIONDocument24 pagesCOMMON REQUIREMENTS FOR STRUCTURAL STEEL FABRICATIONEarl HarbertNo ratings yet

- En 10025 s275 s355Document2 pagesEn 10025 s275 s355Alex LeungNo ratings yet

- Ruukki Hot Rolled Steels Standard Steel Grades Comparison Designation and Codes1Document6 pagesRuukki Hot Rolled Steels Standard Steel Grades Comparison Designation and Codes1Cad AutocadNo ratings yet

- Norsok STDDocument77 pagesNorsok STDMajeed RumaniNo ratings yet

- Comparaison en 10253-4 Et DinDocument32 pagesComparaison en 10253-4 Et Dinodaue100% (2)

- Astm B163 PDFDocument12 pagesAstm B163 PDFSuellen FerreiraNo ratings yet

- Structural Steel Fabrication Norsok Standard M101Document67 pagesStructural Steel Fabrication Norsok Standard M101nigel_copsey100% (2)

- NORSOK Structural Steel Fabrication StandardDocument0 pagesNORSOK Structural Steel Fabrication StandardmastorfaizalNo ratings yet

- Norsok M101 Structural Steel FabricationDocument67 pagesNorsok M101 Structural Steel FabricationbreeeeezzzzzeNo ratings yet

- ENG Structural SteelsDocument2 pagesENG Structural SteelsOlalla CuiñaNo ratings yet

- EN 10025: 2004 Is The New European Standard For Structural SteelDocument6 pagesEN 10025: 2004 Is The New European Standard For Structural Steelvimalkumar_trjNo ratings yet

- 115-How To Specify SteelDocument2 pages115-How To Specify SteelTimmy VoNo ratings yet

- Chinese To DinDocument7 pagesChinese To Dindnageshm4n244No ratings yet

- Annex 1.8 I Beams European GradesDocument12 pagesAnnex 1.8 I Beams European GradesAbdullah NajjarNo ratings yet

- Standard Designation of SteelsDocument7 pagesStandard Designation of SteelsRidvan GecuNo ratings yet

- Din 3357Document7 pagesDin 3357sheik MohammedNo ratings yet

- En 10025 2004 BDocument10 pagesEn 10025 2004 BPrasanna RajaNo ratings yet

- Seamless Precision Steel Tubes For Hydraulic Cylinders - TN 008-00Document8 pagesSeamless Precision Steel Tubes For Hydraulic Cylinders - TN 008-00Erhan BeylihanNo ratings yet

- FPD190 - Differential Pressure - Restriction Orifice PlatesDocument12 pagesFPD190 - Differential Pressure - Restriction Orifice PlatesPeter MarkwellNo ratings yet

- Structural Steel Design L 03A-19.11.2021Document74 pagesStructural Steel Design L 03A-19.11.2021LUGHANO NGAJILONo ratings yet

- en 10025Document4 pagesen 10025brianmanson78No ratings yet

- Structurals and Standard Pipe: ProducersDocument4 pagesStructurals and Standard Pipe: ProducersRudyNo ratings yet

- Shear StudDocument7 pagesShear StudcongtubatdaNo ratings yet

- A3-40 External MetalworkDocument17 pagesA3-40 External Metalworklwin_oo2435No ratings yet

- Iacs RulesDocument387 pagesIacs RulesTharakesh AttiliNo ratings yet

- Table of Material Properties For Structural Steel S235, S275, S355, S420Document4 pagesTable of Material Properties For Structural Steel S235, S275, S355, S420Arjun Soman100% (1)

- Table of Material Properties For Structural Steel S235, S275, S355, S420Document4 pagesTable of Material Properties For Structural Steel S235, S275, S355, S420vodounnou0% (1)

- Conditions of Supply and Steel Grades for Sheet PilingDocument1 pageConditions of Supply and Steel Grades for Sheet PilingHushes CheongNo ratings yet

- Jis G 3507-2 - 2005Document14 pagesJis G 3507-2 - 2005Harold_katzerNo ratings yet

- Acroni PDFDocument15 pagesAcroni PDFIgor GrujićNo ratings yet

- Standard Steels HR 2 3 02 01 2010 - ENDocument6 pagesStandard Steels HR 2 3 02 01 2010 - ENBigman1983No ratings yet

- CNH Mat 1007 - 07-2009Document5 pagesCNH Mat 1007 - 07-2009rgi178No ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20From EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20No ratings yet

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- Brittle Fracture in Steel StructuresFrom EverandBrittle Fracture in Steel StructuresG.M. BoydNo ratings yet

- Thixoforming: Semi-solid Metal ProcessingFrom EverandThixoforming: Semi-solid Metal ProcessingGerhard HirtNo ratings yet

- Data Dosen PPNS Per Juni 2016 Sumber PDPT (Forlap)Document21 pagesData Dosen PPNS Per Juni 2016 Sumber PDPT (Forlap)wida putra cahyanto100% (1)

- Perhtungan Pressure VesselDocument1 pagePerhtungan Pressure VesselMuhammad YusufNo ratings yet

- ClassNK Register of Ships - M - S HIGH BEAM (CNoDocument2 pagesClassNK Register of Ships - M - S HIGH BEAM (CNoMuhammad YusufNo ratings yet

- Diagram Hamlin PDFDocument2 pagesDiagram Hamlin PDFMuhammad YusufNo ratings yet

- Ship Theory - Numerical IntegrationDocument30 pagesShip Theory - Numerical IntegrationMuhammad YusufNo ratings yet

- ts502 PDFDocument152 pagests502 PDFMung Duong XuanNo ratings yet

- Mil HDBK 697a PDFDocument122 pagesMil HDBK 697a PDFkulto_kultoNo ratings yet

- C2quick PDFDocument34 pagesC2quick PDFJose Maria PedrazasNo ratings yet

- ASTM A536 Grade 60-40-18 Ductile Cast IronDocument2 pagesASTM A536 Grade 60-40-18 Ductile Cast IronbaladiroyaNo ratings yet

- Lifting Lug DesignDocument7 pagesLifting Lug DesignadammzjinNo ratings yet

- Hole-Drilling Method For Measuring Residual Stresses-V1 PDFDocument188 pagesHole-Drilling Method For Measuring Residual Stresses-V1 PDFsumatrablackcoffee453100% (1)

- Reinforced Concrete Design ReportDocument11 pagesReinforced Concrete Design ReportAchala Fernando67% (3)

- Nylon Screws Test DataDocument6 pagesNylon Screws Test DatadineshNo ratings yet

- Timber Examples - TeddsDocument19 pagesTimber Examples - TeddsTom KwoNo ratings yet

- Preparation and Characterization of Polyurethane /charcoal Foam CompositeDocument7 pagesPreparation and Characterization of Polyurethane /charcoal Foam CompositeTarani TharanNo ratings yet

- Campus Data BaseDocument77 pagesCampus Data BaseFERNANDO JOSE NOVAESNo ratings yet

- HSFG Bolts On BridgesDocument16 pagesHSFG Bolts On BridgesParchuri PraveenNo ratings yet

- 4b. Nonlinear Structural Analysis For Seismic Design - Spring 2018Document42 pages4b. Nonlinear Structural Analysis For Seismic Design - Spring 2018Nguyen DuyNo ratings yet

- Technical Data Sheet For Hilti HIT HY 200Document39 pagesTechnical Data Sheet For Hilti HIT HY 200ValeriuNo ratings yet

- Design of Flexible and Rigid PavementsDocument29 pagesDesign of Flexible and Rigid PavementssanchayNo ratings yet

- Review of Sand Production Control and Management TechniquesDocument9 pagesReview of Sand Production Control and Management TechniquesFarqad AliNo ratings yet

- Moment Connections Bolted WeltedDocument6 pagesMoment Connections Bolted WeltedRavirajsinh JadejaNo ratings yet

- Lecture 2Document30 pagesLecture 2hania dogar0% (1)

- Strength of Materials I-1Document67 pagesStrength of Materials I-1Adebisi IbraheemNo ratings yet

- NFEM Ch02Document17 pagesNFEM Ch02SandipNo ratings yet

- Visual Inspection of Main BearingDocument74 pagesVisual Inspection of Main BearingDaniel AmanorNo ratings yet

- Mohr's Circle for Plane StressDocument9 pagesMohr's Circle for Plane StressshrnbolonneNo ratings yet

- Strenx 960: General Product DescriptionDocument2 pagesStrenx 960: General Product DescriptionJean Paulo SalvatiNo ratings yet

- ASTM C42. Standard Test Method For Obtaining and Test Drilled Cores and Sawed Beams of ConcreteDocument7 pagesASTM C42. Standard Test Method For Obtaining and Test Drilled Cores and Sawed Beams of ConcreteENGYA2007No ratings yet

- ASTM D7078 - Shear Test of Composite MaterialDocument4 pagesASTM D7078 - Shear Test of Composite MaterialFARUK ELALDINo ratings yet

- Solutions Ch20Document12 pagesSolutions Ch20Joyce Casiano100% (2)

- UHX - Osweiller - WhitePaper PDFDocument20 pagesUHX - Osweiller - WhitePaper PDFMichael BasaNo ratings yet

- Suzuki Garphyttan Product Information 2016Document29 pagesSuzuki Garphyttan Product Information 2016stevemwilliamsNo ratings yet

- ASME Div 2 allowable stressesDocument19 pagesASME Div 2 allowable stressesRakesh RanjanNo ratings yet

- Journal of Constructional Steel Research: Ying Xing, Qinghua Han, Jie Xu, Qi Guo, Yihong WangDocument14 pagesJournal of Constructional Steel Research: Ying Xing, Qinghua Han, Jie Xu, Qi Guo, Yihong WangAvinash Bhakta 18MST0043No ratings yet