Professional Documents

Culture Documents

Eurocopter AS332-EC225

Uploaded by

AxelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eurocopter AS332-EC225

Uploaded by

AxelCopyright:

Available Formats

Type Acceptance Report

TAR 13/21B/25

Eurocopter AS332/EC225 Series

Aircraft Certification Unit

Type Acceptance Report

TABLE OF CONTENTS

EXECUTIVE SUMMARY 1

1. INTRODUCTION 1

2. ICAO TYPE CERTIFICATE DETAILS 1

3. TYPE ACCEPTANCE CERTIFICATE 3

4. NZCAR §21.43 DATA REQUIREMENTS 4

ATTACHMENTS 12

APPENDIX 1 12

Rev.0 : 2 October 2013 i TAR 13/21B/25 –Eurocopter AS332/EC225

Type Acceptance Report

Executive Summary

New Zealand Type Acceptance has been granted to the Eurocopter AS332/EC225 Series

based on validation of EASA Type Certificate number R.002. There are no special

requirements for import.

Applicability is currently limited to the Models and/or serial numbers detailed in Appendix

1, which are now eligible for the issue of an Airworthiness Certificate in the Standard

Category in accordance with NZCAR §21.177, subject to any outstanding New Zealand

operational requirements being met. (See Section 5 of this report for a review of

compliance of the basic type design with the operating Rules.) Additional variants or serial

numbers approved under the foreign type certificate can become type accepted after supply

of the applicable documentation, in accordance with the provisions of NZCAR §21.43(b).

1. Introduction

This report details the basis on which Type Acceptance Certificate No.13/21B/25 was

granted in the Standard Category in accordance with NZCAR Part 21 Subpart B.

Specifically the report aims to:

(a) Specify the foreign type certificate and associated airworthiness design standard

used for type acceptance of the model(s) in New Zealand; and

(b) Identify any special conditions for import applicable to any model(s) covered by the

Type Acceptance Certificate; and

(c) Identify any additional requirements which must be complied with prior to the issue

of a NZ Airworthiness Certificate or for any subsequent operations.

2. ICAO Type Certificate Details

TC Holder: Eurocopter

Type Certificate: Number R.002

Issued by: European Aviation Safety Agency

Models: AS 332 C, C1, L, L1, L1e*

MCTOW 8,350 kgs [18,410 lbs] - AS332C, L

8,600 kgs [18,960 lbs] - AS332C1, L1 (C, L after SB 01.03)

Max. No. of pax Seats: 19 – AS 332 C, C1

24 – AS 332 L, L1

Noise Standard: N/A

* L1e is the commercial designation for the L1 equipped with the AHCAS system.

Rev.0 : 2 October 2013 1 TAR 13/21B/25 –Eurocopter AS332/EC225

Type Acceptance Report

Engine: Turbomeca Makila 1A – AS 332 C, L

Turbomeca Makila 1A1 – AS 332 C1, L1

Type Certificate: Number E.072

Issued by: European Aviation Safety Agency

Model: AS 332 L2

MCTOW 9,300 kgs [20,502 lbs]

Max. No. of pax Seats: 25

Noise Standard: ICAO Annex 16, Volume 1, Part II, Chapter 8 and Appendix 4

Engine: Turbomeca Makila 1A2

Type Certificate: Number E.072

Issued by: European Aviation Safety Agency

Models: EC 225 LP

MCTOW 11,000 kgs [24,251 lbs]

Max. No. of pax Seats: 25

Noise Standard: ICAO Annex 16, Volume 1, Part II, Chapter 8 and Appendix 4

Engine: Turbomeca Makila 2A/2A1

Type Certificate: Number E.006

Issued by: European Aviation Safety Agency

TAR 13/21B/25 – Eurocopter AS332/EC225 2 Rev.0 : 2 October 2013

Type Acceptance Report

3. Type Acceptance Certificate

The application for New Zealand type acceptance of the AS 332/EC 225 series was from

Heli-Harvest Ltd dated 22 March 2013. The AS 332/EC 225 series (known as the “Super

Puma”) is a twin-turbine multi-purpose helicopter in the 5/6 tonne class which uses a

conventional four or five-blade single main-rotor system and a conventional tail rotor.

Type Acceptance Certificate Number 13/21B/25 was granted on 2 October 2013 to the

Eurocopter AS 332/EC 225 series based on validation of EASA Type Certificate R.002.

Specific applicability is limited to the coverage provided by the operating documentation

supplied. There are no special requirements for import into New Zealand. As part of the

type acceptance process engineers from the CAANZ Aircraft Certification Unit carried out

a validation visit to Eurocopter at Marignane.

The Turbomeca Makila 1A engine series approved under EASA Type Certificate number

E.072 has been type accepted separately under CAA reference 14/21B/2. The Turbomeca

Makila 2A series approved under EASA Type Certificate number E.006 has been type

accepted separately under CAA reference 14/21B/3.

The Super Puma was developed from the original SA 330 Puma, which first flew in 1965

and was extensively developed for both civil and military applications. Modifications for

the AS 332 Super Puma included new more powerful engines, improved structure and

undercarriage, and improved drivetrain and rotor systems. It was always intended to

produce the fuselage in two lengths, the standard length and a lengthened version allowing

more passengers to be carried where weight is not so critical. The first Super Puma first

flew in 1978 and type certification was issued in 1981.

The AS 332 C/C1 and L/L1 models are classed as the Mark I Super Puma, the “L”

designation denoting the long fuselage version, and the “1” suffix indicating an uprated

engine and increased weight. (C and L models can be converted to C1 and L1 models in

accordance with SB 01.00.26). The AS 332 L2 is the only civilian model classed as the

Mark II Super Puma, developed in the 1980s. It features more powerful engines, increased

weight and an EFIS cockpit.

The EC 225 is developed from the AS 332 L2 and features more powerful Makila 2A

engines, increased weight, new five bladed main rotor system, and an all-new glass

cockpit. The EC 225 LP first flew in 1980 and was type certificated in 2004.

The C1 and L1 are still in production as a low cost alternative to the EC 225 and are

commercially suffixed by an ‘e’ letter to indicate an avionics upgrade to the EC 225 level.

Rev.0 : 2 October 2013 3 TAR 13/21B/25 –Eurocopter AS332/EC225

Type Acceptance Report

4. NZCAR §21.43 Data Requirements

The type data requirements of NZCAR Part 21B Para §21.43 have been satisfied by supply

of the following documents, or were already held by the CAA:

(1) ICAO Type certificate:

EASA Type Certificate Number R.002 (Replaces French DGAC TC No 56)

EASA Type Certificate Data Sheet no. R.002 at Issue 11, dated 10 July 2013

– Model AS 332 C approved (by DGAC) 24 April 1981

– Model AS 332 L approved (by DGAC) 2 December 1980

– Model AS 332 C1 approved (by DGAC) 14 March 1985

– Model AS 332 L1 approved (by DGAC) 14 March 1985

– Model AS 332 L2 approved (by DGAC) 12 June 1991

– Model EC 225 LP approved 27 July 2004

(2) Airworthiness design requirements:

(i) Airworthiness Design Standards:

The certification basis for the AS 332C, L, C1, and L1 was FAR 29 effective

February 1, 1965, including Amendments 29-1 through 29-16. Three Special

Conditions were imposed, there were no Exemptions, Deviations or Equivalent

Safety Findings. These have been reviewed and accepted by the CAA. (Note: For

aircraft equipped with the AHCAS system, commercial reference AS332L1(e), the

certification basis was updated in affected areas, three additional Special

Conditions were imposed and four Equivalent Safety Findings were made. See

Note 8 on the TCDS for full details.)

The certification basis for the AS 332 L2 was FAR 29 effective February 1, 1965,

including Amendments 29-1 through 29-24. Five Special Conditions were imposed,

there were four Deviations but no Exemptions or Equivalent Safety Findings. These

have been reviewed and accepted by the CAA.

The certification basis for the EC 225 LP is JAR 29 at Change 1 effective

December 1, 1999. There were six Special Conditions, three Exemptions and one

Partial Exemption, one reversion and two partial reversions to FAR 29 Amendment

24, and ten Equivalent Safety Findings. These have been reviewed and accepted by

the CAA.

These are acceptable certification bases in accordance with NZCAR Part 21B Para

§21.41 and Advisory Circular 21-1A, as FAR 29 is the basic standard for Transport

Category Rotorcraft called up under Part 21 Appendix C, and JAR 29 is an

acceptable alternative in accordance with the Advisory Circular. There are no non-

compliances and no additional special conditions have been prescribed by the

Director under §21.23.

(ii) Special Conditions:

AS 332 C, C1, L, L1:

DGAC Condition Spéciale n°1 – Icing – Pilot view for safe operation, FAR

§29.773(b)(1)(ii) is modified to read “in the icing conditions specified in FAR 25,

TAR 13/21B/25 – Eurocopter AS332/EC225 4 Rev.0 : 2 October 2013

Type Acceptance Report

Appendix C”. Ice protection, FAR §29.877 method of substantiation is detailed.

Induction system, FAR §29.1093(b) is amended. Static Air Vent, FAR §29.1325(b)

is amended.

DGAC Condition Spéciale n°2 – Lightning, as applicable to previous SA 330 J

model and notified in the appendix to the letter 02827 SFACT/TC dated March 30,

1978, for the flight in icing conditions – “The rotorcraft must be protected in such a

manner as to minimize lightning risks”.

DGAC Condition Spéciale 20.2 dated May 11, 1982 - Category II, IFR flight –

Definition of the method of certification, minimum equipment and conditions for

category II radio precision approaches for an IFR approved rotorcraft.

AS 332 L2:

DGAC Letter 53445/SFACT/TC dated 27 April 1989 listed the following special

conditions:

C.S.A1 – Condition to specify additional flight test time for showing reliability and

evaluating crew workload.

C.S.D1 – Condition to design for bird and foreign object strikes.

C.S.E1 – Condition to demonstrate protection against external electro-magnetic

disturbances.

C.S. E2 – Condition to show the new Maintenance assistance system (optional

system) is at least as safe as normally used methods and a program for collection of

in-service data.

DGAC Letter 53610/SFACT/N.HE dated 11 July 1991 listed the following super

emergency special condition:

30 seconds and 2 minutes contingency ratings were applied to FAR 29.67 Climb:

one engine inoperative, FAR 29.361 Engine Torque, FAR 29.549(e) Fuselage and

rotor pylon structures, FAR 29.923 Rotor drive system and control mechanism

tests, FAR 29.1143 Cooling tests, FAR 29.1305 Powerplant instruments, FAR

29.1549 Instructions for Continued Airworthiness.

Also, the following were modified:

- FAR 29.1045 Climb cooling test procedures at amendment 26 is

applicable (includes OEI requirement).

- FAR 29.1047 Takeoff cooling test procedures at amendment 26 is

applicable (includes OEI requirement).

- FAR 29.1521 Powerplant limitations at amendment 26 is applicable

(includes OEI requirement) with further OEI requirements added.

EC 225 LP (* = also applicable to AS 332 L1e):

Minimum In-Flight Experience – CRI B-01 – Conditions and definition of required

minimum number of flight hours, takes into account AS 332 L2 experience. *

SAR (Search and Rescue) System – CRI B-02 – Conditions applicable to the SAR

operation and use of a dedicated SAR mode of the Automatic Flight Control

System (AFCS), including use in IFR. *

Rev.0 : 2 October 2013 5 TAR 13/21B/25 –Eurocopter AS332/EC225

Type Acceptance Report

Water Bombing System – CRI B-05 – Conditions for the novel water bombing

system, and it’s operation, which installs a collapsible water tank inside the cabin..

External Loads, JAR 29.865 amendment 2 – CRI D-06 – Eurocopter accepted to

comply with JAR 29.865 Amendment 2 dated March 1, 2001 for each new hoist

installation intended to be used for human external cargo applications..

Protection from the effects of High Intensity radiated Fields (HIRF) – CRI F-02 –

Because the EC 225 LP has digital electronic systems (including the engine) the SC

was as per the interim policy INT/POL/27,29/1 Issue 2 dated 1/06/97. *

Helicopter Limited Icing Approval as prescribed by EASA – CRI O-01 –

Conditions which allow flight into limited icing conditions without full icing

equipment installed.

(iii) Deviations:

AS 332 L2:

Reversion to FAR 29 original requirement:

FAR §29.1, §29.605, §29.671, §29.1323

Reversion to FAR 29 at amendment 12:

FAR §29.603

Reversion to FAR 29 at amendment 14:

FAR §29.1303

FAR §29.1309 regarding equipment used on previous AS 332 versions.

EC 225 LP:

Reversion to FAR 29 at amendment 24:

FAR §29.561(b)(3) – Emergency Landing Conditions - General – CRI C-01 –

Eurocopter were granted a reversion to the original AS 332 L2 certification basis

providing no significant changed parts (including seats, seat locations, items of

mass) inside the cabin.

Partial reversion to FAR 29 at amendment 24:

FAR §29.571 – Fatigue Evaluation of Structure – CRI C-03 – Partial reversion only

for existing metallic parts fitted unchanged from previous AS 332 models so that

tolerance to flaw substantiation of JAR 29 is not carried out based on JAR 21.101

(b)(1) Not Significant Changes. Re-evaluation of safe life will be carried out based

on new loads.

FAR §29.785 – Seat, Berth, Safety Belts and Harnesses – CRI D-01 – Reversion

required due to cross-references to the JAR 29.562 and to the JAR 29.561(b) for

which EC requested respectively an exemption and a reversion.

(iv) Equivalent Level of Safety Findings:

EC 225 LP (* = also applicable to AS 332 L1e):

JAR §29.173, 175 – Static Longitudinal Stability – CRI B-03 – JAA NPA 29-26

was used to show an equivalent level of safety to the requirement for positive static

longitudinal stability.

TAR 13/21B/25 – Eurocopter AS332/EC225 6 Rev.0 : 2 October 2013

Type Acceptance Report

JAR 29 App B §IV – Static Longitudinal Stability – Airspeed Stability– CRI B-04

– The behaviour of the EC 225 LP was deemed to be safely equivalent to the

requirements of JAR 29 Appendix B §IV. *

JAR §29.571 – Fatigue Evaluation of Structure for changed metallic PSE – CRI C-

04 – Rule requirement was superseded by NPRM §29.571.

JAR §29.807(c)(1) – Passenger Emergency Exits other than side-of-fuselage – CRI

D-02 – The main cabin door offers an equivalent level of safety to Type II exit and

emergency exit layout is derived from AS 332L2.

JAR §29.813(a) and 29.815 – Emergency Exit access – Main Aisle Width – CRI D-

03 – The EC 225 LP is derived from the AS 332 L2 model and comparative

evacuation flow demonstrations showed that the evacuation flow was not affected.

JAR §29.807(d)(2) – Ditching Emergency Exits for passengers – CRI D-07 – The

EC 225 LP is derived from the AS 332 L2 model and ditching provisions are

retained from this original model. The greater weight of the EC 225 LP was shown

to not jeopardise safe evacuation.

JAR §29.923(a)(2) – Rotor Drive System and Control Mechanism Tests – CRI E-

03 – Tests were performed on a representative iron bird instead of an aircraft.

JAR §29.1303(j) – VNE Aural Warning – CRI F-01 – No aural warning fitted but

additional red strip on VNE indicator provides an equivalent level of safety. *

JAR §29.1545(b)(4) – Airspeed Indicators Markings – CRI G-01 – No green arc for

safe operating range but marking of abnormal limits and display design provide an

equivalent level of safety. *

JAR §29.1549(b) – Powerplant Instruments Markings – CRI G-02 – No green arc

for normal operating range but marking of abnormal limits and display design

provide an equivalent level of safety. *

(v) Exemptions:

EC 225 LP

JAR §29.562 – CRI No. C-02 – Emergency Landing Dynamic Landing Conditions

– Exemption based on similarity to AS 332 LP and reversion covered by CRI No.

C-01.

FAR §29.952(a)(c)(d)(e)(f)(g) – CRI No. E-01 – Fuel System Crash resistance– An

exemption to all sections except (b) was requested based on no significant change

in the fuel system compared to the AS 332 L2 system.

FAR §29.555(b) – CRI No. E-05 – Fuel Transfer – The right and left fuel tanks

have significantly different capacities, the fuel system design is such that the

transfer between the two groups of fuel tanks is not essential for the safety of flight

and does not impose an excessive workload on the flight crew, and is considered to

be unchanged from that used on the AS 332 L2 model.

FAR §29.963(b) – CRI No. E-02 (Partial Exemption) – Fuel Tanks: General;

Puncture resistance – A partial exemption was requested to keep the original AS

332 L2 requirement of FAR29.963 amendment 24, without the addition of

‘puncture resistance’. Note that puncture resistant bladder tanks that meet TSO-C80

are available as an option.

Rev.0 : 2 October 2013 7 TAR 13/21B/25 –Eurocopter AS332/EC225

Type Acceptance Report

(vi) Airworthiness Limitations:

AS 332 C, L, C1, L1: See the Airworthiness Limitations Chapter 05.99 of the

Maintenance Servicing Recommendations

AS 332 L2: See the Airworthiness Limitations Chapter 05.99 of the Maintenance

Servicing Recommendations

EC 225 LP: See the Airworthiness Limitations Chapter 05.99 of the Maintenance

Servicing Recommendations

(3) Aircraft Noise and Engine Emission Standards:

(i) Environmental Standard:

The AS 332 L2 and EC 225 LP have been certificated for noise against ICAO

Annex 16 Volume 1

(ii) Compliance Listing:

EASA Type Certificate Data Sheet for Noise Number R.002:

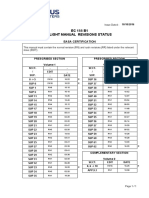

AS 332 L2: Noise Level Results - MTOW 9,300kg:

Takeoff: 94.3 EPNL Overflight: 93.5 EPNL Approach: 96.1 EPNL

AS 332 L2: Noise Level Results - MTOW 9,300kg (installation of large sponsons):

Takeoff: 94.6 EPNL Overflight: 93.4 EPNL Approach: 96.1 EPNL

EC 225 LP: Noise Level Results - MTOW 11,000kg (Makila 2A):

Takeoff: 95.6 EPNL Overflight: 93.5 EPNL Approach: 98.9 EPNL

EC 225 LP: Noise Level Results - MTOW 11,000kg (Makila 2A1):

Takeoff: 95.6 EPNL Overflight: 93.5 EPNL Approach: 98.9 EPNL

(4) Certification Compliance Listing:

AS 332 C (weight 7800kg): 332A05.0008, 1st issue dated 24 April 1981,

Certification Documents for the AS 332 C based on FAR Part 29 amendment 16

AS 332 C (weight 8350kg): 332A-055-0027, dated 7.12.81, AS 332 C weight

increase to 8.35T, maximum take-off power increase to 2235KW,compliance with

FAR 29 amendment 16,

AS 332 L (weight 8350kg): 332A.05.0028, dated 7.12.81, AS 332 L compliance

with FAR 29 amendment 16

AS 332 C/L (weight 8600kg): 332ABN.0001, dated 16/04/84, AS 332 C/L

increasing the gross weight to 8.6 Tons compliance with FAR 29 amendment 16,

AS 332 C1/L1: 332ABN.0004, dated 22.08.85, 332 C1/L1 Compliance with FAR

29 including amendment 16

AS 332 L2 (weight 9150kg): 332ABN-0057, dated 5/5/92, AS 332 L2 DGAC

certification compliance check list

AS 332 L2 (weight 9300kg): 332ABN-0093, dated 15/06/94, AS 332 L2 – 9300kg

certification DGAC conformité FAR 29 amendement 24

EC 225 LP: 332ABN-0187, dated 19.07.04, EC 225 LP Compliance Record

Document

TAR 13/21B/25 – Eurocopter AS332/EC225 8 Rev.0 : 2 October 2013

Type Acceptance Report

(5) Flight Manual: DGAC-Approved Rotorcraft Flight Manual AS332C

CAA Accepted as AIR 3261

DGAC-Approved Rotorcraft Flight Manual AS332L

CAA Accepted as AIR 3262

DGAC-Approved Rotorcraft Flight Manual AS332C1

CAA Accepted as AIR 3256

DGAC-Approved Rotorcraft Flight Manual AS332L1

CAA Accepted as AIR 3254

EASA-Approved Rotorcraft Flight Manual AS332L1(e)

CAA Accepted as AIR 3255

EASA-Approved Rotorcraft Flight Manual AS332L2

CAA Accepted as AIR 3260

EASA-Approved Rotorcraft Flight Manual EC225LP

CAA Accepted as AIR 3257

EASA-Approved Rotorcraft Flight Manual EC225LP (MPAI)

CAA Accepted as AIR 3258

(6) Operating Data for Aircraft and Engine:

(i) Maintenance Manual:

AS 332 B,B1,C,C1,F1,L,L1,M,M1 Maintenance Manual

Super Puma Version L2 Aircraft Maintenance Manual

EC 225 LP Aircraft Maintenance Manual

AS 332 B,B1,C,C1,F1,L,L1,M,M1 Wiring Diagram Manual (Typ I)

AS 332 B,B1,C,C1,F1,L,L1,M,M1 Wiring Diagram Manual (Typ II)

AS 332 B,B1,C,C1,F1,L,L1,M,M1 Fault Isolation Manual

AS 332 B,B1,C,C1,F1,L,L1,M,M1 Repair manual

AS 332 Mk2 Version L2 Structural Repair Manual

EC 225 LP Structural Repair Manual

(ii) Current service Information:

AS 332 Mk 1 (C,C1,L,L1) SIM: Index of Modifications

AS 332 Mk 2 (L2) SIM: Index of Modifications

EC 225 LP SIM: Index of Modifications

Service Information and Service Bulletins

(iii) Illustrated Parts Catalogue:

AS 332 Mk 1 (C,C1,L,L1) Illustrated Parts Catalog

AS 332 Mk 2 (L2) Illustrated Parts Catalog

EC 225 LP Illustrated Parts Catalog

(7) Agreement from manufacturer to supply updates of data in (5), and (6):

Access is provided through the Eurocopter website http://keycopter.eurocopter.com

(8) Other information:

AS 332 / 532 Mk 1 Illustrated Tools Catalog

Rev.0 : 2 October 2013 9 TAR 13/21B/25 –Eurocopter AS332/EC225

Type Acceptance Report

AS 332 / 532 Mk 2 Illustrated Tools Catalog

EC 225 LP Illustrated Tools Catalog

AS 332 B,B1,C,C1,F1,L,L1,M,M1 Description and Operation Manual

5. Additional New Zealand Requirements

Compliance with the retrospective airworthiness requirements of NZCAR Part 26 is a

prerequisite for the grant of a type acceptance certificate.

Civil Aviation Rules Part 26

Subpart B - Additional Airworthiness Requirements

Appendix B - All Aircraft

PARA: REQUIREMENT: MEANS OF COMPLIANCE:

B.1 Marking of Doors and Emergency Exits To be determined on an individual aircraft basis

B.2 Crew Protection Requirements – CAM 8 Appdx. B # .35 Not Applicable – Agricultural Aircraft only

Appendix E - Helicopters

PARA: REQUIREMENT: MEANS OF COMPLIANCE:

E.1 Doors and Exits FAR §29.783(c) and (e)

E.2.1 Emergency Exit Marking FAR §29.811(b) and (f)

Compliance with the following additional NZ operating requirements has been reviewed

and were found to be covered by either the original certification requirements or the basic

build standard of the aircraft, except as noted:

Civil Aviation Rules Part 91

Subpart F - Instrument and Equipment Requirements

PARA: REQUIREMENT: MEANS OF COMPLIANCE:

91.505 Seating and Restraints – Safety belt/Shoulder Harness FAR §29.785(c)

91.507 Pax Information Signs - Smoking, safety belts fastened FAR §29.1413

91.509 (1) ASI FAR §29.1303(a) (8) Coolant Temp N/A – Turbine engine

Min. (2) Machmeter N/A (9) Oil Temperature FAR §29.1413

VFR (3) Altimeter FAR §29.1303(b) (10) Manifold Pressure N/A – Turbine engine

(4) Magnetic Compass FAR §29.1303(c) (11) Cylinder Head Temp. N/A – Turbine engine

(5) Fuel Contents FAR §29.1305(a)(3) (12) Flap Position N/A – No flaps

(6) Engine RPM FAR §29.1305(a)(13) (13) U/c Position FAR §29.729(e)

(7) Oil Pressure FAR §29.1305(a)(6) (14) Ammeter/Voltmeter FAR §29.1351(b)(6)

Flight and navigation equipment - Operational Requirement – Compliance as applicable

91.511 (1)Turn and Slip Artificial Horizon fitted as Std (3) Anti-collision Lights Fitted as Std – See FM

Night – See FM (4) Instrument Lighting Fitted as Std – See FM

(2) Position Lights Fitted as Std – See FM

91.517 IFR Instruments and Equipment Operational Requirement – Compliance as applicable

91.519 IFR Communication and Navigation Equipment Operational Requirement – Compliance as applicable

91.523 Emergency Equipment

(a) More Than 9 pax - First Aid Kits per Table 7 Operational Requirement – Compliance as applicable

- Fire Extinguishers per Table 8 Operational Requirement – Compliance as applicable

(b) More than 20 pax - Axe readily accessible to crew Operational Requirement – Compliance as applicable

(c) More than 61 pax - Portable Megaphones per Table 9 Not Applicable – Less than 61 passenger seats

91.529 ELT - TSO C91a or C126 after 1/4/97 (or replacement) Operational Requirement – Compliance as applicable

91.531 Oxygen Indicators - Volume/Pressure/Delivery Operational Requirement – Compliance as applicable

91.533 Oxygen for Non-Pressurised Aircraft Operational Requirement – Compliance as applicable

>30 min above FL100 - Supplemental for crew, 10% Pax (Certificated for operations between 20,000 – 25,000

- Therapeutic for 3% of Pax depending on model).

Above FL100 - Supplemental for all Crew, Pax

- Therapeutic for 1% Pax, - 120l PBE each crew member

91.541 SSR Transponder and Altitude Reporting Equipment Operational Requirement – Compliance as applicable

91.543 Altitude Alerting Device - Turbojet or Turbofan Not Applicable – Not turbo jet or turbofan powered

91.545 Assigned Altitude Indicator Operational Requirement – Compliance as applicable

A.15 ELT Installation Requirements To be determined on an individual aircraft basis

TAR 13/21B/25 – Eurocopter AS332/EC225 10 Rev.0 : 2 October 2013

Type Acceptance Report

Civil Aviation Rules Part 135

Subpart F - Instrument and Equipment Requirements

PARA: REQUIREMENT: MEANS OF COMPLIANCE:

135.355 Seating and Restraints – Shoulder harness flight-crew seats Crew seats are equipped with a 4-point seat-belt system with

inertial-reel locking for the shoulder belts – See FM

135.357 Additional Instruments (Powerplant and Propeller) FAR §29.1305

135.359 Night Flight Landing light, Pax compartment Operational Requirement – Compliance as applicable

135.361 IFR Operations Speed, Alt, spare bulbs/fuses Operational Requirement – Compliance as applicable

135.363 Emergency Equipment (Part 91.523 (a) and (b)) Operational Requirement – Compliance would be required

135.367 Cockpit Voice Recorder Operational Requirement – Compliance would be required

135.369 Flight Data Recorder Operational Requirement – Compliance would be required

135.371 Additional Attitude Indicator Not Applicable – Not turbo jet or turbofan powered

Attachments

The following documents form attachments to this report:

Three-view drawing Eurocopter Model AS 332 L1

Copy of EASA Type Certificate Data Sheet Number R.002

Sign off

…………………………………….. ……………………………...............

Peter Gill Checked – Greg Baum

Airworthiness Engineer Airworthiness Engineer

Appendix 1

List of Type Accepted Variants:

Model: Applicant: CAA Work Request: Date Granted:

AS 332 C Heli-Harvest Ltd 13/21B/25 2 October 2013

AS 332 L Heli-Harvest Ltd 13/21B/25 2 October 2013

AS 332 C1 Heli-Harvest Ltd 13/21B/25 2 October 2013

AS 332 L1* Heli-Harvest Ltd 13/21B/25 2 October 2013

AS 332 L2 Heli-Harvest Ltd 13/21B/25 2 October 2013

EC 225 LP Heli-Harvest Ltd 13/21B/25 2 October 2013

*Including AS332L1e

Rev.0 : 2 October 2013 11 TAR 13/21B/25 –Eurocopter AS332/EC225

You might also like

- Remote control button functions guideDocument1 pageRemote control button functions guideAlp Erdem100% (1)

- As350 B2 13-100Document3 pagesAs350 B2 13-100JizzPontesNo ratings yet

- Heliwise Manual Rev - N PDFDocument386 pagesHeliwise Manual Rev - N PDFanderson75% (4)

- AS 350 B3e: Flight ManualDocument2 pagesAS 350 B3e: Flight ManualHeydi Serrano López0% (1)

- As350b3 VemdDocument40 pagesAs350b3 VemdRussell GouldenNo ratings yet

- Austin's Cover Letter Example - Cultivated CultureDocument1 pageAustin's Cover Letter Example - Cultivated CultureYash SNo ratings yet

- AFCSDocument84 pagesAFCSLeilson ArouchaNo ratings yet

- 412 B1.3 Bell Training ManualDocument276 pages412 B1.3 Bell Training ManualJan Kneissl100% (1)

- Bell 429 FMDocument66 pagesBell 429 FMjuan romero0% (1)

- 135 T3H P3H Technical Data Low ResolutionDocument126 pages135 T3H P3H Technical Data Low ResolutionAxel100% (2)

- 145 - D-2 - 18.101.01 - E - Technical - Data - LQDocument108 pages145 - D-2 - 18.101.01 - E - Technical - Data - LQAxel0% (2)

- Eurocopter AS332-EC225Document15 pagesEurocopter AS332-EC225Axel50% (2)

- EC-135 T1 (CDS) Normal ProceduresDocument16 pagesEC-135 T1 (CDS) Normal ProceduresHighspeed Flyboy100% (1)

- As332 Tech Data l1Document57 pagesAs332 Tech Data l1Lee Jihoon100% (3)

- EC 135 / BK117 C - 2 Training Manual FcdsDocument54 pagesEC 135 / BK117 C - 2 Training Manual FcdsCapt Greg100% (1)

- 155b1 FLM EasaDocument1,548 pages155b1 FLM EasarobinyNo ratings yet

- AW139 Chapter 5 2016-05-13Document136 pagesAW139 Chapter 5 2016-05-13anony8103100% (5)

- Pim 02277 R18Document11 pagesPim 02277 R18malsrNo ratings yet

- 1AW139 CMP Initial Pages 31.10.2012Document5 pages1AW139 CMP Initial Pages 31.10.2012Fayssal BkzNo ratings yet

- Rolls-Royce: 250-C30 Series Operation and MaintenanceDocument16 pagesRolls-Royce: 250-C30 Series Operation and MaintenanceJosé Edwin Roldán67% (3)

- Eurocopter TD AS365 N3Document58 pagesEurocopter TD AS365 N3arthikster100% (1)

- AirbusHelicopters Tools-GSE Catalog Dauphin Family July16Document160 pagesAirbusHelicopters Tools-GSE Catalog Dauphin Family July16robiny50% (4)

- BK117 D-2 Flight ManualDocument1,786 pagesBK117 D-2 Flight ManualCarlos Eduardo100% (2)

- Eurocopter EC 135Document14 pagesEurocopter EC 135Dharmendra Sumitra Upadhyay100% (1)

- Airbus EC120 MSM 120 MSM 05 E MC02 A4 VOL01 1 Low PDFDocument120 pagesAirbus EC120 MSM 120 MSM 05 E MC02 A4 VOL01 1 Low PDFAxelNo ratings yet

- BH Tif03Document21 pagesBH Tif03Andres R. OlguinNo ratings yet

- VV016042 Service Manual OS4 PDFDocument141 pagesVV016042 Service Manual OS4 PDFCamilo Andres Uribe Lopez100% (1)

- Type Acceptance Report for Beech 400A AircraftDocument13 pagesType Acceptance Report for Beech 400A AircraftAlexandrosNo ratings yet

- Flight Manual Additional Performance DataDocument155 pagesFlight Manual Additional Performance Data韩超No ratings yet

- OMNIFLIGHT EC-135 T1 WARNING AND CAUTION LIGHTSDocument48 pagesOMNIFLIGHT EC-135 T1 WARNING AND CAUTION LIGHTSHighspeed FlyboyNo ratings yet

- AW109SP - CockpitDocument1 pageAW109SP - Cockpitadwad100% (1)

- AS350B3-tech Data 2009 PDFDocument70 pagesAS350B3-tech Data 2009 PDFJorge Farias GomezNo ratings yet

- AS355NP Technical DataDocument76 pagesAS355NP Technical DatamycopteraviationNo ratings yet

- AgustaWestland AW 139 SN 41008 Reg M OLJMDocument3 pagesAgustaWestland AW 139 SN 41008 Reg M OLJMPedro TaverasNo ratings yet

- FAA Type Certificate Data Sheet for Airbus Helicopters AS350 SeriesDocument21 pagesFAA Type Certificate Data Sheet for Airbus Helicopters AS350 Serieskike002No ratings yet

- Flight Manual AS350B3 Arriel 2B1Document566 pagesFlight Manual AS350B3 Arriel 2B1Нагато Узумаки100% (1)

- Agusta AB139 Helicopter Servicing ProceduresDocument42 pagesAgusta AB139 Helicopter Servicing ProceduresŞükrü Çarkçi100% (1)

- Aw109sp RFMDocument1,056 pagesAw109sp RFMdrchristiantroy100% (5)

- Aw109sp RFM Faa Rev 23 3jul20Document1,152 pagesAw109sp RFM Faa Rev 23 3jul20Deborah AstieNo ratings yet

- Aw 109Document31 pagesAw 109Alex AbadNo ratings yet

- EC130 B4 Technical DataDocument30 pagesEC130 B4 Technical DataBruno Alonso PachecoNo ratings yet

- Bell 429 ProdSpecsDocument52 pagesBell 429 ProdSpecsJan Thys100% (1)

- C90GT Pre-Course Study GuideDocument32 pagesC90GT Pre-Course Study GuideRaoul Penent d'Izarn100% (1)

- AW189 HELICOPTER 04 - Air Vehicle Airworthiness LimitationsDocument10 pagesAW189 HELICOPTER 04 - Air Vehicle Airworthiness Limitationsmortada101No ratings yet

- Technical DataDocument56 pagesTechnical DataArturo Zu100% (1)

- Os Erj Legacy Operations ManualDocument26 pagesOs Erj Legacy Operations Manualednaus0% (1)

- AB/AW139 Main Rotor Blades and Rotating ControlsDocument56 pagesAB/AW139 Main Rotor Blades and Rotating ControlsJamesNo ratings yet

- H145 Normal Checklist 1.3Document1 pageH145 Normal Checklist 1.3Pili Simon100% (1)

- Transponder 20KT70 71Document4 pagesTransponder 20KT70 71JavierNo ratings yet

- Manual For Ecureuil HelicopterDocument63 pagesManual For Ecureuil Helicoptershahidcarlos100% (2)

- AW139 Quick Reference HandbookDocument266 pagesAW139 Quick Reference HandbookJorge BorgesNo ratings yet

- EC135 LimitationsDocument1 pageEC135 LimitationsHighspeed Flyboy100% (1)

- EC-155B1 Complimentary Flight Manual - Section 7 Description and SystemsDocument118 pagesEC-155B1 Complimentary Flight Manual - Section 7 Description and SystemsFlightdispatch Airjuan100% (1)

- AW139 Cat A Helicopter ProceduresDocument44 pagesAW139 Cat A Helicopter ProceduresMATHEUS MOURA100% (1)

- Maintenance Manual: Twinned Turboshaft EngineDocument32 pagesMaintenance Manual: Twinned Turboshaft EnginePanca XpNo ratings yet

- Model 250 C40BDocument2 pagesModel 250 C40Bsnappish1No ratings yet

- Air Tractor AT-500 Series W - PT6A-34 - 36 LibraryDocument2 pagesAir Tractor AT-500 Series W - PT6A-34 - 36 LibraryBruno FerrazNo ratings yet

- Ec 135Document100 pagesEc 135choppingcloudsNo ratings yet

- AW139Document14 pagesAW139Amy KlezanNo ratings yet

- MANDATORY LANDING GEAR INSPECTIONDocument17 pagesMANDATORY LANDING GEAR INSPECTIONGarrett ReeveNo ratings yet

- A109 PW206 - 207 AF SER A00 - A3Format - LowResDocument36 pagesA109 PW206 - 207 AF SER A00 - A3Format - LowResbetochal100% (2)

- Customer Technical Briefing On EC225 103112 PDFDocument19 pagesCustomer Technical Briefing On EC225 103112 PDFdiasfmNo ratings yet

- S76A RFM Pt. 1Document254 pagesS76A RFM Pt. 1zero610100% (2)

- The Australian Air Transport Pilot Licence (Helicopter) S76 Performance and Operations HandbookDocument75 pagesThe Australian Air Transport Pilot Licence (Helicopter) S76 Performance and Operations Handbookgreg mNo ratings yet

- Beechcraft Service Bulletin Master Index GuideDocument188 pagesBeechcraft Service Bulletin Master Index GuideEstevam Gomes de Azevedo100% (1)

- Airbus A320Document14 pagesAirbus A320radi8100% (7)

- Airbus EC120 MSM 120 MSM 05 E MC02 A4 VOL01 1 LowDocument46 pagesAirbus EC120 MSM 120 MSM 05 E MC02 A4 VOL01 1 LowAxelNo ratings yet

- 130 18 101 01 E Technical-DataDocument82 pages130 18 101 01 E Technical-DataAxel100% (1)

- H130 Brochure 2018Document8 pagesH130 Brochure 2018Axel100% (1)

- EASBAS332630083ENR0Document25 pagesEASBAS332630083ENR0AxelNo ratings yet

- Ec 225LP Hlo 1 Easa PMV SRD PDFDocument1 pageEc 225LP Hlo 1 Easa PMV SRD PDFAxelNo ratings yet

- CAP 1145 Offshore Helicopter Review and Annexes 24214 PDFDocument293 pagesCAP 1145 Offshore Helicopter Review and Annexes 24214 PDFAxelNo ratings yet

- H135 Brochure 2018Document8 pagesH135 Brochure 2018AxelNo ratings yet

- AAIB Bulletin 7-2014 v2Document102 pagesAAIB Bulletin 7-2014 v2AxelNo ratings yet

- Ec225 2013 230 Hrs PDFDocument1 pageEc225 2013 230 Hrs PDFAxelNo ratings yet

- HSSG May Newsletter - G-REDW DitchingDocument5 pagesHSSG May Newsletter - G-REDW DitchingUnion userNo ratings yet

- Easa Airworthiness Directive: AD No.: 2013-0069Document3 pagesEasa Airworthiness Directive: AD No.: 2013-0069AxelNo ratings yet

- Easa Airworthiness Directive: AD No.: 2013-0069Document3 pagesEasa Airworthiness Directive: AD No.: 2013-0069AxelNo ratings yet

- RescueSwimmer 1-2014 LRDocument40 pagesRescueSwimmer 1-2014 LRAxelNo ratings yet

- Havarirapport For Helikopterstyrt I Nordsøen 2009 PDFDocument209 pagesHavarirapport For Helikopterstyrt I Nordsøen 2009 PDFAxelNo ratings yet

- Super PumaDocument10 pagesSuper PumaAxelNo ratings yet

- Rotor 100 UkDocument36 pagesRotor 100 UkAxelNo ratings yet

- 225 LP 18.101.01 eDocument84 pages225 LP 18.101.01 eAxel100% (5)

- EASBAS332630083ENR0Document25 pagesEASBAS332630083ENR0AxelNo ratings yet

- AAIB Bulletin 7-2014 v2Document102 pagesAAIB Bulletin 7-2014 v2AxelNo ratings yet

- Ec225 2013 230 HrsDocument1 pageEc225 2013 230 HrsAxelNo ratings yet

- Easa Airworthiness Directive: AD No.: 2013-0069Document3 pagesEasa Airworthiness Directive: AD No.: 2013-0069AxelNo ratings yet

- H225 Brochure 2018Document8 pagesH225 Brochure 2018AxelNo ratings yet

- AAIB Bulletin 7-2014 v2Document102 pagesAAIB Bulletin 7-2014 v2AxelNo ratings yet

- Transactionreceipt Ethereum: Transaction IdentifierDocument1 pageTransactionreceipt Ethereum: Transaction IdentifierVALR INVESTMENTNo ratings yet

- Session CommandsDocument1,033 pagesSession Commandshan seongNo ratings yet

- Application of Carbon-Polymer Based Composite Electrodes For Microbial Fuel CellsDocument26 pagesApplication of Carbon-Polymer Based Composite Electrodes For Microbial Fuel Cellsavinash jNo ratings yet

- ScreenwritingDocument432 pagesScreenwritingkunalt09100% (4)

- Mafia Bride by CD Reiss (Reiss, CD)Document200 pagesMafia Bride by CD Reiss (Reiss, CD)Aurniaa InaraaNo ratings yet

- Vedic Astrology OverviewDocument1 pageVedic Astrology Overviewhuman999100% (8)

- Class 9 - Half Yearly Examination - 2023 - Portions and BlueprintDocument16 pagesClass 9 - Half Yearly Examination - 2023 - Portions and BlueprintSUBRAMANI MANOHARANNo ratings yet

- Communication & Collaboration: Lucy Borrego Leidy Hinojosa Scarlett DragustinovisDocument44 pagesCommunication & Collaboration: Lucy Borrego Leidy Hinojosa Scarlett DragustinovisTeacherlucy BorregoNo ratings yet

- PublicReviewDraft2742 (1) (002)Document75 pagesPublicReviewDraft2742 (1) (002)dhruv.encontrolsNo ratings yet

- Final Case Study 0506Document25 pagesFinal Case Study 0506Namit Nahar67% (3)

- Gizmotchy 3 Element Complete Assembly InstructionsDocument5 pagesGizmotchy 3 Element Complete Assembly InstructionsEuropaNo ratings yet

- Radial Drill Catalog-110620Document14 pagesRadial Drill Catalog-110620Anto SiminNo ratings yet

- Assurance Audit of Prepaid ExpendituresDocument7 pagesAssurance Audit of Prepaid ExpendituresRatna Dwi YulintinaNo ratings yet

- Demo TeachingDocument22 pagesDemo TeachingCrissy Alison NonNo ratings yet

- Mapúa Welding Shop PracticeDocument7 pagesMapúa Welding Shop PracticeJay EmNo ratings yet

- Curriculum Vitae: Name: Bhupal Shrestha Address: Kamalamai Municipality-12, Sindhuli, Nepal. Email: ObjectiveDocument1 pageCurriculum Vitae: Name: Bhupal Shrestha Address: Kamalamai Municipality-12, Sindhuli, Nepal. Email: Objectivebhupal shresthaNo ratings yet

- AESCSF Framework Overview 2020-21Document30 pagesAESCSF Framework Overview 2020-21Sandeep SinghNo ratings yet

- GooglepreviewDocument69 pagesGooglepreviewtarunchatNo ratings yet

- IRC-114-2013 Use of Silica Fume in Rigid PavementDocument14 pagesIRC-114-2013 Use of Silica Fume in Rigid PavementZakee MohamedNo ratings yet

- Specification: F.V/Tim e 3min 5min 8min 10MIN 15MIN 20MIN 30MIN 60MIN 90MIN 1.60V 1.67V 1.70V 1.75V 1.80V 1.85VDocument2 pagesSpecification: F.V/Tim e 3min 5min 8min 10MIN 15MIN 20MIN 30MIN 60MIN 90MIN 1.60V 1.67V 1.70V 1.75V 1.80V 1.85VJavierNo ratings yet

- Restaurant Social Media GuideDocument30 pagesRestaurant Social Media GuideHoàng gia NghiêmNo ratings yet

- Modul English For Study SkillsDocument9 pagesModul English For Study SkillsRazan Nuhad Dzulfaqor razannuhad.2020No ratings yet

- Solution Proposal For SGF - BomDocument2 pagesSolution Proposal For SGF - BomABHISHEK ADHIKARYNo ratings yet

- Unit 5 Vocabulary Basic 1 Match 1-10 With A-J To Make Innovations and InventionsDocument6 pagesUnit 5 Vocabulary Basic 1 Match 1-10 With A-J To Make Innovations and InventionsCristina Garcia50% (2)

- Vikash Kumar: 1. Aunico India May 2018Document4 pagesVikash Kumar: 1. Aunico India May 2018Rama Krishna PandaNo ratings yet

- Caribbean Studies - Lesson 8 - Concept and Indicator of Development PDFDocument37 pagesCaribbean Studies - Lesson 8 - Concept and Indicator of Development PDFDarrion BruceNo ratings yet