Professional Documents

Culture Documents

A Thermal Wheel

Uploaded by

rkibCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Thermal Wheel

Uploaded by

rkibCopyright:

Available Formats

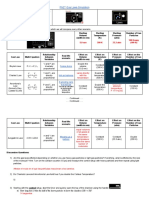

A thermal wheel, also known as a rotary heat exchanger, or rotary air-to-air enthalpy wheel, or heat recovery wheel, is a

type of energy recovery heat exchanger positioned within the supply and exhaust air streams of an air-handling system

or in the exhaust gases of an industrial process, in order to recover the heat energy. Other variants include enthalpy

wheels and desiccant wheels. A cooling-specific thermal wheel is sometimes referred to as a Kyoto wheel. A thermal

wheel consists of a circular honeycomb matrix of heat-absorbing material, which is slowly rotated within the supply and

exhaust air streams of an air-handling system. As the thermal wheel rotates, heat is picked up from the exhaust air

stream in one half of the rotation and given up to the fresh air stream in the other half of the rotation. Thus waste heat

energy from the exhaust air stream is transferred to the matrix material and then from the matrix material to the fresh air

stream, raising the temperature of the supply air stream by an amount proportional to the temperature differential

between air streams, or "thermal gradient", and depending upon the efficiency of the device. Heat exchange is most

efficient when the streams flow in opposite directions, since this causes a favourable temperature gradient across the

thickness of the wheel. The principle of course works in reverse, and "cooling" energy can be recovered to the supply air

stream if so desired and the temperature differential allows. The heat exchange matrix may be aluminium, plastic, or

synthetic fiber. The heat exchanger is rotated by a small electric motor and belt drive system. The motors are often

inverter speed-controlled for improved control of the leaving air temperature. If no heat exchange is required, then the

motor can be stopped altogether. Because of the nature of thermal wheels in the way that heat is transferred from the

exhaust air stream to the supply air stream without having to pass directly through an exchange medium, the gross

efficiencies are usually much higher than that of any other air-side heat recovery system. The shallower depth of the

heat exchange matrix, as compared to that, say, for a plate heat exchanger, means that the pressure drop through the

device is normally lower in comparison. Generally, a thermal wheel will be selected for face velocities between 1.5 and

3.0 metres per second (4.9 and 9.8 ft/s), and with equal air volume flow rates, gross "sensible" efficiencies of 85% can

be expected. Although there is a small extra energy requirement to rotate the wheel, the motor energy consumption is

usually very low and has little effect upon the seasonal efficiency of the device. In addition, the ability to recover "latent"

heat, depending upon the materials and coatings used, can improve gross efficiencies by 10–15%. Normally the heat

transfer between airstreams provided by the device is termed as "sensible", which is the exchange of energy, or

enthalpy, resulting in a change in temperature of the medium (air in this case), but with no change in moisture content.

However, if moisture or relative humidity levels in the return air stream are high enough to allow condensation to take

place in the device, then this will cause "latent" heat to be released, and the heat transfer material will be covered with a

film of water. Despite a corresponding absorption of latent heat, as some of the water film is evaporated in the opposite

airstream, the water will reduce the thermal resistance of the boundary layer of the heat exchanger material and thus

improve the heat transfer coefficient of the device, and hence increase efficiency. The energy exchange of such devices

now comprises both sensible and latent heat transfer; in addition to a change in temperature, there is also a change in

moisture content of the air streams.

You might also like

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemFrom EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemNo ratings yet

- Recuperator - Wikipedia, The Free EncyclopediaDocument3 pagesRecuperator - Wikipedia, The Free EncyclopediaAvijit DasNo ratings yet

- Heating Coil in The Main Air Handling UnitDocument13 pagesHeating Coil in The Main Air Handling UnitApurv GoyalNo ratings yet

- AHU Heat Recovery OptionsDocument6 pagesAHU Heat Recovery OptionsManmeet KumarNo ratings yet

- Air ConditioningDocument11 pagesAir ConditioningBrilliantJohnMalandacRubiaNo ratings yet

- Heat Exchanger Flow Configurations: Parallel vs CounterDocument16 pagesHeat Exchanger Flow Configurations: Parallel vs CounterLight OneNo ratings yet

- HVAC Air Coils Explained: Heating, Cooling and Humidification ElementsDocument3 pagesHVAC Air Coils Explained: Heating, Cooling and Humidification ElementsAshiqNo ratings yet

- Assignment: Cogeneration and Waste Heat Recovery SystemsDocument8 pagesAssignment: Cogeneration and Waste Heat Recovery Systemsd_raj187No ratings yet

- Air Handling Unit (AHU)Document6 pagesAir Handling Unit (AHU)bibombioNo ratings yet

- Air To Air Heat Exchangers For AirDocument8 pagesAir To Air Heat Exchangers For AirOmair FarooqNo ratings yet

- Stirling Engine GuideDocument23 pagesStirling Engine GuideHruday DanamNo ratings yet

- Cooling Systems 101Document4 pagesCooling Systems 101shrey_jackie794No ratings yet

- How Heat Pumps Transfer Thermal Energy Between SpacesDocument3 pagesHow Heat Pumps Transfer Thermal Energy Between SpacesSho TiNo ratings yet

- Heat Pumps - ArticleDocument6 pagesHeat Pumps - Articlearnol_fo2No ratings yet

- Design and Evaluation of a 3 TR Ammonia-Water VAR SystemDocument37 pagesDesign and Evaluation of a 3 TR Ammonia-Water VAR SystemEman El DsoukyNo ratings yet

- Return air energy recovery methods for HVAC systemsDocument3 pagesReturn air energy recovery methods for HVAC systemsmister_no34No ratings yet

- HVAC Systems Guide: Types, Components & How AC WorksDocument3 pagesHVAC Systems Guide: Types, Components & How AC WorksDen Mas DeepNo ratings yet

- Gas Turbine 1Document25 pagesGas Turbine 1Muhammed SabeehNo ratings yet

- Chapter 1 NewDocument7 pagesChapter 1 NewSaheera HazarikaNo ratings yet

- Alter Polymerization Reactors for Enhanced Heat TransferDocument7 pagesAlter Polymerization Reactors for Enhanced Heat TransferafifiNo ratings yet

- Conjugate Heat Transfer in AirtoRefrigerant Airfoil Heat ExchangersDocument12 pagesConjugate Heat Transfer in AirtoRefrigerant Airfoil Heat ExchangersMohammed AshiqueNo ratings yet

- Thermal Power Plant Lay OutDocument8 pagesThermal Power Plant Lay OutSaheli ChoudhuriNo ratings yet

- Improvement in The Performance of Cooling Tower of Thermal Power PlantDocument4 pagesImprovement in The Performance of Cooling Tower of Thermal Power PlantVetihiNo ratings yet

- Technical HP Factsheet For WebDocument12 pagesTechnical HP Factsheet For WebDanutz MaximNo ratings yet

- Heat Pipe ApplicationDocument3 pagesHeat Pipe ApplicationAnonymous mRBbdopMKfNo ratings yet

- Boost Boiler Efficiency With An Air PreheaterDocument26 pagesBoost Boiler Efficiency With An Air Preheaterkowsar0221No ratings yet

- Cascade Control in BmsDocument2 pagesCascade Control in BmsritwikNo ratings yet

- Cooling Tower Lab Report AnalysisDocument10 pagesCooling Tower Lab Report Analysisseraj ibramemNo ratings yet

- Script:-.Air Condition ScriptDocument11 pagesScript:-.Air Condition Scriptaimri_cochinNo ratings yet

- Characterizing of Cooling Equipment For Closed GreenhousesDocument8 pagesCharacterizing of Cooling Equipment For Closed GreenhousesJaviercm10No ratings yet

- Boost Boiler Efficiency with EconomizersDocument5 pagesBoost Boiler Efficiency with Economizersreyalene gallegos100% (1)

- Air Cooled Heat Exchnger FormatedDocument43 pagesAir Cooled Heat Exchnger FormatedMustafa Anwar50% (2)

- Powerplant - Cooling Sytem Cooling Tower Feedwater Heater Condenser EvaporatorDocument32 pagesPowerplant - Cooling Sytem Cooling Tower Feedwater Heater Condenser EvaporatorYehosuah RanoaNo ratings yet

- 1.1 Background of StudyDocument12 pages1.1 Background of StudyazlanNo ratings yet

- HVAC Dictionary GuideDocument25 pagesHVAC Dictionary GuideRanjitNo ratings yet

- Cooling Tower Heat and MassDocument18 pagesCooling Tower Heat and MassChris Mark100% (2)

- How Heat Pumps Reverse Natural Heat Transfer Using RefrigerantsDocument2 pagesHow Heat Pumps Reverse Natural Heat Transfer Using RefrigerantsanandanNo ratings yet

- Solar Air ConditingDocument12 pagesSolar Air Conditingmukesh3021No ratings yet

- ReportDocument50 pagesReportMICHAEL PRADEEPNo ratings yet

- Advance Cooling and Heating System For CabinetDocument5 pagesAdvance Cooling and Heating System For CabinetANKITNo ratings yet

- Heat Exchanger IntroductionDocument8 pagesHeat Exchanger Introductionalan_yaobin8409No ratings yet

- Design of Vacuum Systems For Crude Oil Vacuum Tower DistillationDocument5 pagesDesign of Vacuum Systems For Crude Oil Vacuum Tower DistillationnasirmuzaffarNo ratings yet

- Peltier Air-ConditionerDocument2 pagesPeltier Air-ConditionerVIPIN KUMARNo ratings yet

- Cooling Systems ExplainedDocument6 pagesCooling Systems ExplainedYehosuah RanoaNo ratings yet

- Ppe Pit Obando's PartDocument8 pagesPpe Pit Obando's PartJane PondulanNo ratings yet

- Regenerative Heat ExchangerDocument4 pagesRegenerative Heat ExchangerSalehAfadlehNo ratings yet

- Waste Heat Boiler Plate Heat ExchangersDocument8 pagesWaste Heat Boiler Plate Heat ExchangerskondusamyNo ratings yet

- Cooling System of High Power Synchronous GeneratorDocument5 pagesCooling System of High Power Synchronous GeneratorLorem53No ratings yet

- BodyDocument69 pagesBodyRoi Benedict BuenaNo ratings yet

- Thermo Heat PumpDocument15 pagesThermo Heat PumpAkshay BhadangeNo ratings yet

- Regenerator: Types of Stirling Engine RegeneratorDocument3 pagesRegenerator: Types of Stirling Engine RegeneratorAhver ChaudharyNo ratings yet

- Thermal Management of Electronics DevicesDocument4 pagesThermal Management of Electronics Devicesrpselvakumar2008No ratings yet

- Introduction To Steam DistributionDocument26 pagesIntroduction To Steam DistributionEmeka Nkwocha100% (1)

- Cfakepathlayoutofthermalpowerplant 091031114144 Phpapp01Document21 pagesCfakepathlayoutofthermalpowerplant 091031114144 Phpapp01Shruti GuptaNo ratings yet

- Solar Refrigeration GuideDocument31 pagesSolar Refrigeration GuideAMIT PRAJAPATI88% (8)

- Thermal Power Plant 1Document30 pagesThermal Power Plant 1ckissyou04No ratings yet

- Oral and Practical Review: Reflections on the Part 147 CourseFrom EverandOral and Practical Review: Reflections on the Part 147 CourseNo ratings yet

- Thermodynamic analysis of geothermal heat pumps for civil air-conditioningFrom EverandThermodynamic analysis of geothermal heat pumps for civil air-conditioningRating: 5 out of 5 stars5/5 (2)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AFrom EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANo ratings yet

- Benefits of Variable Speed Pumped Storage for Transient Island Grid StabilityDocument18 pagesBenefits of Variable Speed Pumped Storage for Transient Island Grid StabilityspyroszafNo ratings yet

- ComfortDocument10 pagesComfortrkibNo ratings yet

- المصطلحات والرموزDocument10 pagesالمصطلحات والرموزnaser150No ratings yet

- المصطلحات والرموزDocument10 pagesالمصطلحات والرموزnaser150No ratings yet

- Verso S 20 X H PM - Ie5 - 1 - 4 - X F7 X X R1 C5 - 1 XDocument5 pagesVerso S 20 X H PM - Ie5 - 1 - 4 - X F7 X X R1 C5 - 1 XrkibNo ratings yet

- Three-fluid heat exchangers effectiveness evaluationDocument9 pagesThree-fluid heat exchangers effectiveness evaluationrkibNo ratings yet

- Did You Know - (7) Interesting Facts About CoilsDocument2 pagesDid You Know - (7) Interesting Facts About CoilsrkibNo ratings yet

- Top 5 Reasons HVAC Coils Prematurely FailDocument3 pagesTop 5 Reasons HVAC Coils Prematurely FailrkibNo ratings yet

- Why Use Insulated Chilled Water Coil Cabinets in Duct Systems - LinkedIn PDFDocument3 pagesWhy Use Insulated Chilled Water Coil Cabinets in Duct Systems - LinkedIn PDFrkibNo ratings yet

- EHS DOC 022 CryogenicsGuidelinesDocument9 pagesEHS DOC 022 CryogenicsGuidelinesrkibNo ratings yet

- Exchange News 1 1Document7 pagesExchange News 1 1rkibNo ratings yet

- Rts Using+excelDocument63 pagesRts Using+excelrkibNo ratings yet

- Cryocooler Fundamentals ExplainedDocument36 pagesCryocooler Fundamentals ExplainedpraphultmenonNo ratings yet

- Management For Building Water Systems: LegionellaDocument1 pageManagement For Building Water Systems: LegionellarkibNo ratings yet

- Chilled beams: An efficient HVAC convection systemDocument1 pageChilled beams: An efficient HVAC convection systemrkibNo ratings yet

- Hampson Linde CycleDocument2 pagesHampson Linde CyclerkibNo ratings yet

- HVAC Skills Workshop Explains Active Chilled BeamsDocument3 pagesHVAC Skills Workshop Explains Active Chilled BeamsrkibNo ratings yet

- Rts Using+excel PDFDocument6 pagesRts Using+excel PDFabhiNo ratings yet

- Water Source VRF BrochureDocument8 pagesWater Source VRF BrochurerkibNo ratings yet

- The Essentials of Chilled Beams - Part 2: Skills WorkshopDocument3 pagesThe Essentials of Chilled Beams - Part 2: Skills WorkshoprkibNo ratings yet

- Load Calculation Spreadsheets: Quick Answers Without Relying On Rules of ThumbDocument5 pagesLoad Calculation Spreadsheets: Quick Answers Without Relying On Rules of ThumbrkibNo ratings yet

- Water CoolDocument4 pagesWater CoolrkibNo ratings yet

- Zoning Application ManualDocument44 pagesZoning Application Manualrkib100% (1)

- HVAC Skills Workshop explores chilled beamsDocument3 pagesHVAC Skills Workshop explores chilled beamsrkibNo ratings yet

- Basics of Duct Design FundamentalsDocument3 pagesBasics of Duct Design FundamentalsHamidullah Asady WardakNo ratings yet

- HVACRNation - 2009 02 F03 PDFDocument2 pagesHVACRNation - 2009 02 F03 PDFrkibNo ratings yet

- Chart HvacDocument1 pageChart HvacrkibNo ratings yet

- 12 Low Temperature Air Distribution PDFDocument2 pages12 Low Temperature Air Distribution PDFrkibNo ratings yet

- Selecting Supply Air Conditions for a Dedicated Outdoor Air System (DOASDocument10 pagesSelecting Supply Air Conditions for a Dedicated Outdoor Air System (DOASrkibNo ratings yet

- CIRIA Restraint WallDocument5 pagesCIRIA Restraint WallMajdoline SadeddineNo ratings yet

- Quiz 3Document2 pagesQuiz 3Vishruta KathuriaNo ratings yet

- Web Compression Buckling Capacity Prediction For Unstiffened I-Sections With Opposite Patch LoadingDocument19 pagesWeb Compression Buckling Capacity Prediction For Unstiffened I-Sections With Opposite Patch LoadingGogyNo ratings yet

- Gravity Dam Engineering: Design, Forces, Stability Analysis & Failure ModesDocument43 pagesGravity Dam Engineering: Design, Forces, Stability Analysis & Failure ModesMadan Mohan ReddyNo ratings yet

- PhET Gas Laws Simulation ExplainedDocument3 pagesPhET Gas Laws Simulation Explainedx0% (1)

- Equations of Stellar Structure - 7Document7 pagesEquations of Stellar Structure - 7John BirdNo ratings yet

- Thermal Properties of MaterialsDocument15 pagesThermal Properties of MaterialsTEBATSONo ratings yet

- Chapter 3 2D Simulations GuideDocument23 pagesChapter 3 2D Simulations GuideTran Van TienNo ratings yet

- Aerodynamic principles and equations in Anderson-98101Document1 pageAerodynamic principles and equations in Anderson-98101Daniel OrhanNo ratings yet

- Building Strategies for Sustainability SimulationDocument39 pagesBuilding Strategies for Sustainability Simulationpil;zoNo ratings yet

- CIVE233+2021-22+Timber+Lab+Brief+v1 NnGe33uDocument5 pagesCIVE233+2021-22+Timber+Lab+Brief+v1 NnGe33uPRATEEK SHARMANo ratings yet

- Lecture 7: Convective Heat Transfer: Reynolds AnalogyDocument16 pagesLecture 7: Convective Heat Transfer: Reynolds Analogy06me395No ratings yet

- Worksheet: - Earthquake P-Wave & S-Wave Travel Time Chart TutorialDocument31 pagesWorksheet: - Earthquake P-Wave & S-Wave Travel Time Chart TutorialJoanna Nicole MercadoNo ratings yet

- SGT PDFDocument383 pagesSGT PDFDushyanthkumar DasariNo ratings yet

- 4500 CFM - 0.3 InwgDocument1 page4500 CFM - 0.3 InwgResti HapsariNo ratings yet

- Galambos Ravindra 1976Document103 pagesGalambos Ravindra 1976Eric NolascoNo ratings yet

- Bluff Body (Ahmed Body)Document131 pagesBluff Body (Ahmed Body)Muhammad FaridhwanNo ratings yet

- Wing DesignDocument22 pagesWing DesignKudzie Craig Kelvin Mutasa100% (1)

- Water Supply CalculationsDocument8 pagesWater Supply CalculationsAshiq NishmaNo ratings yet

- KULIAH3 EC3 UNRESTRAINED BEAM-kl PDFDocument66 pagesKULIAH3 EC3 UNRESTRAINED BEAM-kl PDFZazliana Izatti100% (1)

- 07 01ChapGereDocument14 pages07 01ChapGereChristina BuckleNo ratings yet

- Rectangular Concrete Beam, Column Analysis and DesignDocument27 pagesRectangular Concrete Beam, Column Analysis and DesignFernando Sernaqué CalleNo ratings yet

- ANALYSIS OF STEAM CYCLESDocument4 pagesANALYSIS OF STEAM CYCLESahmedytxzNo ratings yet

- Fluid Mechanics (XE (B) ) PDFDocument5 pagesFluid Mechanics (XE (B) ) PDFLucas SchroederNo ratings yet

- Thesis PDFDocument97 pagesThesis PDFmostafa shahrabiNo ratings yet

- Applying Energy Concepts from MechanicsDocument4 pagesApplying Energy Concepts from MechanicsFatyma AlcantaraNo ratings yet

- Mini Project On Solar Water Heater Complete 2Document19 pagesMini Project On Solar Water Heater Complete 2jadhavakshay610No ratings yet

- Hand Calculations in Structural AnalysisDocument3 pagesHand Calculations in Structural AnalysisArdalan YazarNo ratings yet

- A Drop S Journey AnswersDocument2 pagesA Drop S Journey AnswersMuhammad Muzammil58% (48)

- LPG Tanker WoolcottDocument80 pagesLPG Tanker WoolcottnickurfriendNo ratings yet