Professional Documents

Culture Documents

Asme Material Specs PDF

Uploaded by

Julio Cesar Morales CruzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asme Material Specs PDF

Uploaded by

Julio Cesar Morales CruzCopyright:

Available Formats

ARTICLE 3 — STRESSES AND THICKNESSES Table HF-300.

TABLE HF-300.1 98

MAXIMUM ALLOWABLE STRESS VALUES FOR FERROUS MATERIALS, ksi A99

(Multiply by 1000 to Obtain psi)

External Spec. Min. Spec. Min. Max. Allow.

Spec. Nominal Group Pressure Tensile Strength, Yield Strength, Stress Value,

No. Grade Composition P-No. No. Chart ksi ksi Note(s) ksi

Plate Steels

Carbon Steels

SA-36 ... C–Mn–Si 1 1 CS-2 58.0 36 (7)(19) 11.6

SA-285 A C 1 1 CS-1 45.0 24 ... 9.0

SA-285 B C 1 1 CS-1 50.0 27 ... 10.0

SA-285 C C 1 1 CS-1 55.0 30 ... 11.0

SA-455 ... C–Mn 1 2 CS-2 75.0 38 (8) 15.0

SA-455 ... C–Mn 1 2 CS-2 73.0 37 (9) 14.6

SA-455 ... C–Mn 1 2 CS-2 70.0 35 (10) 14.0

SA-515 60 C–Si 1 1 CS-2 60.0 32 ... 12.0

SA-515 65 C–Si 1 1 CS-2 65.0 36 ... 13.0

SA-515 70 C–Si 1 2 CS-2 70.0 38 ... 14.0

SA-516 55 C–Si 1 1 CS-2 55.0 30 ... 11.0

SA-516 60 C–Mn–Si 1 1 CS-2 60.0 32 ... 12.0

SA-516 65 C–Mn–Si 1 1 CS-2 65.0 36 ... 13.0

SA-516 70 C–Mn–Si 1 2 CS-2 70.0 38 ... 14.0

Sheet Steels

Carbon Steels

SA-414 A C 1 1 CS-1 45.0 25 ... 9.0

SA-414 B C 1 1 CS-2 50.0 30 ... 10.0

SA-414 C C 1 1 CS-2 55.0 33 ... 11.0

SA-414 D C–Mn 1 1 CS-2 60.0 35 ... 12.0

SA-414 E C–Mn 1 1 CS-2 65.0 38 ... 13.0

SA-414 F C–Mn 1 2 CS-3 70.0 42 ... 14.0

SA-414 G C–Mn 1 2 CS-3 75.0 45 ... 15.0

SA-620 ... C 1 1 CS-6 40.0 20 ... 8.0

Pipe and Tubes

Seamless Carbon Steel

SA-53 A C 1 1 CS-2 48.0 30 ... 9.6

SA-53 B C–Mn 1 1 CS-2 60.0 35 ... 12.0

SA-106 A C–Si 1 1 CS-2 48.0 30 ... 9.6

SA-106 B C–Si 1 1 CS-2 60.0 35 ... 12.0

SA-106 C C–Si 1 2 CS-3 70.0 40 ... 14.0

SA-192 ... C–Si 1 1 CS-1 (47.0) 26 (1) 9.4

SA-210 A-1 C–Si 1 1 CS-2 60.0 27 ... 12.0

89

ASME B&PVC sec4$$$u50 05-27-99 03:22:00 pd: sec4 Rev 14.04

Table HF-300.1 1998 SECTION IV

98 TABLE HF-300.1 (CONT’D)

A99 MAXIMUM ALLOWABLE STRESS VALUES FOR FERROUS MATERIALS, ksi

(Multiply by 1000 to Obtain psi)

External Spec. Min. Spec. Min. Max. Allow.

Spec. Nominal Group Pressure Tensile Strength, Yield Strength, Stress Value,

No. Grade Composition P-No. No. Chart ksi ksi Note(s) ksi

Pipe and Tubes (Cont’d)

Electric Resistance Welded Carbon Steel

SA-53 A C 1 1 CS-2 48.0 30 (2) 8.2

SA-53 B C–Mn 1 1 CS-2 60.0 35 (2) 10.2

SA-135 A C 1 1 CS-2 48.0 30 (2) 8.2

SA-135 B C–Mn 1 1 CS-2 60.0 25 (2) 10.2

SA-178 A C 1 1 CS-1 (47.0) 26 (1)(2) 8.0

SA-178 C C 1 1 CS-2 60.0 37 (2) 10.2

SA-226 ... C–Si 1 1 CS-1 (47.0) 26 (1)(2) 8.0

Butt Welded

SA-53 Steel C 1 1 ... 48.0 30 (4) 5.8

Forgings

Carbon Steels

SA-105 ... C–Si 1 2 ... 70.0 36 ... 14.0

SA-181 Class 60 C–Si 1 1 CS-2 60.0 30 ... 12.0

SA-181 Class 70 C–Si 1 2 CS-2 70.0 36 ... 14.0

SA-266 1 C–Si 1 1 CS-2 60.0 30 ... 12.0

SA-266 2 C–Si 1 2 CS-2 70.0 36 ... 14.0

SA-266 3 C–Si 1 2 CS-2 75.0 37.5 ... 15.0

Castings

Carbon Steels

SA-216 WCA C–Si 1 1 CS-2 60.0 30 (5) 9.6

SA-216 WCB C–Si 1 2 CS-2 70.0 36 (5) 11.2

Bolting

Carbon Steels

SA-307 B C ... ... ... 60.0 ... (6) 15.0

SA-193 B5 5Cr–1⁄2Mo ... ... ... 100.0 ... (6) 25.0

SA-193 B7 1Cr–0.2Mo ... ... ... 100.0 ... (6) 25.0

SA-311 1018, ... ... ... ... ... ... (20) (20a) 14.0

Class A

... ... ... ... ... ... (20b) 13.0

SA-311 1035, ... ... ... ... ... ... (20) (20a) 17.0

Class A

... ... ... ... ... ... (20b) 16.0

SA-311 1045, ... ... ... ... ... ... (20) (20a) 19.0

Class A

... ... ... ... ... ... (20b) 18.0

SA-311 1045, ... ... ... ... ... ... (20) (20a) 23.0

Class B

SA-311 1050, ... ... ... ... ... ... (20) (20a) 20.0

Class A

... ... ... ... ... ... (20b) 19.0

SA-320 L7 1Cr–0.2Mo ... ... ... 125.0 ... (6) 25.0

SA-320 L43 13⁄4Ni–3⁄4Cr– ... ... ... 125.0 ... (6) 25.0

1⁄ Mo

4

SA-325 1 C ... ... ... ... ... (6) 7.0

SA-354 BC C ... ... ... ... ... (6) 25.0

SA-354 BD C ... ... ... ... ... (6) 25.0

90

ASME B&PVC sec4$$$u50 05-27-99 03:22:00 pd: sec4 Rev 14.04

ARTICLE 3 — STRESSES AND THICKNESSES Table HF-300.1

TABLE HF-300.1 (CONT’D) 98

MAXIMUM ALLOWABLE STRESS VALUES FOR FERROUS MATERIALS, ksi A99

(Multiply by 1000 to Obtain psi)

External Spec. Min. Spec. Min. Max. Allow.

Spec. Nominal Group Pressure Tensile Strength, Yield Strength, Stress Value,

No. Grade Composition P-No. No. Chart ksi ksi Note(s) ksi

Bars and Stays

Carbon Steels

SA-36 ... C–Mn–Si 1 1 ... 58.0 ... (7) 11.6

SA-675 45 C 1 1 ... 45.0 ... ... 9.0

SA-675 50 C 1 1 ... 50.0 ... ... 10.0

SA-675 55 C 1 1 ... 55.0 ... ... 11.0

SA-675 60 C 1 1 ... 60.0 ... ... 12.0

SA-675 65 C 1 1 ... 65.0 ... ... 13.0

SA-675 70 C 1 2 ... 70.0 ... ... 14.0

Plate

Alloy Steel

SA-240 304 18Cr–8Ni 8 1 HA-1 75.0 30 (16) 15.0

SA-240 304L 18Cr–8Ni 8 1 HA-3 70.0 25 (16) 14.0

SA-240 316 16Cr–12Ni– 8 1 HA-2 75.0 30 (16) 15.0

2Mo

SA-240 316L 16Cr–12Ni– 8 1 HA-4 70.0 25 (16) 14.0

2Mo

SA-240 316Ti 16Cr–12Ni– 8 1 HA-2 75.0 30 (16) 15.0

2Mo–Ti

SA-240 439 18Cr–Ti 7 2 ... 65.0 30 (11)(12)(13) 13.0

SA-240 S44400 18Cr–2Mo 7 2 CS-2 60.0 40 (11)(18) 12.0

Tube

Alloy Steel

SA-213 TP304 Smls. 18Cr– 8 1 HA-1 75.0 30 (14)(15)(16) 15.0

8Ni

SA-213 TP304L Smls. 18Cr– 8 1 HA-3 70.0 25 (14)(15)(16) 14.0

8Ni

SA-213 TP316 Smls. 16Cr– 8 1 HA-2 75.0 30 (14)(15)(16) 15.0

12Ni–2Mo

SA-213 TP316L Smls. 16Cr– 8 1 HA-4 70.0 25 (14)(15)(16) 14.0

12Ni–2Mo

SA-249 TP304 Wld. 18Cr– 8 1 HA-1 75.0 30 (2)(14)(15)(16) 12.8

8Ni

SA-249 TP304L Wld. 18Cr– 8 1 HA-3 70.0 25 (2)(14)(15)(16) 11.9

8Ni

SA-249 TP316 Wld. 16Cr– 8 1 HA-2 75.0 30 (2)(14)(15)(16) 12.8

12Ni–2Mo

SA-249 TP316L Wld. 16Cr– 8 1 HA-4 70.0 25 (2)(14)(15)(16) 11.9

12Ni–2Mo

SA-268 S44400 18Cr–2Mo 7 2 CS-2 60.0 40 (11)(18) 12.0

SA-268 TP439 18Cr–Ti 7 2 CS-2 60.0 40 (11)(12)(13) 12.0

SA-268 S44735 Smls. 29Cr– 10J 1 CS-2 75.0 60 (22) 15.0

4Mo

SA-268 S44735 Wld. 29Cr– 10J 1 CS-2 75.0 60 (2)(22) 12.7

4Mo

91

ASME B&PVC sec4$$$u50 05-27-99 03:22:00 pd: sec4 Rev 14.04

Table HF-300.1 1998 SECTION IV

98 TABLE HF-300.1 (CONT’D)

A99 MAXIMUM ALLOWABLE STRESS VALUES FOR FERROUS MATERIALS, ksi

(Multiply by 1000 to Obtain psi)

External Spec. Min. Spec. Min. Max. Allow.

Spec. Nominal Group Pressure Tensile Strength, Yield Strength, Stress Value,

No. Grade Composition P-No. No. Chart ksi ksi Note(s) ksi

Pipe

Alloy Steel

SA-312 TP304 Smls. 18Cr– 8 1 HA-1 75.0 30 (15)(16) 15.0

8Ni

SA-312 TP304L Smls. 18Cr– 8 1 HA-3 70.0 25 (15)(16) 14.0

8Ni

SA-312 TP316 Smls. 16Cr– 8 1 HA-2 75.0 30 (15)(16) 15.0

12Ni– 2Mo

SA-312 TP316L Smls. 16Cr– 8 1 HA-4 70.0 25 (15)(16) 14.0

12Ni– 2Mo

SA-312 TP304 Wld. 18Cr– 8 1 HA-1 75.0 30 (2)(15)(16) 12.8

8Ni

SA-312 TP304L Wld. 18Cr– 8 1 HA-3 70.0 25 (2)(15)(16) 11.9

8Ni

SA-312 TP316 Wld. 16Cr– 8 1 HA-2 75.0 30 (2)(15)(16) 12.8

12Ni–2Mo

SA-312 TP316L Wld. 16Cr– 8 1 HA-4 70.0 25 (2)(15)(16) 11.9

12Ni–2Mo

Bar

Alloy Steel

SA-479 S44400 18Cr–2Mo 7 2 ... 60.0 ... (11)(18) 12.0

SA-479 439 18Cr–Ti 7 2 HA-27 70.0 40 (11)(12)(13) 14.0

Forgings

Alloy Steel

SA-182 F304 18Cr–8Ni 8 1 HA-1 75.0 30 (15)(16)(21) 15.0

SA-182 F304L 18Cr–8Ni 8 1 HA-3 70.0 25 (15)(16)(21) 14.0

SA-182 F316 16Cr– 8 1 HA-2 75.0 30 (15)(16)(21) 15.0

12Ni–2Mo

SA-182 F316L 16Cr–12Ni– 8 1 HA-4 70.0 25 (15)(16)(21) 14.0

2Mo

Castings

Alloy Steel

SA-351 CF8C 18Cr–10Ni– 8 1 ... 70.0 ... (5)(16)(17) 11.2

Cb

SA-351 CF3M 16Cr–12Ni– 8 1 ... 70.0 ... (5)(16)(17) 11.2

2Mo

NOTES: See next page.

92

ASME B&PVC sec4$$$u50 05-27-99 03:22:00 pd: sec4 Rev 14.04

You might also like

- Ptfe Torque Chart Aps KitsDocument2 pagesPtfe Torque Chart Aps KitsJo KingsNo ratings yet

- Spectacle Blind FlangeDocument3 pagesSpectacle Blind Flangel kishoreNo ratings yet

- Trigonometry - Excel Spreadsheet by WWW - Mathematics.me - UkDocument3 pagesTrigonometry - Excel Spreadsheet by WWW - Mathematics.me - UkrodwellheadNo ratings yet

- Metal Chemical CompositionDocument1 pageMetal Chemical CompositionprathmeshNo ratings yet

- Split Tee CatalogoDocument3 pagesSplit Tee Catalogobotella berNo ratings yet

- ASME B31.3 CalculatorDocument144 pagesASME B31.3 CalculatorLeoNo ratings yet

- Samson Valve Specification: Process DataDocument49 pagesSamson Valve Specification: Process DataMuhammed TamerNo ratings yet

- Boq For AS BoilerDocument1 pageBoq For AS BoilerGayan ChathurangaNo ratings yet

- Heat Ex Changers EstimationDocument46 pagesHeat Ex Changers Estimationshankarbt83No ratings yet

- IMI Remosa ValvesDocument4 pagesIMI Remosa ValvesDhananjay B KNo ratings yet

- Pressure & Temperature ClassificationDocument1 pagePressure & Temperature Classificationkeo85100% (1)

- ASTM A53 Vs A500 EquivalenceDocument6 pagesASTM A53 Vs A500 Equivalenceemmanuilmoulos6339No ratings yet

- Chart For Factor B of CSDocument8 pagesChart For Factor B of CSnguyenvanphu1977No ratings yet

- Nps Table Welded Seamless Stainless Steel PipeDocument3 pagesNps Table Welded Seamless Stainless Steel PipeOmar HasounNo ratings yet

- Asme Calculation For Renewal-A-317-Id Based - Rev-2Document29 pagesAsme Calculation For Renewal-A-317-Id Based - Rev-2ariya100% (1)

- Global Marketing For Tube & PipeDocument4 pagesGlobal Marketing For Tube & PipedsyashankaNo ratings yet

- Ejemplo Tubesheet Asme UHXDocument14 pagesEjemplo Tubesheet Asme UHXPedro Montes MarinNo ratings yet

- ASME U-1 Blank FormDocument2 pagesASME U-1 Blank Formjeff501No ratings yet

- Comco Pipe Supply Company Green BookDocument28 pagesComco Pipe Supply Company Green BookinfoNo ratings yet

- Pipeline & Piping ScheduleDocument12 pagesPipeline & Piping SchedulebeyNo ratings yet

- QT 16Cr PDFDocument1 pageQT 16Cr PDFYaroslav RuizNo ratings yet

- Ansi B 1500 PDFDocument1 pageAnsi B 1500 PDFMilena Lemus FonsecaNo ratings yet

- Calculo Brida Ejemplo PV - EliteDocument8 pagesCalculo Brida Ejemplo PV - ElitePedro Montes MarinNo ratings yet

- Material P NumberDocument11 pagesMaterial P NumberChaitanya Sai TNo ratings yet

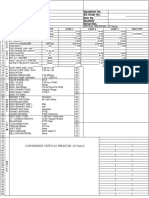

- Pt. Pertamina Ep Asset 3 Field Jatibarang: Calculation SheetDocument2 pagesPt. Pertamina Ep Asset 3 Field Jatibarang: Calculation Sheetrobiansah100% (1)

- ASME Formula DerivationDocument1 pageASME Formula Derivationvm153748763No ratings yet

- Apendice 11 Valvula Seguridad ASMEDocument4 pagesApendice 11 Valvula Seguridad ASMEOrlando NavarreteNo ratings yet

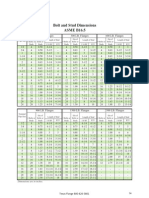

- Bolt and Stud DimentionDocument1 pageBolt and Stud DimentionwhngomjNo ratings yet

- 2 PN40 (WCB)Document2 pages2 PN40 (WCB)siddhesh_guessNo ratings yet

- Stored Energy CalculationDocument4 pagesStored Energy Calculationaauppal0% (1)

- Code Construction: ASME B16.49 (Induction Bend) Outside Diameter O.D. (MM) Angle Bending Ø Tangent Length at Each End Wall Thickness (MM)Document4 pagesCode Construction: ASME B16.49 (Induction Bend) Outside Diameter O.D. (MM) Angle Bending Ø Tangent Length at Each End Wall Thickness (MM)Edwardhutauruk100% (1)

- Stress Young Modulus and Thermal Expansion Coefficients of SteelsDocument51 pagesStress Young Modulus and Thermal Expansion Coefficients of Steelswili_ab8040No ratings yet

- Blind Flanges - ANSI B16.5Document7 pagesBlind Flanges - ANSI B16.5Paul SolorzanoNo ratings yet

- Difference Between Wrought Fittings and Forged Fittings - Google GroupsDocument1 pageDifference Between Wrought Fittings and Forged Fittings - Google Groupsim4uim4uim4uNo ratings yet

- Pressure Vessel Guide BooksDocument1 pagePressure Vessel Guide BooksLcm TnlNo ratings yet

- Investigations of Butterfly Control Valve Flow CharacteristicsDocument16 pagesInvestigations of Butterfly Control Valve Flow CharacteristicsKalimuthu Ps100% (1)

- TK Corporation Weld FittingsDocument140 pagesTK Corporation Weld FittingsJoão VidalNo ratings yet

- Title: ASME Electronic Stress Tables, 2004 Metric Edition Table: Table 1A - Maximum Allowable Stress Values S For Ferrous MaterialsDocument5 pagesTitle: ASME Electronic Stress Tables, 2004 Metric Edition Table: Table 1A - Maximum Allowable Stress Values S For Ferrous MaterialsAdhar ChawlaNo ratings yet

- ASME B 31.3 2016 Process PipingDocument30 pagesASME B 31.3 2016 Process Pipingr.devendran25% (4)

- Sa516 70Document3 pagesSa516 70Thinh ViproNo ratings yet

- Bleed Ring - ANSI Class 150-2500 (In)Document2 pagesBleed Ring - ANSI Class 150-2500 (In)ulfatNo ratings yet

- Sa 320Document13 pagesSa 320gst ajahNo ratings yet

- Training Manual-Piping: GasketsDocument6 pagesTraining Manual-Piping: GasketsMithun Unni NairNo ratings yet

- Nozzle CatalogueDocument53 pagesNozzle CatalogueMike UpNo ratings yet

- 20C1001 Pick ListDocument15 pages20C1001 Pick ListLeavithNo ratings yet

- JCM Split Tee and Weld On Outlets For Industrial ServiceDocument1 pageJCM Split Tee and Weld On Outlets For Industrial ServiceochableNo ratings yet

- JAG Neway Ball Valves PDFDocument32 pagesJAG Neway Ball Valves PDFprsiva2420034066No ratings yet

- 2019 ASME Section VIII Division 1 SynopsisDocument58 pages2019 ASME Section VIII Division 1 SynopsisCristian Xavier Avendaño BelloNo ratings yet

- Api 602 Forged Steel Valve PDFDocument4 pagesApi 602 Forged Steel Valve PDFThomasFrenchNo ratings yet

- Flange Dimension & Templates For Drilling: Dimensions of Class 150 Steel Flange Valves and FittingsDocument6 pagesFlange Dimension & Templates For Drilling: Dimensions of Class 150 Steel Flange Valves and FittingsadelNo ratings yet

- Carbon Steel ASME B36.10M Stainless Steel ASME B36.19M Cu-Ni Brass Bronze Thermoplastic ThermosettingDocument9 pagesCarbon Steel ASME B36.10M Stainless Steel ASME B36.19M Cu-Ni Brass Bronze Thermoplastic ThermosettingkaviramanNo ratings yet

- Hidden Defects in FittingsDocument3 pagesHidden Defects in FittingsFerlie IndrapatiNo ratings yet

- Calculation of Pipe Reinforcement ASME B31 3Document5 pagesCalculation of Pipe Reinforcement ASME B31 3Umar Aslam0% (1)

- NaturalConvectionHeatTransferCoefficients SI Units Final ProtectedDocument44 pagesNaturalConvectionHeatTransferCoefficients SI Units Final ProtectedFabio MiguelNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument7 pagesInspection & Testing Requirements Scope:: Test and Inspection PerWael ChouchaniNo ratings yet

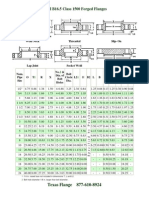

- Texas Flange - Product Catalog PDFDocument47 pagesTexas Flange - Product Catalog PDFFranco Saenz SolisNo ratings yet

- Flange Asmeviii Div.1 App.2 Rev0Document10 pagesFlange Asmeviii Div.1 App.2 Rev0lk700615100% (1)

- SKF Vibracon BrochureDocument4 pagesSKF Vibracon BrochureMo ZeidNo ratings yet

- ST 102Document20 pagesST 102amrNo ratings yet

- Product Code:: Pkg/Ro/41 Special SteelsDocument9 pagesProduct Code:: Pkg/Ro/41 Special SteelsPranav TripathiNo ratings yet

- Astm A216 PDFDocument4 pagesAstm A216 PDFilliasuddinNo ratings yet

- F 1469 RyR NDTDocument5 pagesF 1469 RyR NDTJulio Cesar Morales Cruz100% (1)

- Astm D56 05Document12 pagesAstm D56 05Jose Antonio Sanchez MarinNo ratings yet

- ASTM D6792 Practice For Quality System in Petroleum ProductsDocument19 pagesASTM D6792 Practice For Quality System in Petroleum ProductsJulio Cesar Morales Cruz100% (1)

- Ansi b36.10 Pipe SizeDocument9 pagesAnsi b36.10 Pipe SizeSpoonful BurnsideNo ratings yet

- Ansi b36.10 Pipe SizeDocument9 pagesAnsi b36.10 Pipe SizeSpoonful BurnsideNo ratings yet

- Oiml R 80: Nternational EcommendationDocument35 pagesOiml R 80: Nternational EcommendationpurwantoNo ratings yet

- E 125 - 63Document3 pagesE 125 - 63José Ramón GutierrezNo ratings yet

- E94 PDFDocument13 pagesE94 PDFJulio Cesar Morales Cruz100% (1)

- ASTM A 105 Bridas PDFDocument5 pagesASTM A 105 Bridas PDFJulio Cesar Morales CruzNo ratings yet

- Article - CO2 Diffusion From PET Bottles - For Packaging India April 19Document8 pagesArticle - CO2 Diffusion From PET Bottles - For Packaging India April 19Darshan VartakNo ratings yet

- Synthesis of DibenzalacetoneDocument8 pagesSynthesis of DibenzalacetoneCamille EscobarNo ratings yet

- Federal Project Implementation Unit: Basic Labour & Material RateDocument12 pagesFederal Project Implementation Unit: Basic Labour & Material RateDurga SinghNo ratings yet

- 2020 Al Chemistry Part I MCQ Paper New Syllabus Sinhala Medium Alevelapi PDFDocument9 pages2020 Al Chemistry Part I MCQ Paper New Syllabus Sinhala Medium Alevelapi PDFerbgbggtrbbrbNo ratings yet

- F2658 PDFDocument10 pagesF2658 PDFAhmad Zubair RasulyNo ratings yet

- w0167 PreDocument1 pagew0167 PreKandeke DaviesNo ratings yet

- Installation of Exterior Windows, Doors and Skylights: Standard Practice ForDocument88 pagesInstallation of Exterior Windows, Doors and Skylights: Standard Practice ForBetsy WiedenfeldNo ratings yet

- DemetraDocument2 pagesDemetraPierpaolo VergatiNo ratings yet

- ITEM 404 - BluebookDocument4 pagesITEM 404 - BluebookEster MarianNo ratings yet

- Certificado - Flange Adapter 125MM - XindaDocument3 pagesCertificado - Flange Adapter 125MM - XindaGR CarlosNo ratings yet

- Iron Total High Level - AP-16 - 900Document4 pagesIron Total High Level - AP-16 - 900wulalan wulanNo ratings yet

- Formwork ExampleDocument4 pagesFormwork ExampleDarwish Wahab100% (1)

- Plastering-Method Statement (R)Document4 pagesPlastering-Method Statement (R)TATATAHERNo ratings yet

- Utilization of Recycled Glass Waste As Partial Replacement of Fine Aggregate in Concrete ProductionDocument7 pagesUtilization of Recycled Glass Waste As Partial Replacement of Fine Aggregate in Concrete ProductionSocheata channNo ratings yet

- BakerHughes Fluids Mixing Procedures STG1Document10 pagesBakerHughes Fluids Mixing Procedures STG1badermalhajriNo ratings yet

- AERI-09-16-5 Matadeen Ramchandra Agrawal - Cement PhysicalDocument2 pagesAERI-09-16-5 Matadeen Ramchandra Agrawal - Cement PhysicalAhmedabad Engineering Research InstituteNo ratings yet

- Compatibility Examination of Explosive and Polymer Materials by Thermal MethodsDocument5 pagesCompatibility Examination of Explosive and Polymer Materials by Thermal MethodsBojan TanaskovskiNo ratings yet

- Ireps Tender 3Document22 pagesIreps Tender 3Project DS EnterpriseNo ratings yet

- Jurnal Kimia Sains Dan Aplikasi: Natural Zeolite Modification Using Dithizone and Its Application As Adsorbent of Cu (II)Document4 pagesJurnal Kimia Sains Dan Aplikasi: Natural Zeolite Modification Using Dithizone and Its Application As Adsorbent of Cu (II)Isna DewiyantiNo ratings yet

- Kerto® LVL Q-Panels Combine Excellent Technical Performance With Ease of UseDocument3 pagesKerto® LVL Q-Panels Combine Excellent Technical Performance With Ease of UseMatheus FlorianiNo ratings yet

- Heavy Equipment: Oil & GasDocument8 pagesHeavy Equipment: Oil & GasJoeNo ratings yet

- Earthing Protection SpecificationDocument5 pagesEarthing Protection SpecificationNi ReNo ratings yet

- Portable Cabins For Security StaffDocument2 pagesPortable Cabins For Security StaffKuldeep ChakerwartiNo ratings yet

- AJN Panles BrouchureDocument35 pagesAJN Panles BrouchureKumar HemantNo ratings yet

- Chem 1 PDFDocument33 pagesChem 1 PDFJelena ZdravkovicNo ratings yet

- MSDS Polvo QuimicoDocument2 pagesMSDS Polvo QuimicoÁlvaro MartínezNo ratings yet

- Sba MekpresentationDocument11 pagesSba MekpresentationPrashit JainNo ratings yet

- Handbook 2017Document106 pagesHandbook 2017Arnaud LegrosNo ratings yet

- A Review Paper On Fire Resistance PropertiesDocument7 pagesA Review Paper On Fire Resistance PropertiesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- TDS 926 CarbopolUltrez30Document4 pagesTDS 926 CarbopolUltrez30Eri HSNo ratings yet