Professional Documents

Culture Documents

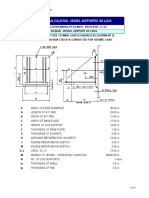

Agitator Support Design

Uploaded by

Sabir NasimCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Agitator Support Design

Uploaded by

Sabir NasimCopyright:

Available Formats

SECTION A

ENGINEERING SALES MANUAL

PAGE 7.0

REVISION 5

SUGGESTED BRIDGE DESIGN DATE 11/17/05

The following method can be used for design of support structures for MixPro agitators. This method

goes into detail for bridge supports. Similar methods can be used for flange mounts.

The support structure for an agitator must meet two criteria:

1. The support must be capable of withstanding the design loads without failure.

2. The support must be sufficiently rigid. This is necessary to limit deflections of the agitator

assembly. This takes two primary forms, twist and vertical deflection. This twist must not

exceed 1/3°, the total vertical deflection in either beam must not exceed 1/16" per 10 feet of

beam length.

The following shows how to apply the rigidity criteria and then the deflection criteria to determine the

bridge structure necessary. This example assumes the following:

- the bridge consists of two main beams running across the top of the tank and supported on

rigid supports.

- The agitator is centered between the beams and between the supports.

1. Determine the loads the bridge must support. The loads for the agitator are shown in the upper

left corner of the Certified Unit Drawing.

2. Determine the beam separation that will be used. This is typically achieved by matching up of

appropriate bolt locations on the beam with mounting bolt positions for the agitator. For initial

determinations the mounting bolt spacing can be used.

3. Determine the allowable deflection, from twist, in the main beams. Under worst case loading

one beam will deflect upwards and the other downwards in a twisting action. In this case only

half the beam spacing is used to calculate allowable deflection:

d = w/2 * sin(1/3°), where d = beam deflection (inches)

w = beam spacing (inches)

4. Determine the overall length of the beams between supports. The support structure for the

bridge must also be sufficiently rigid such that the deflection limits for the agitator are not

exceeded when it is included. In this example it is assumed that the supports are rigid and the

only deflections are in the bridge.

5. Determine the force applied to each beam by the bending moment supplied in the design loads.

In this case each beam will carry half the load:

F = M/w, where F = force on beam (lbs)

M = bending moment (lbs)

w = beam spacing (inches)

Professional Mixing Equipment Inc.

22 Melanie Dr., Unit 10 Brampton, ON Canada L6T 4K9

Phone: (905) 790-5444 Fax: (905) 790-5420 E-mail: Info@mixproagitators.com

SECTION A

ENGINEERING SALES MANUAL

PAGE 7.1

REVISION 5

SUGGESTED BRIDGE DESIGN DATE 11/17/05

6. Determine the moment of inertia required for the beams to resist twist. This can be

accomplished by treating the beam as a “simple support structure”. The maximum deflection of

such a structure is:

d = F*L³/(48*E*I), where d = maximum deflection (in.)

F = force (lbs)

L = beam length (in.)

E = modulus of elasticity (psi)

I = moment of inertia (in4)

For steel beams, E = 29,000,000 (psi)

I = F* L³/(1.392 x 109*d)

This is the minimum required to resist twisting.

7. Determine the moment of inertia required to resist total vertical deflection. This can be

accomplished by treating the beam as a “simple support structure” and applying all vertical

loads. The maximum deflection of such a structure is:

d total = d weight + d bending + d beam

d weight = W/2*L3/(48*E*I), where d = deflection (inches)

W = mixer weight (lbs)

L = beam length (inches)

E = modulus of elasticity (psi)

I = moment of inertia (in4)

d bending = F*L3/(48*E*I), See section 6.

d beam = 5*b*L4/(384*E*I), where d = deflection (in.)

b = beam weight (lbs/in)

L = beam length (in.)

E = modulus of elasticity (psi)

I = moment of inertia (in4)

Professional Mixing Equipment Inc.

22 Melanie Dr., Unit 10 Brampton, ON Canada L6T 4K9

Phone: (905) 790-5444 Fax: (905) 790-5420 E-mail: Info@mixproagitators.com

SECTION A

ENGINEERING SALES MANUAL

PAGE 7.2

REVISION 5

SUGGESTED BRIDGE DESIGN DATE 11/17/05

For the initial calculation, beam weight is ignored. The calculation will need to be redone once a beam

has been selected to ensure that deflection criteria is still met. This reduces the deflection equation to:

d total = d weight + d bending

d total = W/2*L3/(48*E*I) + F*L3/(48*E*I)

For steel beams, E = 29,000,000 psi

Also, d = 0.0005208*L (1/16" per 10 feet)

I = (W/2 + F) * L2/(7.25 x 105)

This is the minimum required to resist total deflection.

8. Consult a beam catalog and determine which ones satisfy both moment of inertia criteria.

9. Calculate the total deflection including the beam weight to verify that the selected beam meets

this criteria.

10. Check the beams selected to ensure that they satisfy stress level requirements for both the

combined bending and downward loads, and the torque.

11. Beams will still require cross bracing and support.

Configurations that differ from the one shown here will require different approaches. The end result

remains the same. The bridge must be sufficiently strong to support the loads without deflecting more

than 1/16" per 10 feet of span and sufficiently rigid such that the agitator does not deflect through an

angle greater than 1/3°. This also applies to flanges.

Professional Mixing Equipment Inc.

22 Melanie Dr., Unit 10 Brampton, ON Canada L6T 4K9

Phone: (905) 790-5444 Fax: (905) 790-5420 E-mail: Info@mixproagitators.com

You might also like

- Work Instruction - Nozzle Load TransferDocument3 pagesWork Instruction - Nozzle Load Transfervpjagannaath100% (1)

- Anchor Chair Design - Version 1Document3 pagesAnchor Chair Design - Version 1Rey Fiedacan100% (2)

- ASTM E23-12c PDFDocument25 pagesASTM E23-12c PDFSantiago Oliva100% (2)

- Lug Support DesignDocument11 pagesLug Support Designimrancenakk100% (6)

- 100cub API 650 STEEL SiloDocument19 pages100cub API 650 STEEL SiloUDayNo ratings yet

- Swing Bolt CalculationDocument2 pagesSwing Bolt CalculationNicolaSavili100% (2)

- Calculating saddle dimensions for pipesDocument2 pagesCalculating saddle dimensions for pipesrinabiswas50% (2)

- Sample Design Calculation - Vessel Supported On LugsDocument4 pagesSample Design Calculation - Vessel Supported On LugsAbhay Upadhyay0% (1)

- WIND MOMENT (Per API-650 SECTION 5.11)Document9 pagesWIND MOMENT (Per API-650 SECTION 5.11)ramu karri100% (1)

- For Buildings and Other Structures For Wind LoadsDocument28 pagesFor Buildings and Other Structures For Wind LoadsMarinos Giannoukakis100% (1)

- Example Tank Calculation PDFDocument108 pagesExample Tank Calculation PDFPricop Cosmin100% (2)

- Anchor Bolt Chairs - CalculationDocument8 pagesAnchor Bolt Chairs - Calculationchicaiza123No ratings yet

- SADDLE SUPPORT DESIGNDocument6 pagesSADDLE SUPPORT DESIGNSISIR KR BARMAN0% (1)

- Design of Reactor With Agitator Shaft 1Document40 pagesDesign of Reactor With Agitator Shaft 1gholiNo ratings yet

- Baffle Thickness CalculationDocument22 pagesBaffle Thickness CalculationAdrian Stoicescu100% (1)

- Evaluation For VesselDocument10 pagesEvaluation For VesselEngineering ESIINo ratings yet

- Stack Design CalculationDocument6 pagesStack Design CalculationSabir Nasim100% (2)

- Ethane Pressure Enthalpy Diagram PDFDocument1 pageEthane Pressure Enthalpy Diagram PDFNatalia Rosa SimanjuntakNo ratings yet

- Jominy End Quench ReportDocument14 pagesJominy End Quench ReportMuhammad Luqman60% (5)

- Curb AngleDocument1 pageCurb Angle940623015859No ratings yet

- Lug SupportDocument2 pagesLug SupportSachin5586No ratings yet

- FIRE WATER TANK-API-650-Calculation-Report - RVDDocument42 pagesFIRE WATER TANK-API-650-Calculation-Report - RVDahmed aboyosefNo ratings yet

- Tank Design As Per IS803 and API650Document36 pagesTank Design As Per IS803 and API650Vikash Kumar Singh100% (1)

- Trunnion Check - Node 710Document13 pagesTrunnion Check - Node 710Prashant ChauhanNo ratings yet

- Stiffness Coefficients and Allowable Nozzles in API 650 TanksDocument11 pagesStiffness Coefficients and Allowable Nozzles in API 650 TanksUjwal Khandokar0% (1)

- Agitator FINITE ELEMENT METHODDocument5 pagesAgitator FINITE ELEMENT METHODRoopesh S AcharyaNo ratings yet

- PPE-STD-CAL-ME-006 Rectangular Tank Thickness CalculationDocument4 pagesPPE-STD-CAL-ME-006 Rectangular Tank Thickness CalculationNadya Askar100% (1)

- Rectangular Tubesheet Design Guideline by HEIDocument6 pagesRectangular Tubesheet Design Guideline by HEIm5416No ratings yet

- Rectangular Tank CalculationDocument28 pagesRectangular Tank CalculationMohammed EljammalNo ratings yet

- Rectangular Tank (With Horizontal Stiffner)Document5 pagesRectangular Tank (With Horizontal Stiffner)DURGAIRAJ100% (1)

- WRC-107 Lifting Lugs - Vert. Vessel Vertical LiftDocument5 pagesWRC-107 Lifting Lugs - Vert. Vessel Vertical LiftManoj MulikNo ratings yet

- Design of an anchor chair for offshore structuresDocument1 pageDesign of an anchor chair for offshore structuresMohammed Faizal Nv100% (2)

- Design of Support BC BhattacharyaDocument24 pagesDesign of Support BC BhattacharyaRADHE GRAPHICSNo ratings yet

- Skirt To Dish Joint PDFDocument64 pagesSkirt To Dish Joint PDFPrajwal ShettyNo ratings yet

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Document32 pagesPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNo ratings yet

- Silo Design Powdered Activated CarbonDocument187 pagesSilo Design Powdered Activated Carbonprasanth bhadranNo ratings yet

- Anchor ChairDocument3 pagesAnchor ChairrsubramaniNo ratings yet

- Rectangular TankDocument38 pagesRectangular TankSam LowNo ratings yet

- 28 Roark Flat PlatesDocument14 pages28 Roark Flat Platesgutmont0% (1)

- PFS FWKO Tank EvaluationDocument12 pagesPFS FWKO Tank EvaluationkoyahassanNo ratings yet

- Design of HCL FRP Storage TANKDocument21 pagesDesign of HCL FRP Storage TANKHaries Bugarin GarciaNo ratings yet

- COMPARISON OF LIMIT LOAD, LINEAR AND NONLINEAR FE ANALYSIS OF A VESSEL NOZZLEDocument6 pagesCOMPARISON OF LIMIT LOAD, LINEAR AND NONLINEAR FE ANALYSIS OF A VESSEL NOZZLEVaraprasad EthaNo ratings yet

- 7-12-0006 Rev6 (Angle Leg Support)Document2 pages7-12-0006 Rev6 (Angle Leg Support)sumit kumarNo ratings yet

- Horizontal Vessel Stress AnalysisDocument12 pagesHorizontal Vessel Stress AnalysissridharNo ratings yet

- IS 9178-Part-1 PDFDocument32 pagesIS 9178-Part-1 PDFvijay84mech100% (2)

- Stiffness Coefficients For Nozzles in API 650 Tanks PDFDocument8 pagesStiffness Coefficients For Nozzles in API 650 Tanks PDFvijay10484100% (1)

- Mechanical Calculation Storage Tank 110 KL (T-04)Document4 pagesMechanical Calculation Storage Tank 110 KL (T-04)Priyo Jati WahyonoNo ratings yet

- Design Calculation For Coil in The HFO Tank - TK14 & TK 15Document4 pagesDesign Calculation For Coil in The HFO Tank - TK14 & TK 15chintanNo ratings yet

- Variable Design Point Method.Document56 pagesVariable Design Point Method.jwochNo ratings yet

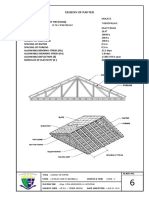

- API 650 Rafter DesignDocument12 pagesAPI 650 Rafter Designrongweius100% (1)

- How To Calculate Flat Plate Thickness of Flat Bottom Storage TankDocument3 pagesHow To Calculate Flat Plate Thickness of Flat Bottom Storage TankSiva baalanNo ratings yet

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFDocument4 pagesBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiNo ratings yet

- Taylor Forge - Modern Flange Design Bulletin 502Document53 pagesTaylor Forge - Modern Flange Design Bulletin 502bobnms86% (7)

- Week 10 Lecture Material - WatermarkDocument71 pagesWeek 10 Lecture Material - WatermarkVaibhav SharmaNo ratings yet

- AAiT - Lecture 04 Railway Track Structure - Part IIDocument66 pagesAAiT - Lecture 04 Railway Track Structure - Part IImenur blatuNo ratings yet

- Bolted Connections - Evaluation of Resistance: ApproachDocument5 pagesBolted Connections - Evaluation of Resistance: ApproachprabukcivilNo ratings yet

- Slab design calculations for two-storey residential projectDocument6 pagesSlab design calculations for two-storey residential projectZulkiflee TaugNo ratings yet

- Boring BasicsDocument4 pagesBoring Basicsnandhu1977No ratings yet

- Design steel tubular pile subject to axial & bending loadsDocument5 pagesDesign steel tubular pile subject to axial & bending loadsEdward Albert BañagaNo ratings yet

- Part 6 Analysis and Design of PurlinsDocument18 pagesPart 6 Analysis and Design of PurlinsPaul P.No ratings yet

- Design Calculation of Frame: AbstractDocument4 pagesDesign Calculation of Frame: AbstractDr. Aung Ko LattNo ratings yet

- FinalDocument33 pagesFinalAnonymous sfkedkymNo ratings yet

- Structural Beam Bending Equations / Calculation Supported On Both Ends Uniform LoadingDocument2 pagesStructural Beam Bending Equations / Calculation Supported On Both Ends Uniform LoadingJoel Miguel Angel PachecoNo ratings yet

- Project DescritionDocument7 pagesProject DescritionWatcharapol SukhaboteNo ratings yet

- Slab Deflection and DepthDocument10 pagesSlab Deflection and Depthsyed AffanNo ratings yet

- Water Fill Test Morepen LabDocument4 pagesWater Fill Test Morepen LabSabir NasimNo ratings yet

- Annexure - I Inspection and Test Plan: Name of The VendorDocument1 pageAnnexure - I Inspection and Test Plan: Name of The VendorSabir NasimNo ratings yet

- BS4994 Vs AsmeDocument1 pageBS4994 Vs AsmeSabir NasimNo ratings yet

- Website DataDocument5 pagesWebsite DataSabir NasimNo ratings yet

- Agitation: Introduction To Principles and PracticeDocument44 pagesAgitation: Introduction To Principles and Practicearun89000100% (9)

- Loads and structural analysis of 8 sections of a conical stackDocument4 pagesLoads and structural analysis of 8 sections of a conical stackSabir NasimNo ratings yet

- Bar Chart For NFC-586Document1 pageBar Chart For NFC-586Sabir NasimNo ratings yet

- Bar Chart For NFC-586Document1 pageBar Chart For NFC-586Sabir NasimNo ratings yet

- IIR Morepen LabDocument4 pagesIIR Morepen LabSabir NasimNo ratings yet

- Design - Sheet - For Self Supported Stack-1Document1 pageDesign - Sheet - For Self Supported Stack-1Sabir NasimNo ratings yet

- Heramb Equipment & Projects LLP: CostingDocument2 pagesHeramb Equipment & Projects LLP: CostingSabir NasimNo ratings yet

- R-Standard Enthalpy of FormationDocument2 pagesR-Standard Enthalpy of FormationS.P.No ratings yet

- Force Values For Different SetupDocument2 pagesForce Values For Different SetupSabir NasimNo ratings yet

- ABB NFLP IE3-Catalogue PDFDocument12 pagesABB NFLP IE3-Catalogue PDFSabir NasimNo ratings yet

- Testing As Per En-13121Document2 pagesTesting As Per En-13121Sabir Nasim100% (1)

- Moment of Inertia For T SectionDocument2 pagesMoment of Inertia For T SectionSabir NasimNo ratings yet

- COmparison of Testing Standard For FlexureDocument1 pageCOmparison of Testing Standard For FlexureSabir NasimNo ratings yet

- Nalysis of Orthotropic PlyDocument16 pagesNalysis of Orthotropic PlySabir NasimNo ratings yet

- r1 Tank SpecificationDocument10 pagesr1 Tank SpecificationSabir NasimNo ratings yet

- 2-Critical Speed of ShaftDocument5 pages2-Critical Speed of ShaftRidani Faulika Amma100% (3)

- PDMWorks Workgroup ContributorDocument112 pagesPDMWorks Workgroup ContributorSabir Nasim100% (2)

- 1 Slide: 2.1 Functions of The Matrix SystemDocument5 pages1 Slide: 2.1 Functions of The Matrix SystemSabir NasimNo ratings yet

- Selection of Antivibration MountsDocument12 pagesSelection of Antivibration MountsSabir NasimNo ratings yet

- BVI To ST TicketDocument2 pagesBVI To ST TicketSabir NasimNo ratings yet

- Agitator Design CalculationDocument21 pagesAgitator Design CalculationRupesh Ubale94% (36)

- Tank Manufaturing DataDocument8 pagesTank Manufaturing DataSabir NasimNo ratings yet

- CM3332 Bus Body DesignDocument13 pagesCM3332 Bus Body DesignSabir NasimNo ratings yet

- Design of UHPC Structural Members: Lessons Learned and ASTM Test RequirementsDocument21 pagesDesign of UHPC Structural Members: Lessons Learned and ASTM Test RequirementsFabianNo ratings yet

- Lecture 2 Materials and Methods 2Document30 pagesLecture 2 Materials and Methods 2Jefferson AltarNo ratings yet

- Basic Concept Ela 1 P1Document21 pagesBasic Concept Ela 1 P1Annamalai VaidyanathanNo ratings yet

- Rock AnchorDocument2 pagesRock AnchorVijay Kumar100% (1)

- Slip-Line Field Theory for Metal FormingDocument14 pagesSlip-Line Field Theory for Metal FormingSri RamNo ratings yet

- Rebound Hammer Test On ConcreteDocument10 pagesRebound Hammer Test On ConcreteSunil KumarNo ratings yet

- Chapter 6-Bending AnnotatedDocument52 pagesChapter 6-Bending AnnotatedOsvaldo IzataNo ratings yet

- Sabic Hdpe B5429: High Density PolyethyleneDocument2 pagesSabic Hdpe B5429: High Density Polyethylenegetasew altasebNo ratings yet

- REWERS I - Numerical Analysis of RC Beam With High Strength Steel REinforcement Using CDP ModelDocument11 pagesREWERS I - Numerical Analysis of RC Beam With High Strength Steel REinforcement Using CDP Modelno_milk_todayNo ratings yet

- Compressive Strength and Behaviour of Gusset PlateDocument19 pagesCompressive Strength and Behaviour of Gusset PlateRavindraKhandelwalNo ratings yet

- 0-Pengantar Fisika Dasar 1-2022Document20 pages0-Pengantar Fisika Dasar 1-2022Chaironi LatifNo ratings yet

- Fluorine and freon teflon chloroform fluorocarbonsDocument20 pagesFluorine and freon teflon chloroform fluorocarbonsHAFIZ IMRAN AKHTERNo ratings yet

- Smart Materials and Structures: Answer Any Fivefull QuestionsDocument1 pageSmart Materials and Structures: Answer Any Fivefull QuestionsRavi TejNo ratings yet

- Diffusional Other TransformationsDocument51 pagesDiffusional Other TransformationsAnil Kumar TNo ratings yet

- Plate 6Document3 pagesPlate 6XDXDXDNo ratings yet

- PSC 35m - 4 Girders - 14.5m Width - M50 (As Per Shuttering) (Ch-109+700) PDFDocument315 pagesPSC 35m - 4 Girders - 14.5m Width - M50 (As Per Shuttering) (Ch-109+700) PDFKhirai HelpNo ratings yet

- NX Nastran DesktopDocument5 pagesNX Nastran DesktopThanakorn VichiensamuthNo ratings yet

- FDM TPU 92A data sheetDocument2 pagesFDM TPU 92A data sheetMarkoZajecNo ratings yet

- CPT Method for Calculating Shallow Foundation Settlements in Piedmont Residual SoilsDocument5 pagesCPT Method for Calculating Shallow Foundation Settlements in Piedmont Residual SoilsAntonio MartinoNo ratings yet

- Tegangan Normal Teg Ijin Dan Teg TermalDocument12 pagesTegangan Normal Teg Ijin Dan Teg Termalashrin masyhudiNo ratings yet

- Purlin & GirtDocument96 pagesPurlin & GirtudayvadapalliNo ratings yet

- DifferentialEquations 02 Strain Disp Eqns 2Document8 pagesDifferentialEquations 02 Strain Disp Eqns 2lipun12ka4No ratings yet

- PEJABAT WILAYAH UTARA SARAWAK TENSILE TEST REPORTDocument3 pagesPEJABAT WILAYAH UTARA SARAWAK TENSILE TEST REPORTSK KG Selanyau SarawakNo ratings yet

- SOM 2-2 (Students Note)Document15 pagesSOM 2-2 (Students Note)HasmitthaNo ratings yet

- Material Science and Metallurgy Question BankDocument3 pagesMaterial Science and Metallurgy Question BankVinay KorekarNo ratings yet

- Reinforced Concrete DesignDocument6 pagesReinforced Concrete DesignJohndee IsipNo ratings yet

- FRP Strengthening of Concrete Structures - DesignDocument15 pagesFRP Strengthening of Concrete Structures - Designshafiullah100% (1)