Professional Documents

Culture Documents

The Compressed Air Braking System: WABCO Vehicle Control Systems

Uploaded by

Costel CaramanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Compressed Air Braking System: WABCO Vehicle Control Systems

Uploaded by

Costel CaramanCopyright:

Available Formats

WABCO Vehicle Control Systems

Companies Austria Belgium France

WABCO Austria GesmbH. WABCO Belgium S.A.-N.V. WABCO France

Murbangasse 8 Petrus Bayensstraat 70 44, avenue Aristide Briand

Postfach 88 B-1702 Groot-Bijgaarden B. P. 12

A-1108 Wien F-77411 Claye-Souilly Cedex

Germany Germany Italy

WABCO WABCO WABCO

Fahrzeugbremsen Perrot Bremsen GmbH Automotive Italia SpA

Am Lindener Hafen 21 Bärlochweg 25 Corso Pastrengo, 50

D-30453 Hannover D-68229 Mannheim l-10093 Collegno/Torino

Postfach 91 12 62 Postfach 71 02 63

D-30432 Hannover D-68222 Mannheim

Korea Netherlands Poland

WABCO Korea Inc. WABCO Automotive B. V. WABCO Polska Sp. z. o. o.

343-1 Manho-Ri Jan Leentvaarlaan 2 Ul. Bierutowska 57/59

Posung-Myon, Pyungtaek-Si NL-3065 DC Rotterdam 51-317 Wroclaw

Kyongki-Do Postbus 8704

© Copyright: WABCO 2000. Printed in Germany. No part of this publication may be reproduced without our permission. The right of amendment is reserved. WABCO 826 001 143 3/07.2000

Korea 451-820 NL-3009 AS Rotterdam

Spain South America Sweden

WABCO España S. A. WABCO Freios-Brasil WABCO Automotive AB

Apartado de Correos 527 Via Anhanguera km 106 - Bloco A Orrekulla Industrigata 36

E-28850 Torrejón de Ardoz BR-13180-480 Sumare, SP S-425 36 Göteborg

(Madrid) Caixa Postal 542

BR-13 001 Campinas SP

Switzerland United Kingdom

WABCO Schweiz AG WABCO Automotive U. K.

Freiburgstraße 384 Beacon Works

Postfach 29 Texas Street

CH-3018 Bern GB-Morley-Leeds, LS27 0HQ

PO Box 6

GB-Morley-Leeds, LS27 0XA

Offices Czech Republic Hongkong Hungary

WABCO WABCO Asia-Pacific WABCO Austria GesmbH.

brzdy k vozidlům spol. s. r. o. 15th Floor St. John’s Bldg. Magyarországi kepviselet

Za parkem 8 33 Garden Road Margit Krt. 43 – 45

CZ-14800 Praha 4 - Kunratice Hongkong-Central H-1024 Budapest

Poland Russia USA

WABCO Ideal Standard Europe B. V. WABCO Vehicle Control Systems

Hamulce Samochodowe Sp. z. o. o. Office WABCO North America

Ul. Przybyszewskiego 99 Fahrzeugbremsen 4500 Leeds Avenue

PL-93-126 Lodz Prospekt Mira, 100 USA-Charleston, SC 29405

RUS-129626 Moscow

USA/Canada/Mexico

WABCO Vehicle Control Systems

North America

100 W. Big Beaver Road

USA-Troy, Michigan 48084

Joint Ventures China India Japan

Shandong Weiming Sundaram-Clayton Ltd. WABCO Japan Inc.

Automotive Products Ltd. Padi 2-8-3 Yoshinodai, Kawagoe

Zhangqiu City, Shandong IND-Chennai 600 050 J-Saitama 350-0833

Postcode 250200

P. R. C.

South Africa USA/Canada/Mexico USA

WABCO MERITOR WABCO WABCO

Automotive South Africa Vehicle Control Systems Compressor Manufacturing Co.

PO Box 45 90 3331 W. Big Beaver Road 4500 Leeds Avenue

ZA-Edenvale 1610 USA-Troy, Michigan 48084 USA-Charleston, SC 29405

The Compressed Air Braking System

Vehicle Control Systems

An American Standard Company

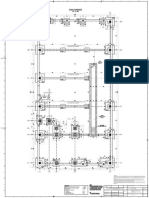

The Compressed Air Braking System for Trucks The Compressed Air Braking System for Trailers

Air Supply (34) and on into the air reservoir (36). From Thus the control pressure on the front axle the valves operate as relay valves and are red actuating button on the double release the hose coupling (11) to the point where

that reservoir it reaches the supply ports is adjusted to the load carried on the used to rapidly increase or decrease the valve (33) which causes the spring the rupture of the control line causes a

The compressed air delivered by the of the ABS relay valves (38 and 40) and vehicle (mainly on lorries). The trailer control pressure in the brake cylinders. chambers of the Tristop® spring-brake rapid fall in pressure in the supply line and

compressor (2) reaches the air dryer (3) the spring-loaded portions of the Tristop® valve (17) actuated by both service braking actuators (42 and 43) to be evacuated the relay emergency valve (34) induces

where any water vapour is extracted from spring brake actuators (42 and 43). circuits pressurizes the control port of the Parking Braking System through the quick-release valve. the trailer to be braked automatically within

the air and emitted to atmosphere through relay emergency valve (34) from the hose the maximum period of 2 seconds as

the dryer’s vent. The unloader valve Operation: coupling (12) and through “control“ When the hand brake valve (16) is actuated Emergency Brake required by law.

integrated in the air dryer automatically Service Braking System connecting hose. Thus the air supply from and moved to its lock-in position, the

controls the pressure within a range of the air reservoir (36) is allowed to pass to spring-loaded portions of the Tristop® Due to the sensitive gradability of the hand The check valve (13) safeguards the

between 7.2 and 8.1 bar, for instance. When the brake valve in the motor vehicle the load-sensing valve (37). spring-brake actuators (19) are evacuated brake valve (16) the semitrailer-tractor parking brake against unintentional actu-

(15) is actuated, compressed air flows via completely. The force required for the combination can, in the event of service ation if the pressure within the supply line

The dried air then flows to the quadruple the ABS solenoid control valve (23) into The ABS relay valves (38 and 40) are foundation brake is now generated by the braking circuits I and II failing, be braked leading to the trailer falls.

circuit protection valve (4) which, in the the brake chambers (14) on the front axle actuated by the load-sensing valve, and heavily prestressed springs of the Tristop® by the spring-loaded portions of the

event of any defect in one or several and to the load-sensing valve (18). the compressed air is allowed to pass spring-brake actuators. Tristop ® spring-brake actuators (19). ABS Components

circuits, protects the intact circuits against to the brake chambers (41) and the ser-

a fall in pressure. In service braking circuits The load-sensing valve reverses and the vice braking portions (brake chambers) At the same time, the line leading from As described for the parking braking The motor vehicle usually has three telltale

I and II, the air from the air reservoirs air now flows through the ABS solenoid of the Tristop® spring-brake actuators the hand brake valve (16) to the trailer system, the brake force required for the lamps (if ASR is installed there will be

(5 and 6) flows to the brake valve (15). control valve (24) into the service braking (42 and 43). control valve (17) is also evacuated. The foundation brake is generated by the more) showing which functions are active,

portion (brake cylinders) of the Tristop® braking process for the semitrailer is prestressed springs of the Tristop® spring- and for consistent monitoring of the

In circuit III the air from the air reservoir (7) spring brake actuators (19). The pressure The control pressure on the semitrailer commenced by the pressure being in- brake actuators (19) although the spring- system. It also has a relay, an information

passes through the 2/2-way valve inte- level in the brake cylinders generating the which corresponds to the output pressure creased in the “control“ connection hose. loaded portions are not evacuated fully module and an ABS socket (25).

grated in the trailer control valve (17) and force required for the foundation brake is from the motor vehicle is adjusted by the but only to the extent required for the

on to the automatic hose coupling (11), dependent on the foot force applied to load-sensing valve (37) to the load carried As the Guideline of the Council of the performance of the brakes. When the driving switch is actuated, the

and through the check valve (13), hand the brake valve and on the vehicle’s load. on the semitrailer. The ABS relay valves European Communities (GCEC) requires yellow telltale will be on if the trailer has

brake valve (16) and the relay valve (20) (on the semitrailer) and the ABS solenoid that the motor vehicle must be able to Automatic Braking of the no ABS or if that connection has been

into the spring-loaded portion of the This pressure is controlled by the load- control valves (on the motor vehicle) are hold the whole of the tractor-trailer Semitrailer severed.

Tristop® spring-brake actuators (19). Circuit sensing valve (18) which is connected to used for controlling (pressure increase, combination, the braking system of the

IV is used to supply compressed air to the rear axle by means of a linkage. The pressure hold or pressure reduce) the semitrailer can subsequently be evacuated In the event of the “supply“ line rupturing, The red telltale goes off as soon as the

any ancillary consumers which are repre- continuous change in the distance brake cylinders. by moving the hand brake lever into the the pressure falls abruptly and the relay vehicle is moving at a speed in excess

sented by the engine brake in this case. between the vehicle’s fame and its axle “control position“. emergency valve (34) causes full braking of approx. 7 k.p.h. and no error or defect

while the vehicle is being loaded or If the valves are activated by the electronic of the semitrailer. has been detected by the safety circuit

When the supply hose is connected, the unloaded causes the control pressure to control unit for ABS (21 or 35), this control This can be done to ascertain whether of the electronic control unit for ABS.

braking system of the semitrailer receives be adjusted continuously. At the same is achieved regardless of the pressure the parking braking system of the motor In the event of the “control“ line rupturing

its compressed air through the hose time, the empty-load valve integrated in which is allowed to pass by the brake vehicle meets the requirements of the and the service brake being actuated, the

coupling (11). The air flows through the the brake valve receives information on valve or the relay emergency valve. When GCEC. The parking brake of the detached 2/2-way valve integrated in the trailer

line filter (31) to the relay emergency valve the change in the load through a pilot line. not required (solenoids are currentless) semitrailer is actuated by pulling out the control valve (17) throttles the passage to

You might also like

- Trigano Van Twin Fiat March 2021 Airtop 40 EvoDocument22 pagesTrigano Van Twin Fiat March 2021 Airtop 40 EvoCostel CaramanNo ratings yet

- Suzuki gsx1400 - Service - ManualDocument353 pagesSuzuki gsx1400 - Service - ManualCostel CaramanNo ratings yet

- ACTIA SmarTach - Workshop SheetDocument90 pagesACTIA SmarTach - Workshop SheetCostel CaramanNo ratings yet

- EFAS-4 Application Examples EN20130415TH08b - 2fpsDocument53 pagesEFAS-4 Application Examples EN20130415TH08b - 2fpsCostel CaramanNo ratings yet

- VDO-DTCO Message Summaries EN 2.2 PDFDocument78 pagesVDO-DTCO Message Summaries EN 2.2 PDFCostel CaramanNo ratings yet

- GF07.02-W-2110-01MP PLD Unit Pump, LocationDocument31 pagesGF07.02-W-2110-01MP PLD Unit Pump, LocationCostel Caraman100% (1)

- Resoftare 1381 Rel2 La Rel2.1Document2 pagesResoftare 1381 Rel2 La Rel2.1Costel CaramanNo ratings yet

- New Microsoft Word DocumentDocument1 pageNew Microsoft Word DocumentCostel CaramanNo ratings yet

- KITAS Overview 17 Dec 2012Document1 pageKITAS Overview 17 Dec 2012Costel CaramanNo ratings yet

- GS DescDocument4 pagesGS DescCostel CaramanNo ratings yet

- Bulet. Teh. 1324Document348 pagesBulet. Teh. 1324Costel Caraman100% (2)

- Digital Tachograph DTCO 1381 - Release 2.0: Technical DescriptionDocument332 pagesDigital Tachograph DTCO 1381 - Release 2.0: Technical DescriptionCostel CaramanNo ratings yet

- Plan Fundatii Sc. 1:50: S.C. Structexo Proiect SRLDocument1 pagePlan Fundatii Sc. 1:50: S.C. Structexo Proiect SRLCostel CaramanNo ratings yet

- ECAS Remorci Engleza 2Document24 pagesECAS Remorci Engleza 2Costel CaramanNo ratings yet

- ECAS Camioane Engleza 1Document82 pagesECAS Camioane Engleza 1Costel Caraman100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Jamalpur Earthing Calculation Final PDFDocument10 pagesJamalpur Earthing Calculation Final PDFarafinNo ratings yet

- Boe (Boiler Operation Engineer) Short Type Question Answer For Examination - AskpowerplantDocument15 pagesBoe (Boiler Operation Engineer) Short Type Question Answer For Examination - AskpowerplantRaju MaityNo ratings yet

- 520-540 Watt: Key FeaturesDocument2 pages520-540 Watt: Key FeaturesCH MOHAMMAD ATTIR KHAYYAMNo ratings yet

- Automation Direct - An Industry Guide To Control System EngineeringDocument93 pagesAutomation Direct - An Industry Guide To Control System EngineeringCesar CamachoNo ratings yet

- En D6T CatalogDocument20 pagesEn D6T CatalogHeddy ErizalNo ratings yet

- PORAM Standard SpecificationDocument3 pagesPORAM Standard SpecificationAristonNo ratings yet

- 1 TransformerDocument3 pages1 TransformerSyed Noman AhmedNo ratings yet

- Sources of Energy Class 10Document17 pagesSources of Energy Class 10Maan NmNo ratings yet

- HSC Physics Paper 2 Target PDFDocument17 pagesHSC Physics Paper 2 Target PDFAnonymous QvdxO5XTR63% (8)

- Load Dispatch Centre: By-Siddharth KumarDocument16 pagesLoad Dispatch Centre: By-Siddharth KumarSIDDHARTHNo ratings yet

- Ethylene Plant Contaminants: A Database and Interactive ToolDocument23 pagesEthylene Plant Contaminants: A Database and Interactive ToolEmmanuel LecrenayNo ratings yet

- Analysis of Commercial Proanthocyanidins. Part 1 The Chemical Composition of Quebracho (Schinopsis Lorentzii and Schinopsis Balansae) Heartwood Extract 2012 Phytochemistry 1Document11 pagesAnalysis of Commercial Proanthocyanidins. Part 1 The Chemical Composition of Quebracho (Schinopsis Lorentzii and Schinopsis Balansae) Heartwood Extract 2012 Phytochemistry 1Eric FernandoNo ratings yet

- VolvoDocument38 pagesVolvoMarculescu Nicolae CatalinNo ratings yet

- A Guide To Photovoltaic (PV) System Design and Installation: California Energy CommissionDocument40 pagesA Guide To Photovoltaic (PV) System Design and Installation: California Energy CommissionKuroko TetsuyaNo ratings yet

- Operations Manual 18WDocument137 pagesOperations Manual 18Wto_john100% (1)

- Greenstar Oil System and Regular Boilers Technical and Specification InformationDocument64 pagesGreenstar Oil System and Regular Boilers Technical and Specification InformationBabis PapadopoulosNo ratings yet

- Ship Shaft EarthingDocument12 pagesShip Shaft EarthingEdi LeeNo ratings yet

- Tunisia - Nawara Southern Tunisian Gas Pipeline - ESIA Executive SummaryDocument28 pagesTunisia - Nawara Southern Tunisian Gas Pipeline - ESIA Executive SummaryodeinatusNo ratings yet

- Pipe - Line Bevel MachineDocument24 pagesPipe - Line Bevel MachineSun SunNo ratings yet

- Your Guide To Hydraulic FracturingDocument1 pageYour Guide To Hydraulic FracturingMartin GriffinNo ratings yet

- Mechanizing Philippine Agriculture For Food SufficiencyDocument21 pagesMechanizing Philippine Agriculture For Food SufficiencyViverly Joy De GuzmanNo ratings yet

- Natural Gas Dehydration: October 2012Document21 pagesNatural Gas Dehydration: October 2012ShakerMahmoodNo ratings yet

- As 1038.14.2-2003 Coal and Coke - Analysis and Testing Higher Rank Coal Ash and Coke Ash - Major and Minor ElDocument7 pagesAs 1038.14.2-2003 Coal and Coke - Analysis and Testing Higher Rank Coal Ash and Coke Ash - Major and Minor ElSAI Global - APAC100% (1)

- PHD Thesis On Thermal Power PlantDocument6 pagesPHD Thesis On Thermal Power Plantafkneafpz100% (1)

- Honeywell Mag Meter 4000Document28 pagesHoneywell Mag Meter 4000cgasior1No ratings yet

- Automation Control ProductsDocument112 pagesAutomation Control Productsnavin jollyNo ratings yet

- Modeling of Power System in PSCAD/EMTDC ProgramDocument22 pagesModeling of Power System in PSCAD/EMTDC ProgramboopelectraNo ratings yet

- MCQ On Smart GridmisalpavDocument4 pagesMCQ On Smart GridmisalpavSomnath Hadpe67% (3)

- Transmission Lines and NetworksDocument18 pagesTransmission Lines and NetworkszgxfsbjbnNo ratings yet

- The Expanse - Sci-Fi Roleplaying at Humanity's Edge (Updated) PDFDocument260 pagesThe Expanse - Sci-Fi Roleplaying at Humanity's Edge (Updated) PDFZorrro85% (13)