Professional Documents

Culture Documents

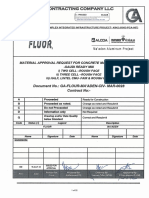

Fluor: Gulf Asia Contracting Company LLC

Uploaded by

Rajesh JoeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fluor: Gulf Asia Contracting Company LLC

Uploaded by

Rajesh JoeCopyright:

Available Formats

AW – PROCEED / WITH COMMENTS ®

Authorization to proceed does not relieve Contractor/Supplier of its responsibility

or liability under the Contract and or Purchase Order.

By Mark Welch (mark.welch@fluor.com) at 4:14 pm, 27 Jul 2012

GULF ASIA CONTRACTING COMPANY LLC.

MA'ADEN ALUMINUM COMPLEX INTEGRATED INFRASTRUCTURE PROJECT· K042(K003·PCA067)

FLUOR, ~

.~~~

*

~ ALCOA I !!'~:~!,~!~~~~

ONETEAM Ma 'a d e n A l uminum Pro j ect

METHOD STATEMENT FOR JUNCTION BOX INSTALLATION

Document No.: GA-FLUOR-MA' ADEN-ELE-MS-007,REV.OO

Contract No:-

A Proceed Ready for Construction

B Proceed as noted. Change as noted and Resubmit

C Do not Proceed Change as noted and Resubmit

Not Required

Correct and Resubmit

Comments:

00 16·07·12 FOR APPROVAL

METHOD STATEMENT FOR JUNCTION BOX INSTALLATION Page 1 of7

MA’ADEN ALUMINUM COMPLEX

INTEGRATED INFRASTRUCTURE PROJECT-K042(K003-

PCA067)

METHOD STATEMENT FOR JUNCTION BOX INSTALLATION

Document No.: GA-FLUOR-MA’ADEN-ELE-MS-007 REV.00, Date : 16-07-12

CONTENTS

1.0 SCOPE

2.0 DEFINITIONS

3.0 PURPOSE

4.0 REFERENCES

5.0 DUTIES AND RESPONSIBILITIES

6.0 EQUIPMENT AND TOOLS

7.0 WORK PROCEDURE FOR JUNCTION BOX INSTALLATION

8.0 SAFETY ACTION PLAN

METHOD STATEMENT FOR JUNCTION BOX INSTALLATION Page 2 of 7

MA’ADEN ALUMINUM COMPLEX

INTEGRATED INFRASTRUCTURE PROJECT-K042(K003-

PCA067)

METHOD STATEMENT FOR JUNCTION BOX INSTALLATION

Document No.: GA-FLUOR-MA’ADEN-ELE-MS-007 REV.00, Date : 16-07-12

1.0 SCOPE

This method statement covers requirements for the Junction box installation in MA’ADEN

ALUMINUM COMPANY INTEGRATED INFRASTRUCTURE PROJECT- K042 (K003-PCA 067) RAS

AL KHAIR, KSA.

The purpose of this procedure is made to ensure the Power system installation, shall be

Carried out in a neat and efficient workmanship, assuring satisfactory / proper operation. The

Power, Control Cable installation, termination and testing work shall be in accordance with

the requirements of the project specifications and shall be fulfil their true intent and

Meaning.

2.0 DEFINITIONS

EMP EMPLOYER (FLUOR ARABIA LTD)

GA GULF ASIA CONTRACTING COMPANY LLC.

MAC MA’ADEN ALUMINUM COMPANY.

3.0 PURPOSE

The purpose of this method statement is to outline detailed information about Junction box

installation activities, responsibilities of personals, procedure for safe system of work in

accordance with project specification and as per latest issued AFC drawings.

4.0 REFERENCES

The latest revision of the following Project Specifications shall be used as

References and is part of this Method Statement in the execution of the works.

MA’ADEN ENGINEERING STANDARDS

IEC International Electro technical Commission

NEC National Electrical Code

BS British Standards

SASO Saudi Arabian Standards Organization

METHOD STATEMENT FOR JUNCTION BOX INSTALLATION Page 3 of 7

MA’ADEN ALUMINUM COMPLEX

INTEGRATED INFRASTRUCTURE PROJECT-K042(K003-

PCA067)

METHOD STATEMENT FOR JUNCTION BOX INSTALLATION

Document No.: GA-FLUOR-MA’ADEN-ELE-MS-007 REV.00, Date : 16-07-12

MD-405-10P0-EG-EL-SPC-00014 Buildings Electrical Design Criteria

MD-405-10P0-EG-EL-SPC-00021 General Spec for Electrical Installation

MD-405-10P0-EG-EL-SPC-00005 Plant Lighting

5.0 DUTIES AND RESPONSIBILITIES

PROJECT MANAGER/ CONSTRUCTION MANAGER

Project manager/ Construction manager has overall control of all construction

activities, and all personnel report to him. Method statements, Manufacture data

sheet, and other Documents related to construction shall rout through him. He is the

responsible person for giving instruction to Construction personnel in matters

concerning work.

QA/QC MANAGER

QA/QC Manager is responsible for the overall activities of QA/QC Department. He is

assisted by QA/QC ENGINEER, who reports all daily QC activities, deficiencies

drawbacks at site.

QA/QC ENGINEER

He reports to QA/QC Manager. All Asst QC Engineers and Inspectors are directly

under QA/QC ENGINEER, Who intern divide works and oversee each person

activities.

ASST QA/QC ENGINEER & QA/QC INSPECTOR

The Asst QA/QC Engineer & QA/QC inspector is responsible for the necessary

inspections and tests to be carried out for activities involved in the Junction box

METHOD STATEMENT FOR JUNCTION BOX INSTALLATION Page 4 of 7

MA’ADEN ALUMINUM COMPLEX

INTEGRATED INFRASTRUCTURE PROJECT-K042(K003-

PCA067)

METHOD STATEMENT FOR JUNCTION BOX INSTALLATION

Document No.: GA-FLUOR-MA’ADEN-ELE-MS-007 REV.00, Date : 16-07-12

installation works as per Project procedures, Specifications, Drawings, Inspection

Test Plan (ITP).

ELECTRICAL MANAGER /SUPERINTENDENT

Electrical and Instrument Manager / Superintendent is responsible for plan the daily

work schedule, allocate the job to supervisors, and controlling the installation works

in all the areas.

ELECTRICAL ENGINEER/SUPERVISOR

Electrical Engineer / supervisor is responsible to monitor all day to day field

activities, assuring that implementation is as per this procedure and relevant

referenced standards and as per Human Safety & Environment policy manual.

Quality tracking, knowledge of job scope, technical issues and assurance that the

installation has been completed.

FOREMAN

The Foreman is responsible for the direct execution of works involved in the

Junction box installation as per work plan. He has direct control, responsibility, and

authority to give proper and correct instruction to work force under him, in carrying

out the activities with required quality level, as per Project Procedures,

specifications, Drawings, Manufactured Data Sheet, approved Method Statements

and ITP. He shall also ensure that works are performed with proper tools/equipment,

PPE and there is good housekeeping in the working area.

SAFETY MANAGER/SUPERVISOR

Safety Manager / Supervisor shall ensure that Safe Work Plan and work permit are

available at work place prior to start of the work and implemented during the work

activities.

6.0 EQUIPMENT AND TOOLS

METHOD STATEMENT FOR JUNCTION BOX INSTALLATION Page 5 of 7

MA’ADEN ALUMINUM COMPLEX

INTEGRATED INFRASTRUCTURE PROJECT-K042(K003-

PCA067)

METHOD STATEMENT FOR JUNCTION BOX INSTALLATION

Document No.: GA-FLUOR-MA’ADEN-ELE-MS-007 REV.00, Date : 16-07-12

The following necessary construction equipment / instrument, tools & tackles shall

be used to carry out the Junction box installation works.

1. Fitter Tool Box

2. Drilling Machine

3. Grinding Machine

4. Cutting Machine

5. Welding Machine

7.0 WORK PROCEDURE FOR JUNCTION BOX INSTALLATION

Junction boxes shall be rated IP66 in accordance with IEC 60529.

All junction boxes shall be installed in locations as per approved drawings, ensuring

free access for maintenance and no obstruction to other services.

Junction boxes installed indoors in corrosive locations or outdoors shall be stainless

Shall be in accordance with Specification

steel or other material approved by FAL/MAC.

MD-405-10PO-EG-EL-SPC-00021

All accessories shall be approved type. Junction boxes being installed in hazardous

area shall be classified as being suitable for installation in the area.

All junction boxes supports shall be installed independent of the connected conduit.

All unused holes shall be plugged or capped.

Junction box shall have an earthing stud additional to an earthing bar

or terminals for earthing cables.

8.0 SAFETY ACTION PLAN

All safety precautions will be followed as per HSE Plan. GA Safety Officer shall carry

out the safety inspections to ensure that safety requirements laid out in the safe

work plan are followed during and after installation work.GA Safety Manager /

Officers shall review Safety Action Plan and secure Work Permit if necessary prior to

start of any activities shall be strictly followed as per JSA. Equipment, tools and

materials inspection for cable system installation works shall be inspected by GA

METHOD STATEMENT FOR JUNCTION BOX INSTALLATION Page 6 of 7

MA’ADEN ALUMINUM COMPLEX

INTEGRATED INFRASTRUCTURE PROJECT-K042(K003-

PCA067)

METHOD STATEMENT FOR JUNCTION BOX INSTALLATION

Document No.: GA-FLUOR-MA’ADEN-ELE-MS-007 REV.00, Date : 16-07-12

Safety Manager / Officers prior to use. The inspection Reports shall be kept for

record.

METHOD STATEMENT FOR JUNCTION BOX INSTALLATION Page 7 of 7

You might also like

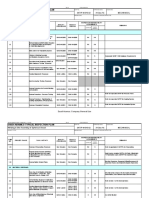

- 039-Itp For Embedded Plate PDFDocument7 pages039-Itp For Embedded Plate PDFKöksal PatanNo ratings yet

- 0709 - Electrical Installation Specification - RevBDocument40 pages0709 - Electrical Installation Specification - RevBbrandonNo ratings yet

- Method of Statement For GroutingDocument7 pagesMethod of Statement For Groutingmohammad.a.d94No ratings yet

- RAPID-P0003-TRSA-CON-ITP-0001-0010 - ITP For Lighting System - R0Document12 pagesRAPID-P0003-TRSA-CON-ITP-0001-0010 - ITP For Lighting System - R0Namta GeorgeNo ratings yet

- 002-PDS-CON-010 Method Statement For Site Preparation WorksDocument15 pages002-PDS-CON-010 Method Statement For Site Preparation WorksMalik ZamanNo ratings yet

- Ms For Fire Fighting Pump HouseDocument16 pagesMs For Fire Fighting Pump Housekienking80No ratings yet

- Inspection and Test Plan - General Civil Works at Adr&Ruwais RefineryDocument4 pagesInspection and Test Plan - General Civil Works at Adr&Ruwais RefineryJithesh.k.sNo ratings yet

- ITP InstrumentationDocument9 pagesITP InstrumentationzhangyiliNo ratings yet

- Attachment 4 Scope of WorkDocument5 pagesAttachment 4 Scope of WorkMathias OnosemuodeNo ratings yet

- SECTION 13100 Lightning Protection Rev 0Document16 pagesSECTION 13100 Lightning Protection Rev 0Azhar AliNo ratings yet

- DTTN Dt1 PC Rfi ST 0100Document1 pageDTTN Dt1 PC Rfi ST 0100Tariq Ali SialNo ratings yet

- Eni - Iraq Zubair Oil Field Development Project: Alstom Middle East, FZE, Dubai, UAEDocument7 pagesEni - Iraq Zubair Oil Field Development Project: Alstom Middle East, FZE, Dubai, UAEmohammad.a.d94No ratings yet

- Itp Transfer Tower - Xls (Bvi Comment)Document52 pagesItp Transfer Tower - Xls (Bvi Comment)Alif Rahmat FebriantoNo ratings yet

- Larsen & Toubro Limited: Inspection and Test Plan For Above Ground PipingDocument4 pagesLarsen & Toubro Limited: Inspection and Test Plan For Above Ground PipingKheireddine AounallahNo ratings yet

- Supervision Procedure: Oml100 (Fso Unity)Document8 pagesSupervision Procedure: Oml100 (Fso Unity)Ezemeh Nigeria100% (1)

- B-QAC-PLN-210-39157 SARPI ITP For Site Preparation and Earth WorksDocument26 pagesB-QAC-PLN-210-39157 SARPI ITP For Site Preparation and Earth WorksZaidi100% (1)

- QMP-MOA-013 (Rev.1) Preparation of Method Statements (CSC)Document10 pagesQMP-MOA-013 (Rev.1) Preparation of Method Statements (CSC)Vasilica BarbarasaNo ratings yet

- Work Method Statement: Installation of Waste Water Holding TanksDocument9 pagesWork Method Statement: Installation of Waste Water Holding TanksStansilous Tatenda NyagomoNo ratings yet

- Pump Commissioning Checklist - SafetyCultureDocument3 pagesPump Commissioning Checklist - SafetyCultureAnurag IngleNo ratings yet

- Soil Inspection Checklist For BackfillingDocument1 pageSoil Inspection Checklist For BackfillingBasker BaluNo ratings yet

- KR Parco Ps6 Ms 0001 M.S For ConcreteDocument11 pagesKR Parco Ps6 Ms 0001 M.S For ConcretebulzaeNo ratings yet

- Xyz Company: PurposeDocument3 pagesXyz Company: PurposeAnonymous 3eHGEDbxNo ratings yet

- Itp Forabove Grade and Embedded Conduits Rev. 0Document6 pagesItp Forabove Grade and Embedded Conduits Rev. 0sartaj0% (1)

- Saudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalpravinNo ratings yet

- DOD-MST-INS-003 Insta. & Testing of Inst. Cables-Rev-0Document11 pagesDOD-MST-INS-003 Insta. & Testing of Inst. Cables-Rev-0BharathiNo ratings yet

- 30.99.97.1616 Rev. 1 - ITP For Civil WorksDocument26 pages30.99.97.1616 Rev. 1 - ITP For Civil Worksshajahan eNo ratings yet

- Testing and CommisioningDocument2 pagesTesting and CommisioningKrishna PatilNo ratings yet

- Procurement Plan: FOR Epc For Constructing Pipe Line and Power Line For Sangsam Oil DevelopmentDocument9 pagesProcurement Plan: FOR Epc For Constructing Pipe Line and Power Line For Sangsam Oil DevelopmentHaekal RamadhanNo ratings yet

- For Construction: Reliance Bangladesh LNG & Power LimitedDocument21 pagesFor Construction: Reliance Bangladesh LNG & Power LimitedCaspian DattaNo ratings yet

- S 1153824 CST G01 0008 MS For Maintenance ToolDocument9 pagesS 1153824 CST G01 0008 MS For Maintenance ToolDedy SupriadiNo ratings yet

- P4586-CPC-WEC-PJ-MS-0004 Method Statement For Installation of HDPE Work Apron ABCDocument19 pagesP4586-CPC-WEC-PJ-MS-0004 Method Statement For Installation of HDPE Work Apron ABCLahiru IndrajithNo ratings yet

- ITP - Earth WorksDocument8 pagesITP - Earth WorksVasilica BArbarasaNo ratings yet

- EN131528-TCCSA-CS-M04-0003 (02) - Method Statement For Mass Concrete ConstructionDocument32 pagesEN131528-TCCSA-CS-M04-0003 (02) - Method Statement For Mass Concrete Construction章宇No ratings yet

- Job Procedure For Earthwork Excavation and BackfillingDocument6 pagesJob Procedure For Earthwork Excavation and BackfillingJitesh SahiNo ratings yet

- PreComm-Comm & RR Execution Plan Rev 0 PDFDocument22 pagesPreComm-Comm & RR Execution Plan Rev 0 PDFMaulana HaniefNo ratings yet

- 004-MS For Earthing System PDFDocument10 pages004-MS For Earthing System PDFKöksal Patan100% (1)

- QA&QC-DT-FRMC-009 Mouting Structure Installation RecordDocument1 pageQA&QC-DT-FRMC-009 Mouting Structure Installation RecordTariq Ali SialNo ratings yet

- Site Visit ReportDocument15 pagesSite Visit ReportKaushal PatelNo ratings yet

- MS Format-Tata Projects HosurDocument19 pagesMS Format-Tata Projects HosurSukhdeb BiswakarmaNo ratings yet

- 3-22 - Civil Works Inspection and Test Plan (PL212533-SP-ETG-5230-0C)Document6 pages3-22 - Civil Works Inspection and Test Plan (PL212533-SP-ETG-5230-0C)Walid AmdouniNo ratings yet

- TOR Wind Farm - Technical Due Diligencev1 - 0Document9 pagesTOR Wind Farm - Technical Due Diligencev1 - 0Alexandru IonescuNo ratings yet

- CCFM U 00 TP430 010 R5 Field QC ProcedureDocument258 pagesCCFM U 00 TP430 010 R5 Field QC ProcedureCARLOS OLIVEROSNo ratings yet

- RAPID-FE1-TPX-CMM-SPN-0001-0903, Rev 1Document6 pagesRAPID-FE1-TPX-CMM-SPN-0001-0903, Rev 1Đình NamNo ratings yet

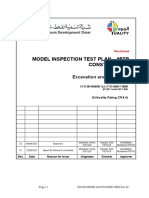

- MITP For Excavation and Backfilling ApprovedDocument7 pagesMITP For Excavation and Backfilling ApprovedMogu MohanNo ratings yet

- Procédure MTDocument11 pagesProcédure MTAslaouiNo ratings yet

- Site Specific Procedure (Junction Box)Document120 pagesSite Specific Procedure (Junction Box)Mohd Khairi AhmadNo ratings yet

- QCS 2010 Section 1 Part 21 Inspection and Hand-Over ProceduresDocument5 pagesQCS 2010 Section 1 Part 21 Inspection and Hand-Over Proceduresbryanpastor106No ratings yet

- 22.MS For HydrotestDocument9 pages22.MS For HydrotestASHWANINo ratings yet

- Firefighting Network Method StatementDocument60 pagesFirefighting Network Method StatementDiaa GobranNo ratings yet

- Itp For Gravel Surfacing and Dust PreventionDocument7 pagesItp For Gravel Surfacing and Dust PreventionShewale PravinNo ratings yet

- ITP Instrument-Cover EXAMPLEDocument6 pagesITP Instrument-Cover EXAMPLECharles RobiansyahNo ratings yet

- FP - Method of Statement - Al PheniqDocument9 pagesFP - Method of Statement - Al PheniqelbaraniNo ratings yet

- Site Organization ChartDocument1 pageSite Organization ChartAbhay KumarNo ratings yet

- B-QAC-PLN-210-39154 SARPI ITP For Structural Steel Erection WorksDocument19 pagesB-QAC-PLN-210-39154 SARPI ITP For Structural Steel Erection WorksZaidi50% (2)

- 022 Itp For Fence Gate PDFDocument5 pages022 Itp For Fence Gate PDFJithesh.k.sNo ratings yet

- NS1 Work Plan Procedure For CW Piping Installation Rev.4Document47 pagesNS1 Work Plan Procedure For CW Piping Installation Rev.4namdq-1No ratings yet

- Internal Audit Non-Conformity ReportDocument4 pagesInternal Audit Non-Conformity ReportSparrow Green StudiosNo ratings yet

- Method Statement For Installation of Earthing & Bonding SystemDocument14 pagesMethod Statement For Installation of Earthing & Bonding SystemProjects INTSNo ratings yet

- MS CN0P-MTD-736-007 - Lighting Fixture, Receptacles and Wiring REV CDocument12 pagesMS CN0P-MTD-736-007 - Lighting Fixture, Receptacles and Wiring REV Cbrian sanchezNo ratings yet

- MOS FOR STORM WATER GRP PIPES INSTALLATION & TESTING - FinalDocument11 pagesMOS FOR STORM WATER GRP PIPES INSTALLATION & TESTING - Final01095902062ahmedNo ratings yet

- A6pm-Iip-40-K042-00008 Rev0-DDocument5 pagesA6pm-Iip-40-K042-00008 Rev0-DRajesh JoeNo ratings yet

- Fluor: Gulf Asia Contracting Company LLCDocument3 pagesFluor: Gulf Asia Contracting Company LLCRajesh JoeNo ratings yet

- Ma'Aden Aluminum Complex Integrated Infrastructure Project-K042 (K003-Pca-067)Document22 pagesMa'Aden Aluminum Complex Integrated Infrastructure Project-K042 (K003-Pca-067)Rajesh JoeNo ratings yet

- Fluor: Gulf Asia Contrac Ling Company LLCDocument6 pagesFluor: Gulf Asia Contrac Ling Company LLCRajesh JoeNo ratings yet

- A6pm-Iip-40-K042-00006 Rev0-CDocument35 pagesA6pm-Iip-40-K042-00006 Rev0-CRajesh JoeNo ratings yet

- 02 M E StrucDocument36 pages02 M E StrucRajesh JoeNo ratings yet

- ENSTRUC - Komatsu Bucket Teeth Adapters CatalogueDocument7 pagesENSTRUC - Komatsu Bucket Teeth Adapters CataloguedharisaroyaNo ratings yet

- JOIE - Volume 12 - Issue 2 - Pages 21-32Document12 pagesJOIE - Volume 12 - Issue 2 - Pages 21-32sam mammoNo ratings yet

- Assignment-1 Computer Aided Manufacturing ME-418Document21 pagesAssignment-1 Computer Aided Manufacturing ME-418Prateek Kharbanda 79No ratings yet

- Product and Manufacturing Information PMIDocument3 pagesProduct and Manufacturing Information PMIlaboratorioNo ratings yet

- Kick of Meeting ReportDocument4 pagesKick of Meeting ReportJudy TrijogaNo ratings yet

- Encyclopedia of WaterDocument966 pagesEncyclopedia of Watersasa.vukoje33% (3)

- Lab#3 Compression TestDocument7 pagesLab#3 Compression TestLarisaVladNo ratings yet

- Pos Safeguards Plant and Machinery 1004642-EN-03Document1 pagePos Safeguards Plant and Machinery 1004642-EN-03micros zenerNo ratings yet

- Iglu'® Ventilated Roof - Disposable Formwork For Sloped or Flat Ventilated RoofsDocument7 pagesIglu'® Ventilated Roof - Disposable Formwork For Sloped or Flat Ventilated RoofsDaliform GroupNo ratings yet

- Main CatalogueDocument117 pagesMain CatalogueFilipNo ratings yet

- 3 Phase GeneratorsDocument9 pages3 Phase GeneratorsAndrew CroninNo ratings yet

- Foundations NotesDocument9 pagesFoundations Notesapi-26041653100% (1)

- 2021 Batch: Curriculum For M.Tech. Degree ProgrammeDocument56 pages2021 Batch: Curriculum For M.Tech. Degree ProgrammeP V S RaoNo ratings yet

- Guide To Site - Box CulvertDocument4 pagesGuide To Site - Box Culvertjs kalyana ramaNo ratings yet

- TruLaser 8000 enDocument4 pagesTruLaser 8000 enVenkatesh BantwalNo ratings yet

- Ketentuan Detail Tulangan Pada Struktur Beton Bertulang - Yogyakarta - 14-15nov.20118 BW PDFDocument235 pagesKetentuan Detail Tulangan Pada Struktur Beton Bertulang - Yogyakarta - 14-15nov.20118 BW PDFAris AriyadiNo ratings yet

- Aditya Damar Jati: Personal DataDocument2 pagesAditya Damar Jati: Personal DataAditya Damar JatiNo ratings yet

- Frequently Asked Questions (FAQ) On Water MetersDocument3 pagesFrequently Asked Questions (FAQ) On Water Metersharish1000No ratings yet

- Company Profile BMT AP IndonesiaDocument10 pagesCompany Profile BMT AP Indonesiaslamet4riadiNo ratings yet

- Design and Analysis of Reinforced Concrete Multistory Commercial Building Using Aci-318 Metric Manually and Extensive Design by Robot AnalysisDocument178 pagesDesign and Analysis of Reinforced Concrete Multistory Commercial Building Using Aci-318 Metric Manually and Extensive Design by Robot AnalysisAbdul Azeem Baig100% (2)

- Constitutive Modelling of Granular MaterialsDocument556 pagesConstitutive Modelling of Granular MaterialsAnupEkboteNo ratings yet

- CoDocument154 pagesCoFazal JadoonNo ratings yet

- Better Diesel Yield.: High Performance Dewaxing With MIDW Catalyst Technology and ServicesDocument2 pagesBetter Diesel Yield.: High Performance Dewaxing With MIDW Catalyst Technology and ServicesAnonymous Sy7yVvNo ratings yet

- Engineering PrinciplesDocument3 pagesEngineering PrinciplesFloyd Raniel AguilarNo ratings yet

- IQ/OQ Protocol: Installation Qualification/ Operation QualificationDocument12 pagesIQ/OQ Protocol: Installation Qualification/ Operation QualificationRambabu komati - QANo ratings yet

- Assignment: Mehran University of Engineering & Technology, Szab Campus, Khairpur Mir'SDocument4 pagesAssignment: Mehran University of Engineering & Technology, Szab Campus, Khairpur Mir'SSibghatullahNo ratings yet

- Siemens - FMR FlyerDocument8 pagesSiemens - FMR FlyerAnonymous ZrP5LqNo ratings yet

- Date Tested: Performance Check of Sieves With Designation Larger Than 4.75mm/no. 4 (ASTM E11)Document64 pagesDate Tested: Performance Check of Sieves With Designation Larger Than 4.75mm/no. 4 (ASTM E11)Hamza MukhtarNo ratings yet

- CE 241 - 01 Composite BeamsDocument91 pagesCE 241 - 01 Composite BeamsSwarna RkNo ratings yet

- Quality Assurance Plan For Building ConstructionDocument18 pagesQuality Assurance Plan For Building ConstructionAmit Kumar Pandey100% (1)