Professional Documents

Culture Documents

Operations Research

Uploaded by

Leechel Ella Recalde (Ellie)0 ratings0% found this document useful (0 votes)

16 views5 pagesIntroduction to Operations Research

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentIntroduction to Operations Research

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views5 pagesOperations Research

Uploaded by

Leechel Ella Recalde (Ellie)Introduction to Operations Research

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 5

OPERATIONS RESEARCH

COURSE CODE: IEN05

OPERATIONS RESEARCH

The discipline of applying advanced[1] analytical[2] methods to help make

better decisions[3]

[1] OR uses highly developed tools

[2] OR resolves problems by breaking them down to basic principles

[3] OR is not about the ideal, but about sound judgments and conclusions

THE ORIGINS OF OPERATIONS RESEARCH

The beginning of the activity called Operations Research has generally

been attributed to the military services early in World War II.

Because of the war effort, there was an urgent need to allocate scarce

resources to the various military operations and to the activities within

each operation in an effective manner.

The British and then the US military management called upon a large

number of scientists to apply a scientific approach to dealing with this

and other strategic and tactical problem.

They were asked to do research on (military) operations. These teams of

scientists were the first OR teams).

By developing effective methods of using the new tool of radar, these

teams were instrumental in winning the Air Battle of Britain.

Through their research on how to better manage convoy and anti-

submarine operations, they also played a major role in winning the Battle

of the North Atlantic.

Similar efforts assisted the Island Campaign in the Pacific.

When the war ended, the success of OR in the war effort spurred interest

in applying OR outside the military as well.

At least two other factors that played a key role in the rapid growth of OR

during this period:

o Substantial progress that was made early in improving the

techniques of OR.

o Onslaught of the computer revolution.

THE VALUE CREATED BY OPERATIONS RESEARCH

Some of the proven benefits of OR in the industry:

a. Business insight i. Productivity

b. Business performance j. Profits

c. Cost reduction k. Project development

d. Decision making l. Quality

e. Forecasting m. Recovery

f. Improved scheduling n. Resources

g. Planning o. Risk

h. Pricing p. Throughput

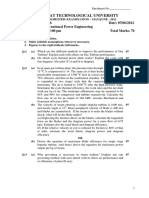

IMPACTS OF OPERATIONS RESEARCH

ANNUAL

ORGANIZATION NATURE OF APPLICATION YEAR

SAVINGS

Manage oil and coal inventories for 1989 $59 M

Electric Power

electric utilities to balance inventory cost

Research Institute

and risk of shortage

Optimally blend available ingredients 1989 $30 M

Texaco, Inc. into gasoline products to meet quality

and sales requirements

Integrate a national network of spare 1990 $20 M +

parts inventories to improve service $250 M

IBM

support less

inventory

Yellow Freight Optimize design of national trucking 1990 $17.3 M

System Inc. network and the routing of shipments

Quickly coordinate aircraft, crew cargo 1992 VICTORY

U.S. Military Airlift

and passengers to run the Operation

Command

Desert Storm airlift

Design a system of fare structures, 1992 $500 M

American Airlines overlooking and coordinating flights to more

increase revenues revenues

New Haven Design an effective needle exchange 1993 33% less

Health program to combat the spread of HIV/AIDS

Department HIV/AIDS

FIVE SIGNS THAT OPERATIONS RESEARCH CAN HELP

1. You face complex decisions.

2. You’re having problems with processes.

3. You’re troubled by risk.

4. Your organization is not making the most of its data.

5. You need to beat stiff competition.

CLASSIFICATIONS OF OPERATIONS RESEARCH TECHNIQUES

Despite the wealth of labels available in the field of OR, most projects

apply one of three broad groups of methods, which may be described as:

Optimization and Heuristic methods

Simulation methods

Data Analysis methods

OPERATIONS RESEARCH TECHNIQUES

1. Linear Programming – problem solving approach that has been

developed for situations involving maximizing or minimizing a linear

functions subject to linear constraints that limit the degree to which the

objective can be pursued.

2. Integer Linear Programming – approach used for problems that can set u

as linear programming with additional requirement that some or all of the

decision recommendations be integer values.

3. Network Models – specialized solution procedures for a problem consisting

of nodes that are interconnected by lines intended for areas such as

transportation system design, information system design and project

scheduling

4. Project Scheduling PERT/CPM – techniques that helps managers to carry

out their project scheduling responsibilities.

5. Inventory Models – used by managers faced with the dual problems of

maintaining sufficient inventories to meet demand for goods and, at the

same time, incurring the lowest possible inventory holding costs.

6. Waiting-line/Queuing Models – developed to help managers understand

and make better decisions concerning the operation of systems involving

waiting lines.

7. Computer Simulation – technique used to model the operation of a

system which employs computer program to model the operation and

perform simulation computations.

8. Decision Analysis – determine the optimal strategies in situations involving

decision alternatives and an uncertain or risk-filled pattern of events.

9. Goal Programming – technique for solving multi-criteria decisions

problems usually within the framework of linear programming.

10. Analytic Hierarchy Process – multi-criteria decision-making technique that

permits the inclusion of subjective factors in arriving at as recommended

decision.

11. Forecasting – technique that can be used to predict future aspects of a

business operation.

12. Markov-Process Models – useful in studying the evolution of certain

systems over repeated trials.

Example: Used to describe the probability that a machine,

functioning in one period, will function or break down in another

period.

13. Dynamic Programming – an approach that allows us to break up a large

problem in such a fashion that once all the smaller problems have been

solved, we are left with an optimal solution to the large problem.

THE SEVEN STEP MODEL BUILDING PROCESS

When Operations Research is used to solve and organization’s problem,

the following seven-step model-building procedure should be followed:

Define Observe Formulate Verify Select Present Implement

1. DEFINE THE PROBLEM

o Specify the organization’s objectives, the scope of the problem

and the areas in the organization that must be studied before

the problem can be solved.

o Identify the best measure(s) or performance.

2. OBSERVE THE SYSTEM

o Determine the steady state behavior of the system.

o Identify the constraints of the problem.

o Collect data to estimate the value of parameters that affect the

organization’s problem.

3. FORMULATE A MATHEMATICAL MODEL OF THE PROBLEM

o Construct mathematical relationships between the factors

identified and objective of the study.

o Make use of various mathematical techniques available.

4. VERIFY THE MODEL AND USE THE MODEL FOR PREDICTION

o Determine if the mathematical model developed is an accurate

representation of reality.

o Test the model using other data that were not used to estimate

5. SELECT A SUITABLE ALTERNATIVE

o Choose the best alternative that meets the organization’s

objectives.

o Using various scientific tools that may help in selection.

6. PRESENT THE RESULTS AND CONCLUSIONS OF THE STUDY

o Present the model and recommendation to the decision-making

individuals or groups in the organization.

7. IMPLEMENT, EVALUATE, AND CONTROL RECOMMENDATIONS

o If the organization has accepted the study, then the analyst aids

in implementing the recommendations.

VARIOUS MODEL CLASSIFICATION

1. ICONIC MODELS – physical replicas or representation of real objects.

Example: Scale model of an airplane

2. ANALOG MODELS – models that are physical in form but do not have the

same physical appearance as the object being modeled.

Example: Speedometer, Thermometer

3. MATHEMATICAL MODELS – models that represent a problem by a system

of symbols and mathematical relationships or expressions.

Example: Maximize cx

s.t.ax ≤ b

x≥0

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Maintenance Manual: Models 8300, 8400, and 8500 Pallet Trucks and Model 8600 Tow TractorDocument291 pagesMaintenance Manual: Models 8300, 8400, and 8500 Pallet Trucks and Model 8600 Tow TractorJosé Luis Ang Soto92% (13)

- Statistical Process Control ChartDocument69 pagesStatistical Process Control ChartLeechel Ella Recalde (Ellie)No ratings yet

- (Advances in Biochemical Engineering - Biotechnology 119) Takayuki Nishizaka (Auth.), Isao Endo, Teruyuki Nagamune (Eds.) - Nano - Micro Biotechnology (2010, Springer-Verlag Berlin Heidelberg) PDFDocument271 pages(Advances in Biochemical Engineering - Biotechnology 119) Takayuki Nishizaka (Auth.), Isao Endo, Teruyuki Nagamune (Eds.) - Nano - Micro Biotechnology (2010, Springer-Verlag Berlin Heidelberg) PDFAlejandra EscalonaNo ratings yet

- Visual Basic ApplicationDocument1 pageVisual Basic ApplicationLeechel Ella Recalde (Ellie)No ratings yet

- GMP - Garment PDFDocument34 pagesGMP - Garment PDFLeechel Ella Recalde (Ellie)No ratings yet

- Engineering EconomyDocument45 pagesEngineering EconomyLeechel Ella Recalde (Ellie)No ratings yet

- FacilitiesDocument5 pagesFacilitiesGarry Lopez FamorcaNo ratings yet

- Unit Load Retrieval EquipmentDocument34 pagesUnit Load Retrieval EquipmentLeechel Ella Recalde (Ellie)No ratings yet

- Final Project FormatDocument5 pagesFinal Project FormatLeechel Ella Recalde (Ellie)No ratings yet

- Facility Planning - Chapter 4Document4 pagesFacility Planning - Chapter 4Leechel Ella Recalde (Ellie)No ratings yet

- Unit Load Retrieval Equipment Types and FunctionsDocument42 pagesUnit Load Retrieval Equipment Types and FunctionsLeechel Ella Recalde (Ellie)No ratings yet

- Information Systems - Transaction Processing System To Artificial IntelligenceDocument60 pagesInformation Systems - Transaction Processing System To Artificial IntelligenceLeechel Ella Recalde (Ellie)No ratings yet

- Introduction To Industrial Quality ControlDocument2 pagesIntroduction To Industrial Quality ControlLeechel Ella Recalde (Ellie)No ratings yet

- Christ Christ Christ Christ Christ: Love Love Love Love LoveDocument2 pagesChrist Christ Christ Christ Christ: Love Love Love Love LoveLeechel Ella Recalde (Ellie)No ratings yet

- Sample Linear Programming ProblemsDocument1 pageSample Linear Programming ProblemsLeechel Ella Recalde (Ellie)No ratings yet

- Concept Generation ProcessDocument8 pagesConcept Generation ProcessLeechel Ella Recalde (Ellie)No ratings yet

- Product Development - Concept GenerationDocument30 pagesProduct Development - Concept GenerationLeechel Ella Recalde (Ellie)No ratings yet

- IEN04 - Reviewer (Chapter 13)Document1 pageIEN04 - Reviewer (Chapter 13)EllieNo ratings yet

- IEN04 - Reviewer (Chapter 14 - Stopwatch)Document1 pageIEN04 - Reviewer (Chapter 14 - Stopwatch)EllieNo ratings yet

- Websphere Application Server Runtime Architecture: Welcome ToDocument24 pagesWebsphere Application Server Runtime Architecture: Welcome ToluweinetNo ratings yet

- Turan Balik - ResumeDocument3 pagesTuran Balik - Resumeapi-250561031No ratings yet

- Refrigeration Cycles and Systems: A Review: ArticleDocument18 pagesRefrigeration Cycles and Systems: A Review: ArticleSuneel KallaNo ratings yet

- Covey Stephen RDocument90 pagesCovey Stephen RcemgallNo ratings yet

- DabbawalaDocument27 pagesDabbawalaAditya ShresthaNo ratings yet

- RS124 ManualDocument13 pagesRS124 ManualSoakaosNo ratings yet

- Is 9459Document13 pagesIs 9459Anonymous mcHqIfbnV1No ratings yet

- R07 Set No. 2Document8 pagesR07 Set No. 2dileepNo ratings yet

- Sumit Pandey CVDocument3 pagesSumit Pandey CVSumit PandeyNo ratings yet

- Problem Based Task Dfc2043Document3 pagesProblem Based Task Dfc2043player6675100% (1)

- Ligaya NG Buhay EnsembleDocument2 pagesLigaya NG Buhay EnsembleFrinzess VelascoNo ratings yet

- Hybrid Inverter SPH Series Technical SpecificationDocument2 pagesHybrid Inverter SPH Series Technical SpecificationJulio CesarNo ratings yet

- IEC 61850 and ION Technology: Protocol DocumentDocument52 pagesIEC 61850 and ION Technology: Protocol DocumentCristhian DíazNo ratings yet

- Emision StandardsDocument4 pagesEmision StandardsAshish RoongtaNo ratings yet

- GTU BE- Vth SEMESTER Power Engineering ExamDocument2 pagesGTU BE- Vth SEMESTER Power Engineering ExamBHARAT parmarNo ratings yet

- ETA 11 0006 For HAC Cast in Anchor ETAG Option Approval Document ASSET DOC APPROVAL 0198 EnglishDocument27 pagesETA 11 0006 For HAC Cast in Anchor ETAG Option Approval Document ASSET DOC APPROVAL 0198 Englishlaeim017No ratings yet

- MMP - Intro To ElectronicDocument12 pagesMMP - Intro To ElectronicAye Chan OoNo ratings yet

- 9829d23b-6e45-4cbd-b732-f870faff49a0Document6 pages9829d23b-6e45-4cbd-b732-f870faff49a0Swamy Dhas DhasNo ratings yet

- Altera 5M1270ZF256C5N DatasheetDocument30 pagesAltera 5M1270ZF256C5N DatasheetIonut Daniel FigherNo ratings yet

- General DataDocument8 pagesGeneral DataGurvinderpal Singh MultaniNo ratings yet

- Dme 401Document13 pagesDme 401PacoNo ratings yet

- CIECO PPC1000R Installation Manual V3.3Document61 pagesCIECO PPC1000R Installation Manual V3.3TomNo ratings yet

- Ias Public Administration Mains Test 1 Vision IasDocument2 pagesIas Public Administration Mains Test 1 Vision IasM Darshan UrsNo ratings yet

- Bab III.2.1. Generator Sinkron (Lanjutan)Document28 pagesBab III.2.1. Generator Sinkron (Lanjutan)Hariz AudirahmawanNo ratings yet

- Mechanical Advantage and EfficiencyDocument16 pagesMechanical Advantage and EfficiencyYadana1No ratings yet

- Safety and Reliability in Turbine Sealing CompoundsDocument2 pagesSafety and Reliability in Turbine Sealing CompoundsProject Sales CorpNo ratings yet

- Compiler Design (2170701) : Epartment of Omputer NgineeringDocument3 pagesCompiler Design (2170701) : Epartment of Omputer NgineeringRancho ChauhanNo ratings yet

- Assignment 5 - AirportDocument2 pagesAssignment 5 - AirportSaroj AcharyaNo ratings yet