Professional Documents

Culture Documents

Aluminum Manual 70

Uploaded by

LUIS45630 ratings0% found this document useful (0 votes)

6 views2 pagesOriginal Title

Aluminum Manual 70.txt

Copyright

© © All Rights Reserved

Available Formats

TXT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views2 pagesAluminum Manual 70

Uploaded by

LUIS4563Copyright:

© All Rights Reserved

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

You are on page 1of 2

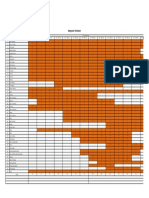

TABLE 4.

6 Color Code for Aluminum

Specification Alloys

Alloy Color

1100 White

2014 Gray

2024 Red

3003 Green

3004 �

3005 �

3105 �

5005 �

5050 �

5052 Purple

5083 Red and Gray

5086 Red and Orange

5154 Blue and Green

5454 �

5456 Gray and Purple

6005 �

6061 Blue

6063 Yellow and Green

6066 Red and Green

6070 Blue and Gray

6105 �

6351 Purple and Orange

7075 Black

Certificate of Inspection and Test Results: Gives minimum and maximum

mechanical properties obtained from testing each lot and lists the applicable

chemical-composition limits (not the actual chemical-composition).

Certificate of Inspection and Test Results including Chemical Analysis:

Gives minimum and maximum mechanical properties and chemical analysis

obtained from testing each lot.

These certificates are listed in ascending order of cost. For most routine

structural applications, a certificate of compliance or inspection is usually

sufficient.

5 Explanation of the

Aluminum Specification

This chapter could also have been titled ��Structural Design with Metals��

because it covers a range of metal behavior beyond that covered by the metal

specification we all learned in school (the AISC Specification [38, 39]). In a

number of ways, hot-rolled steel design is just a special case of metal design,

while the Aluminum Specification offers a more panoramic view. Ironically,

learning about aluminum can actually give you better insight into steel design;

in college, most of us studiously avoided any metal but hot-rolled steel.

Design with hot-rolled steel is typically limited to the so-called ��compact

sections.�� These shapes have sufficiently stocky cross-sectional elements so

local buckling is not a concern. In the real world, many metal structures are

made of lighter gauge components instead, whose capacities may be influenced

by local buckling. We�ll lead you into the land of postbuckling strength,

where no compact section has ever gone. If you master this concept, you�ll

not only be able to deal with the wide range of shapes available in aluminum,

you will also gain some insight into the design of light-gauge steel structures.

While the Aluminum Specification addresses the full spectrum of element

slenderness, in steel you have to leave the comfort of the Steel Manual and

wade into the complex provisions of the AISI cold-formed steel specification

(40) to design members that have very slender elements. Although the Aluminum

Specification and the cold-formed steel specification use entirely different

methods to address slender elements, they both deal with the same

fundamental behavior.

We�ll discuss the Aluminum Specification�s approach to metal design in

this chapter, giving examples and highlighting sections of the Specification

as we cover them. For the plug-and-chug oriented, you can skip to Chapter

7, where we�ll keep the discussion to a minimum and provide the step-bystep

procedures for applying the Aluminum Specification. Finally, for a

checklist of the applicable provisions of the Specification for each mode of

behavior, refer to Appendix G.

5.1 TENSION MEMBERS

If you�re like most engineers, you appreciate the simplicity of tensile stresses.

After all, tensile stresses and strengths are so much easier to calculate than

You might also like

- Aluminum Manual 79Document1 pageAluminum Manual 79LUIS4563No ratings yet

- Aluminum Manual 79Document1 pageAluminum Manual 79LUIS4563No ratings yet

- Aluminum Manual 78Document1 pageAluminum Manual 78LUIS4563No ratings yet

- Aluminum Manual 80Document2 pagesAluminum Manual 80LUIS4563No ratings yet

- Aluminum Manual 77Document1 pageAluminum Manual 77LUIS4563No ratings yet

- Aluminum Manual 72Document1 pageAluminum Manual 72LUIS4563No ratings yet

- Aluminum Manual 75Document1 pageAluminum Manual 75LUIS4563No ratings yet

- Aluminum Manual 76Document1 pageAluminum Manual 76LUIS4563No ratings yet

- Aluminum Manual 72Document1 pageAluminum Manual 72LUIS4563No ratings yet

- Aluminum Manual 78Document1 pageAluminum Manual 78LUIS4563No ratings yet

- Aluminum Manual 73Document1 pageAluminum Manual 73LUIS4563No ratings yet

- Aluminum Manual 74Document1 pageAluminum Manual 74LUIS4563No ratings yet

- Aluminum Manual 70Document2 pagesAluminum Manual 70LUIS4563No ratings yet

- Aluminum Manual 68Document2 pagesAluminum Manual 68LUIS4563No ratings yet

- Aluminum Manual 69Document1 pageAluminum Manual 69LUIS4563No ratings yet

- Aluminum Manual 67Document2 pagesAluminum Manual 67LUIS4563No ratings yet

- Aluminum Manual 59Document1 pageAluminum Manual 59LUIS4563No ratings yet

- Aluminum Manual 71Document1 pageAluminum Manual 71LUIS4563No ratings yet

- Aluminum Manual 64Document1 pageAluminum Manual 64LUIS4563No ratings yet

- Aluminum Manual 65Document1 pageAluminum Manual 65LUIS4563No ratings yet

- Aluminum Manual 66Document1 pageAluminum Manual 66LUIS4563No ratings yet

- Aluminum Manual 60Document2 pagesAluminum Manual 60LUIS4563No ratings yet

- Aluminum Manual 58Document1 pageAluminum Manual 58LUIS4563No ratings yet

- Aluminum Manual 65Document1 pageAluminum Manual 65LUIS4563No ratings yet

- Aluminum Manual 63Document1 pageAluminum Manual 63LUIS4563No ratings yet

- Aluminum Manual 61Document1 pageAluminum Manual 61LUIS4563No ratings yet

- Aluminum Manual 62Document1 pageAluminum Manual 62LUIS4563No ratings yet

- Aluminum Manual 58Document1 pageAluminum Manual 58LUIS4563No ratings yet

- Aluminum Manual 57Document1 pageAluminum Manual 57LUIS4563No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- U2S3-4 - Environmental Impact of Textile IndustriesDocument9 pagesU2S3-4 - Environmental Impact of Textile IndustriesHieu100% (7)

- Cineo 2560servicemanualDocument732 pagesCineo 2560servicemanualjrusalen1100% (1)

- Manpower Schedule ProjectDocument1 pageManpower Schedule ProjectColitz D. KhenNo ratings yet

- Mtech Ranklist4!7!2015Document164 pagesMtech Ranklist4!7!2015Arjun T PNo ratings yet

- Transpowr Acsr Bare Overhead Conductor To Can/Csa C61089: Aluminum Conductor Steel-Reinforced Concentric-Lay-StrandedDocument18 pagesTranspowr Acsr Bare Overhead Conductor To Can/Csa C61089: Aluminum Conductor Steel-Reinforced Concentric-Lay-Strandedravi474No ratings yet

- Blocks M Sand RegisterDocument2 pagesBlocks M Sand RegisterSarinNo ratings yet

- Bill No. 1 Preliminaries and General ConditionsDocument14 pagesBill No. 1 Preliminaries and General ConditionsOmoi CamillusNo ratings yet

- HAZOP Study Part IIDocument18 pagesHAZOP Study Part IIBoy farhanNo ratings yet

- Inspeccion Visual Ta1 Tractor d6r II (B)Document7 pagesInspeccion Visual Ta1 Tractor d6r II (B)RAMON CALDERONNo ratings yet

- Wan Bao Construction Limited: Register of Legal and Other RequirementsDocument49 pagesWan Bao Construction Limited: Register of Legal and Other RequirementsVictorNo ratings yet

- K to 12 TLE Horticulture Course Teaches Farming SkillsDocument5 pagesK to 12 TLE Horticulture Course Teaches Farming SkillsRonel Suan100% (1)

- Eciv 303 PPTDocument17 pagesEciv 303 PPTapi-401204381No ratings yet

- Service Manual Toshiba Satellite Pro 6000Document11 pagesService Manual Toshiba Satellite Pro 6000lachiondoNo ratings yet

- Pressure Vessel InspectionsDocument17 pagesPressure Vessel InspectionsLipika GayenNo ratings yet

- Atomic 4 Parts ListDocument72 pagesAtomic 4 Parts ListRobertNo ratings yet

- Slope Stability Analysis Analiza Interna Input DataDocument22 pagesSlope Stability Analysis Analiza Interna Input DatananesculNo ratings yet

- Enhancing Student Interest in The Agricultural Sciences Through AquaponicsDocument4 pagesEnhancing Student Interest in The Agricultural Sciences Through AquaponicsAquaponicsNo ratings yet

- MVSR Engineering College Department of Computer Science and Engineering Course Name: Mini Project Course Code: Cs 218 Course ObjectivesDocument2 pagesMVSR Engineering College Department of Computer Science and Engineering Course Name: Mini Project Course Code: Cs 218 Course ObjectivesPammi KavithaNo ratings yet

- Portal Crane Systems - Dynamic Storm Brake System IIDocument2 pagesPortal Crane Systems - Dynamic Storm Brake System IIpresydentyNo ratings yet

- A Study of Biomass Briquette in BangladeshDocument97 pagesA Study of Biomass Briquette in BangladeshPamela Nicole ManaloNo ratings yet

- U.S. Air Force Munitions Facilities Standards GuideDocument214 pagesU.S. Air Force Munitions Facilities Standards GuideTotsapon Roongkaew100% (1)

- Extended Warranty Program WiFi Temperature & Humidity Data Logger User's GuideDocument7 pagesExtended Warranty Program WiFi Temperature & Humidity Data Logger User's GuideAENo ratings yet

- Wafer Thinning and Through Silicon ViasDocument41 pagesWafer Thinning and Through Silicon ViasJohn RecheNo ratings yet

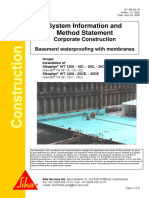

- Basement Waterproofing Sikaplan WTDocument45 pagesBasement Waterproofing Sikaplan WTMartin Urbieta100% (1)

- st3td 210 MW PDFDocument203 pagesst3td 210 MW PDFDevesh BadsiwalNo ratings yet

- What Is Cross Wall Construction - Features and BenefitsDocument4 pagesWhat Is Cross Wall Construction - Features and BenefitswaynectwNo ratings yet

- CVT 8-Speed Transmission Overhaul GuideDocument4 pagesCVT 8-Speed Transmission Overhaul GuideRodrigo Barrios GaticaNo ratings yet

- CAD BIM Typicals ASSET DOC LOC 8373945 PDFDocument8 pagesCAD BIM Typicals ASSET DOC LOC 8373945 PDFMin KhantNo ratings yet

- AAMA Metal Curtain Wall FastenersDocument3 pagesAAMA Metal Curtain Wall FastenersAthumizNo ratings yet

- Lenox Ge-JenbacharDocument6 pagesLenox Ge-JenbacharJamil Ahmed100% (2)