Professional Documents

Culture Documents

Mining Equipment Fatality

Uploaded by

darl10 ratings0% found this document useful (0 votes)

9 views1 pageFatalities at mines

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFatalities at mines

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views1 pageMining Equipment Fatality

Uploaded by

darl1Fatalities at mines

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

HAZARD ALERT

Industry: Service Age: 40 years Experience: Unknown Area: Central Interior

Worker pinned underneath

heavy mining equipment

While a worker was servicing a piece of heavy mining equipment (a scooptram), the machine was elevated and the tires

were removed. When the scooptram had been elevated, it had been supported at each end with wooden blocking. After

the worker serviced and reinstalled the tires, he further raised the rear end of the scooptram with a 20-ton air/hydraulic

jack to remove the wooden blocking. As the worker climbed under the scooptram to get the wooden blocks, the air/

hydraulic jack failed and the rear of the scooptram dropped 18 cm (7 inches). The worker was pinned under the

scooptram and sustained a broken pelvis and tailbone.

An investigation determined the cause of the accident to be the failure of the air/hydraulic jack. The air/hydraulic jack’s

extension screw retaining pin was extremely worn out allowing the screw to be out of the base. The extension screw was

screwed into the jack’s threaded base by only one and a half threads instead of the four to five threads needed to support

the weight of the scooptram. This lack of support for the threads caused the air/hydraulic jack to fail.

Safe work practices:

• Inspect and maintain threaded jack extensions to acceptable tolerances and the manufacturer’s specifications.

• Ensure that workers are properly trained in the safe use of the equipment.

• Securely block elevated equipment any time a worker is working underneath it.

The WCB has a wide range of health and safety information. For assistance

and information on workplace health and safety, call toll-free within B.C.

INJURY

1 888 621-SAFE (7233) or visit our web site at www.WorkSafebc.com. 03–15

You might also like

- Site Accident Brief: Falls, Objects, Stacking, Confined SpacesDocument22 pagesSite Accident Brief: Falls, Objects, Stacking, Confined SpacesShibabrata RoyNo ratings yet

- OSHA WorkSafe ConstructionDocument36 pagesOSHA WorkSafe ConstructionLan Tian100% (1)

- Crane Safety PDFDocument1 pageCrane Safety PDFporbyNo ratings yet

- OISDCS202223EP03Document3 pagesOISDCS202223EP03Krishna KumarNo ratings yet

- 2008-IADC Alerts PDFDocument66 pages2008-IADC Alerts PDFAnsarMahmood100% (1)

- HKMU Li Ka Shing School of Professional and Continuing Education OSH5002 Assessment Legislative Context in Occupational Health and SafetyDocument21 pagesHKMU Li Ka Shing School of Professional and Continuing Education OSH5002 Assessment Legislative Context in Occupational Health and SafetyWan Ching WongNo ratings yet

- Fall Hazards: Did You Know? Falls From Elevation Account For One Third of All Deaths in ConstructionDocument18 pagesFall Hazards: Did You Know? Falls From Elevation Account For One Third of All Deaths in ConstructionMurat AnlıNo ratings yet

- Abrasive Wheel On Grinder Breaks, Killing Worker: Hazard AlertDocument1 pageAbrasive Wheel On Grinder Breaks, Killing Worker: Hazard Alertdarl1No ratings yet

- Scissor lift-Aerial-lift-Training-awarness TrainingDocument42 pagesScissor lift-Aerial-lift-Training-awarness Trainingfawn100% (1)

- CNX 2-11-13 PpeDocument29 pagesCNX 2-11-13 PpeMichael KovachNo ratings yet

- Fall Protection Wind FarmsDocument18 pagesFall Protection Wind Farmsalexander_bms100% (1)

- MSHA and OSHA laws and best practices for aerial lifts and manliftsDocument27 pagesMSHA and OSHA laws and best practices for aerial lifts and manliftsVicente CondNo ratings yet

- Safety and Health Checklist For Monitoring Transmission Line Construction WorksDocument6 pagesSafety and Health Checklist For Monitoring Transmission Line Construction WorksWinstone Audi100% (3)

- Wner S Anual: M Ehlt (1-4K) & PST (1-3K)Document20 pagesWner S Anual: M Ehlt (1-4K) & PST (1-3K)tintuc_inNo ratings yet

- Consolidated: Consolidated Safety Relief Valve Type 1900Document8 pagesConsolidated: Consolidated Safety Relief Valve Type 1900Peerasak ArunNo ratings yet

- Method of Statement-Rev1Document33 pagesMethod of Statement-Rev1Yusri Yusof100% (1)

- TerexDocument88 pagesTerexSilvio Roman100% (3)

- Ump Fan-Air Om Manual - Rev Dec 2014Document12 pagesUmp Fan-Air Om Manual - Rev Dec 2014api-252481722No ratings yet

- Crane Tiger ManualDocument26 pagesCrane Tiger ManualSurasan ThepsiriNo ratings yet

- JSA ExcavationDocument6 pagesJSA Excavationkermech21607100% (1)

- SF 10 23Document6 pagesSF 10 23Gusman TriadyNo ratings yet

- Osha Bocket Book - ConstructionDocument36 pagesOsha Bocket Book - ConstructionSAYED83% (6)

- Guidelines For Engineers Carrying Out ChecksDocument7 pagesGuidelines For Engineers Carrying Out ChecksSubhransu MohapatraNo ratings yet

- TM 9-2320-361-24-1Document1,176 pagesTM 9-2320-361-24-1sul2000No ratings yet

- Hazards IdentificationsDocument36 pagesHazards IdentificationsRobin Oidem CaniedoNo ratings yet

- Anti Two-Blocking Devices On CranesDocument2 pagesAnti Two-Blocking Devices On CranesJan Francis Wilson MapacpacNo ratings yet

- d245s Hpil Op ManualDocument66 pagesd245s Hpil Op ManualJhair75% (4)

- Construction Caught-in or Between Hazards GuideDocument8 pagesConstruction Caught-in or Between Hazards GuidesingenaadamNo ratings yet

- Excavation Safety ProceduresDocument7 pagesExcavation Safety ProceduresHasanuddin HAMIDNo ratings yet

- C211C IT Manual (EditMAR12)Document30 pagesC211C IT Manual (EditMAR12)nicole geraciNo ratings yet

- SG-19 Safety Guideline On Operation and Maintenance of Conveyor BeltsDocument11 pagesSG-19 Safety Guideline On Operation and Maintenance of Conveyor BeltsHIMANSHU SUTHARNo ratings yet

- Safety Training Presentations: Construction HazardsDocument44 pagesSafety Training Presentations: Construction HazardsSheikh TabrezNo ratings yet

- Erection of DPC Clinker Silo Extraction-2Document7 pagesErection of DPC Clinker Silo Extraction-2RajuNo ratings yet

- Circular-Recommendations of Quality Circle Team For Safe WorksDocument2 pagesCircular-Recommendations of Quality Circle Team For Safe WorksvinodNo ratings yet

- Turbo Sharp VDocument4 pagesTurbo Sharp Vnetuno777No ratings yet

- Construction Safety Measures Part 1: PPE, Scaffolding, Electrical SafetyDocument7 pagesConstruction Safety Measures Part 1: PPE, Scaffolding, Electrical SafetyYohannes KassaNo ratings yet

- Top Construction Fatality CausesDocument15 pagesTop Construction Fatality CausesAhmed Hassan SabryNo ratings yet

- Falls From Moving MachineryDocument2 pagesFalls From Moving MachineryZeeshan BajwaNo ratings yet

- cr800 cr850 PDFDocument598 pagescr800 cr850 PDFChristian SanchezNo ratings yet

- Method Statement For ACC BHELDocument7 pagesMethod Statement For ACC BHELHsebepl NkNo ratings yet

- Con-Tech Service Manual Rev 1 - 3 Xe Bon TronDocument379 pagesCon-Tech Service Manual Rev 1 - 3 Xe Bon Tronnghia100% (1)

- CR1000 DataloggerDocument630 pagesCR1000 DataloggersudirmanpriyoNo ratings yet

- Secoroc RotaryDocument84 pagesSecoroc RotaryElgi Zacky ZachryNo ratings yet

- # 20 Installation of Cable Tray Trunking (SWP)Document5 pages# 20 Installation of Cable Tray Trunking (SWP)Anonymous kWfNFbNo ratings yet

- Construction Hazards SMS TrainingDocument45 pagesConstruction Hazards SMS TrainingADEEL ARIFNo ratings yet

- GNFC Safety Rules PDFDocument16 pagesGNFC Safety Rules PDFCawaNo ratings yet

- CR3000 Micrologger®: Want To Get Going? Go To The Quickstart SectionDocument644 pagesCR3000 Micrologger®: Want To Get Going? Go To The Quickstart Sectionkarlitox123No ratings yet

- Uta Ast RiggingDocument34 pagesUta Ast RiggingfawnNo ratings yet

- Hasap 8 10 17Document4 pagesHasap 8 10 17Mohamed HadjkacemNo ratings yet

- Safety Precautions Durring Dismentling of StructresDocument83 pagesSafety Precautions Durring Dismentling of StructresshujaNo ratings yet

- Crane Safety ManualDocument44 pagesCrane Safety ManualacallevillNo ratings yet

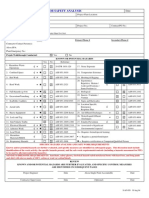

- Safety audit report identifies risks at construction siteDocument2 pagesSafety audit report identifies risks at construction sitePritesh Ramesh Bare93% (27)

- Aerial Lift Safety: Hazard AlertDocument2 pagesAerial Lift Safety: Hazard AlertScribdbahrainNo ratings yet

- Ms-Mec-101 Tank Erection ProcedureDocument23 pagesMs-Mec-101 Tank Erection ProcedureAltayeb YassinNo ratings yet

- Excavation, Trenching and ShoringDocument30 pagesExcavation, Trenching and ShoringAntonio Jose De JesusNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- 5 Whys AnalysisDocument7 pages5 Whys AnalysisShubhankar GuptaNo ratings yet

- Water Usage Tracking Spreadsheet - 0Document27 pagesWater Usage Tracking Spreadsheet - 0mayangNo ratings yet

- ISO 45001-2018 Briefing Presentation-NSAIDocument70 pagesISO 45001-2018 Briefing Presentation-NSAIOssamaIsmail100% (8)

- 2017 About Face 2017 Audit Protocol FinalDocument92 pages2017 About Face 2017 Audit Protocol FinalHUGO VASQUEZNo ratings yet

- Procurment Management Plan TemplateDocument15 pagesProcurment Management Plan TemplateMonil PatelNo ratings yet

- BSM Study Guide 1602 2ND YEAR PDFDocument204 pagesBSM Study Guide 1602 2ND YEAR PDFdarl10% (1)

- 0000 Indexes Procurement Procedures - Tender ProcedureDocument1 page0000 Indexes Procurement Procedures - Tender Proceduredarl1No ratings yet

- 2.2competitive Advantage and Strategic InitiativesDocument11 pages2.2competitive Advantage and Strategic Initiativesdarl1No ratings yet

- What Is Organisational Maturity and Opm3Document10 pagesWhat Is Organisational Maturity and Opm3darl1No ratings yet

- Pearson MyITLab South Africa How To Work On Assignments PDFDocument10 pagesPearson MyITLab South Africa How To Work On Assignments PDFdarl1No ratings yet

- Mobile Thread SW Linda Oct 2019 PDFDocument4 pagesMobile Thread SW Linda Oct 2019 PDFdarl1No ratings yet

- ConcentrationDocument2 pagesConcentrationdarl1No ratings yet

- 04registration CriteriaDocument5 pages04registration Criteriadarl1No ratings yet

- Draft Construction Regulations 2009 - 2Document33 pagesDraft Construction Regulations 2009 - 2darl1No ratings yet

- Hygiene Survey Action Plan Main 2 2017Document10 pagesHygiene Survey Action Plan Main 2 2017darl1No ratings yet

- 1J ECSA LMIAppformDocument39 pages1J ECSA LMIAppformdarl1No ratings yet

- ABSDocument42 pagesABSdarl1No ratings yet

- CH 13 Materials Handling and StorageDocument18 pagesCH 13 Materials Handling and Storagezahid_497No ratings yet

- Safety Footwear Specialist: 14 EditionDocument14 pagesSafety Footwear Specialist: 14 Editiondarl1No ratings yet

- Man Safe For WindowsDocument6 pagesMan Safe For Windowsdarl1No ratings yet

- 3.19 - Cost Estimating WorksheetDocument4 pages3.19 - Cost Estimating Worksheetdarl1No ratings yet

- 04 130 Feasibility Cost Estimation SheetDocument2 pages04 130 Feasibility Cost Estimation SheetGeorge JaneNo ratings yet

- Critical Path Method and Its SignificancDocument66 pagesCritical Path Method and Its Significancdarl1100% (1)

- TrngandMatlsLib FlammableLiquidsDocument10 pagesTrngandMatlsLib FlammableLiquidsHazel KatipunanNo ratings yet

- Room and Pillar - Wikipedia, The Free EncyclopediaDocument2 pagesRoom and Pillar - Wikipedia, The Free Encyclopediadarl1No ratings yet

- Cob A GuidelinesDocument5 pagesCob A Guidelinesdarl1No ratings yet

- Coal Mining: From Wikipedia, The Free EncyclopediaDocument12 pagesCoal Mining: From Wikipedia, The Free Encyclopediadarl1No ratings yet

- SMN301S 2013 1 e 1Document2 pagesSMN301S 2013 1 e 1darl1No ratings yet

- BCEA Summary GuideDocument8 pagesBCEA Summary GuideXavier HumanNo ratings yet

- SMNDocument2 pagesSMNdarl1No ratings yet