Professional Documents

Culture Documents

QHSE Alert-024-Anchoring & Mooring

Uploaded by

Somayajula Suryaram0 ratings0% found this document useful (0 votes)

66 views1 pageAnchoring & Mooring incident

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAnchoring & Mooring incident

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

66 views1 pageQHSE Alert-024-Anchoring & Mooring

Uploaded by

Somayajula SuryaramAnchoring & Mooring incident

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

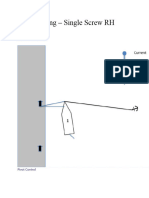

Fleet QHSE Alert

No. 024 31st July 2017

ANCHORING & MOORING

Incident: After disembarking the Reef Pilot off Hay Point,

Australia, the deck crew (AB, OS, RPFW) were instructed from Bridge

to secure the anchors for sea. During securing, the anchor ran out

damaging the windlass motor, shaft and gear and finally held on to

the Bitter end, also damaging the chain locker plating. All attempts to

retrieve the anchor failed as the windlass had extensively damaged.

The Anchor along with the cable had to be jettisoned before the

vessel could proceed on her voyage.

What went wrong?

Failure to secure Bow stopper – While securing the anchor in fully housed position, the ship staff

were not able to secure the Bow stopper due to the position of the anchor chain not fully horizontal in

way of bow stopper. It was decided to secure the anchor on brake and anchor lashings, without

assessing the full situation and taking adequate precautions.

Inadequate brake tightening - The windlass brake was not adequately tightened and anchor lashings

were not taken, before the windlass power was switched off. As soon as the power was switched off, the

anchor ran out freely under its own weight with slight jerk, while vessel’s speed was more than 11kts.

Failure to disengage the windlass gear– The windlass gear was not disengaged prior putting off the

power. As a result, the motor, gear and shaft were also extensively damaged, as the anchor ran out.

Eccentric design for Brake tightening - The brake tightening on the vessel was Anti-clockwise

direction, instead of conventional system of clockwise tightening, which could contribute to human

error. There was no marking on the brake for direction of open/close. An additional placard was not made

available to warn the ship staff regarding the eccentric design for brake tightening.

Inadequate supervision / delegation – Master did not delegate the Chief Officer/experienced officer

to supervise the operation of securing the anchors at sea. Speed was increased before the anchors were

fully secured.

Learning from Incident (LFI)-

Securing procedure and Windlass Power - The windlass power to be switched off only after the bow

stopper has been secured, windlass brakes adequately tightened, anchor lashings taken and windlass

gear disengaged.

Checking of Bow stopper - After picking up anchor in Port, the crew shall check whether the bow

stopper would sit properly in its position. In case not, vessel shall take necessary action to correct the

situation in the port itself, while the vessel is stopped.

Underway securing – Due diligence to be observed by placing senior/experienced officer and ratings at

anchor stations to secure the anchor while vessel is underway. Speed to be increased only after the

anchor has been properly secured for sea.

Markings / warnings - The direction of opening & closing of the windlass brake to be marked on the

brake. Where the brake tightening is in anti-clockwise direction, instead of conventional system of

clockwise tightening, a special placard to be put to warn the ship staff.

Supervision and Familiarization - Securing of anchor is as critical as anchoring operation. Senior/

experienced officers shall supervise such operations. Crew shall be trained for proper use of the

anchoring equipment.

Key learning from incident ‐ Securing of anchor is as cri cal as anchoring opera on. Senior/

experienced officers shall supervise such opera ons. Mark the brakes with the open/close direc ons.

You might also like

- MARS 230 December 2011Document4 pagesMARS 230 December 2011captkcNo ratings yet

- RONDocument7 pagesRONRonnel Ganuelas100% (1)

- Consolidated Version GroundingDocument21 pagesConsolidated Version GroundingSM OHNNo ratings yet

- Capt Swaroop Final Notes MergedDocument77 pagesCapt Swaroop Final Notes Mergedaman kumar100% (1)

- AnchoringDocument12 pagesAnchoringDryanmNo ratings yet

- Safe Anchoring PrecautionsDocument12 pagesSafe Anchoring PrecautionsDank100% (1)

- Anchor ProcedureDocument5 pagesAnchor ProcedureRahulChoudharyNo ratings yet

- Ship Manoeuvring NotesDocument66 pagesShip Manoeuvring NotesvishalNo ratings yet

- Anchor Handling EquipmentDocument33 pagesAnchor Handling EquipmentJayvee Bongon Galos89% (9)

- Mock Drill - EMERGENCY TOWINGDocument4 pagesMock Drill - EMERGENCY TOWINGsaurav naskarNo ratings yet

- Risk Assessment No 01 ANCHOR HANDLING IN GENERAL Rev 03Document5 pagesRisk Assessment No 01 ANCHOR HANDLING IN GENERAL Rev 03Devi Ratna Pratiwi78% (9)

- Anchoring ProceduresDocument3 pagesAnchoring Proceduresapi-2625120775% (8)

- Anchoring in Bad WeatherDocument2 pagesAnchoring in Bad WeatherDujeKnezevicNo ratings yet

- Ship HandlingDocument43 pagesShip HandlingSyamesh SeaNo ratings yet

- CHIEF MATE PHASE 2 Anchoring 10.4 and 10.5Document48 pagesCHIEF MATE PHASE 2 Anchoring 10.4 and 10.5Sudipta Kumar DeNo ratings yet

- How to Prevent Your Ship from Dragging AnchorDocument9 pagesHow to Prevent Your Ship from Dragging AnchorGAMMA FACULTY100% (1)

- Lecture 2. MOORINGDocument3 pagesLecture 2. MOORINGFlint KNo ratings yet

- What Are The Rules and Procedures in Berthing in A Port? ProceduresDocument3 pagesWhat Are The Rules and Procedures in Berthing in A Port? ProceduresZel ZozobradoNo ratings yet

- Lecture 1. ANCHORINGDocument2 pagesLecture 1. ANCHORINGFlint KNo ratings yet

- Seam1 HW Mooring AnchoringDocument2 pagesSeam1 HW Mooring Anchoringcloudinemarie.ermenoNo ratings yet

- Imp Mooring Operations EbookDocument36 pagesImp Mooring Operations EbookMiro HafnerNo ratings yet

- Imp Mooring Operations EbookDocument36 pagesImp Mooring Operations Ebooktarunadewasa94100% (1)

- The Anchor Plan: NB. Masters, or Officers in Charge, Should Consider That Taking The VesselDocument16 pagesThe Anchor Plan: NB. Masters, or Officers in Charge, Should Consider That Taking The VesselRai ShakilNo ratings yet

- Anchor and Anchor Cable LossesDocument25 pagesAnchor and Anchor Cable LossesedotambaNo ratings yet

- Anchoring and Anchoring ProceduresDocument32 pagesAnchoring and Anchoring Proceduresenglisgo100% (1)

- Lessons Learned Towing AccedentDocument2 pagesLessons Learned Towing AccedenthgmNo ratings yet

- Collision Between Tankers Approaching Port AnchorageDocument1 pageCollision Between Tankers Approaching Port AnchorageAjay SinghNo ratings yet

- Navigation Alert 17-13: Executive Ship ManagementDocument2 pagesNavigation Alert 17-13: Executive Ship Managementgandhishivam13No ratings yet

- Alvarez - Bowline - Activity 6Document2 pagesAlvarez - Bowline - Activity 6Humpbrey AlvarezNo ratings yet

- SF-26-22Document7 pagesSF-26-22Shivkumar JadhavNo ratings yet

- A Master's Guide To Berthing PDFDocument39 pagesA Master's Guide To Berthing PDFSaad100% (2)

- What To Do When Your Ship Is Dragging AnchorDocument17 pagesWhat To Do When Your Ship Is Dragging Anchornamsungship140100% (1)

- ANCSYSENG002Document8 pagesANCSYSENG002Tom MoritzNo ratings yet

- Report on Laser sailor's death during 2007 championshipsDocument17 pagesReport on Laser sailor's death during 2007 championshipsSonia GalliNo ratings yet

- BULKDocument6 pagesBULKsaifNo ratings yet

- 04f On The Water ContinuedDocument4 pages04f On The Water ContinuedNgaire Taylor100% (1)

- Factors To Bear in Mind While Determining Safe Anchorage / Anchor PlanningDocument3 pagesFactors To Bear in Mind While Determining Safe Anchorage / Anchor PlanningBehendu PereraNo ratings yet

- Mooring OperationDocument36 pagesMooring OperationMuhamad Nazren Mohamed ZaidiNo ratings yet

- Safe anchoring planning and proceduresDocument2 pagesSafe anchoring planning and proceduresConcepci�n Guti�rrez AraujoNo ratings yet

- As-2019-021 Collision While Drifting at AnchorageDocument4 pagesAs-2019-021 Collision While Drifting at Anchoragejude pereiraNo ratings yet

- AnchoringDocument8 pagesAnchoringDnv BaileyNo ratings yet

- (3.1) Mooring OperationDocument13 pages(3.1) Mooring OperationGaluh Dwi Riyadi100% (1)

- Essential Guidelines for Safe Anchoring and Mooring OperationsDocument7 pagesEssential Guidelines for Safe Anchoring and Mooring OperationsyeimiNo ratings yet

- AnchorDocument1 pageAnchormarwin violagoNo ratings yet

- Safe Anchoring Factors to ConsiderDocument8 pagesSafe Anchoring Factors to ConsiderSetiadi MargonoNo ratings yet

- 14 AnchoringDocument25 pages14 AnchoringCornelia TheodoraNo ratings yet

- Group 4 Procedures in AnchoringDocument30 pagesGroup 4 Procedures in AnchoringJP Perdez100% (1)

- Mooring AnchooringDocument10 pagesMooring AnchooringLuffy KingNo ratings yet

- LINES Edited Anchoring and Anchoring ProceduresDocument26 pagesLINES Edited Anchoring and Anchoring Proceduresannex.chaoticNo ratings yet

- Anchoring procedures and holding powerDocument33 pagesAnchoring procedures and holding powerdanko paićNo ratings yet

- CONTAINER CARGO OPERATIONS AND SECURING GUIDELINESDocument15 pagesCONTAINER CARGO OPERATIONS AND SECURING GUIDELINESintan nNo ratings yet

- Gard As - Case Study - Anchor AwarenessDocument2 pagesGard As - Case Study - Anchor AwarenessArne OlsenNo ratings yet

- Moorings: Open Moor PurposeDocument11 pagesMoorings: Open Moor PurposeKim JunejaNo ratings yet

- Pertemuan X Penanganan Proses Berlabuh JangkarDocument24 pagesPertemuan X Penanganan Proses Berlabuh JangkarRani TribuanaNo ratings yet

- Deck Watch STCW 2010 Notes Phase 2Document8 pagesDeck Watch STCW 2010 Notes Phase 2Satya Prakash Bhardwaj100% (1)

- Introductory Unit: Case Study: The Grounding of AstralDocument8 pagesIntroductory Unit: Case Study: The Grounding of AstralBritney WelsilyaNo ratings yet

- Class 2 & 1Document48 pagesClass 2 & 1aungthein_sanNo ratings yet

- The Island Hopping Digital Guide to the Northwest Caribbean - Part II - The Cayman IslandsFrom EverandThe Island Hopping Digital Guide to the Northwest Caribbean - Part II - The Cayman IslandsNo ratings yet

- The Island Hopping Digital Guide To The Southern Bahamas - Part II - The Jumentos: Including Ragged IslandFrom EverandThe Island Hopping Digital Guide To The Southern Bahamas - Part II - The Jumentos: Including Ragged IslandNo ratings yet

- India TodayDocument66 pagesIndia TodaySomayajula SuryaramNo ratings yet

- Mastrep NewReporting SystemDocument4 pagesMastrep NewReporting SystemSomayajula SuryaramNo ratings yet

- Popeye The Sailor Man - Who KnewDocument2 pagesPopeye The Sailor Man - Who KnewSomayajula SuryaramNo ratings yet

- What Are CATZOC and How To Use It For Passage PlanningDocument30 pagesWhat Are CATZOC and How To Use It For Passage PlanningSomayajula Suryaram100% (1)

- National Institutes of TechnologyDocument15 pagesNational Institutes of TechnologySomayajula SuryaramNo ratings yet

- February 2015Document8 pagesFebruary 2015Somayajula SuryaramNo ratings yet

- Steering Gear System Test Staff FamiliarityDocument2 pagesSteering Gear System Test Staff FamiliaritySomayajula Suryaram100% (1)

- Predicting Optimal Trim For ShipsDocument79 pagesPredicting Optimal Trim For ShipsSomayajula SuryaramNo ratings yet

- E NOIDocument3 pagesE NOISomayajula SuryaramNo ratings yet

- Action To Be Taken For IntermediaryDocument1 pageAction To Be Taken For IntermediarySomayajula SuryaramNo ratings yet

- Unified Form DBTLDocument1 pageUnified Form DBTLkayalonthewebNo ratings yet

- CSR FormsDocument5 pagesCSR FormsSomayajula SuryaramNo ratings yet

- 09 BPReversingDocument93 pages09 BPReversinggmatweakNo ratings yet

- Booklet on PANDocument33 pagesBooklet on PANalohia82No ratings yet

- DynaLiners Weekly 49-2015Document12 pagesDynaLiners Weekly 49-2015Somayajula SuryaramNo ratings yet

- Js Insight Gas Form CDocument64 pagesJs Insight Gas Form CSomayajula SuryaramNo ratings yet

- Gassing-Up & Cooling Down NotesDocument7 pagesGassing-Up & Cooling Down NotesSomayajula SuryaramNo ratings yet

- ETH HandbookDocument68 pagesETH HandbookGianluca Can GenovaNo ratings yet

- CASE: 1 / Changing All Tanks To C3Document1 pageCASE: 1 / Changing All Tanks To C3Somayajula SuryaramNo ratings yet

- SitDocument7 pagesSitSomayajula SuryaramNo ratings yet

- Information Brochure JEE Adv 2015 Ver 2.2!29!12 2014Document76 pagesInformation Brochure JEE Adv 2015 Ver 2.2!29!12 2014Sidharth AryaNo ratings yet

- OSHAS Basic TrainingDocument36 pagesOSHAS Basic TrainingSomayajula SuryaramNo ratings yet

- National Institutes of TechnologyDocument15 pagesNational Institutes of TechnologySomayajula SuryaramNo ratings yet

- About IIIT-H - IIIT HyderabadDocument2 pagesAbout IIIT-H - IIIT HyderabadSomayajula SuryaramNo ratings yet

- IISc UG - FAQDocument4 pagesIISc UG - FAQSomayajula SuryaramNo ratings yet

- Imo Wheelhouse Poster (Musashi Gloria)Document1 pageImo Wheelhouse Poster (Musashi Gloria)Somayajula Suryaram100% (1)

- Rescue SignalsDocument2 pagesRescue Signalssuresh25489042100% (2)

- MLC GuidanceDocument2 pagesMLC GuidanceSomayajula Suryaram100% (1)

- Self Checklist For SMS 2010Document8 pagesSelf Checklist For SMS 2010Somayajula Suryaram100% (2)

- Disaster Preparedness Training For Community OrganizationsDocument75 pagesDisaster Preparedness Training For Community OrganizationsRyan-Jay AbolenciaNo ratings yet

- Action Plan For The Human EnvironmentDocument71 pagesAction Plan For The Human EnvironmentRobert PollardNo ratings yet

- Cape Communication Studies 2011 AmsDocument4 pagesCape Communication Studies 2011 AmsannmarieNo ratings yet

- Group 6 - Food Security of India and Impact of Climate Change On Food Security.-1Document12 pagesGroup 6 - Food Security of India and Impact of Climate Change On Food Security.-1Darshil RaveshiaNo ratings yet

- Contigency Planning GuideDocument68 pagesContigency Planning GuideRuben Cano Revillas100% (1)

- River Environments PowerpointDocument44 pagesRiver Environments PowerpointsunilghajuNo ratings yet

- Future World Tourism Policy IssuesDocument24 pagesFuture World Tourism Policy IssuesKharisma Putri Aurum100% (5)

- Towards An Earthquake Resistant Design Code For United Arab EmiratesDocument8 pagesTowards An Earthquake Resistant Design Code For United Arab EmiratesSewGuanNo ratings yet

- ASCE 7-16 SSC Ballot3 ProposalsDocument474 pagesASCE 7-16 SSC Ballot3 ProposalsYami YugiNo ratings yet

- Syntheses Vanillyl AlcoholsDocument48 pagesSyntheses Vanillyl AlcoholsIlmuncMakesuill100% (1)

- Science 8 2nd Quarter WDocument3 pagesScience 8 2nd Quarter WFord VirtudazoNo ratings yet

- DRRMDocument9 pagesDRRMHans Kirby Pacatang DumdumNo ratings yet

- Gulf of Mexico Offshore Oil ProductionDocument35 pagesGulf of Mexico Offshore Oil ProductionzapspazNo ratings yet

- CBRN Disaster Management: Dr. Rakesh Kumar SharmaDocument122 pagesCBRN Disaster Management: Dr. Rakesh Kumar SharmaHaider Zaman100% (2)

- Chapter 4 Nagi A SeismicDocument11 pagesChapter 4 Nagi A SeismicPablo TorresNo ratings yet

- Blok-Aid Sewer Overflow Monitoring and Alarm SystemDocument2 pagesBlok-Aid Sewer Overflow Monitoring and Alarm SystemTomas LarsenNo ratings yet

- Secure BackupDocument6 pagesSecure Backupsanky08No ratings yet

- Basic ICS Training Course Design 1Document7 pagesBasic ICS Training Course Design 1Dex Castro Narrido100% (2)

- Fmds0532 Data CentersDocument51 pagesFmds0532 Data CentersWERMERMNo ratings yet

- Baghjan Well No. 5 Blowout: Sequence of EventsDocument3 pagesBaghjan Well No. 5 Blowout: Sequence of EventsbhupenderNo ratings yet

- DDMP - BeedDocument218 pagesDDMP - Beedbombonde_797469No ratings yet

- Death March Kara Hajimaru Isekai Kyousoukyoku - v01 (w01-1 w03-3) PDFDocument218 pagesDeath March Kara Hajimaru Isekai Kyousoukyoku - v01 (w01-1 w03-3) PDFKarthi KNNo ratings yet

- Philippine Popular CultureDocument40 pagesPhilippine Popular CultureMylene Rocaberte33% (3)

- What Causes Earthquakes? The 4 Main TypesDocument5 pagesWhat Causes Earthquakes? The 4 Main TypesNatesa IndrasenanNo ratings yet

- Filipino Armageddon - A 9.0-Magnitude Quake Will Destroy Metro Manila and Kill at Least 5.53-Million Inhabitants Even Without A Tsunami Following ItDocument17 pagesFilipino Armageddon - A 9.0-Magnitude Quake Will Destroy Metro Manila and Kill at Least 5.53-Million Inhabitants Even Without A Tsunami Following ItNyxstoryNo ratings yet

- 3rd Periodic - Science 6Document8 pages3rd Periodic - Science 6Benj AlejoNo ratings yet

- Behaviour of Non-Structural Elements During EarthquakeDocument11 pagesBehaviour of Non-Structural Elements During EarthquakeSumaidha ParmarNo ratings yet

- Data Center Audit ChecklistDocument4 pagesData Center Audit Checklistqadir147100% (2)

- The Virtue of Courage: Douglas N. WaltonDocument15 pagesThe Virtue of Courage: Douglas N. WaltonmihaitacheNo ratings yet