Professional Documents

Culture Documents

Pipe Sizing For Hot and Cold Water: Part 1 - Basic Principles

Uploaded by

dosandosanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Sizing For Hot and Cold Water: Part 1 - Basic Principles

Uploaded by

dosandosanCopyright:

Available Formats

Pipe Sizing for Hot and Cold Water

Part 1 - Basic Principles

W

hen deciding the tube totalled for a group of appliances and

diameters required for then converted into a flow rate in litres 200 2

plumbing systems a number of per second using Figure 1.

factors have to be taken into If necessary, any other water fittings

account if an adequate flow rate is to be requiring high or continuous flow rates 1.5

achieved without using oversized tube. can then be added to give a total flow

The volume flow rate required and the rate. 100

Design flow rate, litres per second

pressure available are very important, An example: consider a mains water

other factors to consider include the service with a minimum pressure of

length of the tube and the number of 3 bar serving a dwelling with a kitchen, 1.0

fittings used. bathroom, en-suite shower and cloaks

In this first half of a two part article WC.

50 0.8

we shall look at the basic principles and This might comprise the following

procedures to determine copper tube discharge points:

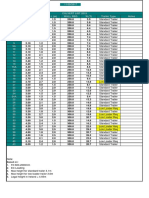

diameters which will satisfy the demand Loading units

required and give an economical 0.6

installation. Bathroom Loading units

3/4" bath taps 2 @ 10 = 20 0.5

Assessment of likely demand 1/2" basin taps 2 @ 1.5 = 3

As the number of discharge points WC cistern 1@2 = 2 20

fitted to an installation increases the En-suite 0.4

proportion that will be in use at any one Shower 2@3 = 6

time reduces. Research has provided a Kitchen

system to estimate probable demand 1/2" sink taps 2@3 = 6

based on Loading Units. These take into 15mm w/machine taps 2@3 = 6 10 0.3

account the flow rate, frequency and Cloaks

length of use of common sanitary Basin spray tap 1@0 = 0 Figure 1

appliances. See Table 1 for values, it also WC cistern 1@2 = 2

gives BS 6700 recommended design flow

rates. To use it the number of each type Total loading units 45 Head loss through tube, fittings

of appliance fed by a pipe is multiplied by and valves

the loading unit. These can then be Figure 1 gives us a probable flow rate of Copper tube has a smooth bore and

0.72 l/s. this means that relatively little head is

Table 1 Loading units and flow lost as the water flows. The relationship

rates, hot or cold water supplies Available head between tube diameter, length, flow

On mains pressure systems the rate and head loss are illustrated

Sanitary Loading Flow minimum pressure at peak demand in Figure 2. The head loss and water

fitting unit value rate (l/s) periods can be obtained from the water velocity can be found by aligning a ruler

supplier or measured on site. On cistern with the particular tube diameter and

WC Cistern 2 0.1

fed systems the head available should be flow rate required. Using the previously

1/2” Washbasin tap 1.5 0.15 determined flow rate, a 22mm service

measured vertically from the cistern

Spray mixer tap - 0.04 outlet to the discharge point. Where the passing 0.72 l/s would use about

supply is sufficient half the cistern height 0.33 metres head for each metre run of

3/4” Bath tap 10 0.3 or 0.5m can be added. tube.The water velocity would be about

Shower mixer 3 0.1 One bar pressure is approximately 2.5m/s, this is below the BS 6700

equal to ten metres head. So, multiply by recommended maximum of 3m/s for

1/2”

Sink or Washing 3 0.2

machine tap 10 to convert bars to metres head, in cold water and so not likely to create

this case 3 bar is 30m. flow noises.

about 1.75 metres head.

10 80

8 50

40 76.1 75 Figure 4 gives the head required

6 30 70

for a given float valve orifice and

Formula applicable between these limits only

5 20 67 65

4 6 60 Lamont’s smooth pipe formula S3

3 5

10 55 v = 0.5545 d0.6935 ¡0.5645 flow rate.

Outside diameter of copper tube to Table X of Bs 2871: Part 1: 1971, millimetres

4 8 54

2

3

6

5

50

where: v is the velocity (m/s); For example a float operated

4 45

2.5 d is the diameter (mm);

1 2

3

2 42 40 ¡ is the hydraulic gradient;

valve with a 4mm orifice passing

0.8

0.6

1.5

1.0 Flow, litres per second 35 0.1 l/s requires a head pressure of

0.5 35

0.4 1.0 0.8

0.6 30 and R = 10 [ v

1.7715 ] about 6m.

Velocity, metres per second

0.3 0.75 0.5 0.5545 d0.6935

0.4

0.3 28

0.2 25 where: R is the wall friction gradient (kPa)

0.5 0.2

Water meters

Wall friction gradient (head loss) in kPa per metre

22

0.1

0.08

0.25

0.1

0.08

20

Where a water meter is to be

0.07 0.06

0.06

0.05

0.05

18 fitted the loss of head at the

0.04 15

0.03 15

required flow rate should be

0.02 0.1

subtracted from the head available.

Actual bore of pipe, millimetres

0.01

12

10

The manufacturers data sheet can

0.008

0.006

10 be consulted to find the head loss.

0.005

0.004

0.003 8 Permissible head loss

0.002

Once the head pressure

0.001 6 5 available and the effective length of

tube has been found the

permissible loss of head per metre

Fittings Taps and valves run can be determined. This is

The loss of head due to bends, Head loss through stop valves is done by dividing the head available by

elbows and tees can best be given as an relatively large, see Table 2 for equivalent the total effective length of tube.

equivalent length of tube. A bend has lengths.These equivalent lengths can also In the case of our service pipe

about half the resistance of an elbow, so, be added to the length of tube. Losses example with a head of water of 30m

where pressure is low it is better to use through gate valves and quarter turn ball and an effective length of 18.6m, this

bends where possible. Losses for tees are valves can be ignored. would be: 30 / 18.6 = 1.6m/m.

added on a change of direction only. If the actual length of the 22mm

Where the numbers of fittings to be service mentioned previously was 10 Residual head

used can be estimated they can be metres and 4 bends and a stop valve Referring back to Figure 2 our 22mm

multiplied to give an equivalent length. were fitted the total equivalent length service pipe with a flow of 0.72 l/s only

This can then be added to the actual would be: uses about 0.33m/m of head. So, in total

length of the tube. An alternative, where actual length of tube 10.0m 18.6 x 0.33 = 6.1m, say 6m, head would

the numbers of fittings cannot be equivalent length of bends 4 at 0.4 = 1.6m be used up leaving 30 - 6 = 24m residual

forecast, is to add a percentage to the equivalent length of valve 1 at 7.0 = 7.0m head remaining for the internal

length of tube. This can vary between giving a total equivalent length of 18.6m installation.

about 10% and 40% depending on the Alternatively, the actual head loss for

complexity of the layout. valves can be established using Figure 3 Final tube diameter

and then subtracted from the head If insufficient residual head remains

available. select a larger tube diameter to reduce

6

For example the 22mm stop valve the head used. If only a small percentage

4 flowing at 0.72 l/s has a resistance of of the head available has been used

6

3 consider a smaller tube diameter. In any

4

case, however, check that the flow

42

2 3 1

2

velocity is not greater than the BS 6700

35

recommendation of 3m/s for cold and

1 2

0.8

1 2.5m/s for hot water. Also, to prevent

28

0.8

0.6 0.6

1.0 sluggish flow and the settlement of

0.8

4 detritus in long runs of horizontal tube,

Flow rate litres/second

0.4 10 0.6

0.4

keep the velocity above 0.5m/s by

Head loss in metres

Stopvalve diameter

orifice diameter mm

22

8 0.4

6

0.2 6 avoiding use of oversized tube.

head of water required m

8 0.2

0.2

10

5

The above procedures can be used

4

0.1

to determine tube diameters for

flow rate l/s

0.08 0.1

3

15

0.08

0.06 a complete installation. Keep this

0.1

0.05

0.08 0.04

20

article handy and next month we will

0.06 30

put them into practice with a

Figure 3 Loss of head through stop valves Figure 4 Head loss through float valve orifices

straightforward systematic method

based on a tabulation chart.

www.copperplumbing.org.uk

You might also like

- !! DishwasherTraining BoschDocument102 pages!! DishwasherTraining BoschIslandGreco86% (7)

- Horse Power (H.P.) Selection: Calculation of Discharge Rate of Bore Well, Water Level, Friction Loss in Pipes, Valves & Fittings, H.P. Selection For Submersible Pump Sets, Unit ConversionDocument12 pagesHorse Power (H.P.) Selection: Calculation of Discharge Rate of Bore Well, Water Level, Friction Loss in Pipes, Valves & Fittings, H.P. Selection For Submersible Pump Sets, Unit ConversionSantosh Kumar93% (14)

- BookDocument82 pagesBookashutoshpathakcivilNo ratings yet

- Institute of PlumbingDocument249 pagesInstitute of PlumbingPatel Kalinga100% (1)

- ASPE Sump Pump SizingDocument60 pagesASPE Sump Pump Sizingzaqhusanz100% (5)

- Timber ManualDocument145 pagesTimber Manualspiderlance100% (1)

- Friction Factor ManualDocument4 pagesFriction Factor ManualM K TEHSEENNo ratings yet

- Discharge Coefficients For Irregular Overfall Spillways PDFDocument59 pagesDischarge Coefficients For Irregular Overfall Spillways PDFZiza LukovacNo ratings yet

- Hydronic System Design Bell & GossettDocument30 pagesHydronic System Design Bell & Gossettmartym100% (3)

- Groundwater Monitoring Well DrillingDocument39 pagesGroundwater Monitoring Well DrillingJoan Sifuentes0% (1)

- Electrolux Technical Service Manual Dishwasher 2015Document30 pagesElectrolux Technical Service Manual Dishwasher 2015dosandosan100% (1)

- A Spreadsheet Program For The Calculation of Piping Systems and The Selection of Pumps PDFDocument12 pagesA Spreadsheet Program For The Calculation of Piping Systems and The Selection of Pumps PDFtebo8teboNo ratings yet

- Fluids Lab 1Document12 pagesFluids Lab 1Ryan Poh100% (1)

- BN Eg UE109 Vessel SizingDocument40 pagesBN Eg UE109 Vessel Sizingbadelitamarius100% (1)

- Pump System CurveDocument133 pagesPump System Curvemohamed abd eldayem0% (1)

- Methods of Setting Water Distribution System Layout PDFDocument5 pagesMethods of Setting Water Distribution System Layout PDFvenkateswara rao PothinaNo ratings yet

- Design of Centralized Hot Water Supply SystemDocument43 pagesDesign of Centralized Hot Water Supply SystemAbhik Bhattacharjee100% (1)

- Calculation ReportDocument29 pagesCalculation Reportvictor.sNo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- 00 BLANK - Hot and Cold Water LU Calculation SheetDocument17 pages00 BLANK - Hot and Cold Water LU Calculation SheetmaxmorekNo ratings yet

- Design of Centralized Hot Water Supply SystemDocument36 pagesDesign of Centralized Hot Water Supply SystemAbhik BhattacharjeeNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Application Chart For Various Turbine TypesDocument18 pagesApplication Chart For Various Turbine TypescortforceNo ratings yet

- Notes - Aggregates - SR 21 SpecificationDocument3 pagesNotes - Aggregates - SR 21 SpecificationdosandosanNo ratings yet

- Pumps & Pumping Systems 150730Document48 pagesPumps & Pumping Systems 150730Sazali Khamsan100% (1)

- Lab 2-Venturi MeterDocument4 pagesLab 2-Venturi MeterNor C-lah67% (3)

- Design of Water Supply System-High Rise BLDGDocument108 pagesDesign of Water Supply System-High Rise BLDGcris bunagNo ratings yet

- Flash Mixer and FlocculationDocument13 pagesFlash Mixer and FlocculationPratik Kachalwar67% (3)

- Sanitary Classroom Training 1 MaterialDocument17 pagesSanitary Classroom Training 1 MaterialMisgan engineeringNo ratings yet

- Sizing Drain and Condensate Lines To TrapsDocument18 pagesSizing Drain and Condensate Lines To TrapsMubarik Ali100% (1)

- Hydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedFrom EverandHydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedNo ratings yet

- Pipe Sizing Basic PrinciplesDocument2 pagesPipe Sizing Basic PrinciplesLeonard ChanNo ratings yet

- Tap Flow RateDocument2 pagesTap Flow RateMeng SunNo ratings yet

- Impo of IPC-2018Document6 pagesImpo of IPC-2018MENo ratings yet

- Ato Ayele Adugna Residence Design Report ON Plumbing ServicesDocument12 pagesAto Ayele Adugna Residence Design Report ON Plumbing ServicesdawitgggNo ratings yet

- Ato Asnake SerawitDocument11 pagesAto Asnake SerawitHaymanot BaynesagnNo ratings yet

- 2 3 9 A SR ResidentialplumbingcoderequirementsDocument4 pages2 3 9 A SR Residentialplumbingcoderequirementsapi-348618361No ratings yet

- CH 11 Building Water Supply & Sanitary InstallationDocument38 pagesCH 11 Building Water Supply & Sanitary InstallationMikiyas AkliluNo ratings yet

- Birhane Design Report For Residence BuildingDocument10 pagesBirhane Design Report For Residence BuildingHaymanot BaynesagnNo ratings yet

- WS Fixture Flow Rates PDFDocument1 pageWS Fixture Flow Rates PDFbilal almelegyNo ratings yet

- ch7 Flow Measurement and Basic Water CalculationDocument9 pagesch7 Flow Measurement and Basic Water CalculationRiaul UbaldeNo ratings yet

- Dis 15Document8 pagesDis 15IranthaMuthuNo ratings yet

- Engineering Utilities 2Document8 pagesEngineering Utilities 2Vanissa MontillaNo ratings yet

- Ambor, Randi T. 10-19-2021Document31 pagesAmbor, Randi T. 10-19-2021AbdulJabbarLawiNo ratings yet

- Universal State Plumbing CodeDocument118 pagesUniversal State Plumbing CodecruzserNo ratings yet

- Plumbing Services Design Report For Semi-Basement & G+2 Residential BLDGDocument13 pagesPlumbing Services Design Report For Semi-Basement & G+2 Residential BLDGdawitgggNo ratings yet

- 15 - Efficient Hot-Water Piping-JLCDocument6 pages15 - Efficient Hot-Water Piping-JLCFILID MADNo ratings yet

- Lecture 8 WsfuDocument28 pagesLecture 8 WsfuJam MangalinoNo ratings yet

- CH 11 BUILDING WATER SUPPLY & SANITARY INSTALLATIONDocument38 pagesCH 11 BUILDING WATER SUPPLY & SANITARY INSTALLATIONMikiyas AkliluNo ratings yet

- How To Determine Suitable Pipe Sizes For Water Distribution in BuildingsDocument5 pagesHow To Determine Suitable Pipe Sizes For Water Distribution in BuildingsSathishNo ratings yet

- Floor Drains: Floor Drain Sizing and LocationDocument1 pageFloor Drains: Floor Drain Sizing and LocationBruhaha HahaNo ratings yet

- 08 DEEDS-Sump-Pump-SizingDocument60 pages08 DEEDS-Sump-Pump-SizingJosephine Marie TrinidadNo ratings yet

- Fluid FrictionDocument18 pagesFluid Frictioncakhoa100% (2)

- Wasserkraft How To Measure HeadDocument3 pagesWasserkraft How To Measure HeadmicroondesNo ratings yet

- How To Calculate Water Pump HorsepowerDocument24 pagesHow To Calculate Water Pump Horsepowermary joy PanamaNo ratings yet

- Plumbing Services Design Report For G+2 Residential BLDG.: Owner: Ato Abdulkader MuzemilDocument15 pagesPlumbing Services Design Report For G+2 Residential BLDG.: Owner: Ato Abdulkader MuzemildawitgggNo ratings yet

- Chapter 7 Flow MeasurementDocument19 pagesChapter 7 Flow MeasurementAce ThunderNo ratings yet

- Pipe SizingDocument8 pagesPipe SizingJer Si100% (3)

- Design of Water Supply System-High Rise BLDGDocument108 pagesDesign of Water Supply System-High Rise BLDGJolo ManiagoNo ratings yet

- Fric Flow Ours FINAL VR 2Document14 pagesFric Flow Ours FINAL VR 2Edwin Jesu DassNo ratings yet

- 5.13. ProblemsDocument3 pages5.13. Problemsاسماعیل ادریس عبدالعزیزNo ratings yet

- 336 TB 03metricsforimprovingwatermanagementinagricultureDocument4 pages336 TB 03metricsforimprovingwatermanagementinagricultureمؤمن سعيد طلحةNo ratings yet

- WS Fixture Flow Rates PDFDocument1 pageWS Fixture Flow Rates PDFbilal almelegyNo ratings yet

- I Am Sharing 'Review Module Hydraulics 03 Part 02 May 2023' With YouDocument2 pagesI Am Sharing 'Review Module Hydraulics 03 Part 02 May 2023' With YouAlexander P. BelkaNo ratings yet

- Residential Pump FundamentalsDocument25 pagesResidential Pump FundamentalsperoooNo ratings yet

- ZMR Drainage Systems Sizing 2023Document6 pagesZMR Drainage Systems Sizing 2023Moudi MaltiNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Irrigation Works: The Principles on Which Their Design and Working Should Be Based, with Special Details Relating to Indian Canals and Some Proposed ImprovementsFrom EverandIrrigation Works: The Principles on Which Their Design and Working Should Be Based, with Special Details Relating to Indian Canals and Some Proposed ImprovementsNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Hydrodynamics of Gas-Liquid Reactors: Normal Operation and Upset ConditionsFrom EverandHydrodynamics of Gas-Liquid Reactors: Normal Operation and Upset ConditionsNo ratings yet

- Culvert List 2017 PDFDocument1 pageCulvert List 2017 PDFdosandosanNo ratings yet

- Karst PublicationsDocument1 pageKarst PublicationsdosandosanNo ratings yet

- Guidance Note 22 - Repeatable Rooms Used Outside of P21plus - V1 - JC - 20140721125511Document6 pagesGuidance Note 22 - Repeatable Rooms Used Outside of P21plus - V1 - JC - 20140721125511dosandosanNo ratings yet

- Upload 3Document1 pageUpload 3dosandosanNo ratings yet

- Culvert List 2017 PDFDocument1 pageCulvert List 2017 PDFdosandosanNo ratings yet

- Guidance Note 22 - Repeatable Rooms Used Outside of P21plus - V1 - JC - 20140721125511Document6 pagesGuidance Note 22 - Repeatable Rooms Used Outside of P21plus - V1 - JC - 20140721125511dosandosanNo ratings yet

- UploadDocument1 pageUploaddosandosanNo ratings yet

- UploadDocument1 pageUploaddosandosanNo ratings yet

- UploadDocument1 pageUploaddosandosanNo ratings yet

- UploadDocument1 pageUploaddosandosanNo ratings yet

- This Is An Upload. This Is An Upload. This Is An UploadDocument1 pageThis Is An Upload. This Is An Upload. This Is An UploaddosandosanNo ratings yet

- UploadDocument1 pageUploaddosandosanNo ratings yet

- Boardwalk DesignDocument9 pagesBoardwalk DesigndosandosanNo ratings yet

- Service Manual - Cid60w12Document165 pagesService Manual - Cid60w12dosandosanNo ratings yet

- This Is An Upload. This Is An Upload. This Is An Upload. This Is An Upload. This Is An Upload. This Is An Upload. This Is An Upload. This Is An Upload. This Is An UploadDocument1 pageThis Is An Upload. This Is An Upload. This Is An Upload. This Is An Upload. This Is An Upload. This Is An Upload. This Is An Upload. This Is An Upload. This Is An UploaddosandosanNo ratings yet

- Boardwalk Maintenance and Construction-R1aDocument15 pagesBoardwalk Maintenance and Construction-R1aPrateek VyasNo ratings yet

- This Is An Upload. This Is An Upload. This Is An Upload. This Is An Upload. This Is An Upload. This Is An UploadDocument1 pageThis Is An Upload. This Is An Upload. This Is An Upload. This Is An Upload. This Is An Upload. This Is An UploaddosandosanNo ratings yet

- This Is An Upload. This Is An UploadDocument1 pageThis Is An Upload. This Is An UploaddosandosanNo ratings yet

- Upload 20Document1 pageUpload 20dosandosanNo ratings yet

- Electrolux Buildin SMDocument47 pagesElectrolux Buildin SMjohn_wire8974No ratings yet

- Electrolux Buildin SMDocument47 pagesElectrolux Buildin SMjohn_wire8974No ratings yet

- Upload 2Document1 pageUpload 2dosandosanNo ratings yet

- Topic 1 - 5 Open Ended Laboratory ImplementationDocument50 pagesTopic 1 - 5 Open Ended Laboratory ImplementationAmirul Shahrin991109No ratings yet

- Summary KH2134 Fluid MechanicsDocument4 pagesSummary KH2134 Fluid MechanicsAzman SamerNo ratings yet

- Water Hammer ArticleDocument14 pagesWater Hammer ArticleayoungaNo ratings yet

- Advance SSC Je 2017 NewDocument176 pagesAdvance SSC Je 2017 Newamrit100% (1)

- Bernoulli Venturi NozzleDocument4 pagesBernoulli Venturi NozzleFrank PingolNo ratings yet

- Christmas BonusDocument3 pagesChristmas BonusJazmin RamosNo ratings yet

- CivilsyllDocument131 pagesCivilsyllYashwanth YashuNo ratings yet

- Hydraulic Engineering - Lec - 3 - Students - UpdatedDocument13 pagesHydraulic Engineering - Lec - 3 - Students - Updated20-cle-26 Usama SaleemNo ratings yet

- Worked Example On FHHR DesignDocument6 pagesWorked Example On FHHR DesignKolos Char YiuNo ratings yet

- Comparison of the Effects of k-, k-ω, and Zero Equation Models on Characterization of Turbulent Permeability of Porous MediaDocument8 pagesComparison of the Effects of k-, k-ω, and Zero Equation Models on Characterization of Turbulent Permeability of Porous MediaGanesh GPNo ratings yet

- Blueberry Irrigation ProjectDocument19 pagesBlueberry Irrigation Projectjonathan_guthrie_5No ratings yet

- Lesson 1 Bentley Systems WaterGEMS - Design Evaluation of Hydraulic Models Using WaterGEMSDocument5 pagesLesson 1 Bentley Systems WaterGEMS - Design Evaluation of Hydraulic Models Using WaterGEMSMedardo Delapoz, Jr.No ratings yet

- IS 2951 (Part 2) - Pressure Drop Calc On Pipe FittingsDocument16 pagesIS 2951 (Part 2) - Pressure Drop Calc On Pipe FittingspritamNo ratings yet

- MIDTERM EXAM: CEE 460: Groundwater Hydraulics August 23, 2020 Time: 1 HR 20 Mins Answer The Following Questions. (6 X 10 60)Document2 pagesMIDTERM EXAM: CEE 460: Groundwater Hydraulics August 23, 2020 Time: 1 HR 20 Mins Answer The Following Questions. (6 X 10 60)Avijit SahaNo ratings yet

- Lab 2 Permeability PDFDocument13 pagesLab 2 Permeability PDFhoney arguellesNo ratings yet

- D5856 Standard Test Method For Measurement of Hydraulic Conductivity of Porous Material Using A Rigid-WallDocument9 pagesD5856 Standard Test Method For Measurement of Hydraulic Conductivity of Porous Material Using A Rigid-WallGabriela GuillenNo ratings yet

- Hydraulics 3Document2 pagesHydraulics 3IZNo ratings yet

- Fluid Mechanics Mory 2Document438 pagesFluid Mechanics Mory 2azamatNo ratings yet

- M389 Process Pumps, Valves, & Pipe Spreadsheet AnalysisDocument52 pagesM389 Process Pumps, Valves, & Pipe Spreadsheet AnalysisSaidFerdjallahNo ratings yet

- Fluids 2 Lab Report 6 JanyDocument6 pagesFluids 2 Lab Report 6 JanyJay-ar BensOnNo ratings yet

- FMHM BitsDocument5 pagesFMHM BitsallakagopichandNo ratings yet