Professional Documents

Culture Documents

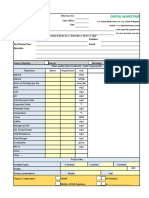

Al-Abdulla Petroleum Co - LTD Mauritius

Uploaded by

Nitish AshleyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Al-Abdulla Petroleum Co - LTD Mauritius

Uploaded by

Nitish AshleyCopyright:

Available Formats

15

7.0 Disposal of Used/Waste oil

7.1 Composition

The typical composition of used lubricating oil (Oil Feed Stock)

Water 2 to 5%

Diesel 5 to 10%

Additives 5 to 15 %

Carbon Particles 1 to 5%

Light oils 10 to 12 %

Medium base oil 60 to 65%

Heavy gear oil 10 to 15 %

Asphalt 7 to 8%

7.2 The Petroleum oils do not get decomposed or biodegraded. It’s therefore essential

that used lubricating oils should be properly disposed off.

The importance of proper management of Used/Waste oil is essential to:

1. Protect the Environment

2. Protect against ill effects and the consequent-associated long-term liabilities.

3. Protect human health.

4. Economical / un-hazardous reuse of waste oil

Thus it is the subject of great National Importance and concern to all, to ensure proper

collection/ storage and safe disposal of Used/Waste oil.

7.3 Methods of disposal:

1. Use as fuel

2. Re-refine for producing lubricants

7.3.1 Use as fuel - disadvantages:

Burning Used/Waste oil or lightly processed Used/Waste oil as fuel in industrial

furnaces and boilers is an option that is easiest to practice but most detrimental to

environment. Even before investigating the combustion by-products for their

hazardous nature and effect on human health, consider the basic product of any

combustion reaction; Carbon Dioxide (CO2 ). Combustion of one gallon of

Used/Waste oil will produce 21.4 lb of CO2.

a). The high levels of contaminants including lead, arsenic and other toxic heavy

metals get carried away in the flue gases- polluting air.

b). The combustion products – flue gases contain high volumes of Sulphur die-oxide

SO2, Nitrous oxide Nox, Carbon mono oxide CO and others which are air pollutants.

The legislation and rules regards safe use of used lubricating oil, as fuel is therefore

limited due to above threat to environment.

c). - Uncontrolled burning of Used/Waste oils may result in significant levels of

hazardous emissions to the environment. This may expose humans, wildlife and

vegetation to harmful substances. The environmental impacts of burning Used/Waste

16

oils will depend upon the concentration of hazardous contaminants, burner design,

emission control equipment, stack height etc.

7.3.2 Re-refine for producing lubricants:

Many common re-refining technologies, as mentioned below, have been developed

over time, some of them use hazardous Acids (sulphuric acid) or hydrogen gas, or

chemicals such as propane or Butyl & isopropyl alcohol or hydrogen etc., which

produce acidic sludge as residue.

Non Environment friendly:

1. Acid Clay Process - uses sulphuric acid- Results in Acid Sludge

2. Institut Français Du Pétrole (IFP) process – uses propane & acid - Results in

Acid Sludge

3. Kinetics Technology International (KTI) – Hydrogen added hence not useful

4. Bertlesville Research Centre Process – uses butyl and isopropyl alcohol as

solvent – results in acidic sludge.

Environment friendly:

1. High Vacuum Molecular Distillation - acid free process – uses natural

polymer-safe & environment friendly

M/s. Al Abdulla Petroleum Co. Ltd., Mauritius proposes to use the safe and

environment friendly method of re-refining by using “High Vacuum Molecular

Distillation Process” - Natural Polymer as flocculating agent and Activated clay

(Acid free used lube oil reclamation Plant).

This technology has been approved and being offered by National Research and

Development Corporation (A Govt. of India Enterprise) - Annexure “C”.

A similar plant manufactured by the same supplier is already operational at M/s.

Prime Lubricants, Multan, Pakistan. A Sample of Re-refined oil at that plant was

tested and found acceptable in line with international standards. A copy of the Test

report by M/s. Analysts, Inc., Canada (an ISO 9002 certified test house) - Annexure

“D”.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Lubricant Testing and DifferentiationDocument35 pagesLubricant Testing and DifferentiationRichard De Medeiros CastroNo ratings yet

- DocumentDocument45 pagesDocumentMuhammad IqmalNo ratings yet

- Republic Act No. 9275 The Philippine Clean Water Act of 2004Document6 pagesRepublic Act No. 9275 The Philippine Clean Water Act of 2004Rustan FrozenNo ratings yet

- RA 002 - HFO Line Pressure TestDocument4 pagesRA 002 - HFO Line Pressure Testdassi99100% (1)

- Eis Fareast Fuel PDFDocument50 pagesEis Fareast Fuel PDFricchrist dela cruzNo ratings yet

- Philippines Small-Scale Wastewater Treatment Systems for 3 MarketsDocument11 pagesPhilippines Small-Scale Wastewater Treatment Systems for 3 MarketsCris-Anne Juangco III100% (1)

- Guidance For Used Oil Handlers AlabamaDocument34 pagesGuidance For Used Oil Handlers AlabamaNitish AshleyNo ratings yet

- GEIRcasestudyforGreece 2007-12-14Document3 pagesGEIRcasestudyforGreece 2007-12-14Nitish AshleyNo ratings yet

- Swami DayanandDocument187 pagesSwami DayanandWorldwide Ahmadiyya Anjumans Ishaat IslamNo ratings yet

- Al-Abdulla Petroleum 2014Document3 pagesAl-Abdulla Petroleum 2014Nitish AshleyNo ratings yet

- Circuits Lecture Slides Intro&Module1HandoutsDocument30 pagesCircuits Lecture Slides Intro&Module1HandoutsNitish AshleyNo ratings yet

- Linear Circuits: Concept MapDocument30 pagesLinear Circuits: Concept MapNitish AshleyNo ratings yet

- Circuits Lecture Slides Module2HandoutsDocument63 pagesCircuits Lecture Slides Module2HandoutsNitish AshleyNo ratings yet

- OK Topic 2 Biological Treatment of WastewaterDocument168 pagesOK Topic 2 Biological Treatment of WastewaterPriyatno JuniantoNo ratings yet

- Why Environmental Engineering Is Vital for Our Sustainable FutureDocument6 pagesWhy Environmental Engineering Is Vital for Our Sustainable FutureMadeline Castro PangilinanNo ratings yet

- Cbse Class 5 Our Environment Question AnswerDocument2 pagesCbse Class 5 Our Environment Question AnswerNeel NasuNo ratings yet

- Prueba de InglesDocument7 pagesPrueba de Inglessalomon torresNo ratings yet

- Abdulshikur MohammedDocument136 pagesAbdulshikur MohammedTesfaye Teferi ShoneNo ratings yet

- Permitting Procedures HazardousDocument35 pagesPermitting Procedures HazardousCarol YD56% (9)

- MBDAF and OZONE Data Sheet For Wastewater TreatmentDocument1 pageMBDAF and OZONE Data Sheet For Wastewater TreatmentjayNo ratings yet

- Consultant Full ListDocument7 pagesConsultant Full ListirpansejatiNo ratings yet

- BBIA Landside Infrastructure Final Design ReportDocument167 pagesBBIA Landside Infrastructure Final Design ReportTayyabah ZafarNo ratings yet

- Foundation Course-II EcologyDocument3 pagesFoundation Course-II Ecologyansari naseem ahmadNo ratings yet

- RGPV Syllabus 3rd Sem Biomedical EngineeringDocument10 pagesRGPV Syllabus 3rd Sem Biomedical Engineeringoliver senNo ratings yet

- Aquafilteruae 800 GPDDocument1 pageAquafilteruae 800 GPDoffpageseodigitalmarketingNo ratings yet

- Definition and Scope of EcologyDocument7 pagesDefinition and Scope of EcologySonica NoirNo ratings yet

- Volvo FiltersDocument1 pageVolvo FiltersjayaramNo ratings yet

- Jane Buhayan's AbstractDocument2 pagesJane Buhayan's AbstractCMU - College of Forestry and Environmental ScienceNo ratings yet

- Introduction - Environmental EngineeringDocument4 pagesIntroduction - Environmental EngineeringMike Mor'zNo ratings yet

- Accumulation of Selected Metals in The Fruits of Medicinal Plants Grown in Urban Environment of Islamabad, PakistanDocument10 pagesAccumulation of Selected Metals in The Fruits of Medicinal Plants Grown in Urban Environment of Islamabad, PakistanFilsyaNo ratings yet

- Fogarassy, Cs. - Szarka, K. - Lehota, J.: Transition Thinking and SustainabilityDocument16 pagesFogarassy, Cs. - Szarka, K. - Lehota, J.: Transition Thinking and SustainabilitySzent Istvan University Climate Change Research CentreNo ratings yet

- Managing Municipal Waste in Banaue's Rice TerracesDocument12 pagesManaging Municipal Waste in Banaue's Rice TerracesAginaya Dinumla-CabanayanNo ratings yet

- Prepared By: Mary R. Gamboa - I.M 1Document5 pagesPrepared By: Mary R. Gamboa - I.M 1maryNo ratings yet

- Evm BioDocument11 pagesEvm BioKaab MullaNo ratings yet

- 9th Tankha BangloreDocument30 pages9th Tankha Bangloremanjeet.ca007No ratings yet

- Test Yourself 4: D. Cook D. Town D. Seat D. TR SportDocument4 pagesTest Yourself 4: D. Cook D. Town D. Seat D. TR SportNguyễn Thương ThảoNo ratings yet

- Health 6 DLP COT 2023Document4 pagesHealth 6 DLP COT 2023Ela F M Pullig100% (4)

- ESIA - 1283 Limuru Sewerage ReportDocument117 pagesESIA - 1283 Limuru Sewerage ReportAmos MutoroNo ratings yet