Professional Documents

Culture Documents

General Damage Mechanisms and Corrosion Failure Modes

Uploaded by

Shrikant Moje100%(1)100% found this document useful (1 vote)

129 views6 pagesAPI 571 Index

Original Title

API 571 Index

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAPI 571 Index

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

129 views6 pagesGeneral Damage Mechanisms and Corrosion Failure Modes

Uploaded by

Shrikant MojeAPI 571 Index

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 6

GENERAL DAMAGE MECHANISMS – ALL INDUSTRIES

4.2.1 Graphitization ..................................................................................................................... 4-3

4.2.2 Softening (Spheroidization) .............................................................................................. 4-7

4.2.3 Temper Embrittlement ..................................................................................................... 4-10

4.2.4 Strain Aging ...................................................................................................................... 4-14

4.2.5 885°F (475oC) Embrittlement ........................................................................................... 4-16

4.2.6 Sigma Phase Embrittlement ............................................................................................ 4-19

4.2.7 Brittle Fracture .................................................................................................................. 4-27

4.2.8 Creep and Stress Rupture ............................................................................................... 4-32

4.2.9 Thermal Fatigue ................................................................................................................ 4-39

4.2.10 Short Term Overheating – Stress Rupture .................................................................... 4-46

4.2.11 Steam Blanketing ............................................................................................................. 4-51

4.2.12 Dissimilar Metal Weld (DMW) Cracking ......................................................................... 4-54

4.2.13 Thermal Shock .................................................................................................................. 4-63

4.2.14 Erosion/Erosion – Corrosion .......................................................................................... 4-65

4.2.15 Cavitation .......................................................................................................................... 4-70

4.2.16 Mechanical Fatigue .......................................................................................................... 4-74

4.2.17 Vibration-Induced Fatigue ............................................................................................... 4-81

4.2.18 Refractory Degradation ................................................................................................... 4-84

4.2.19 Reheat Cracking ...............................................................................................................4-87

4.2.20 Gaseous Oxygen-Enhanced Ignition and Combustion ................................................ 4-93

4.3 Uniform or Localized Loss of Thickness

4.3.1 Galvanic Corrosion ........................................................................................................ 4-101

4.3.2 Atmospheric Corrosion ................................................................................................. 4-105

4.3.3 Corrosion Under Insulation (CUI) ................................................................................. 4-108

4.3.4 Cooling Water Corrosion ............................................................................................... 4-117

4.3.5 Boiler Water Condensate Corrosion ............................................................................ 4-120

4.3.6 CO2 Corrosion ................................................................................................................. 4-124

4.3.7 Flue-Gas Dew-Point Corrosion ..................................................................................... 4-128

4.3.8 Microbiologically Induced Corrosion (MIC) ................................................................. 4-130

4.3.9 Soil Corrosion ................................................................................................................. 4-136

4.3.10 Caustic Corrosion .......................................................................................................... 4-140

4.3.11 Dealloying ....................................................................................................................... 4-143

4.3.12 Graphitic Corrosion ....................................................................................................... 4-147

4.4 High Temperature Corrosion [>400°F (204°C)]

4.4.1 Oxidation ......................................................................................................................... 4-153

4.4.2 Sulfidation ....................................................................................................................... 4-159

4.4.3 Carburization .................................................................................................................. 4-166

4.4.4 Decarburization .............................................................................................................. 4-169

4.4.5 Metal Dusting .................................................................................................................. 4-172

4.4.6 Fuel Ash Corrosion ........................................................................................................ 4-175

4.4.7 Nitriding ........................................................................................................................... 4-180

4.5 Environment – Assisted Cracking

4.5.1 Chloride Stress Corrosion Cracking (Cl-SCC) ............................................................. 4-184

4.5.2 Corrosion Fatigue .......................................................................................................... 4-193

4.5.3 Caustic Stress Corrosion Cracking (Caustic Embrittlement) .................................... 4-199

4.5.4 Ammonia Stress Corrosion Cracking .......................................................................... 4-206

4.5.5 Liquid Metal Embrittlement (LME) ................................................................................ 4-210

4.5.6 Hydrogen Embrittlement (HE) ....................................................................................... 4-215

4.5.7 Ethanol Stress Corrosion Cracking (SCC) .................................................................. 4-220

4.5.8 Sulfate Stress Corrosion Cracking ............................................................................... 4-227

5.1.1 Uniform or Localized Loss in Thickness Phenomena

5.1.1.1 Amine Corrosion ............................................................................................................ 5-3

5.1.1.2 Ammonium Bisulfide Corrosion (Alkaline Sour Water) ............................................ 5-9

5.1.1.3 Ammonium Chloride Corrosion ................................................................................. 5-13

5.1.1.4 Hydrochloric Acid (HCl) Corrosion ............................................................................ 5-16

5.1.1.5 High Temp H2/H2S Corrosion ...................................................................................... 5-19

5.1.1.6 Hydrofluoric (HF) Acid Corrosion .............................................................................. 5-23

5.1.1.7 Naphthenic Acid Corrosion (NAC) ............................................................................. 5-31

5.1.1.8 Phenol (Carbolic Acid) Corrosion .............................................................................. 5-35

5.1.1.9 Phosphoric Acid Corrosion ........................................................................................ 5-37

5.1.1.10 Sour Water Corrosion (Acidic) ............................................................................... 5-39

5.1.1.11 Sulfuric Acid Corrosion .......................................................................................... 5-41

5.1.1.12 Aqueous Organic Acid Corrosion .......................................................................... 5-45

5.1.2 Environment-Assisted Cracking

5.1.2.1 Polythionic Acid Stress Corrosion Cracking (PASCC) ............................................ 5-49

5.1.2.2 Amine Stress Corrosion Cracking ............................................................................. 5-55

5.1.2.3 Wet H2S Damage (Blistering/HIC/SOHIC/SSC) .......................................................... 5-60

5.1.2.4 Hydrogen Stress Cracking - HF .................................................................................. 5-70

5.1.2.5 Carbonate Stress Corrosion Cracking (ACSCC) ...................................................... 5-72

5.1.3 Other Mechanisms

5.1.3.1 High Temperature Hydrogen Attack (HTHA) ............................................................. 5-83

5.1.3.2 Titanium Hydriding ...................................................................................................... 5-90

You might also like

- Damage Mechanisms Fixed Equipment in Refining IndustryDocument13 pagesDamage Mechanisms Fixed Equipment in Refining IndustryMansoor Ali100% (3)

- Johnson Matthey - Mercury Removal in Oil & GasDocument33 pagesJohnson Matthey - Mercury Removal in Oil & GasSo NicNo ratings yet

- The Interaction of Mercury and Aluminium in Heat Exchangers in A Natural Gas PDFDocument7 pagesThe Interaction of Mercury and Aluminium in Heat Exchangers in A Natural Gas PDFToth IstvanNo ratings yet

- Imprimir API 571Document88 pagesImprimir API 571ismael archila100% (1)

- API 580 Program InformationDocument1 pageAPI 580 Program InformationAbu Huraira100% (1)

- API 571 DemoDocument14 pagesAPI 571 Demophan hoang diep100% (1)

- API 579 Fitness For Service For Nozzles and Flanges (APIFFSB) Module OverviewDocument49 pagesAPI 579 Fitness For Service For Nozzles and Flanges (APIFFSB) Module Overviewck19654840No ratings yet

- Daily Exam 7 (Closed) : Professional Training and ConsultationDocument5 pagesDaily Exam 7 (Closed) : Professional Training and ConsultationCss SfaxienNo ratings yet

- API RP 571 corrosion questionsDocument5 pagesAPI RP 571 corrosion questionsأحمد صبحى100% (1)

- WRC 490 Ed. 2004 Damage Mechanisms Affecting Fixed Equipment in The Fossil Electric Power IndustryDocument118 pagesWRC 490 Ed. 2004 Damage Mechanisms Affecting Fixed Equipment in The Fossil Electric Power IndustryMarcus Rezende100% (3)

- Case Studies of Steel Structure Failures PDFDocument6 pagesCase Studies of Steel Structure Failures PDFAvim Wira RagendaNo ratings yet

- Introduction To LNG & Material Used in LNG ServicesDocument104 pagesIntroduction To LNG & Material Used in LNG ServicesVishaka ThekkedathNo ratings yet

- DEP 39011012 - Inf - 2018-02 - A01Document67 pagesDEP 39011012 - Inf - 2018-02 - A01g_325899365No ratings yet

- 4-API RP-571 - Chapter 4-5 Environmental DamagesDocument74 pages4-API RP-571 - Chapter 4-5 Environmental DamagesLily & Ameer لى لى و أمير100% (2)

- QSGTL Tank Jacking & Bottom Replacement ProjectDocument28 pagesQSGTL Tank Jacking & Bottom Replacement ProjectShrikant Moje100% (1)

- Api RP 571 (B) 51-100Document5 pagesApi RP 571 (B) 51-100alvaedison00100% (1)

- API-571 Mockup Test-02-QuestionsDocument12 pagesAPI-571 Mockup Test-02-QuestionsMetzer LLC100% (1)

- API 571 Damage Mechanisms Affecting Fixed Equipment in The Refining and Petrochemical IndustriesDocument3 pagesAPI 571 Damage Mechanisms Affecting Fixed Equipment in The Refining and Petrochemical IndustriesMonica CifuentesNo ratings yet

- Mercury Contamination RisksDocument78 pagesMercury Contamination RisksguruhnurizalNo ratings yet

- API 571 Part 1Document20 pagesAPI 571 Part 1Bashu Poudel100% (4)

- Duplex MetrodeDocument16 pagesDuplex MetrodeShrikant MojeNo ratings yet

- API 571 SummaryDocument119 pagesAPI 571 SummaryBilal Ghazanfar100% (1)

- Rethink Mercury Removal LNG PlantsDocument10 pagesRethink Mercury Removal LNG PlantshortalemosNo ratings yet

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsFrom EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsNo ratings yet

- General damage mechanisms and corrosion types overviewDocument1 pageGeneral damage mechanisms and corrosion types overviewBashu PoudelNo ratings yet

- Mechanical FatigueDocument6 pagesMechanical FatigueRamyMoustafaNo ratings yet

- Material Selection Guidelines for LNG Plant to Prevent Corrosion and CrackingDocument9 pagesMaterial Selection Guidelines for LNG Plant to Prevent Corrosion and CrackingVinothkumar KaliyamoorthyNo ratings yet

- The Challenges of LNG Materials SelectionDocument15 pagesThe Challenges of LNG Materials SelectionrachedNo ratings yet

- API RP 571 Test QuestionsDocument22 pagesAPI RP 571 Test QuestionsShrikant Moje100% (1)

- API RP 571 Test QuestionsDocument22 pagesAPI RP 571 Test QuestionsShrikant Moje100% (1)

- Api 571 Parte 12Document14 pagesApi 571 Parte 12Obe Mendoza100% (2)

- API 570 Day 1 Quiz: Key Concepts for Piping InspectionDocument63 pagesAPI 570 Day 1 Quiz: Key Concepts for Piping InspectionmelvinNo ratings yet

- The Challenges of LNG Materials SelectionDocument14 pagesThe Challenges of LNG Materials SelectionLiu YangtzeNo ratings yet

- RBI certification prepDocument6 pagesRBI certification prepAgustin A.No ratings yet

- API 571 Damage Mechanisms MasterclassDocument6 pagesAPI 571 Damage Mechanisms MasterclassRahim A Ahmad100% (1)

- CLSCC LiteratureDocument62 pagesCLSCC LiteratureNakarin PotidokmaiNo ratings yet

- 2010 SummerDocument16 pages2010 SummerRa'oufAli-zadeh100% (1)

- Manufacturing ProcessesDocument477 pagesManufacturing ProcessesVinod89% (19)

- Manufacturing ProcessesDocument477 pagesManufacturing ProcessesVinod89% (19)

- API - 510 Points To Remember - 6Document3 pagesAPI - 510 Points To Remember - 6EswaranNo ratings yet

- General Damage Mechanisms and Corrosion Failure ModesDocument6 pagesGeneral Damage Mechanisms and Corrosion Failure ModesShrikant Moje100% (1)

- General Damage Mechanisms and Corrosion Failure ModesDocument6 pagesGeneral Damage Mechanisms and Corrosion Failure ModesShrikant Moje100% (1)

- General Damage Mechanisms and Corrosion Failure ModesDocument6 pagesGeneral Damage Mechanisms and Corrosion Failure ModesShrikant Moje100% (1)

- API RP 571 Damage Mechanisms SpreadsheetDocument12 pagesAPI RP 571 Damage Mechanisms SpreadsheetSoftware ManagerNo ratings yet

- API 571-Damage Mechanism (October 4-7-2010)Document4 pagesAPI 571-Damage Mechanism (October 4-7-2010)ananda_27No ratings yet

- API 571 Coloured KeyDocument1 pageAPI 571 Coloured Keymuhammad faisal100% (1)

- ch6 - API 571 PDFDocument20 pagesch6 - API 571 PDFRAMADOSSNo ratings yet

- Interpass Temperature WeldingDocument2 pagesInterpass Temperature Weldinghareesh13hNo ratings yet

- Api 571 2Document7 pagesApi 571 2Mahmoud Abdelaal100% (1)

- Gas Shielded Flux Cored Arc Welding (FCAW) GuideDocument19 pagesGas Shielded Flux Cored Arc Welding (FCAW) GuideSanthosh Kumar100% (1)

- Gas Shielded Flux Cored Arc Welding (FCAW) GuideDocument19 pagesGas Shielded Flux Cored Arc Welding (FCAW) GuideSanthosh Kumar100% (1)

- PDF Api 570 Awareness Coursepdf DDDocument23 pagesPDF Api 570 Awareness Coursepdf DDkareemNo ratings yet

- Api 571Document41 pagesApi 571majid100% (1)

- API-571 Question BankDocument13 pagesAPI-571 Question BankMetzer LLCNo ratings yet

- Api 571 Questions PDFDocument18 pagesApi 571 Questions PDFRaghavan Venkatraman100% (1)

- API 571 Corrosion Certification PrepDocument6 pagesAPI 571 Corrosion Certification PrepImran KaiNo ratings yet

- API-571 Mockup Test-03-QuestionsDocument12 pagesAPI-571 Mockup Test-03-QuestionsMetzer LLC100% (1)

- Electrode PDFDocument32 pagesElectrode PDFShrikant MojeNo ratings yet

- API 571 Corrosion and Materials ProfessionalDocument2 pagesAPI 571 Corrosion and Materials ProfessionalKhepa BabaNo ratings yet

- Hot-Dip Galvanizing of Cold-Formed Steel Hollow Sections - A State-Of-The-Art ReviewDocument17 pagesHot-Dip Galvanizing of Cold-Formed Steel Hollow Sections - A State-Of-The-Art ReviewJesús Ribera100% (1)

- API 571 Study NoteDocument1 pageAPI 571 Study Notebmkale100% (1)

- API 653 - Section 571 Flashcards - Quizlet (Sep.2011)Document3 pagesAPI 653 - Section 571 Flashcards - Quizlet (Sep.2011)ام يمنى ايمنNo ratings yet

- Api RP 571 (B) 51-100Document6 pagesApi RP 571 (B) 51-100alvaedison00100% (1)

- API 571 damage mechanisms refining petrochemicalDocument3 pagesAPI 571 damage mechanisms refining petrochemicalMahmoud Elmahdy100% (1)

- Some Grades of Carbon Steel and 0.5mo SteelsDocument27 pagesSome Grades of Carbon Steel and 0.5mo SteelsNidharshan Selvaraj RNo ratings yet

- API 571 Test Registration Applicant's Name: Exam ID #Document2 pagesAPI 571 Test Registration Applicant's Name: Exam ID #Ali AhmedNo ratings yet

- API 571 Exam InfoDocument1 pageAPI 571 Exam InfoSathiyaseelan Sakthi ShanmugamNo ratings yet

- API 571 Damage Mechanisms Affecting Fixed Equipment in The Refining and Petrochemical Industries PDFDocument1 pageAPI 571 Damage Mechanisms Affecting Fixed Equipment in The Refining and Petrochemical Industries PDFAzhar Ahmad100% (1)

- Examen de Evaluación API 571Document18 pagesExamen de Evaluación API 571berray2007100% (2)

- API 571 Damage Mechanism Affecting Fixed Refining EquipmentsDocument4 pagesAPI 571 Damage Mechanism Affecting Fixed Refining EquipmentsKmt_AeNo ratings yet

- API571 - NEW APP - Effective 2011 - CompletedDocument12 pagesAPI571 - NEW APP - Effective 2011 - Completedtong2jeNo ratings yet

- Pinnacle 571 Training FlyerDocument2 pagesPinnacle 571 Training FlyerDennis Arley SanchezNo ratings yet

- (PDF) PRACTICE QUESTIONS FOR API RP 577 Quizlet - Gustavo HC - Academia - EduDocument4 pages(PDF) PRACTICE QUESTIONS FOR API RP 577 Quizlet - Gustavo HC - Academia - EduKumar R100% (1)

- Api RP 571Document1 pageApi RP 571yckimNo ratings yet

- 2015 Pinnacle 580 Training FlyerDocument2 pages2015 Pinnacle 580 Training FlyerAlbertoNo ratings yet

- API 571+à+ç+å+Document7 pagesAPI 571+à+ç+å+Bilal Ghazanfar100% (1)

- Daily Points To Recall (Day 5) : Professional Training and ConsultationDocument3 pagesDaily Points To Recall (Day 5) : Professional Training and Consultationraobabar21No ratings yet

- Keyword For API 580 PDFDocument9 pagesKeyword For API 580 PDFRaymundo ACNo ratings yet

- 1Z0 580 PDFDocument61 pages1Z0 580 PDFJohnNo ratings yet

- Prepking 000-936 Exam QuestionsDocument11 pagesPrepking 000-936 Exam Questionscollen23No ratings yet

- KubotaDocument12 pagesKubotaFebri Ramdani NugrahaNo ratings yet

- Failure Mechanisms of C-Steels (API 571)Document18 pagesFailure Mechanisms of C-Steels (API 571)Mohmed AllamNo ratings yet

- Longitudinal JointDocument26 pagesLongitudinal JointirfanNo ratings yet

- Clock Spring CS600 Quad Qualification Test ReportDocument7 pagesClock Spring CS600 Quad Qualification Test ReportMOHD ASHRAF MOHD ROSITNo ratings yet

- ICP™ Application Submission: User Guide For API 571, 577 and 580 ApplicantsDocument23 pagesICP™ Application Submission: User Guide For API 571, 577 and 580 ApplicantsShrikant MojeNo ratings yet

- ICP™ Application Submission: User Guide For API 571, 577 and 580 ApplicantsDocument23 pagesICP™ Application Submission: User Guide For API 571, 577 and 580 ApplicantsShrikant MojeNo ratings yet

- ICP™ Application Submission: User Guide For API 571, 577 and 580 ApplicantsDocument23 pagesICP™ Application Submission: User Guide For API 571, 577 and 580 ApplicantsShrikant MojeNo ratings yet

- Key Concepts 2 Heat InputDocument4 pagesKey Concepts 2 Heat InputBama RamachandranNo ratings yet

- Rajasthan Tour 9n10dDocument2 pagesRajasthan Tour 9n10dShrikant MojeNo ratings yet

- World Pipelines June 2007 - Integrity ManagementDocument55 pagesWorld Pipelines June 2007 - Integrity ManagementShrikant MojeNo ratings yet

- Api 571 HNDocument1 pageApi 571 HNShrikant MojeNo ratings yet

- World Pipelines June 2007 - Integrity Management PDFDocument6 pagesWorld Pipelines June 2007 - Integrity Management PDFShrikant MojeNo ratings yet

- Piping DesignDocument8 pagesPiping Designswabha102No ratings yet

- Welding ProcessesDocument78 pagesWelding ProcessesShrikant MojeNo ratings yet

- Key Concepts 2 Heat InputDocument4 pagesKey Concepts 2 Heat InputBama RamachandranNo ratings yet

- Piping Surges PDFDocument14 pagesPiping Surges PDFiboNo ratings yet

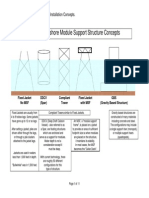

- 6.offshore ConceptsDocument0 pages6.offshore Conceptshaidar1992No ratings yet

- Key Concepts 2 Heat InputDocument4 pagesKey Concepts 2 Heat InputBama RamachandranNo ratings yet

- ASME P-Numbers PDFDocument2 pagesASME P-Numbers PDFShrikant Moje100% (1)

- Fabrication Procedure FOR Evaporators: MFF Larsen & Toubro Limited Hazira Works, SuratDocument51 pagesFabrication Procedure FOR Evaporators: MFF Larsen & Toubro Limited Hazira Works, SuratShrikant MojeNo ratings yet

- Welding Consumanle SelectionDocument85 pagesWelding Consumanle SelectionShrikant MojeNo ratings yet

- Ductile Iron Pipe Methods of DesignDocument22 pagesDuctile Iron Pipe Methods of DesignShrikant MojeNo ratings yet

- API 571 Flashcards - Quizlet GoodDocument18 pagesAPI 571 Flashcards - Quizlet Goodks_irdeNo ratings yet

- Geometrical Degradation of Electrode and Liquid Metal Embrittlement Cracking in Resistance Spot WeldingDocument15 pagesGeometrical Degradation of Electrode and Liquid Metal Embrittlement Cracking in Resistance Spot WeldingMathews LimaNo ratings yet

- Heat-Affected Zone Infiltration in Dissimilar Metal WeldsDocument9 pagesHeat-Affected Zone Infiltration in Dissimilar Metal WeldsshivabejugamaNo ratings yet

- Liquid Metal Embrittlement ReviewDocument13 pagesLiquid Metal Embrittlement ReviewangelogontijoNo ratings yet

- Risk Analysis of Mercury-Contaminated Aluminum Heat ExchangersDocument16 pagesRisk Analysis of Mercury-Contaminated Aluminum Heat Exchangersmostafa_1000No ratings yet

- Liquid Metal EmbrittlementDocument1 pageLiquid Metal EmbrittlementalphadingNo ratings yet

- 208 217Document10 pages208 217amit_iitNo ratings yet

- Liquid Metal Embrittlement (LME)Document13 pagesLiquid Metal Embrittlement (LME)a_omar_iitmNo ratings yet

- AHSS Implementation - Liquid Metal Embrittlement Study - AHSS InsightsDocument5 pagesAHSS Implementation - Liquid Metal Embrittlement Study - AHSS InsightsSilverio AcuñaNo ratings yet

- Section - 4 General Damage Mechanisms - 475deg C EmbrittlementDocument3 pagesSection - 4 General Damage Mechanisms - 475deg C EmbrittlementlokelooksNo ratings yet

- ISFI2012Proceedings MetallurgyandFireInvestigation EBucDocument14 pagesISFI2012Proceedings MetallurgyandFireInvestigation EBucRafael CastroNo ratings yet

- Introduction to Corrosion & Cooling Water TreatmentsDocument212 pagesIntroduction to Corrosion & Cooling Water TreatmentsSameer Kimmatkar100% (2)

- Liquid Metal Embrittlement: Larissa Chiesa M. de Souza COT-736 - Téc. Est. Controle de CorrosãoDocument11 pagesLiquid Metal Embrittlement: Larissa Chiesa M. de Souza COT-736 - Téc. Est. Controle de CorrosãoLarissa Chiesa Mendonça De SouzaNo ratings yet

- Helicopter Fatal Crash Due to Screw Failure in Fuel Control UnitDocument21 pagesHelicopter Fatal Crash Due to Screw Failure in Fuel Control UnitUllas UNo ratings yet

- Pilling & Bedworth Ratio.. EmbrittlementDocument9 pagesPilling & Bedworth Ratio.. EmbrittlementAdrian JamesNo ratings yet

- Worldautosteel Lmestudy Public Reports 20200603Document220 pagesWorldautosteel Lmestudy Public Reports 20200603LuisNo ratings yet