Professional Documents

Culture Documents

WPHT Asco 00187gb

Uploaded by

NCOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPHT Asco 00187gb

Uploaded by

NCCopyright:

Available Formats

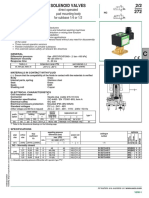

SOLENOID VALVES 3/2 NC

12 2 4 12 2 4 3/2-5/2

Series

pilot operated, spool type

551

3 1 5 3 1 5

single/dual solenoid (mono/bistable function) 12 2 4 1012 2 4 14

brass body, “NAMUR” style, 1/4 5/2 3 1 5 3 1 5

FEATURES

• The solenoid operated spool valves have threaded port connections and NAMUR

interface

• The same spool valve can be adapted for 3/2 NC or 5/2 functions for controlling

double-acting and single-acting actuators

• All the exhaust ports of the spool valve are connectable, providing better environmental

protection. Particularly recommended for sensitive areas, such as clean rooms, and

applications in the pharmaceutical and food processing sectors

• The valves offer environmental protection against the ingress of liquids, dusts or

other foreign matter (environmentally-protected construction)

• Can be externally piloted (external air pilot supply) to convert valve to zero minimum

operation by flipping a gasket

• The monostable spool valves in conformity with IEC 61508 Standard (2010 route 2H

version) have TÜV certified with integrity levels: SIL 2 for HFT = 0 / SIL 3 for HFT = 1

• The solenoid valves satisfy all relevant EU directives

GENERAL

Differential pressure 2 - 10 bar [1 bar = 100 kPa]

Flow (Qv at 6 bar) 700 l/min (ANR)

Pilot mounting interface surface ISO 15218 (CNOMO E06.36.120N, size 15)

fluids () temperature range (TS) seal materials ()

air, inert gas, filtered -40°C to +60°C VMQ (silicone) + PUR (polyurethane)

MATERIALS IN CONTACT WITH FLUID

() Ensure that the compatibility of the fluids in contact with the materials is verified

Body, end cover, seats Brass

Spool valve internal parts Brass, stainless steel, POM

Core tube Stainless steel

Core and plugnut Stainless steel

Core spring Stainless steel Prefix SC

Top disc PA

Pilot seals FPM, NBR

Interface plates Glass fibre filled PA

Shading coil Copper

OTHERS MATERIALS

Solenoid enclosure (WP) Zinc plated steel (epoxy coated)

ELECTRICAL CHARACTERISTICS

G

Coil insulation class F

Connector (SC) Spade plug (cable Ø 6-10 mm)

Connector specification (SC) ISO 4400 / EN 175301-803, form A

Coil connection (WP) Embedded screw terminal (cable ø 7 - 12 mm)

Cable entry (WP) Cable gland, polyamide (PA), M20x1,5

Electrical safety IEC 335 Prefix WP

Electrical enclosure protection Moulded IP65 (SC) or IP67 (WP) (EN 60529)

Standard voltages DC (=): 24V - 48V

Availability, design and specifications are subject to change without notice. All rights reserved.

(Other voltages and 60 Hz on request) AC (~): 24V - 48V - 115V - 230V / 50 Hz

power ratings operator

ambient replacement coil

prefix inrush holding hot/cold temperature type (1)

option ~ ~ = range (TS) ~ =

(VA) (VA) (W) (W) (C°) 230 V/50 Hz 24 V DC

SC 55 23 10,5 9 / 11,2 -40 to +75 400425-117 400425-142 01

WP 55 23 10,5 9 / 11,2 -40 to +75 400405-117 400405-142 02

Refer to the dimensional drawings on the following page.

(1)

SPECIFICATIONS

operating pressure options

flow differential (bar) catalogue

pipe orifice power coil

man. operator

coefficient number

max. (PS) (W)

maintained

size size

Kv

impulse /

min.

(2) air (*) type 01 (SC) type 02 (WP)

G (mm) (m3/h) (l/min) ~ = ~ = ~/= ~/=

3/2 NC - 5/2 - Solenoid air pilot operated - spring return (monostable)

1/4 6 0,6 10 0/2 10 10 10,5 11,2 SCG551A403 WPG551A403 MO - -

3/2 NC - 5/2 - Solenoid air pilot operated and return (bistable)

00187GB-2016/R01

1/4 6 0,6 10 0/2 10 10 10,5 11,2 SCG551A404 WPG551A404 MO - -

3/2 NC - 5/2 - Solenoid air pilot operated spring return (monostable), certified IEC 61508 Functional Safety data

1/4 6 0,6 10 0/2 10 10 10,5 11,2 SCG551A403SL WPG551A403SL - - -

(2)

Zero minimum is only achieved if external pressure is applied.

All leaflets are available on: www.asco.com

V872-1

SERIES 551

OPTIONS

• Valves configured for external pilot air supply, use TPL 20547

• Explosionproof enclosures for use in zones 0/20-1/21-2/22, categories 1-2-3 to ATEX-Directive 2014/34/EU (see “Explosionproof Solenoids” section)

• Compliance with “UL”, “CSA” and other local approvals available on request

• Coil insulation class H for max. ambient temperature +80°C, prefix HT (“SCHT” or “WPHT”)

• 1/2” NPT (prefix “T”) and M20 x 1.5 (prefix “ET”) conduits (aluminium or 316 SS) available for steel solenoid enclosure

• Valves equipped with exhaust reducers, suffix M

• Set of stainless steel mounting screws, catalogue number 97802212

• Set of two exhaust reducers, catalogue number 88100344

• Other pipe connections are available on request

• Plug with visual indication and peak voltage suppression or with cable length of 2 m (see Solenoids, Coils & Accessories section)

INSTALLATION

• The solenoid valves can be mounted in any position without affecting operation

• 3/2 NC-5/2 spool valve supplied with one interface plate with NAMUR mating surface. Depending on function (3/2 NC or 5/2),

position the plate on the spool valve body before installing on actuator

• Do not connect the pressure supply to the exhaust port 3. The “environmentally-protected” construction is not adapted for NO

function. Contact us for function available in specific version

• Dowel pin (if necessary), bolts and gaskets are standard supplied

• It is necessary to connect pipes or fittings to the exhaust ports to protect the internal parts of the spool valve and its pneumatic

operator if used outside or in harsh environments (dusts, liquids etc.)

• IEC 61508 Functional Safety (suffix SL). Check temperature range of valve body and solenoid for suitability. For probability of

failure, contact us

• Threaded pipe connection is standard: G = G (ISO 228/1)

• Prefix “WP” execution: solenoid enclosure has a cable gland with integral strain relief for cables with an O.D. from 7 to 12 mm

and is provided with internal and external grounding terminals

• Valves with suffix “SL” are supplied with specific exhaust protectors

• Installation/maintenance instructions are included with each valve

ACCESSORIES ORDERING EXAMPLES:

exhaust SC G 551 A 403 230V / 50 Hz

pipe

series protector SC G 551 A 403 SL 230V / 50 Hz

size

(stainless steel) WP G 551 A 404 24V / DC

551 G 1/8 34600418 (1) WP G 551 A 403 MO 115V / 50 Hz

(1)

Supplied with suffix “SL”. WPHT G 551 A 404 MO 230V / 50 Hz

prefix

DIMENSIONS (mm), WEIGHT (kg) voltage

pipe thread

D E 5 1 C C2 B basic number suffix

=

= =

2

32

4

45

=

C C1 24 3 2 x 1/8

A Interface plate

7

82

= =

B Mounting: 2 CHc M5x35 screws, engaged lenght 7 mm

125,5 C One 5 mm dia. hole for dowel pin:

165

- in position C1: 3/2 NC function plate

1/8 - in position C2: 5/2 function plate

1 x 1/4

3 5 D 2 O-ring seals (supplied)

Availability, design and specifications are subject to change without notice. All rights reserved.

1

40

E Exhaust reducer or exhaust protector G 1/8

33

5

19

2 4

A

7

TYPE 01 TYPE 02

Prefix “SC” Solenoid Prefix “WP” Solenoid

Epoxy moulded Metal; epoxy coated

IEC 335 / ISO 4400 IEC 335

IP65 IP67

1/8

1/8

1

360˚

108

90˚ 360˚

108

2 2

3 3

125 22,5 142 38 82

174 87 198 120

prefix weight (1) 1 Cable gland for unarmoured cable with 7 to 12 mm dia. sheath

00187GB-2016/R01

type

option monostable bistable 2 Manual operator location

01 SC 1,45 1,96 3 External pilot air supply, 1/8 pipe size

02 WP 1,62 2,23

(1)

Including coil(s), connector (SC) and cable gland (WP).

All leaflets are available on: www.asco.com

V872-2

You might also like

- Single Stage, Integral Pilot Threaded Body or Compression Fitting 3/4 To 1Document2 pagesSingle Stage, Integral Pilot Threaded Body or Compression Fitting 3/4 To 1VM ExportNo ratings yet

- FDFZGCFWGBDocument2 pagesFDFZGCFWGBayiNo ratings yet

- Solenoid Valves 3 - 2 5 - 2 Stainless Steel Body 551 553 CAT 80114GBDocument8 pagesSolenoid Valves 3 - 2 5 - 2 Stainless Steel Body 551 553 CAT 80114GBwqs_19No ratings yet

- SOLENOID VALVES FEATURES AND SPECIFICATIONSDocument8 pagesSOLENOID VALVES FEATURES AND SPECIFICATIONSTeddy HariyantoNo ratings yet

- Catalog Series 551 553 Ss Namur 1 4 Et 1 2 3 2 5 2 Asco en 6316858Document9 pagesCatalog Series 551 553 Ss Namur 1 4 Et 1 2 3 2 5 2 Asco en 6316858Jeyson BueraNo ratings yet

- Power Pulse Valves PDFDocument12 pagesPower Pulse Valves PDFUrip S. SetyadjiNo ratings yet

- Integral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Document16 pagesIntegral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Kishor JadhavNo ratings yet

- Solenoid Valves 3/2-5/2 551: Single/dual Solenoid (Mono/bistable Function) 1/4Document10 pagesSolenoid Valves 3/2-5/2 551: Single/dual Solenoid (Mono/bistable Function) 1/4Dinesh ChouguleNo ratings yet

- ASCO Series 353 2-2 Pules Valves Dual StageDocument2 pagesASCO Series 353 2-2 Pules Valves Dual StageAdnan AliNo ratings yet

- European Catalog Single Stage Pulse Valves Series 353 Asco en 7028704Document2 pagesEuropean Catalog Single Stage Pulse Valves Series 353 Asco en 7028704AirteamNo ratings yet

- Solenoid Valves-Dust Collector-353-CAT-60059GBDocument2 pagesSolenoid Valves-Dust Collector-353-CAT-60059GBangelosNo ratings yet

- Valvula Asiento Inclinado Serie E290 AscoDocument3 pagesValvula Asiento Inclinado Serie E290 AscoBase SistemasNo ratings yet

- European Catalog Solenoid Valve 2 2 Brass Body 272 1 4 1 2 Asco en 6868880Document2 pagesEuropean Catalog Solenoid Valve 2 2 Brass Body 272 1 4 1 2 Asco en 6868880SonyNo ratings yet

- Solenoid pilot valves optimize pneumatic controlDocument2 pagesSolenoid pilot valves optimize pneumatic controlBalotileNo ratings yet

- ROSS Pneumatic Directional Control Valves 27 SeriesDocument18 pagesROSS Pneumatic Directional Control Valves 27 SeriesQuy HoangNo ratings yet

- PDE2536TCUK-Ev - Indigo - NewDocument50 pagesPDE2536TCUK-Ev - Indigo - NewfuclaNo ratings yet

- ASCO Solenoid ValvesDocument2 pagesASCO Solenoid Valvesjmathew_984887No ratings yet

- ASCO Series 290 390 - ASCO Pressure Operated Solenoid Pilot Valves G1-8 1Document2 pagesASCO Series 290 390 - ASCO Pressure Operated Solenoid Pilot Valves G1-8 1Lassané KINDONo ratings yet

- Pneumatic Directional Control Valves: Type 451-4Document4 pagesPneumatic Directional Control Valves: Type 451-4Francisco Mones RuizNo ratings yet

- SCG238 Series PDFDocument2 pagesSCG238 Series PDFrika monikaNo ratings yet

- Power Pulse Valves S353A720+730+Document2 pagesPower Pulse Valves S353A720+730+Victor Ruiz FuentesNo ratings yet

- European Catalog Pulse Valve Dust Collector Remote Pilot 353 Asco en 5084840Document2 pagesEuropean Catalog Pulse Valve Dust Collector Remote Pilot 353 Asco en 5084840Julio César Herrera MontoyaNo ratings yet

- B 81417 EfaDocument2 pagesB 81417 EfaIshak EnginerNo ratings yet

- En 5.4.335Document8 pagesEn 5.4.335Joy BhattacharyaNo ratings yet

- European Catalog Solenoid Valves 2 2 Pilot Operated Built in Pilot Floating Diaphragm Series 238 Asco en 5080052Document2 pagesEuropean Catalog Solenoid Valves 2 2 Pilot Operated Built in Pilot Floating Diaphragm Series 238 Asco en 5080052Farhan HirsanNo ratings yet

- 15ME304L Automation Lab ObservationDocument75 pages15ME304L Automation Lab Observationkandharaoli100% (1)

- Inline Pilot-Operated Soft Spool ValvesDocument4 pagesInline Pilot-Operated Soft Spool Valvespocetak1No ratings yet

- Standards-based valves meeting ISO 5599-1Document131 pagesStandards-based valves meeting ISO 5599-1José De Holanda Cavalcante Junior HolandaNo ratings yet

- Solenoid Valves Pilot Operated 2/2 Series NCDocument2 pagesSolenoid Valves Pilot Operated 2/2 Series NCKhyle Laurenz DuroNo ratings yet

- Asco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm) PDFDocument2 pagesAsco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm) PDFKhyle Laurenz DuroNo ratings yet

- Solenoid Valves-5 - 2-5 - 3-Aluminium body-551-552-553-CAT-00093GBDocument4 pagesSolenoid Valves-5 - 2-5 - 3-Aluminium body-551-552-553-CAT-00093GBfebri kurniaNo ratings yet

- Actuadores Neumáticos MICRODocument2 pagesActuadores Neumáticos MICRONemoz ZrNo ratings yet

- Catalog Series 353 Diaphragm Pulse Valves Asco en 7694626Document12 pagesCatalog Series 353 Diaphragm Pulse Valves Asco en 7694626Buat AgrovatioNo ratings yet

- tfp342 Ty5151Document4 pagestfp342 Ty5151Raúl Antonio MacíasNo ratings yet

- Pilot Valve Boxes SG110ADocument2 pagesPilot Valve Boxes SG110AVictor Ruiz FuentesNo ratings yet

- Pilot Valve BoxesDocument8 pagesPilot Valve BoxesAmit AGRAWALNo ratings yet

- SOLENOID VALVE SPECIFICATIONSDocument2 pagesSOLENOID VALVE SPECIFICATIONSsahraoui brahimNo ratings yet

- Flotect Vane Operated Flow Switches: Field Adjustable - 1 To 6 Inch Pipe, Leak Proof Body, Chemical ResistanceDocument1 pageFlotect Vane Operated Flow Switches: Field Adjustable - 1 To 6 Inch Pipe, Leak Proof Body, Chemical ResistanceMadhan MohanNo ratings yet

- Valvulas para Gas Industrial v5097Document12 pagesValvulas para Gas Industrial v5097Jesid ApraezNo ratings yet

- Fisher N551 ESVDocument2 pagesFisher N551 ESVWynn ChoNo ratings yet

- Namur Direct Mount Pneumatic Actuator Valves: BulletinDocument4 pagesNamur Direct Mount Pneumatic Actuator Valves: BulletinLuis Eduardo Albarracin RugelesNo ratings yet

- Series 551,552,553,14-12 AluminiumDocument20 pagesSeries 551,552,553,14-12 AluminiumPrathamesh GangalNo ratings yet

- Service and Operating Instruction: Mi-512 ENDocument16 pagesService and Operating Instruction: Mi-512 ENanastasios filiosNo ratings yet

- ISO Manifold Sub-Base Connections and DimensionsDocument8 pagesISO Manifold Sub-Base Connections and DimensionsFrancisco Mones RuizNo ratings yet

- Sub-Bases and Manifolds: Type 451Document8 pagesSub-Bases and Manifolds: Type 451Francisco Mones RuizNo ratings yet

- Solenoid Valve For Aggressive Fluids,: Direct ActingDocument4 pagesSolenoid Valve For Aggressive Fluids,: Direct ActingimtiyazNo ratings yet

- Integrated Pilot Operated, Spool Type Single/dual Solenoid Aluminium Body, 1/4", NAMUR and THREADED StyleDocument4 pagesIntegrated Pilot Operated, Spool Type Single/dual Solenoid Aluminium Body, 1/4", NAMUR and THREADED StyleRandy SihombingNo ratings yet

- Catalog Series 210 Hung Diaphragm Asco Emea Ap en 5084892Document3 pagesCatalog Series 210 Hung Diaphragm Asco Emea Ap en 5084892raobenNo ratings yet

- Series: Direct Solenoid and Solenoid Pilot Operated ValvesDocument28 pagesSeries: Direct Solenoid and Solenoid Pilot Operated ValvesMike Davidson AnwandterNo ratings yet

- Water Level Control Functions: 30-FL Modulating Float ValveDocument1 pageWater Level Control Functions: 30-FL Modulating Float ValveSandy Dwi KurniawanNo ratings yet

- Refiner Dd3000 Beloit JonesDocument4 pagesRefiner Dd3000 Beloit Jonesmynor8josh8juarez100% (1)

- ASCO™ Solenoid Valves 356: Features & BenefitsDocument10 pagesASCO™ Solenoid Valves 356: Features & BenefitssrushtiNo ratings yet

- Crouse Hinds Flexstation Catalog PageDocument5 pagesCrouse Hinds Flexstation Catalog PageFavian Barbosa SanchezNo ratings yet

- Delta Sw4: Controlled Compression of Seat SealDocument2 pagesDelta Sw4: Controlled Compression of Seat SealjhongonzalezgonzalezNo ratings yet

- Direct Operated 2/2 NC Solenoid Valve FeaturesDocument2 pagesDirect Operated 2/2 NC Solenoid Valve Featuresvineeth8624No ratings yet

- Solenoid Valves 3/2 5/2 531Document4 pagesSolenoid Valves 3/2 5/2 531luthfie4uNo ratings yet

- 5 - 2-Way and 4 - 2-Way Pneumatic Valves - TamesonDocument4 pages5 - 2-Way and 4 - 2-Way Pneumatic Valves - TamesonAkileshNo ratings yet

- Valv - Nugget 500Document22 pagesValv - Nugget 500FRANK PRUDENCIO OBREGONNo ratings yet

- O LF CompactDocument4 pagesO LF CompactgabrielNo ratings yet

- SWITZER - PressureSwitchSeries200Document4 pagesSWITZER - PressureSwitchSeries200NCNo ratings yet

- Cella Di Carico Sartorius MP77 eDocument3 pagesCella Di Carico Sartorius MP77 eNCNo ratings yet

- NJ15-30GM-N - P&F - 106491 - EngDocument2 pagesNJ15-30GM-N - P&F - 106491 - EngNCNo ratings yet

- Solenoid - Atos - TE140Document4 pagesSolenoid - Atos - TE140NCNo ratings yet

- WPHT Asco Numatics Solenoid - 00186gbDocument2 pagesWPHT Asco Numatics Solenoid - 00186gbNCNo ratings yet

- RTX Iom Alr R01Document13 pagesRTX Iom Alr R01NCNo ratings yet

- Pull Cord Switch JayashreeDocument1 pagePull Cord Switch JayashreeNCNo ratings yet

- Pilot Operated, Spool Type Single/dual Solenoid (Mono/bistable Function) Brass Body, 1/4Document8 pagesPilot Operated, Spool Type Single/dual Solenoid (Mono/bistable Function) Brass Body, 1/4NCNo ratings yet

- Belt Sway Switch JayashreeDocument1 pageBelt Sway Switch JayashreeindustrialindiaNo ratings yet

- MT8071iE1 DataSheet ENGDocument2 pagesMT8071iE1 DataSheet ENGNCNo ratings yet

- PlackacrequirementDocument1 pagePlackacrequirementNCNo ratings yet

- D5290 DTS0336Document4 pagesD5290 DTS0336NCNo ratings yet

- CSPG Compact Capsule Sensing Pr. Gauges 1Document2 pagesCSPG Compact Capsule Sensing Pr. Gauges 1NCNo ratings yet

- s8jx T041-E1 19 2 csm2005Document61 pagess8jx T041-E1 19 2 csm2005NCNo ratings yet

- Sfe Pba300-1500Document10 pagesSfe Pba300-1500NCNo ratings yet

- PF KFD2 DWB Ex1.D Under Over Speed MonitorDocument4 pagesPF KFD2 DWB Ex1.D Under Over Speed MonitorNCNo ratings yet

- Skin Type RTD AssembliesDocument2 pagesSkin Type RTD AssembliesNCNo ratings yet

- GIC Bourdon SensingDocument2 pagesGIC Bourdon SensingNCNo ratings yet

- Auma - Katalog Techn Unterlagen Antriebe enDocument512 pagesAuma - Katalog Techn Unterlagen Antriebe enNCNo ratings yet

- Drivers For A Safety System Upgrade - Proces-Wp009 - En-PDocument10 pagesDrivers For A Safety System Upgrade - Proces-Wp009 - En-PNCNo ratings yet

- GS33K50F80 50eDocument12 pagesGS33K50F80 50eNCNo ratings yet

- Automation IndustryDocument44 pagesAutomation IndustryNCNo ratings yet

- Bao Nhiet Gia Tang - DSC-EA - 05-2005Document2 pagesBao Nhiet Gia Tang - DSC-EA - 05-2005hongchimtNo ratings yet

- Yokogawa Stardom Compressor Control WP Continuous Control SolutionsDocument12 pagesYokogawa Stardom Compressor Control WP Continuous Control SolutionsJahangir MalikNo ratings yet

- GIC CSPG CatalogueDocument2 pagesGIC CSPG CatalogueNCNo ratings yet

- Hochiki Australia Fire Detection Systems Catalogue V1Document19 pagesHochiki Australia Fire Detection Systems Catalogue V1NCNo ratings yet

- Tec2 Electronic Valve Actuators Engineering Controls Manual Us en 86518Document54 pagesTec2 Electronic Valve Actuators Engineering Controls Manual Us en 86518NCNo ratings yet

- Flow Solutions Guide Proving Calibration en Us 188668Document4 pagesFlow Solutions Guide Proving Calibration en Us 188668NCNo ratings yet

- What Now More Standards For Safety Compliance en 56732Document39 pagesWhat Now More Standards For Safety Compliance en 56732NCNo ratings yet

- Call SANROCCO 11 HappybirthdayBramanteDocument8 pagesCall SANROCCO 11 HappybirthdayBramanterod57No ratings yet

- Chetan Bhagat's "Half GirlfriendDocument4 pagesChetan Bhagat's "Half GirlfriendDR Sultan Ali AhmedNo ratings yet

- Medical filter performance specificationsDocument1 pageMedical filter performance specificationsPT.Intidaya Dinamika SejatiNo ratings yet

- Osora Nzeribe ResumeDocument5 pagesOsora Nzeribe ResumeHARSHANo ratings yet

- Global 6000 SystemsDocument157 pagesGlobal 6000 SystemsJosé Rezende100% (1)

- Zhihua Yao - Dignaga and The 4 Types of Perception (JIP 04)Document24 pagesZhihua Yao - Dignaga and The 4 Types of Perception (JIP 04)Carlos Caicedo-Russi100% (1)

- AJK Newslet-1Document28 pagesAJK Newslet-1Syed Raza Ali RazaNo ratings yet

- Grade 10Document39 pagesGrade 10amareNo ratings yet

- Java MCQ QuestionsDocument11 pagesJava MCQ QuestionsPineappleNo ratings yet

- Electronic Harassment Strahlenfolter - A Short History of Sound Weapons Pt2 - InfrasoundDocument10 pagesElectronic Harassment Strahlenfolter - A Short History of Sound Weapons Pt2 - InfrasoundFrank-BoenischNo ratings yet

- EMECH 2 MarksDocument18 pagesEMECH 2 MarkspavanraneNo ratings yet

- RestrukturisasiDocument17 pagesRestrukturisasimuhammad hayel wallaNo ratings yet

- Assessing Eyes NCM 103 ChecklistDocument7 pagesAssessing Eyes NCM 103 ChecklistNicole NipasNo ratings yet

- 40 Multiple Choice Questions in Basic StatisticsDocument8 pages40 Multiple Choice Questions in Basic StatisticsLevi CorralNo ratings yet

- Analysis of VariancesDocument40 pagesAnalysis of VariancesSameer MalhotraNo ratings yet

- LGFL Service GuideDocument24 pagesLGFL Service GuideThe Return of the NoiristaNo ratings yet

- Marksmanship: Subject: III. Definition of TermsDocument16 pagesMarksmanship: Subject: III. Definition of TermsAmber EbayaNo ratings yet

- Oracle Fusion Financials Book Set Home Page SummaryDocument274 pagesOracle Fusion Financials Book Set Home Page SummaryAbhishek Agrawal100% (1)

- Mythic Magazine 017Document43 pagesMythic Magazine 017William Warren100% (1)

- The Wafer-God and the Bloody History of the VaticanDocument58 pagesThe Wafer-God and the Bloody History of the VaticanMin Hotep Tzaddik BeyNo ratings yet

- Design and Analysis of Algorithms Prof. Madhavan Mukund Chennai Mathematical Institute Week - 01 Module - 01 Lecture - 01Document8 pagesDesign and Analysis of Algorithms Prof. Madhavan Mukund Chennai Mathematical Institute Week - 01 Module - 01 Lecture - 01SwatiNo ratings yet

- Overview for Report Designers in 40 CharactersDocument21 pagesOverview for Report Designers in 40 CharacterskashishNo ratings yet

- Body Scan AnalysisDocument9 pagesBody Scan AnalysisAmaury CosmeNo ratings yet

- Voltaire's Candide and the Role of Free WillDocument3 pagesVoltaire's Candide and the Role of Free WillAngy ShoogzNo ratings yet

- Consumer Behaviour Towards AppleDocument47 pagesConsumer Behaviour Towards AppleAdnan Yusufzai69% (62)

- Interna Medicine RheumatologyDocument15 pagesInterna Medicine RheumatologyHidayah13No ratings yet

- Long Run Average Cost (LRAC) : Economies of ScaleDocument3 pagesLong Run Average Cost (LRAC) : Economies of ScaleA PNo ratings yet

- VARCDocument52 pagesVARCCharlie GoyalNo ratings yet

- Learn Square Roots & Plot on Number LineDocument11 pagesLearn Square Roots & Plot on Number LineADAM CRISOLOGONo ratings yet