Professional Documents

Culture Documents

Big Baler Inspection

Uploaded by

Mohamed Yousif HamadOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Big Baler Inspection

Uploaded by

Mohamed Yousif HamadCopyright:

Available Formats

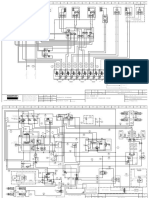

BIG BALER INSPECTION

NEW HOLLAND MAINTENANCE INSPECTION CHECKLIST

ITEM # COMMENTS

W.O. # _____________________________________________ CUSTOMER NAME ____________________________________

DATE _______________________________________________ ADDRESS ___________________________________________

MODEL ____________________________________________ CITY, STATE, ZIP _____________________________________

TECHNICIAN SIGNATURE ______________________________ PHONE _____________________________________________

P.I.N. _________________________ HOURS ______________ CUSTOMER SIGNATURE _______________________________

A B C S Safety Equipment A B C S Pickup and Stuffer Area (cont.) A B C S Plunger, Bale Chamber & Gear Box A B C S Miscellaneous (Cont.)

■ 1. Safety decals

■ 22. Holding finger linkage condition ■ 47. Gearbox mounting hardware ■ 65. Load increase/decrease test

■ 2. Safety railings condition and adjustment ■ 48. Gearbox oil level (change if after ■ 66. Sheet metal condition

■ 3. PTO Shields ■ 23. Stuffer chamber specified number of bales) ■ 67. Structure - cracks/welds

■ 4. Flasher lights ■ 24. Packer/Rotor cutters: ■ 49. Gearbox breather ■ 68. Missing and broken parts

■ 5. Safety chain knife sharpening/replacement ■ 50. Hay dog clearances ■ 69. Centralized grease lines and fittings

■ 6. Fire extinguisher? Yes r No r

Knotter and Needle Area ■ 51. Plunger rollers and plunger

clearances in the bale chamber

■ 70. Automatic greaser operation

(if equipped)

Pickup and Stuffer Area ■ 25. Knotter blower operation

26. Knotter gearbox oil level (change if■

52. Plunger knives: sharpening/ ■ 71. Auto oil pump and lines

■ 7. Pickup assembly, tines, cam track,

cam bearings and augers

■ after number of specified bales)

replacement, and adjustment ■ 72. Monitor function, fault codes

(check, investigate and clear)

■ ■

8. Pickup drive chain condition & tension 27. Knotter brake adjustment PTO Driveline

■ 73. Hydraulic oil level (change oil

■ ■

9. Pickup slip clutch/overrunning clutch 28. Twine disc/disc cleaner adjustment ■ 53. Bearing condition

and filter annually or every

function and adjustment ■ 29. Stripper arm condition and adjustment ■ 54. CV joint condition

10,000 bales)

■ 10. Pickup flotation adjustment ■ 30. Twine knife condition ■ 55. Flywheel clutch condition/adjustment

■ 74. Work lights

■ 11. Packer/Rotor drive chain condition ■ 31. Bill hook (wear or burrs) ■ 56. Flywheel brake adjustment

and tension ■ 32. Knotter gear cam lobe condition ■ 57. Flywheel shear bolt condition,

■ 12. Packer finger crank and bearings ■ 33. Knotter gears including main spare bolts on hand

■ 13. Packer finger slip clutch adjustment knotter gears (wear and condition)

Miscellaneous

■ 14. Stuffer to plunger timing ■ 34. Stripper arm cam lobe condition

■ 58. Switches and inductive sensors

■ ■

15. Stuffer gearbox oil level (change if 35. Needle to bale chamber adjustment

(condition and proper clearance)

after number of specified bales) ■ 36. Needle to twine disc adjustment

■ 59. Electrical connections

■ 16. Stuffer shear bolt condition; ■ 37. Needle penetration

■ 60. Wheel bearings

spare bolts on hand ■ 38. Needle rollers

■

■ 17. Stuffer brake adjustment ■ 39. Slacker arm rollers

■

61. Tires (condition and pressure)

■ 18. Stuffer driveshaft/ ■ 40. Tucker arm rollers

62. Hydraulic lines, valving and cylinders

(conditions and leakage)

■

bushings condition ■ 41. Tucker arm adjustment

■ 63. Hydraulic breathers

■

19. Stuffer clutch linkage ■ 42. Twine finger adjustment

■ 64. Operation of ejector

20. Stuffer and knotter chain condition

■ 43. Twine tension

■

and tension

■ 44. Knotter stack preload

■

21. Stuffer drive gear cam lobe condition 45. Needle to plunger timing A Critical – Must Repair

■ 46. Needle protection linkage adjustment B

C

Operational – Signs of wear

OK

S Passed Inspection - Service Provided

This information is only for the purpose of suggesting possible repair or treatment of equipment. Any remedy will

be limited to the amount of the inspection fee. Dealer makes no expressed or implied warranties, and disclaims any PM-14362

incidental or consequential damages. Rev 3/09

You might also like

- Manual Singer 132K6 Seiko SK-7 SK-8 SK-26 OsDocument10 pagesManual Singer 132K6 Seiko SK-7 SK-8 SK-26 OsAndrew OrmeNo ratings yet

- EL-CU 5 7501-0809-03-EnDocument64 pagesEL-CU 5 7501-0809-03-EnLiviu AndreiNo ratings yet

- Bayliner 175 ManualDocument44 pagesBayliner 175 ManualsandywilsonukNo ratings yet

- Owner S ManualDocument68 pagesOwner S Manualfadrique54No ratings yet

- Schartec P190 Control Box EnglishDocument15 pagesSchartec P190 Control Box EnglishGeorge Ciprian GheorgheNo ratings yet

- LH D6230Document52 pagesLH D6230aurelio38No ratings yet

- NAE061BS - Lainox Install ManualDocument44 pagesNAE061BS - Lainox Install ManualFubas TeixeiraNo ratings yet

- Single & Dual Load Sensing, Accumulator Charging ValveDocument8 pagesSingle & Dual Load Sensing, Accumulator Charging Valvetystar_21No ratings yet

- White 1750 Sewing Machine Instruction ManualDocument31 pagesWhite 1750 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Shaft Alignment and Couplings - Course Sample - 596133-603909Document35 pagesShaft Alignment and Couplings - Course Sample - 596133-603909Kioko PaulNo ratings yet

- Check Line MMX-6 Manual TI-25M-MMXDocument15 pagesCheck Line MMX-6 Manual TI-25M-MMXDragoș L. I. TeodorescuNo ratings yet

- MacRoy D IOMDocument60 pagesMacRoy D IOMRicardo VeraNo ratings yet

- White 869/870 Sewing Machine Instruction ManualDocument34 pagesWhite 869/870 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Construction Manual: 12', 15', 18' and 21' Hopper BinsDocument48 pagesConstruction Manual: 12', 15', 18' and 21' Hopper Binsgabriel sanchez100% (1)

- OYO Elastmeter-2 & Elast Logger-2Document2 pagesOYO Elastmeter-2 & Elast Logger-2ANTONIO LOZANONo ratings yet

- ATRO Field Manual 061214Document68 pagesATRO Field Manual 061214Raja Sekaran Sajja100% (1)

- Manual de Tuerca Hidraulica-Desbloqueado-editadoDocument37 pagesManual de Tuerca Hidraulica-Desbloqueado-editadomauriciojjNo ratings yet

- Ac MaintenanceDocument2 pagesAc MaintenanceGautam Sootgirni100% (1)

- PDFDocument4 pagesPDFalx56No ratings yet

- اصطلاحات دکل حفاري PDFDocument23 pagesاصطلاحات دکل حفاري PDFmhaioocNo ratings yet

- Ficha Tecnica RetroexcavadoraDocument9 pagesFicha Tecnica RetroexcavadoraLeandro LopezNo ratings yet

- 2012 Crown CatalogDocument466 pages2012 Crown CatalogJulio Corzo100% (2)

- 750-234 CB780E - 784E ManualDocument48 pages750-234 CB780E - 784E ManualRicardo Felipe Cortes MenayNo ratings yet

- John Bean Mod. 8.6-8.7Document36 pagesJohn Bean Mod. 8.6-8.7dionisio emilio reyes jimenezNo ratings yet

- AD 22 FuelOilSystemsDocument4 pagesAD 22 FuelOilSystemsCire Lop CastroNo ratings yet

- Manual Citizen No 0870Document9 pagesManual Citizen No 0870argenismensajesNo ratings yet

- Ford 1998 4.0 Intake Gasket ReplacementDocument10 pagesFord 1998 4.0 Intake Gasket Replacementmarvstewart100% (1)

- Roller Cone Design ApplicationDocument60 pagesRoller Cone Design Applicationamin peyvandNo ratings yet

- Power Shuttle - Pinion Cage, Output Shaft, and Control ValveDocument4 pagesPower Shuttle - Pinion Cage, Output Shaft, and Control ValveLuis f. C100% (1)

- Gas Compressor Unit (7 Compressor) ON-Z-1301 A/B/C/D/E/F/GDocument28 pagesGas Compressor Unit (7 Compressor) ON-Z-1301 A/B/C/D/E/F/GSoumitra GuptaNo ratings yet

- 808 - White 675 XDocument48 pages808 - White 675 XADS MultimediaNo ratings yet

- DD311 Planos HidráulicosDocument8 pagesDD311 Planos HidráulicosBrayan vidal López GuzmánNo ratings yet

- Aries Maintenance Manual Rev ADocument314 pagesAries Maintenance Manual Rev AMauro PérezNo ratings yet

- Disc Go Solo User S ManualDocument14 pagesDisc Go Solo User S Manualhurditchaol.comNo ratings yet

- Huddig 1260 BDocument8 pagesHuddig 1260 BForomaquinas0% (1)

- White 5500 Sewing Machine Instruction ManualDocument62 pagesWhite 5500 Sewing Machine Instruction Manualiliiexpugnans100% (1)

- Dec Pump Assembly Cross Sectional Drawing e Agitator d7868Document11 pagesDec Pump Assembly Cross Sectional Drawing e Agitator d7868GabrielNo ratings yet

- Booster Pumps MANUAL PDFDocument70 pagesBooster Pumps MANUAL PDFMallinatha PNNo ratings yet

- Beta Marine BV1305 Operation and Maintenance ManualDocument68 pagesBeta Marine BV1305 Operation and Maintenance ManualJoe Zhao100% (1)

- 994K WHLLDR Course en INSDocument80 pages994K WHLLDR Course en INSAngela AllenNo ratings yet

- C302 (Revised 1-2009) Manual PDFDocument22 pagesC302 (Revised 1-2009) Manual PDFClifford BernardNo ratings yet

- L27 - 38 - MDO Maintenance ProgramDocument2 pagesL27 - 38 - MDO Maintenance Programventa kevaraNo ratings yet

- 09 EP-tronic ControllingDocument8 pages09 EP-tronic ControllingSugiharto RichardNo ratings yet

- Sport Jet Installation: Printed in U.S.ADocument21 pagesSport Jet Installation: Printed in U.S.Aopa952ya.ruNo ratings yet

- John Deere Lawn Garden Tractor Parts Manual JD P pc1507Document9 pagesJohn Deere Lawn Garden Tractor Parts Manual JD P pc1507TippiNo ratings yet

- DISC-GO-ROBOTO ManualDocument20 pagesDISC-GO-ROBOTO Manualpeterl@discgotech.comNo ratings yet

- Serp5171-08 - Cdmaster Manual Partes R1600G 9YZ PDFDocument817 pagesSerp5171-08 - Cdmaster Manual Partes R1600G 9YZ PDFNil MarNo ratings yet

- DIN - Metric: D0 CF CE CADocument51 pagesDIN - Metric: D0 CF CE CADinesh SaravanaNo ratings yet

- (NISSAN) Manual de Taller Nissan Motor GA16Document18 pages(NISSAN) Manual de Taller Nissan Motor GA16Andres Fdo Mora DNo ratings yet

- Bombas de Lodo Blackmer MODELS: MLX4B, MLXW4B, MRLX4B, MRLXW4BDocument4 pagesBombas de Lodo Blackmer MODELS: MLX4B, MLXW4B, MRLX4B, MRLXW4Bnardo_ingNo ratings yet

- 4150K and 4160K Series Wizard II Pressure Transmitters ControllersDocument40 pages4150K and 4160K Series Wizard II Pressure Transmitters ControllersAkli DjebbariNo ratings yet

- Catalogo McGUILLDocument16 pagesCatalogo McGUILLJHON FERNEY BOHORQUEZ SALDARRIAGANo ratings yet

- Yanmar GMHMWorkshopManualDocument240 pagesYanmar GMHMWorkshopManualMarius Circeie100% (1)

- 1091624R2-SM-ENG-IH International Diesel Engine-D-155, D-179, D-206, D-239, D-246, D-268, D-310, D-358, DT-239, DT-358Document108 pages1091624R2-SM-ENG-IH International Diesel Engine-D-155, D-179, D-206, D-239, D-246, D-268, D-310, D-358, DT-239, DT-358VìctorMqz89% (9)

- DSR Ex 125Document120 pagesDSR Ex 125hugocalero4No ratings yet

- GB RockBreaker Manual PDFDocument84 pagesGB RockBreaker Manual PDFSerkanAl100% (4)

- Step 2 Vol 11 Steering SystemDocument118 pagesStep 2 Vol 11 Steering SystemPuput KheciilNo ratings yet

- Ection Aintenance: Revision March 2008Document20 pagesEction Aintenance: Revision March 2008Jonathan Montes coronaNo ratings yet

- Hawkjaw Jr. Manual 65K-950JR Serial Numbers 72 To 223Document155 pagesHawkjaw Jr. Manual 65K-950JR Serial Numbers 72 To 223MASAGUS MANGKU GAMANo ratings yet

- Brake SystemDocument106 pagesBrake SystemMohamed Yousif HamadNo ratings yet

- BodyDocument159 pagesBodyMohamed Yousif HamadNo ratings yet

- 2019 Toyota VIN DecoderDocument11 pages2019 Toyota VIN DecoderMohamed Yousif Hamad100% (1)

- Error CodesDocument4 pagesError CodesMohamed Yousif HamadNo ratings yet

- Cat Electronic Technician 2021B v1.0 Product Status ReportDocument7 pagesCat Electronic Technician 2021B v1.0 Product Status ReportMohamed Yousif HamadNo ratings yet

- Caterpillar: Confidential GreenDocument3 pagesCaterpillar: Confidential GreenMohamed Yousif Hamad100% (1)

- Hauling Systems Baseline Production Study TEXR0493Document48 pagesHauling Systems Baseline Production Study TEXR0493Mohamed Yousif HamadNo ratings yet

- Mining and Earthmoving: Elements of ProductionDocument16 pagesMining and Earthmoving: Elements of ProductionMohamed Yousif HamadNo ratings yet

- ETS Operator Training Services-North AmericaDocument2 pagesETS Operator Training Services-North AmericaMohamed Yousif HamadNo ratings yet

- CT Manual 3.0.2Document31 pagesCT Manual 3.0.2Mohamed Yousif HamadNo ratings yet

- Command For Dozing: Build Efficiency and Enhance Safety With Dozing AutomationDocument2 pagesCommand For Dozing: Build Efficiency and Enhance Safety With Dozing AutomationMohamed Yousif HamadNo ratings yet

- Pel.6.SIMS ProblemDocument6 pagesPel.6.SIMS ProblemMohamed Yousif HamadNo ratings yet

- 885b BulletinDocument7 pages885b BulletinMohamed Yousif HamadNo ratings yet

- Technical Training 2016 Market Dealer Name Brand Training CentreDocument6 pagesTechnical Training 2016 Market Dealer Name Brand Training CentreMohamed Yousif HamadNo ratings yet

- Multiple Files Are Bound Together in This PDF Package.: Click Here To Download The Latest Version of Adobe ReaderDocument1 pageMultiple Files Are Bound Together in This PDF Package.: Click Here To Download The Latest Version of Adobe ReaderMohamed Yousif HamadNo ratings yet

- Sims Report Description Code: Letter Code Description Numeric Code Letter Code Description Numeric CodeDocument1 pageSims Report Description Code: Letter Code Description Numeric Code Letter Code Description Numeric CodeMohamed Yousif HamadNo ratings yet

- Incident Details WorksheetDocument2 pagesIncident Details WorksheetMohamed Yousif HamadNo ratings yet

- Timing ChainDocument6 pagesTiming ChainMohamed Yousif HamadNo ratings yet

- Part Number Qty Description 47635916 1 Hydraulic Oil Filter 47587350 1 Breather MMJ80060 1 Hydraulic Oil FilterDocument1 pagePart Number Qty Description 47635916 1 Hydraulic Oil Filter 47587350 1 Breather MMJ80060 1 Hydraulic Oil FilterMohamed Yousif HamadNo ratings yet

- Proforma Invoice: Terms and ConditionsDocument1 pageProforma Invoice: Terms and ConditionsMohamed Yousif HamadNo ratings yet

- Crawler Excavator CX350B - CX370B Service Manual: 1 General InformationDocument1 pageCrawler Excavator CX350B - CX370B Service Manual: 1 General InformationMohamed Yousif HamadNo ratings yet

- BEAM1224 Data SheetDocument2 pagesBEAM1224 Data SheetWilliam DiasNo ratings yet

- SG Iconia Tab w500 BookDocument521 pagesSG Iconia Tab w500 BookAbhilash VamanNo ratings yet

- History of Stainless SteelDocument24 pagesHistory of Stainless SteelSaravanan KanagavelNo ratings yet

- Company Profile 2022 (Feb)Document24 pagesCompany Profile 2022 (Feb)Johanes Pauji SihombingNo ratings yet

- John Mark Laranan Zambale LongDocument2 pagesJohn Mark Laranan Zambale LongKevin LlemosNo ratings yet

- Flexible Manufacturing SystemsDocument40 pagesFlexible Manufacturing SystemsHanoz Patel100% (1)

- Mechanics of Materials - Stress Risers in A Cantilever Flexure TestDocument20 pagesMechanics of Materials - Stress Risers in A Cantilever Flexure TestDavid Clark100% (1)

- CEE+3346b WZ PartII 2016Document80 pagesCEE+3346b WZ PartII 2016Chachi CNo ratings yet

- Sap GRCDocument8 pagesSap GRCrajesh.sapNo ratings yet

- Phys QUIZDocument345 pagesPhys QUIZvpo1673No ratings yet

- Special Purpose Lathes: Manufacturing Technology and Surface EngineeringDocument15 pagesSpecial Purpose Lathes: Manufacturing Technology and Surface EngineeringKarthi KeyanNo ratings yet

- Pending WIR Updated StatusDocument9 pagesPending WIR Updated StatusResearcherNo ratings yet

- Allen Bradley SMC 150 - CatDocument2 pagesAllen Bradley SMC 150 - Catjohn_jjNo ratings yet

- Substation GroundingDocument4 pagesSubstation GroundingNassar AbdulrahimanNo ratings yet

- Mastertools Precision Engineers & Toolmakers CatalogueDocument3 pagesMastertools Precision Engineers & Toolmakers CatalogueNcir TaherNo ratings yet

- Chapter 7 Introduction To Rock EngineeringDocument78 pagesChapter 7 Introduction To Rock EngineeringsyafiqNo ratings yet

- Line Station Manual: QTR TechnicalDocument269 pagesLine Station Manual: QTR TechnicalSAIF YOUNSINo ratings yet

- 123 KV Dry Flexible Termination TFD 123: Cable Accessories and ConnectorsDocument2 pages123 KV Dry Flexible Termination TFD 123: Cable Accessories and ConnectorsnarinderNo ratings yet

- Adr 132 BDocument5 pagesAdr 132 Btandin tshewangNo ratings yet

- Specsheet Chromebase Commercial 22 PDFDocument2 pagesSpecsheet Chromebase Commercial 22 PDFMarisagarcia2014No ratings yet

- Yamaha - RX v620 - HTR 5460 - RX v620rds 1 PDFDocument84 pagesYamaha - RX v620 - HTR 5460 - RX v620rds 1 PDFLuis BarreirinhasNo ratings yet

- A320 NEO Abbreviations LEAP-1ADocument5 pagesA320 NEO Abbreviations LEAP-1AwenjukwaxNo ratings yet

- SAP BiddingDocument36 pagesSAP BiddingLakhya Pratim BaruahNo ratings yet

- PFI ES-25-1993 Random Radiography of Pressure Retaining Girth Butt WeldsDocument6 pagesPFI ES-25-1993 Random Radiography of Pressure Retaining Girth Butt WeldsThao NguyenNo ratings yet

- Eaton SIHA PURANIT TechnicalDataSheet enDocument2 pagesEaton SIHA PURANIT TechnicalDataSheet enEnriqueNo ratings yet

- Ceilcote 2000 Flakeline+wp+engDocument3 pagesCeilcote 2000 Flakeline+wp+engMohamed NouzerNo ratings yet

- Mech VibrationDocument14 pagesMech VibrationSquakx BescilNo ratings yet

- ABB - KPM - All - Products Eng v1.0 - FINALDocument12 pagesABB - KPM - All - Products Eng v1.0 - FINALJeff RobertNo ratings yet

- Relé Eletromecânico (COM)Document32 pagesRelé Eletromecânico (COM)Ederson AparecidoNo ratings yet

- Moumita ResumeDocument2 pagesMoumita Resumemoumita2007No ratings yet