Professional Documents

Culture Documents

Installation Manual: JY997D26401A

Uploaded by

carlcoxOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Manual: JY997D26401A

Uploaded by

carlcoxCopyright:

Available Formats

JY997D26401A

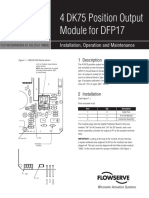

Certification of UL, cUL standards 1.3 External Dimensions, Part Names, and Pin Configuration 1.4 Pin Configuration

The FX3U-232ADP-MB unit supports UL and cUL standards. 1.3.1 External Dimensions and part name The pin configuration of the RS-232C port on the 232ADP-MB is as shown below.

UL, cUL file number :E95239 [13] Screws to fix Pin

[3] [4] [5] RS-232C Signal Name Function

No.

connector

Compliance with EC directive(CE Marking ) [6] FX3U-232ADP

-MB

Receive ON when carrier for data reception

This document does not guarantee that a mechanical system including this product will [7] 1 CD carrier is detected.

FX3U-232ADP-MB comply with the following standards.

[2]

[8] 5

9 detection (RS-232C device to 232ADP-MB)

Compliance to EMC directive of the entire mechanical system should be checked by

Installation Manual the user / manufacturer. For more details please contact the local Mitsubishi Electric

sales site. [9] 6

2

RD

(RXD)

Receive

data

Receive data

(RS-232C device to 232ADP-MB)

106(4.18")

1

90(3.55")

98(3.86")

Manual Number JY997D26401 Requirement for Compliance with EMC directive [1] SD Send data

3 Send data

The FX 3U-232ADP-MB is compliant through direct testing (of the identified standards (TXD) (232ADP-MB to RS-232C device)

Revision A Screw holes:

below) and design analysis (through the creation of a technical construction file) to the #4-40UNC ON when RS-232C device is ready

[10] ER Send

Date April 2007 European Directive for Electromagnetic Compatibility (89/336/EEC) when used as (inch screw 4 to receive data.

directed by the appropriate documentation. thread) (DTR) request

[11] (232ADP-MB to RS-232C device)

This manual describes the part names, dimensions, mounting, and SG Signal Signal ground

specifications of the product. Before use, read this manual and manuals of Standard Remark 5

(GND) ground (232ADP-MB to RS-232C device)

relevant products fully to acquire proficiency in handling and operating the EN61131-2:2003 Compliance with all relevant aspects of the

product. Make sure to learn all the product information, safety information, and Programmable controllers standard. 7(0.28") 74(2.92") 7.5 ON when send request is made

precautions. 15.1 DR Send

- Equipment requirements and • Radiated Emissions (0.29") [12] 6 toward RS-232C device.

And, store this manual in a safe place so that you can take it out and read it (0.6") (DSR) enable

tests (RS-232C device to 232ADP-MB)

whenever necessary. Always forward it to the end user. • Mains Terminal Voltage Emissions [14] 17.6

Registration • RF immunity (0.7") 7,8,9 Not used Do not wire.

Special adapter

MODBUS® is a registered trademark of Schneider Electric S.A. • Fast Transients connector cover

The company name and the product name to be described in this manual are is removed

the registered trademarks or trademarks of each company. • ESD • Surge

• Voltage drops and interruptions

Weight: Approx. 80g (0.18 lbs) 2. Channel Allocation

Effective April 2007 Up to two communication ports can be added to the main unit.

Specifications are subject to change without notice. • Conducted

[1] DIN rail mounting groove (DIN rail: DIN46277) Communication port channels are automatically allocated. The closer

© 2007 Mitsubishi Electric Corporation • Power magnetic fields communication special adapter to the main unit is ch1.

[2] Name plate

[3] Special adapter slide lock: • Using one communication special adapter + communication expansion board

Safety Precaution (Read these precautions before use.) Used to connect special adapter on left side of this special adapter. (ch2) Communication

This manual classify the safety precautions into two categories: Caution for compliance with EC Directive [4] Special adapter connector cover: expansion board (ch1)

Installation in Enclosure Remove this cover for connecting special adapter on the left side.

and .

Programmable logic controllers are open-type devices that must be installed and used [5] Direct mounting hole:2 holes of φ4.5 (0.18") (mounting screw: M4 screw) Analog Analog FX3U- Analog Analog

within conductive control boxes. Please use the FX3U Series programmable logic special special 232ADP special special

Indicates that incorrect handling may cause hazardous [6] POWER LED (green): Lit while 5V DC power is supplied from main unit. function function -MB function function Main unit

controllers while installed in conductive shielded control boxes. Please secure the

conditions, resulting in death or severe injury. control box lid to the control box (for conduction). Installation within a control box [7] RD LED (red): adapter adapter adapter adapter

greatly affects the safety of the system and aids in shielding noise from the Lit while receiving data from connected RS-232C device.

Indicates that incorrect handling may cause hazardous programmable logic controller. [8] SD LED (red):

• Using two communication special adapters

conditions, resulting in medium or slight personal injury Lit while sending data to connected RS-232C device.

or physical damage. [9] Special adapter connector: (ch2) (ch1) FX3U-CNV-BD

1. Outline

The FX3U-232ADP-MB communication special adapter (hereinafter called 232ADP- Used to connect this special adapter to PLC main unit or special adapter.

Depending on circumstances, procedures indicated by may also be MB) is a special adapter for RS-232C communication with an 9-pin D-Sub connector. [10] RS-232C connector (9-pin D-Sub, male):

Analog Analog FX3U- Analog Analog FX3U-

linked to serious results. 232ADP-MB is an isolated signal exchange unit of the RS-232C serial data Connect RS-232C device to this RS-232C connector special special 232ADP special special 232ADP

In any case, it is important to follow the directions for usage. function function -MB function function -MB Main unit

communication between the PLC and RS-232C device. [11] Screws to fix a cable connector: Screw holes #4-40UNC (inch screw thread)

The FX3U-232ADP-MB features all functionality that is available with the FX3U- adapter adapter adapter adapter

[12] DIN rail mounting hook

232ADP, except that it also has MODBUS communication available. [13] Special adapter fixing hook

Associated Manuals [14] Special adapter connector:

1.1 Communication Function Used to connect communication special adapter or analog special adapter to

Manual name Manual No. Description

this adapter on left side.

Communication type Function

FX3U Series JY997D16501 Explains FX 3U Series PLC

specification details for I/O, Data transfer via dedicated protocol between PLC and

User’s Manual MODEL CODE: Computer link

wiring, installation, and computer (specified as the master station).

- Hardware Edition 09R516 maintenance.

Non-protocol Serial communication via non-protocol between PLC and

FX3U /FX3UC Series

JY997D16601 Describes PLC programming communication RS-232C device.

Programming Manual

MODEL CODE: for basic/applied instructions

- Basic & Applied Programming Optional port available for suitable programming tool when

09R517 and devices.

Instruction Edition communication 232ADP-MB is connected to PLC.

FX Series User’s Explains N:N link, parallel

JY997D16901 Program transfer or monitoring enabled via modem and

Manual link, computer link, no Remote maintenance

MODEL CODE: phone line connected to serial port of PLC.

- Data Communication protocol communication by

09R715 RS instructions/FX2N-232IF.

Edition MODBUS

Data transfer between a master and a slave.

FX3U Series User’s communication

Manual Explains the MODBUS serial

JY997D26201

- MODBUS Serial communication network.

Communication Edition

1.2 Incorporated Items

Check if the following product and items are included in the package:

How to obtain manuals Product Manual

For the necessary product manuals or documents, consult with the Mitsubishi FX3U-232ADP

Electric dealer from where you purchase your product. -MB

POWER

RD

SD This

manual

3. Installation 4. Wiring 5.4 Performance Specification

The product can be mounted on a DIN rail (DIN46227) or mounted directly using For details of wiring, refer to FX Series User's Manual - Data Communication Edition,

Item Specification

screws. and FX3U Series User’s Manual - MODBUS Serial Communication Edition.

For installation/uninstallation and safety precautions, refer to the following Transmission

WIRING Conforming to RS-232C

manuals: standard

PRECAUTIONS

→ Refer to the FX3U Series User's Manual - Hardware Edition.

Type of isolation Photocoupler isolation

• Cut off all phases of power source externally, before installation or wiring work in

INSTALLATION order to avoid electric shock or damage of product. Transmission

PRECAUTIONS 15m (49’ 2") or less

distance

• Cut off all phases of the power source externally before starting the WIRING Connection method 9-pin D-Sub connector (male)

installation or wiring work, thus avoiding electric shock or damages to the PRECAUTIONS

Number of occupied 0 point (This number is not related to the maximum number

product.

• Never let cutting chips and wire chips enter the ventilation slits of this product or I/O points of input/output points of the PLC.)

PLC when performing wiring.

INSTALLATION Otherwise, fire, failure or malfunction may occur. Communication

Full-duplex

PRECAUTIONS method

• Make sure to observe the precautions below in order to prevent any damage to a

• Use the product in the environment within the general specifications machine or any accident which might be caused by abnormal data written in the C omp ute r l in k , n on- pr oto c ol c om muni c at i on, an d

described in PLC main unit manual (Hardware Edition). PLC due to the influence of noise: MODBUS:

Never use the product in areas with dust, oily smoke, conductive dusts, 1) Do not lay close or bundle with the main circuit, high-voltage power line, or Baud rate 300/600/1200/2400/4800/9600/19200 bps

corrosive gas (salt air, Cl2, H2S, SO 2, or NO2), flammable gas, vibrations or load line. Programming communication:

impacts, or expose it to high temperature, condensation, or wind and rain. Otherwise effects of noise or surge induction are likely to take place. 9600/19200/38400/57600/115200bps

If the product is used in such a place described above, electrical shock, fire, Keep a safe distance of more than 100 mm (3.94") from the above when Computer link (dedicated protocol: format 1/format 4),

malfunction, damage, or deterioration may be caused. wiring. Communication

Non-protocol, Programming communication,

2) Ground the shield wire or shield of a shielded cable at one point on the PLC. format

• When drilling screw holes or wiring, cutting chips or wire chips should not and MODBUS (RTU, ASCII)

enter ventilation slits. However, do not ground at the same point as high voltage lines.

LED display:

Such an accident may cause fire, failure or malfunction. Power: green, RD: red, SD: red

LED color

• Do not touch the conductive parts of the product directly, thus avoiding failure

or malfunction.

• Fix the special adapter securely to the specified connector.

5. Specification

Incorrect connection may cause malfunction.

STARTUP AND

MAINTENANCE

PRECAUTIONS

3.1 Connection to the FX 3U Series PLC

• Refer to the procedure 2) for configuring a new system. • Do not disassemble or modify the unit.

• Refer to the procedure 1) for adding product to an existing system. Doing so may cause failure, malfunction or fire.

* For repair, contact your local Mitsubishi Electric distributor.

Procedure • Do not drop the product or do not exert strong impact, doing so may cause

1) Turn off the power. damage.

Disconnect all the cables connected to the PLC main unit and special adapter.

Dismount the main unit and special adapter mounted on DIN rail or mounted DISPOSAL

directly using screws. PRECAUTIONS

2) Install an expansion board to the main unit.

For installation of expansion board, refer to the following manual: • Please contact a company certified in the disposal of electronic waste for

→ Refer to the FX3U Series User's Manual - Hardware Edition. environmentally safe recycling and disposal of your device.

3) Remove the special adapter connector cover

on the expansion board (Right fig.A). TRANSPORT AND

In case of connecting this product to another STORAGE PRECAUTIONS

S

/E

R

8M

-48M

special adapter, please replace the 4)

-4

3U

3U

FX

FX

'expansion board' in the above description • During transportation avoid any impact as the product is a precision instrument.

with a 'special adapter' and perform the Check the operation of the product after transportation.

N

RU

procedure as indicated. ST

OP

4) Slide the special adapter slide lock (Right B 3)

fig.B) of the main unit. 4) 5.1 Applicable PLC

In case of connecting this product to another This manual confers no industrial property rights or any rights of any other kind,

special adapter, please replace the 'main A Model name Applicability nor does it confer any patent licenses. Mitsubishi Electric Corporation cannot be

unit' in the above description with a 'special Ver. 2.40 and later for MODBUS communication held responsible for any problems involving industrial property rights which may

adapter' and perform the procedure as FX 3U Series PLC Ver. 2.20 and later for all communication functions except occur as a result of using the contents noted in this manual.

indicated. (Please replace the following MODBUS

procedures similarly.) B Warranty

5) Connect the The version number can be checked by monitoring D8001, as well the last three digits Mitsubishi will not be held liable for damage caused by factors found not to be

special adapter B FX -48M 3U

indicate the version number. the cause of Mitsubishi; opportunity loss or lost profits caused by faults in the

(Right fig.C) to C R/E

S

Mitsubishi products; damage, secondary damage, accident compensation

F

X

-48M

3U

-2

8M

32 -M

3U

caused by special factors unpredictable by Mitsubishi; damages to products

A B

FX

-4

D

P

the main unit as

3U

P

O

FX

W

5.2 General Specifications

R

E

D

R

S

D

6) other than Mitsubishi products; and to other duties.

shown on the

For general specifications, refer to the PLC main unit manual.

right. N

The following items are not equivalent to the PLC main unit.

RU

OP

6) Slide back the

For safe use

ST

special adapter 5) Item Specification

slide lock (Right 6)

Dielectric withstand • This product has been manufactured as a general-purpose part for general

fig.B) of the main 500 V AC, 1 min

voltage Conforming to JEM-1021 industries, and has not been designed or manufactured to be incorporated in

unit to fix the 5) Between terminal block and ground a device or system used in purposes related to human life.

special adapter 5MΩ or more, 500 V terminal of PLC main unit

Insulation resistance • Before using the product for special purposes such as nuclear power, electric

(Right fig.C). DC by Megger power, aerospace, medicine or passenger movement vehicles, consult with

5) Mitsubishi Electric.

B

• This product has been manufactured under strict quality control. However

5.3 Power Supply Specification when installing the product where major accidents or losses could occur if the

product fails, install appropriate backup or failsafe functions in the system.

Connection precautions Item Specification

Connect all the high-speed I/O special adapters before connecting other

Current 30mA

special adapters when they are used in combination.

consumption 5V DC power is supplied internally from the main unit.

Do not connect a high-speed I/O special adapter on the left side of a

communication or analog special adapter. HEAD OFFICE : TOKYO BUILDING, 2-7-3 MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310,

JAPAN

HIMEJI WORKS : 840, CHIYODA CHO, HIMEJI, JAPAN

You might also like

- k3fCU2A SheetDocument2 pagesk3fCU2A SheetAlNo ratings yet

- PTC Creo Parametric generator base dimensionsDocument2 pagesPTC Creo Parametric generator base dimensionsmahranNo ratings yet

- Installation Guide AUA234C Issue 3 SLC 5 SLC 2000 Intelligent All Rate DS0 DataportDocument2 pagesInstallation Guide AUA234C Issue 3 SLC 5 SLC 2000 Intelligent All Rate DS0 DataportKendric ShahidNo ratings yet

- Parametros Keb F5 Gearless PDFDocument40 pagesParametros Keb F5 Gearless PDFcarlos netoNo ratings yet

- Nokia 6233 rm-145 6234 rm-123Document10 pagesNokia 6233 rm-145 6234 rm-123me academyNo ratings yet

- Service Schematics: Exploded View and Component DisposalDocument9 pagesService Schematics: Exploded View and Component DisposalВладимир КлюевNo ratings yet

- SR-X Series: Built-In AI Code Reader Instruction ManualDocument8 pagesSR-X Series: Built-In AI Code Reader Instruction Manualgerco12No ratings yet

- Setting up the SC-VK92D DVD playerDocument1 pageSetting up the SC-VK92D DVD playerSwj OkeNo ratings yet

- Acs 6t UsermanualDocument4 pagesAcs 6t UsermanualMuhammad rizkiNo ratings yet

- Sony Kdl-26m3000 Kdl-32m3000 Kdl-26ml130 Kdl-32ml130 Chassis Ma1 PartlistDocument28 pagesSony Kdl-26m3000 Kdl-32m3000 Kdl-26ml130 Kdl-32ml130 Chassis Ma1 PartlistJosé julio AlejoNo ratings yet

- CHK Ksau MCS 00Document7 pagesCHK Ksau MCS 00AhmedNo ratings yet

- Schematics and SchedulesDocument24 pagesSchematics and SchedulesWassim DaherNo ratings yet

- EGX100 - Installation Guide PDFDocument2 pagesEGX100 - Installation Guide PDFRodolfoAntonioLeónCárdenasNo ratings yet

- GW-01 Setup Manual: Package Checklist Dimensions Installation Procedure Configuring IP and Network SettingsDocument1 pageGW-01 Setup Manual: Package Checklist Dimensions Installation Procedure Configuring IP and Network SettingsGeovanni CandoNo ratings yet

- IC Card Instruction Manual A00Document1 pageIC Card Instruction Manual A00Mahmoud Omar Rob50% (2)

- 3070-8010 Englisch PDFDocument45 pages3070-8010 Englisch PDFBryan AndresNo ratings yet

- BG NAC 3 Install GuideDocument2 pagesBG NAC 3 Install GuideArnie SaysonNo ratings yet

- 00f5sebk320 (1) - KEB FR - VáltóDocument41 pages00f5sebk320 (1) - KEB FR - Váltóanon_642273631No ratings yet

- KT-302H Series: Instruction ManualDocument1 pageKT-302H Series: Instruction ManualputrastevanofyNo ratings yet

- Fx3u 4ad, Installation ManualDocument3 pagesFx3u 4ad, Installation Manualrov1976No ratings yet

- Fx3u 4ad, Installation ManualDocument3 pagesFx3u 4ad, Installation ManualELIAS FARCIROLINo ratings yet

- FBC9080 Fieldbus Converter Installation ManualDocument2 pagesFBC9080 Fieldbus Converter Installation ManualTHANGABALU RAJENDIRANNo ratings yet

- Guia Práctica de Interpretacià N de La Resolucià N SRT 9002015 Protocolo de Medicià N de Puesta A TierraDocument2 pagesGuia Práctica de Interpretacià N de La Resolucià N SRT 9002015 Protocolo de Medicià N de Puesta A TierraSergio Fabian VasicekNo ratings yet

- V-RTU2000 Catalogue WebDocument13 pagesV-RTU2000 Catalogue Webh.torabyNo ratings yet

- Powerflex 520-Series Ac Drive Specifications: Technical DataDocument50 pagesPowerflex 520-Series Ac Drive Specifications: Technical DataaguilerabrNo ratings yet

- k3fFUEA SheetDocument2 pagesk3fFUEA SheetAlNo ratings yet

- Trans-Auto Eng Short v15Document28 pagesTrans-Auto Eng Short v15asif MehmoodNo ratings yet

- GTA04b7v2 Block Diagram Work in ProgressDocument1 pageGTA04b7v2 Block Diagram Work in Progressjornada660No ratings yet

- Drive Servo Motor OmronDocument169 pagesDrive Servo Motor OmronppeserviceNo ratings yet

- SomatecDocument123 pagesSomatecAdi kurniantoNo ratings yet

- EIGRP Configuration and Operation: ScenarioDocument5 pagesEIGRP Configuration and Operation: ScenarioAdedayoNo ratings yet

- AF-600 FP General Electric VFDDocument91 pagesAF-600 FP General Electric VFDRodo RequenaNo ratings yet

- nb868 User Guide v2.2.3Document25 pagesnb868 User Guide v2.2.3BENTABET AKILANo ratings yet

- Installation Manual: FX - CanDocument2 pagesInstallation Manual: FX - CanELIAS FARCIROLINo ratings yet

- SYS-1019D-16C-RAN13TP+ Quick Reference GuideDocument1 pageSYS-1019D-16C-RAN13TP+ Quick Reference GuideSribller DribbleNo ratings yet

- RTL9210-VB-CG Demo V203 PDFDocument5 pagesRTL9210-VB-CG Demo V203 PDFCenusa MihaiNo ratings yet

- Quectel L96 Reference Design V1.1Document10 pagesQuectel L96 Reference Design V1.1Raul LunaNo ratings yet

- HDX Static Hydraulic Universal Testing System Reference ManualDocument36 pagesHDX Static Hydraulic Universal Testing System Reference Manualasep rifky subagja (Rifky)No ratings yet

- Toshiba Aplio 300 Service ManualDocument507 pagesToshiba Aplio 300 Service Manualkriton88% (26)

- Default Switch/Jumper SettingsDocument16 pagesDefault Switch/Jumper SettingsRafael Avella100% (1)

- Wcenim2064 en AqDocument4 pagesWcenim2064 en AqaleNo ratings yet

- Service Manual (Unique) : History Information For The Following ManualDocument27 pagesService Manual (Unique) : History Information For The Following ManualClubedoTecnicoNo ratings yet

- Installation Overview D9/D16 MG MCC: MCC Electrical Connection Box AUX, Emergency and CombinedDocument2 pagesInstallation Overview D9/D16 MG MCC: MCC Electrical Connection Box AUX, Emergency and CombinedKareem TosonNo ratings yet

- MNF. Name PlateDocument2 pagesMNF. Name PlateSuper 7No ratings yet

- 42PFL4007G-78 Service+fonte PDFDocument74 pages42PFL4007G-78 Service+fonte PDFPedro AfonsoNo ratings yet

- 42PFL4007G-78 Service+fonte PDFDocument74 pages42PFL4007G-78 Service+fonte PDFAntonio MacedoNo ratings yet

- TRANS-AMF Automatic Mains Failure Unit Installation GuideDocument28 pagesTRANS-AMF Automatic Mains Failure Unit Installation GuideAdeelNo ratings yet

- Toshiba Aplio 300 Service Manual - Maintenance VolumeDocument102 pagesToshiba Aplio 300 Service Manual - Maintenance Volumestrcp75% (4)

- Fx3u 485adp MBDocument3 pagesFx3u 485adp MBSangNgominhNo ratings yet

- Installation and Operation Manual For Supertrack Model K4 Ku-Band Tv-Ro AntennasDocument68 pagesInstallation and Operation Manual For Supertrack Model K4 Ku-Band Tv-Ro AntennasHaidar Al MosawiNo ratings yet

- DIMM-RM9200: Hardware ManualDocument25 pagesDIMM-RM9200: Hardware ManualvestasvesNo ratings yet

- Electrical and Instrument DiagramsDocument154 pagesElectrical and Instrument DiagramsMehmet Efe OzbekNo ratings yet

- Cambridge Audio Azur 640c Service ManualDocument34 pagesCambridge Audio Azur 640c Service ManualMartin Szathmári100% (1)

- Esa08f A12f G2422 EngDocument2 pagesEsa08f A12f G2422 EngStanisław ZakrzewskiNo ratings yet

- Valbia Actuator SetupDocument1 pageValbia Actuator SetupkikinNo ratings yet

- RG-1000e Remote Gateway: User GuideDocument40 pagesRG-1000e Remote Gateway: User GuideThanh Kieu TienNo ratings yet

- Practical Embedded Controllers: Design and Troubleshooting with the Motorola 68HC11From EverandPractical Embedded Controllers: Design and Troubleshooting with the Motorola 68HC11No ratings yet

- Connector Industry: A Profile of the European Connector Industry - Market Prospects to 1999From EverandConnector Industry: A Profile of the European Connector Industry - Market Prospects to 1999No ratings yet

- Token Ring Technology ReportFrom EverandToken Ring Technology ReportNo ratings yet

- StarLAN Technology ReportFrom EverandStarLAN Technology ReportRating: 3 out of 5 stars3/5 (1)

- CoDeSys Visu V23 E PDFDocument108 pagesCoDeSys Visu V23 E PDFcarlcoxNo ratings yet

- CoDeSys V2.3 - m07590333 - 00000000 - 1en PDFDocument469 pagesCoDeSys V2.3 - m07590333 - 00000000 - 1en PDFPaulo MandingaNo ratings yet

- SFC-DC enDocument114 pagesSFC-DC encarlcoxNo ratings yet

- Boostc V7 C Compiler: Reference ManualDocument102 pagesBoostc V7 C Compiler: Reference ManualcarlcoxNo ratings yet

- Unix Authentication Api For Sas® Release 9.3M2Document24 pagesUnix Authentication Api For Sas® Release 9.3M2carlcoxNo ratings yet

- S Weave TemplateDocument2 pagesS Weave TemplatecarlcoxNo ratings yet

- ProModel User Guide PDFDocument642 pagesProModel User Guide PDFMeliza SuarezNo ratings yet

- CoDeSys SoftMotion V23 EDocument185 pagesCoDeSys SoftMotion V23 EcarlcoxNo ratings yet

- Remote OPC DA - Quick Start Guide (DCOM) PDFDocument23 pagesRemote OPC DA - Quick Start Guide (DCOM) PDFcarlcoxNo ratings yet

- 3D Animator User GuideDocument85 pages3D Animator User GuidecarlcoxNo ratings yet

- Us200401 PDFDocument53 pagesUs200401 PDFcarlcoxNo ratings yet

- 03 Ch1 IntroDocument4 pages03 Ch1 IntrocarlcoxNo ratings yet

- Stat FitDocument135 pagesStat FitCarlos Angel Vicente RodríguezNo ratings yet

- Unix Authentication Api For Sas® Release 9.3M2Document24 pagesUnix Authentication Api For Sas® Release 9.3M2carlcoxNo ratings yet

- SADP User ManualDocument24 pagesSADP User ManualcarlcoxNo ratings yet

- Tendencias IODocument12 pagesTendencias IOcarlcoxNo ratings yet

- Zhu Joe - Quantitative Models For Performance Evaluation and Benchmarking. Data Envelopment Analysis With Spreadsheets - 2008 PDFDocument274 pagesZhu Joe - Quantitative Models For Performance Evaluation and Benchmarking. Data Envelopment Analysis With Spreadsheets - 2008 PDFcarlcoxNo ratings yet

- An 2764Document60 pagesAn 2764Pvn MurthyNo ratings yet

- DEA Caso PrácticoDocument14 pagesDEA Caso PrácticocarlcoxNo ratings yet

- Automata LogoDocument49 pagesAutomata LogoHebert CcahuanaNo ratings yet

- FST 2004-03 682300g1Document300 pagesFST 2004-03 682300g1Horacio TerragnoNo ratings yet

- Libro Matlab OPTDocument12 pagesLibro Matlab OPTcarlcoxNo ratings yet

- 4 Project ManagementDocument40 pages4 Project ManagementAries TsaiNo ratings yet

- n900 Schematics PDFDocument18 pagesn900 Schematics PDFcarlcoxNo ratings yet

- Teoria Control Analogo Completo ModDocument2 pagesTeoria Control Analogo Completo ModcarlcoxNo ratings yet

- RS-CE Rotary Actuators: External Dimensions Torque ProfilesDocument3 pagesRS-CE Rotary Actuators: External Dimensions Torque ProfilescarlcoxNo ratings yet

- Mitsubishi L08211engaDocument60 pagesMitsubishi L08211engacarlcoxNo ratings yet

- Siemens A56Document45 pagesSiemens A56carlcoxNo ratings yet

- Designing For Board Level EMC AN2321Document36 pagesDesigning For Board Level EMC AN2321Dodge WorthingtonNo ratings yet

- Developing Teachers Through CoachingDocument1 pageDeveloping Teachers Through CoachingEdri Jan80% (5)

- Igrid SV LV 3kva Split Phase Hybrid Solar Inverter: 110V-120V Grid Tie Solar Inverter With Energy StorageDocument1 pageIgrid SV LV 3kva Split Phase Hybrid Solar Inverter: 110V-120V Grid Tie Solar Inverter With Energy Storagejccl2No ratings yet

- TAM Acquisition and Analysis ManualDocument92 pagesTAM Acquisition and Analysis ManualJulian UribeNo ratings yet

- Cyber Security and Reliability in A Digital CloudDocument95 pagesCyber Security and Reliability in A Digital CloudBob GourleyNo ratings yet

- SAN11 Paper Guide 16-17Document4 pagesSAN11 Paper Guide 16-17ghgheNo ratings yet

- Custom Storage ClassesDocument2 pagesCustom Storage ClassesSameer KumthekarNo ratings yet

- Process Analysis.2018Document30 pagesProcess Analysis.2018Geena boengaiNo ratings yet

- Acceptance Criteria Boiler (API 573)Document1 pageAcceptance Criteria Boiler (API 573)Nur Achmad BusairiNo ratings yet

- Durability of Culvert PipeDocument21 pagesDurability of Culvert PipeIftiNo ratings yet

- Flight 60T Turbine Operating ManualDocument128 pagesFlight 60T Turbine Operating Manualtravieso112No ratings yet

- Tabcontents ScreenDocument3 pagesTabcontents ScreenarstjunkNo ratings yet

- Log FileDocument67 pagesLog Filenani2003No ratings yet

- 0 Delphi Labs DataSnap XE CallbacksDocument7 pages0 Delphi Labs DataSnap XE Callbacksduna tarimaNo ratings yet

- Development Control Rules 2014Document155 pagesDevelopment Control Rules 2014ChandraPrabhaNo ratings yet

- The Aesthetics of Interactive Music Systems: Robert RoweDocument5 pagesThe Aesthetics of Interactive Music Systems: Robert Rowesertimone0% (1)

- Films Mentioned by Straub HuilletDocument3 pagesFilms Mentioned by Straub HuilletthephantomoflibertyNo ratings yet

- Ciscenje Hadnjaka HyundaiDocument4 pagesCiscenje Hadnjaka HyundaiAjdin Herc AhmetovicNo ratings yet

- PDFDocument76 pagesPDFRavishankarNo ratings yet

- How To Install SecurePlatform - Gaia From A USB Device On Check Point Appliance and Open ServersDocument3 pagesHow To Install SecurePlatform - Gaia From A USB Device On Check Point Appliance and Open ServersshikhaxohebkhanNo ratings yet

- OlxDocument23 pagesOlxPoonam Dimple Ruchwani0% (1)

- 231 PC00165 - Cerificate English PDFDocument1 page231 PC00165 - Cerificate English PDFrajenrao51777564No ratings yet

- Boss DD 2 Digital Delay Pedal SchematicDocument1 pageBoss DD 2 Digital Delay Pedal Schematicfishy joeNo ratings yet

- Risk-MaPP, ICH Q9, ASTM 2500 in Action Project Advantages of Practical QualityDocument7 pagesRisk-MaPP, ICH Q9, ASTM 2500 in Action Project Advantages of Practical Qualitybo.ratchadapornNo ratings yet

- Various Types of W.C and Water Supply ConnectionsDocument12 pagesVarious Types of W.C and Water Supply ConnectionsAtish Kumar100% (1)

- Basic Dust Explosion PDFDocument32 pagesBasic Dust Explosion PDFMauricioNo ratings yet

- RICOH Streamline NX Guia de UsuarioDocument107 pagesRICOH Streamline NX Guia de UsuarioMaria Elena AvilaNo ratings yet

- PCI Journal July - August 2020Document120 pagesPCI Journal July - August 2020Farja_ZzzNo ratings yet

- Latihan HitunganDocument9 pagesLatihan HitunganMuhamad FadilahNo ratings yet

- Water Overflow Rage and Bubble Surface Area Flux in FlotationDocument105 pagesWater Overflow Rage and Bubble Surface Area Flux in FlotationRolando QuispeNo ratings yet

- CL04A3 Specs PDFDocument2 pagesCL04A3 Specs PDFDaniel MartinsNo ratings yet