Professional Documents

Culture Documents

Taper Grip Bushing Installation Guide: Apply Thin Layer of Anti-Seize Paste To Male Threads of Bushing Only

Uploaded by

berkahharianOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Taper Grip Bushing Installation Guide: Apply Thin Layer of Anti-Seize Paste To Male Threads of Bushing Only

Uploaded by

berkahharianCopyright:

Available Formats

Taper Grip® Bushing Installation Guide

Introduction

The keyless Taper-Grip® bushing system provides simple and reliable

shaft attachment for Sumitomo Speed reducers and gearmotors. This

system allows bi-directional shaft rotation and stop-start operation with

a powerful, slip-free grip. To assure peak performance of your equip-

ment, please read, understand and follow these installation instructions.

Safety

Disconnect all power sources from the equipment before beginning this Fig. 1 Taper-Grip® Bushing Parts

installation procedure. Handle the components with care and avoid all

sharp or machined edges to prevent personal injury or damage to the

components.

Before Installing Unit on Driven Shaft

(Steps 1-7)

Carefully inspect the driven equipment shaft. Remove all burrs, corrosion,

lubricants, and foreign matter from the shaft surface. Verify the shaft

diameter is within the dimensional tolerances shown in Table 1.

Fig. 2 Remove

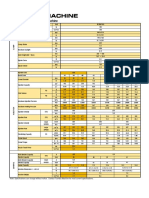

Table 1 Driven Shaft Tolerances Safety Cover

Shaft Diameter (inches) Shaft Tolerance (inches)

3/4” – 1-1/8” +0” – 0.0013”

1-3/16” – 2” +0” – 0.0015”

2-1/16” – 3-1/8” +0” – 0.0018”

3-3/16” – 4-3/4” +0” – 0.0021”

4-13/16” – 6-1/2” +0” – 0.0025”

Clean all surfaces of the shaft, the bushing, the thrust collar and the unit

bore with solvent to remove all grease and oil.

Fig. 3 Slide Thrust

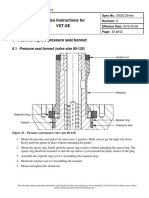

Step 1 – Remove the Taper-Grip® bushing safety cover (see Fig. 2). Collar on Bushing

Step 2 – Remove the cap screws from the bushing. Lightly oil the

threads of the cap screws and partially re-insert them into the threaded

holes in the bushing flange. The ends of the cap screws should not Apply thin layer of anti-seize

extend beyond the rear face of the bushing flange. paste to male threads of

bushing only.

Step 3 – Slide the thrust collar onto the Taper-Grip® bushing

(see Fig. 3).

Step 4 – Apply a thin layer of anti-seize paste to the male threads of

the Taper-Grip® Bushing only (see Fig.4). Based on tests, Sumitomo

recommends Bostik Never-Seez Regular Grade or equivalent. Ensure

that anti-seize paste does not enter the Taper-Grip® Bushing bore. Fig. 4 Apply

Caution: Do not apply anti-seize paste to the female threads in Anti-seize Paste

the hub.

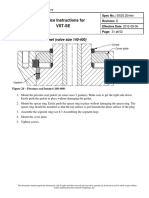

Step 5 – Carefully thread the Taper-Grip® bushing into the hub of the

speed reducer or gearmotor until the thrust collar solidly engages the

unit hub surface and the bushing flange (see Fig. 5). Caution: Do not

cross-thread. Bushing should thread easily into hub.

Step 6 – Unscrew the Taper-Grip® bushing to create a 1mm (0.04”) gap

between the thrust collar and the bushing flange.

Step 7 – Hand-tighten the cap screws until they firmly press the thrust

collar against the unit hub surface. The unit is ready for installation on Fig. 5 Thread

the driven shaft. Bushing into Hub

www.sumitomodrive.com 1-800-SM-CYCLO 19.001.61.008

Page 1

Taper Grip® Bushing Installation Guide continued

Unit Installation

Step 8 – Position unit with the bushing flange located on the outboard

side of the unit. Align the bushing with the driven shaft. Slide the unit

onto the driven shaft as close to the driven shaft support bearing as

possible. Ideally, the driven shaft should extend beyond the bushing

flange face (see Fig. 7). Refer to Fig. 6 and Table 2 below for

minimum shaft to bushing engagement. For maximum depth to the

end of the shaft, refer to Fig. 6 and Table 3 below.

)

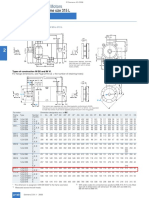

Table 2 Minimum Shaft to Bushing Engagement (T T

nt

me

age

Minimum Shaft Engagement ng

ft E

S ha

HSM Cyclo® HBB Cyclo® BBB4 n .

Mi

Model mm in. Model mm in. Model mm in. Fig. 6 ax. o )

M th t d (TS

107C 119.5 4.70 Z 113.5 4.47 Shaft Engagement p

De aft E

n

115D 127.5 5.02 Sh

203E 136 5.35 A 127 5.00 A 209 8.23

207F 153 6.02 B 144 5.67 B 243 9.57

215G 183 7.20 C 187 7.36 C 280 11.02

307H 205 8.07 D 205 8.07 D 327 12.87

315J 215 8.46 E 225 8.86 E 360 14.17

407S 219 8.62 F 412 16.22

415K 217 8.54

507L 285 11.22

608M 335 13.19

Table 3 Maximum Depth to Shaft End

Maximum Depth to Shaft End

HSM Cyclo® HBB Cyclo® BBB4

Model mm in. Model mm in. Model mm in. Fig. 7 Screw Tightening Sequence

107C 31 1.22 Z 31 1.22

115D 34 1.34

203E 35 1.38 A 35 1.38 A 35 1.38 Table 4 Cap Screw Tightening Torques

207F 45 1.77 B 45 1.77 B 45 1.77 Cyclo® Cap screws Cap screw

215G C C HSM

40 1.57 40 1.57 40 1.57 BBB4 (JIS Grade 12.9) Torque

Model

307H 50 1.97 D 50 1.97 D 50 1.97 Model Qty. Size Nm Lb.Ft.

315J 51 2.01 E 51 2.01 E 51 2.01 107C 6 M10x14 50 37

407S 63 2.48 F 74 2.93 115D 6 M10x14 55 41

415K 70 2.76 203E A 6 M12x16 75 56

507L 70 2.76 207F B 6 M12x16 140 104

608M 70 2.76 215G C 6 M16x20 250 185

307H D 6 M16x20 300 223

Step 9 – With a torque wrench, tighten the cap screws in 20% incre- 315J E 8 M16x20 300 223

ments to engage the bushing system. Use the appropriate tightening 407S F 10 M16x20 300 223

pattern (“star-pattern” see Fig. 7) to assure complete bushing engage- 415K 10 M16x35 300 223

ment. Tighten each cap screw to the torque values shown in Table 4. 507L 12 M16x35 300 223

If the shaft is recessed in the bushing, fill the void with grease to prevent 608M 16 M16x35 300 223

corrosion and fouling.

Cyclo® Cap screws Cap screw

Step 10 – Please read, understand and follow the instructions shown in HBB (JIS Grade 12.9) Torque

the reducer/gearmotor installation and operating manual to complete Model Qty. Size Nm Lb.Ft.

the unit installation and attach the torque arm. Z 6 M10x14 31 23

Step 11 – After the reducer has been running for 20 to 30 hours, re- A 6 M12x16 51 37.5

torque the screws to the values in Table 4. Screw torques should be B 6 M12x16 51 37.5

subsequently checked at normal service intervals (i.e. every 6 months). C 6 M16x20 128 95

D 6 M16x20 200 148

E 8 M16x20 200 148

19.001.61.008 1-800-SM-CYCLO www.sumitomodrive.com

Page 2

Taper Grip® Bushing Installation Guide continued

Removal Procedure

Step 1 – Remove the Taper-Grip® bushing safety cover (see Fig. 8). Step 5 – After the liquid penetrant has been allowed to settle,

remove the cap screws one at a time (see Fig 12).

Fig. 8 Remove the

Safety Cover

Fig. 12 Remove Cap Screws

Step 2 – Before removing the reducer/gearmotor from the driven

shaft, externally support the unit so that all its weight is removed Step 6 – Place a copper or brass bar against the flange of the Taper-

from the driven shaft (see Fig. 9). Caution: Do not raise the unit Grip® Bushing and carefully strike end of bar with a hammer to

too high. It may cause the shaft to bind. release bushing (see Fig 13).

Fig. 9 Externally Support the Unit Fig. 13 Release the Bushing

Step 3 – Check the Taper-Grip® Bushing to assure that there is a gap Step 7 – After releasing the bushing, reinstall the cap screws by

between the thrust collar and the bushing flange. If no gap exists, hand only. Stop tightening them once they touch the thrust col-

unit removal may be difficult (see Fig. 10). lar. They will ensure the reducer will not slide against the bushing

Gap and clamp it against the shaft when the reducer is removed. Apply

a liquid penetrant to the shaft where it contacts the bushing. Allow

time for the liquid to penetrate between the bushing and the shaft,

then carefully slide the unit off of the shaft. (see Fig 14). Note: If

Thrust the bushing releases, but the unit cannot be removed from the

Bushing shaft, apply a puller to the bushing to push the shaft free.

Flange Collar

Fig. 10 Check Gap Between

Collar and Flange

Step 4 – Spray a liquid penetrant onto each of the Taper-Grip®

Bushing cap screws. Allow time for the penetrant to settle into the

threads of the cap screws. (see Fig. 11).

Fig. 14 Slide Unit Off the Shaft

Fig. 11 Spray Penetrant

on Cap Screws

www.sumitomodrive.com 1-800-SM-CYCLO 19.001.61.008

Page 3

Sumitomo Machinery Corporation of America

Headquarters & Manufacturing

4200 Holland Boulevard

Chesapeake, VA 23323

Tel: 757-485-3355 • Fax: 757-485-7490

www.sumitomodrive.com

E-mail: customercare@suminet.com

www.sumitomodrive.com

For worldwide locations, please visit

World Headquarters

www.sumitomodrive.com/worldwide

Japan

Sumitomo Heavy Industries, Ltd.

Power Transmission & Controls Group

ThinkPark Tower, 1-1, Osaki 2-chome,

Shinagawa-ku, Tokyo 141-6025 Japan

Tel: +81-36-737-2511 • Fax: +81-36-866-5160

Manual 19.001.61.008; Supersedes Manual 19.001.61.007

©2014 Sumitomo Machinery Corporation of America Printed in USA

You might also like

- GM Passlock II SystemDocument14 pagesGM Passlock II Systemalmia tronicsNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Assembly ProcedureDocument115 pagesAssembly ProcedureAlex Castillo100% (1)

- Fiber Optic Trainer/ Fiber & OSP TechnicianDocument7 pagesFiber Optic Trainer/ Fiber & OSP Technicianapi-78570706No ratings yet

- Gordon NovelDocument50 pagesGordon NovelNic Hotep100% (2)

- Yamaha XT 250 Service Manual PDFDocument282 pagesYamaha XT 250 Service Manual PDFFreddy Jiron100% (1)

- 2 Coagulation FlocculationDocument26 pages2 Coagulation FlocculationNurSyuhada ANo ratings yet

- TM 9-1245 37-MM Gun, M3, and Carriage, M4-1941Document54 pagesTM 9-1245 37-MM Gun, M3, and Carriage, M4-1941ferdockmNo ratings yet

- Manual SumitomoDocument4 pagesManual SumitomoJorge A Vilal50% (2)

- 5e6b0pt Tunnel Fan Cat029 E0 Ed2Document24 pages5e6b0pt Tunnel Fan Cat029 E0 Ed2berkahharianNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Telma F7 Installation On Meritor RS160-180-185 Axle TL103014Document6 pagesTelma F7 Installation On Meritor RS160-180-185 Axle TL103014Odim41No ratings yet

- BoQ PlumbingDocument30 pagesBoQ PlumbingberkahharianNo ratings yet

- (Replacement Criteria For Traction Sheave) K 608007-01Document4 pages(Replacement Criteria For Traction Sheave) K 608007-01Ali DiabNo ratings yet

- XT 250 Manual Mecanico PDFDocument282 pagesXT 250 Manual Mecanico PDFroberthpz1982No ratings yet

- Taper Grip Installation GuideDocument2 pagesTaper Grip Installation GuideFredy Jesus Quispe ValverdeNo ratings yet

- MZ45 MZ45GDocument2 pagesMZ45 MZ45GSalpa AdenugrahaNo ratings yet

- Hyponic InstallationDocument7 pagesHyponic InstallationDeMen NguyenNo ratings yet

- Eaton: Hydraulic MotorDocument4 pagesEaton: Hydraulic MotorRidha AbbassiNo ratings yet

- Bushing Kit For Front Axle AM/AMA56, AM/AMA61 and AM70: Service Kit, Part No 1 355 387Document2 pagesBushing Kit For Front Axle AM/AMA56, AM/AMA61 and AM70: Service Kit, Part No 1 355 387joaojitoNo ratings yet

- Assembling The Printrbot Play Kit (Model 1505)Document29 pagesAssembling The Printrbot Play Kit (Model 1505)Vishal PaiNo ratings yet

- Seat Belts PDFDocument26 pagesSeat Belts PDFJairo Rodriguez A.No ratings yet

- SEA 2019 Jet Pump SPARK Shop Supp. 219100959-021Document16 pagesSEA 2019 Jet Pump SPARK Shop Supp. 219100959-021Coke Ker JetspeedNo ratings yet

- SRAM SPECTRO S7 Maintenance - en PDFDocument0 pagesSRAM SPECTRO S7 Maintenance - en PDFkuvalda2000No ratings yet

- InstallationDocument17 pagesInstallationEdson CRNo ratings yet

- QVPF22V315S SingleV LockFour BoltPillowBlock - 2Document5 pagesQVPF22V315S SingleV LockFour BoltPillowBlock - 2Wildan PriatnaNo ratings yet

- Bomba de Aceite-InstalaciónDocument5 pagesBomba de Aceite-InstalaciónOscar CAPSSANo ratings yet

- Rear SealDocument9 pagesRear SealHammad Uddin JamilyNo ratings yet

- EC200SXII Injection Molding MachineDocument1 pageEC200SXII Injection Molding MachineJosephNo ratings yet

- Rear Axle ShaftDocument8 pagesRear Axle ShaftSalud y Cuidado AutomotrizNo ratings yet

- Breakage of The Tightening Stud of Cyl - CoverDocument5 pagesBreakage of The Tightening Stud of Cyl - Coverstergios meletisNo ratings yet

- IKO Bearing CatalogueDocument18 pagesIKO Bearing Cataloguenurek2100% (2)

- Genesis 3.8L Section 7Document40 pagesGenesis 3.8L Section 7Nacho MowjiNo ratings yet

- Daniel Senior Orifice Fitting: Fastener Torque GuideDocument20 pagesDaniel Senior Orifice Fitting: Fastener Torque GuideDianaMartínezNo ratings yet

- Deethanizer Reflux Pump InfoDocument5 pagesDeethanizer Reflux Pump InfoarasNo ratings yet

- Getriebebau NORD: 6HUYR'ULYHDGDSWHU7/SH6 (36 (Document4 pagesGetriebebau NORD: 6HUYR'ULYHDGDSWHU7/SH6 (36 (olivier.bigouretNo ratings yet

- MY18 GENERATION Ó GIANT CONTACT SWITCH SEATPOST - ENDocument13 pagesMY18 GENERATION Ó GIANT CONTACT SWITCH SEATPOST - ENAnand sNo ratings yet

- TIL03029 TELMA REPLACEMENT ARM TANDEM Rev12jul07Document16 pagesTIL03029 TELMA REPLACEMENT ARM TANDEM Rev12jul07Paulo PereiraNo ratings yet

- Engine Mechanical System: Timing System - Timing ChainDocument11 pagesEngine Mechanical System: Timing System - Timing ChainoliNo ratings yet

- RM3U0808SBK: Section NN-NN PPDocument1 pageRM3U0808SBK: Section NN-NN PPGustavo MaureiraNo ratings yet

- SYZR InstructionsDocument4 pagesSYZR InstructionsCraigNo ratings yet

- Trorfiro: Drive Shaft Phase AnglesDocument31 pagesTrorfiro: Drive Shaft Phase AnglesSonthi MooljindaNo ratings yet

- Montero Transmision XaviDocument20 pagesMontero Transmision XaviFrancisco HernandezNo ratings yet

- Whyte - 146-T-120-E-120 Supplementary Service Manual Edn1Document16 pagesWhyte - 146-T-120-E-120 Supplementary Service Manual Edn1Jamie WatsonNo ratings yet

- Service Instructions For Vst-Se: 8.1 Pressure Seal Bonnet (Valve Size 90-125)Document1 pageService Instructions For Vst-Se: 8.1 Pressure Seal Bonnet (Valve Size 90-125)AhmadNo ratings yet

- Sab 330Document8 pagesSab 330Manuel perezNo ratings yet

- C7 EngineDocument2 pagesC7 EngineOli MijanaNo ratings yet

- Stick - 3.86 MDocument3 pagesStick - 3.86 Mcristian chuquicondor torresNo ratings yet

- Service Instructions For Vst-Se: 8.2 Pressure Seal Bonnet (Valve Size 140-400)Document1 pageService Instructions For Vst-Se: 8.2 Pressure Seal Bonnet (Valve Size 140-400)AhmadNo ratings yet

- Ringspann GMBH: Operating Instructions ForDocument2 pagesRingspann GMBH: Operating Instructions ForAlaa MaherNo ratings yet

- C4.4 Medida Cigüeñal PermitidasDocument3 pagesC4.4 Medida Cigüeñal PermitidasLuis GutiérrezNo ratings yet

- BmvwinstallDocument16 pagesBmvwinstallAlejandroO.VargasNo ratings yet

- Belimo LF24 SR - USDocument7 pagesBelimo LF24 SR - USAlfredo Ferrari Jr.No ratings yet

- Caution / Notice / HintDocument15 pagesCaution / Notice / HintZouhair WahbiNo ratings yet

- Caution / Notice / HintDocument3 pagesCaution / Notice / HintZouhair WahbiNo ratings yet

- John Deere 450CLC Excavator Service Repair Technical Manual (TM1925)Document14 pagesJohn Deere 450CLC Excavator Service Repair Technical Manual (TM1925)laopaodunNo ratings yet

- Mini 3dx Plans Tiled A4Document20 pagesMini 3dx Plans Tiled A4andrequalNo ratings yet

- Reassembly: (A) Check Bearing PositionDocument21 pagesReassembly: (A) Check Bearing PositionRonfermNo ratings yet

- 35M-36M DespiecesDocument4 pages35M-36M DespiecesCharles SeychNo ratings yet

- Research&Development of America, Inc.: Suzuki 2005 GSX-R1000Document6 pagesResearch&Development of America, Inc.: Suzuki 2005 GSX-R1000Daniel MartínNo ratings yet

- Keyless Bushing Instruction Manual July 2019Document2 pagesKeyless Bushing Instruction Manual July 2019huseyinNo ratings yet

- Air Brake Fittings: Torque SpecificationsDocument2 pagesAir Brake Fittings: Torque SpecificationsGerardo VelazquezNo ratings yet

- IMF51Document4 pagesIMF51juwon aprilagaNo ratings yet

- Disc BrakesDocument17 pagesDisc BrakesBenz Aio Calachua AraujoNo ratings yet

- Rogue Bar InstallDocument18 pagesRogue Bar InstalljustforaspinNo ratings yet

- MC 10119123 9999Document8 pagesMC 10119123 9999johndere2090No ratings yet

- 1823 Chapter VDocument10 pages1823 Chapter VberkahharianNo ratings yet

- Instructions For Installation, Operation and MaintenanceDocument101 pagesInstructions For Installation, Operation and MaintenanceberkahharianNo ratings yet

- Flender Tübingen Mixer Drives: Technical Data Agitator Drives ZR and DR Series in 8 SizesDocument1 pageFlender Tübingen Mixer Drives: Technical Data Agitator Drives ZR and DR Series in 8 SizesberkahharianNo ratings yet

- SKF Industrial Gearbox 2 2Document2 pagesSKF Industrial Gearbox 2 2berkahharianNo ratings yet

- II Test Running Record: 2.1 Vibration Data No LoadDocument10 pagesII Test Running Record: 2.1 Vibration Data No LoadberkahharianNo ratings yet

- Siemens 1LA7 Cat 40Document1 pageSiemens 1LA7 Cat 40berkahharianNo ratings yet

- Siemens 1LA7 Cat 130Document1 pageSiemens 1LA7 Cat 130berkahharianNo ratings yet

- Siemens 1LA7 Cat 48Document1 pageSiemens 1LA7 Cat 48berkahharianNo ratings yet

- Siemens 1LA7 Cat 123Document1 pageSiemens 1LA7 Cat 123berkahharianNo ratings yet

- DRAIN TYPE FLUID COUPLING For Internal Combustion Engines KPTODocument4 pagesDRAIN TYPE FLUID COUPLING For Internal Combustion Engines KPTOberkahharianNo ratings yet

- Full Size Selection ChartDocument88 pagesFull Size Selection ChartberkahharianNo ratings yet

- Loiskov Jednotky YDocument44 pagesLoiskov Jednotky YberkahharianNo ratings yet

- FCL Couplings: Chengdu Leno Machinery Co., LTDDocument1 pageFCL Couplings: Chengdu Leno Machinery Co., LTDjamblang_limNo ratings yet

- Installation Operation Maintenance Manual (Harvest Series)Document36 pagesInstallation Operation Maintenance Manual (Harvest Series)berkahharianNo ratings yet

- Kinematics-03-Subjective SolvedDocument11 pagesKinematics-03-Subjective SolvedRaju SinghNo ratings yet

- Softening N Penetration Test BitumenDocument11 pagesSoftening N Penetration Test BitumenEdwin LeonNo ratings yet

- PNR90 PNR510 PNR91 PNR515 PNR92 PNR520: Manual of - Installation - Operating - Maintenance Heavy Oil Burners TypeDocument28 pagesPNR90 PNR510 PNR91 PNR515 PNR92 PNR520: Manual of - Installation - Operating - Maintenance Heavy Oil Burners Typec_lucian2004No ratings yet

- Acceleration GrpahDocument14 pagesAcceleration GrpahRAFAEL TORRESNo ratings yet

- Write An Algorithm and Flowchart For Computing The Average Number of The Default 4 NumbersDocument3 pagesWrite An Algorithm and Flowchart For Computing The Average Number of The Default 4 NumbersMark Jelan100% (1)

- Trial Manufacture of A Fluid-Type Static Induction TransistorDocument4 pagesTrial Manufacture of A Fluid-Type Static Induction TransistorStanley ClermontNo ratings yet

- Adjusting Well Pump Pressure SwitchesDocument1 pageAdjusting Well Pump Pressure SwitchesD_D_76No ratings yet

- Riscv SpecDocument32 pagesRiscv SpeckartimidNo ratings yet

- Estimate SR 14-15 02 KHANDEKARDocument5 pagesEstimate SR 14-15 02 KHANDEKARAkshay SavvasheriNo ratings yet

- Build-A-Bard ABB - RFQ-807683Reaprovechamiento Relaves - SR For Cotejado 010A - HVACDocument18 pagesBuild-A-Bard ABB - RFQ-807683Reaprovechamiento Relaves - SR For Cotejado 010A - HVACchristianNo ratings yet

- 007-013558-001 SAS PCE SPE With Support For HSM PSE2 Integration Feature Documentation RevCDocument43 pages007-013558-001 SAS PCE SPE With Support For HSM PSE2 Integration Feature Documentation RevCpietoeNo ratings yet

- ITIL Quick ReferenceDocument3 pagesITIL Quick ReferenceKalyaan KrushnaNo ratings yet

- 4 and 6 Pole MotorDocument6 pages4 and 6 Pole Motorarajamani78100% (1)

- Quality ControlDocument10 pagesQuality ControlSabbir AhmedNo ratings yet

- JNTUA B Tech 2018 1 2 May R15 ECE 15A54201 Mathematics IIDocument2 pagesJNTUA B Tech 2018 1 2 May R15 ECE 15A54201 Mathematics IIMRUDULA KULAKARNINo ratings yet

- SOP 829 - 032 Check-Reset KEMS, CrownomaticDocument2 pagesSOP 829 - 032 Check-Reset KEMS, CrownomaticAnonymous XbmoAFtINo ratings yet

- HighpuritysealsDocument6 pagesHighpuritysealstuannhocutNo ratings yet

- Electro Magnetic Induction PDFDocument28 pagesElectro Magnetic Induction PDFPuran BistaNo ratings yet

- Distributed PowerDocument3 pagesDistributed PowertibvalNo ratings yet

- 1 Xpower Safirus Owners Manual enDocument8 pages1 Xpower Safirus Owners Manual enMarianela MasyRubiNo ratings yet

- Woodworking Plans - Wheelbarrow PlanterDocument3 pagesWoodworking Plans - Wheelbarrow PlanterMirel HotescuNo ratings yet

- G270han01 V0Document26 pagesG270han01 V0NemkoNo ratings yet

- PIONEER AUTORADIO Deh-X4850bt Deh-X6850bt Operating Manual Ing - Esp - PorDocument72 pagesPIONEER AUTORADIO Deh-X4850bt Deh-X6850bt Operating Manual Ing - Esp - PorJesus NinalayaNo ratings yet

- SdccmanDocument126 pagesSdccmanGustavo A. Sarache MillanNo ratings yet

- Measurement Advisory Committee Summary - Attachment 3Document70 pagesMeasurement Advisory Committee Summary - Attachment 3MauricioICQNo ratings yet