Professional Documents

Culture Documents

Well Control Assessment NOTE's

Uploaded by

a.qawi0 ratings0% found this document useful (0 votes)

20 views5 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views5 pagesWell Control Assessment NOTE's

Uploaded by

a.qawiCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

1- Objective:

- Well control assessment is measuring the 4man leadership &

commitment while acting with well control problems.

2- Pre-job check list.

- Pre-commence operations Safety meeting to show 4man leadership &

commitment while acting with well control issues.

- Choke manifold line up.

- Stand pipe manifold Line up.

- BOPE pressures check & adjusting as required.

- Flow monitoring system adjusting as required.

3- Well control Assessment from A to Z:

A- Solve kill sheet as required noting that Tabular capacity will give to you as ID.

Tabular capacity in BBL/FT = (ID^2/1029.4).

B- After Completing kill sheet enter to Simulator room & start pre-commence

safety meeting emphasizing on :

1- Driller should record SCR just start operations

SCR should be taken by two pumps.

SCR pressure should take from adjustable choke gauges because this gauges

reading will be used while killing operations.

2- Driller have full authority to make flow check if he have any signs of kick

(ROP increase, cutting shape different, SPP decrease, SPM increase)

3- Driller have full authority & Must shut in the well in case of detecting any

flow signs (PVT alarm due to increase of flow rate, pit volume increase)

without taking any permission from any guys.

4- Driller should keep parameter constant especially flow rate to be easy to

detect flow.

5- Driller Should start pump & Shut in the pump slowly to give choke operator

chance to keep SICP constant while acting with unscheduled events .

6- Explain to driller ARAMCO procedure for well shut in while drilling in case of

kick (position string/ shut off pump / close pipe ram / open HCR / record

pressures)

C- Start line up for choke manifold

Well control assessment notes WOD / DIV-1

Check SELECTOR in adjustable choke panel.

D- Line up stand pipe manifold.

E- Check BOP configuration & adjust pressure as API ( Air : 120 psi / Accumulator :

3000 psi/ manifold : 1500 psi / Annular preventer : 750 – 1500 psi)

F- Check & adjust flow alarm system (PVT) to be as minimum as you can (+2/-2

bbls with maximum 5 bbls) & don’t forget to put alarm button in ON position.

G- Line up adjustable choke to be ready for hard shut in (Both HCR & Adjustable

choke are closed).

H- Minimize adjustable choke closing – open speed from regulator.

I- Now you are ready to commence operations as follow:

1- Record SCR for two pumps & pressures should take from adjustable remote

choke gauges.

2- Continue drilling with selected drilling parameters.

3- In case of have ROP increased, ask driller to perform Flow check:

if positive >>>> Shut in the well hardly (position string/ shut off pump / close

pipe ram / open HCR / record pressures)

if –ve >>>>continue drilling .

4- Just flow alarm sound activated (flow rate increase or pit volume increase),

driller immediately shut in the well & wait for pressure stabilization to

record pressure>>>RECORD SICP from adjustable choke.

5- Record SIDPP :

As SAUDI ARAMCO use float valve in string , after pressure stabilization we

only can record SICP , the way to record SIDPP is to switch pump on slowly

monitoring the SICP , when the SICP start change , this meaning that float valve

opened & in this case Record drill pipe pressure as SIDPP then switch off pump.

6- Now ask the driller to monitor well pressures mean while you as foreman

complete kill sheet:

You have now ( SCR / SICP / SIDPP/ Pit gain)

KMWT = Original mud wt + SIDPP / 0.052 X TVD >>>>>>>Round to closed

one decimal up.

* Example: K.mwt = 19.95433 ppg >>take as 20 ppg

* K.mwt = 19.000000000000000000000000001 ppg >>>>> take as 19.1 ppg

Initial circulating pressure (ICP) = SIDPP + SCR >>>round to one (1) psi up

* Example: ICP = 901.00000000000001 >>> take as 902 psi.

Final circulating pressure (FCP) = SCR X (K.wt / original mud wt)>>>>round to

one (1) psi up.

* Example: FCP = 500.00000001 >>>>Record as 501 psi.

Down step reduction value (Pressure drop per every 100 stroke) = (ICP – FCP)/

Strg capacity in stroke >>>>round to one psi (1) down.

Well control assessment notes WOD / DIV-1

* Example: reduction value = 38.255 psi/ 100 stroke >>>> record as 38 psi/100

stroke.

Fill down step chart :

7- Start well killing operations as per selected killing method (Driller or Wait &

Weight method), taking in your consideration that operator have to give

clear instruction to driller to bring pump slowly while switch on or switch

off pump to give operator chance keep SICP constant (While switch off or

switch on pump the only way to keep Bottom hole pressure constant is to

maintain SICP constant).

4- Unscheduled Events while killing operations

Well control assessment notes WOD / DIV-1

* If plugged nozzles happened while K.wt already out of bit

>> You will continue with the new FCP (IF PLUGGED NOZZLES LED TO INCREASE IN

DPP 300 PSI >> YOU WILL CONTINUE WITH NEW FCP = CALCULATED FCP + 300

PSI)

* If lost nozzles happened while K.wt already out of bit

>> You will continue with the new FCP (IF LOST NOZZLES LED TO DECREASE IN DPP

300 PSI >> YOU WILL CONTINUE WITH NEW FCP = CALCULATED FCP - 300 PSI)

* If plugged nozzles or lost nozzles happened before kill mud

wt arrive to bit you have to make to bring new SCR ,ICP &

FCP then make new down step chart & resume killing

operations.

Best wishes for all with great success

SAH

Work over foreman / Div#1

Well control assessment notes WOD / DIV-1

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Intertek CT Schedule 2013Document1 pageIntertek CT Schedule 2013a.qawiNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

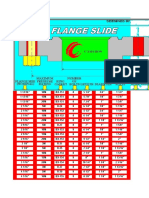

- Flange Slide RuleDocument6 pagesFlange Slide Rulea.qawiNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Top 10 Interview QuestionsDocument7 pagesTop 10 Interview Questionsa.qawiNo ratings yet

- Clean Living at WorkDocument1 pageClean Living at Worka.qawiNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- 0008Document8 pages0008a.qawiNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- sITE aVAIL 29-07-2021Document58 pagessITE aVAIL 29-07-2021ogbodoemaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Chapter 13: Worksheet Mark SchemeDocument2 pagesChapter 13: Worksheet Mark SchemeAdam DanialNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Ram Concrete AnalysisDocument94 pagesRam Concrete AnalysisTom CurryNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Answers of Chapter (8) : Course: Operating SystemDocument7 pagesAnswers of Chapter (8) : Course: Operating SystemasdNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- MD RAKIBUL ISLAM Update CVDocument2 pagesMD RAKIBUL ISLAM Update CVনীল বেদনাNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Overboard Dump ValveDocument3 pagesOverboard Dump ValveekabudiartiNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Snake Game Code in Assembly LanguageDocument22 pagesSnake Game Code in Assembly LanguageMoaz MaalikNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- How To Use MySQL With ErlangDocument2 pagesHow To Use MySQL With ErlangarthurbulivaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Mobile Robots and Autonomous VehiclesDocument2 pagesMobile Robots and Autonomous VehiclesAbel Varghese DavidNo ratings yet

- Cummins ECM Reference NotesDocument11 pagesCummins ECM Reference NotesjuanNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Informatics and Patient SafetyDocument5 pagesInformatics and Patient SafetyCurieNo ratings yet

- Accounting Principles Ifrs Version Global 1st Edition Weygandt Solutions ManualDocument26 pagesAccounting Principles Ifrs Version Global 1st Edition Weygandt Solutions ManualKimberlyMendezyptr98% (40)

- PS2 VerilogDocument11 pagesPS2 Veriloglizhi0007No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- 381Document8 pages381Nidya Wardah JuhanaNo ratings yet

- Advanced Practice Role PaperDocument12 pagesAdvanced Practice Role Paperapi-333817208No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- ID 2051814.1 Oracle Support Sample SetupDocument9 pagesID 2051814.1 Oracle Support Sample SetupFerasHamdanNo ratings yet

- NR 10 Specification 75ADocument2 pagesNR 10 Specification 75AHsalmani1991No ratings yet

- Halo Lighting Product Catalog 1974Document68 pagesHalo Lighting Product Catalog 1974Alan Masters100% (1)

- Global Cardiac Catheters - 2012-2018Document4 pagesGlobal Cardiac Catheters - 2012-2018Axis Research MindNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Viola - David Tudor - The Delicate Art of FallingDocument9 pagesViola - David Tudor - The Delicate Art of FallingRobin ParmarNo ratings yet

- Weatherford Artificial Lifts Reciprocating Rod Lift OverviewDocument7 pagesWeatherford Artificial Lifts Reciprocating Rod Lift OverviewKentodalNo ratings yet

- GH13 Heavy Duty Body Installation Manual PDFDocument132 pagesGH13 Heavy Duty Body Installation Manual PDFPrashant Sharma100% (14)

- Global Edge Interview ExperienceDocument2 pagesGlobal Edge Interview Experienceshafi hasmaniNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Solar Storage System Comp GUIDEGTM 2 1Document10 pagesSolar Storage System Comp GUIDEGTM 2 1harosalesvNo ratings yet

- Status of ECSS E-30 - Space Engineering Handbooks On CDROM: Structural Materials Handbook, Insert Design Handbook and Adhesive Bonding HandbookDocument1 pageStatus of ECSS E-30 - Space Engineering Handbooks On CDROM: Structural Materials Handbook, Insert Design Handbook and Adhesive Bonding HandbookNetrom09No ratings yet

- Indonesia's First Maritime Service Solution Provider: Company ProfileDocument10 pagesIndonesia's First Maritime Service Solution Provider: Company Profilemuh_akbar2451No ratings yet

- Physics 23 Fall 1993 Lab 2 - Adiabatic Processes: PV NRTDocument13 pagesPhysics 23 Fall 1993 Lab 2 - Adiabatic Processes: PV NRTvipul ch v v n s sNo ratings yet

- 6400t Rev-BDocument4 pages6400t Rev-BGloria HamiltonNo ratings yet

- D-1967 (Clean) Quilting Machine ManualDocument33 pagesD-1967 (Clean) Quilting Machine Manualvalter craccoNo ratings yet

- Ece T 2012 ToppersDocument13 pagesEce T 2012 ToppersRajesh LingamalluNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)