Professional Documents

Culture Documents

Steel Corbel Design For Truss Support

Uploaded by

riyazkaderOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Corbel Design For Truss Support

Uploaded by

riyazkaderCopyright:

Available Formats

Reference Documents

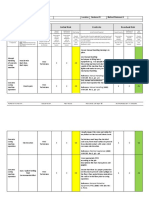

1 UK design code BS 8110 & BS 8007

2 Drawing No. AST-1408-TR189-SHD-NVP1-M-011_R0

3 Soil Investigation Bore Hole Log

Assumptions / Comments

1 Truss is supported at two ends on steel corbel with only vertical support at one end

and With vertical and horizontal support at other end

2 All Bolts are of grade 8.8.

Design Parameters

General:

Concrete Compressive Strength = 40.00 N/mm² fc

Steel Yield Strength = 460.00 N/mm² fy

Grade of Bolt = 8.80

Shear strength of Bolts = 375.00 N/mm² ps

Tensile strength of bolts = 560.00 N/mm² pt

Diameter of bolt = 27.00 mm db

Spacing of Bolts Vertically = 250.00 mm s

Total Number of Bolts = 20.0 No.s

Dimensions:

Depth of Corbel = 1220.00 mm

Width of Column Connecting to Corbel = 800.00 mm

Ultimate Support Reactions

Chord 1 Reactions Vertical = 1460.00 kN Fv1

Horizontal = 168.00 kN Fh1

Grid -19

Chord 2 Reactions Vertical = 1464.00 kN Fv2

Horizontal = 155.00 kN Fh2

Chord 3 Reactions Vertical = 1137.00 kN Fv3

Horizontal = 0.00 kN Fh3

Grid -21

Chord 4 Reactions Vertical = 1141.00 kN Fv4

Horizontal = 0.00 kN Fh4

Maximum Reaction Considered for Design,

Maximum Shear Force = 1464.00 kN Fv2

Maximum Tension = 155.00 kN Fh2

Eccentricity of shear force from face of column = 210.00 mm ex

Eccentricity of Tensile force from centre of bolts = 600.00 mm ey

Moment due to eccentric shear force = Fv * ex = 307.44 kNm M1

Moment due to eccentric Tensile force = Fh * ey = 93 kNm M2

Total Moment due to eccentricity of forces, Mu = M1 + M2 = 400.44 kNm Mu

Spacing between each raw of bolts = 250.00 mm h

Tensile force in the Extreme top bolts due to Moment, Ft = Mu /(7.5*h)= 213.57 kN

As there are two bolts on the top raw,

Force in each bolt at extreme top Ftt = 106.784 kN

Tensile force acting on each bolt due to Tension Force Fht = Fh2/n = 15.5 kN

Total Tensile Force acting on the Extreme top bolt = Fht + Ftt = 122.284

Design Shear Force and Tension Force Acting on each Bolt,

Design Shear Force = 146.40 kN Fvd

Design Tension Force = 122.28 kN Ftd

Considering Threaded M27 Bolts with the following specifications,

Grade of Bolt = 8.80

Diameter of bolt = 27.00 mm db

Area of Cross section at threaded area = 446.37 mm² At

Shear strength of Bolts = 375.00 N/mm² ps

Tensile strength of bolts = 560.00 N/mm² pt

Shear Strength of Bolt, fvb = ps * At = 167.39 kN Fvb

Unity Ratio = Fvd / Fvb = 0.87 OK

Tensile Strength of Bolt, ftb = pt * At = 249.97 kN Ftb

Unity Ratio = Ftd / Ftb = 0.49 OK

Check for Combined Shear and Tension

Fvd + Ftd ≤ 1.4 = 1.36 OK

Fvd Ftb

Check for Embedment:

Embedment Length = 300.00 mm hef

Bond Stress = 0.28 √fcu = 11.70 N/mm² fb

Total Tensile Force acting on each bolt = 122.28 kN Ftd

Area available for bonding = 25434 mm² Ab

Bonding (friction) capacity of anchor = 297.58 kN

Check for Bending Moment Capacity of Base Plate:

Length of Base Plate effected by the load = 200.00 mm wb

Point Load acting on the centre of Plate = 122.28 kN Ftd

Bending Moment acting at centre of plate = Ftd * Lb / 4 = 6.11 kNm Mub

Yield Strength of base plate section = 275.00 N/mm² fyb

Thickness of Base Plate = 30.00 mm tb

Width of Base Plate resisting the load = 250.00 mm wb

3

Section Modulus of Plate section resisting bending = wb x tb^2 / 6 = 37500 mm Zb

Bending capacity of Base Plate section = fyb x Zb = 10.31 kNm Mcb

Unity Ratio = Mub / Mcb = 0.59 OK

You might also like

- Corbel DesignDocument6 pagesCorbel Designasvenk309No ratings yet

- Sign Convention of Plate Element Stresses and MomentsDocument2 pagesSign Convention of Plate Element Stresses and MomentsNikhil Poriya100% (1)

- Deck SheetDocument2 pagesDeck SheetmaheshbandhamNo ratings yet

- Design of monorail beam for main plantDocument12 pagesDesign of monorail beam for main plantmrprabhu16No ratings yet

- Ring Wall Foundation Design CalculationsDocument6 pagesRing Wall Foundation Design Calculationsraghav abudhabiNo ratings yet

- Design of Base Plate and Bolts FinalDocument4 pagesDesign of Base Plate and Bolts FinalManoj Jaiswal100% (1)

- Appendix A.1: Monorail Beam Design With 3MT SWL, S2 Type (Fy 250 Mpa)Document10 pagesAppendix A.1: Monorail Beam Design With 3MT SWL, S2 Type (Fy 250 Mpa)sundarNo ratings yet

- Beam - Deflection CheckDocument8 pagesBeam - Deflection CheckChhour CENo ratings yet

- Calculation For 1.4m X 1.5m RCC Box CulvertDocument4 pagesCalculation For 1.4m X 1.5m RCC Box CulvertManish BhatkarNo ratings yet

- Gantry Beam Design PDFDocument5 pagesGantry Beam Design PDFanwarNo ratings yet

- 8m Unipole Design Calculation (TM Kuala Kangsar) .Document25 pages8m Unipole Design Calculation (TM Kuala Kangsar) .Tam Eng Sun100% (1)

- Typical Anchor BoltsDocument33 pagesTypical Anchor BoltslucianduNo ratings yet

- Joints in Steel Construction - Simple Connections - Part 11 PDFDocument4 pagesJoints in Steel Construction - Simple Connections - Part 11 PDFkakem61No ratings yet

- Fan Foundation DesignDocument71 pagesFan Foundation DesignPalani RNo ratings yet

- Column Splice End Plate DesignDocument3 pagesColumn Splice End Plate DesigninnovativekarthiNo ratings yet

- Design of SpliceDocument4 pagesDesign of SpliceJustinNo ratings yet

- Crack Width Check For Water Tank BaseDocument4 pagesCrack Width Check For Water Tank BaseShamim Ahsan ZuberyNo ratings yet

- 3 - Flush End Plate Moment Conn To Beam WebDocument11 pages3 - Flush End Plate Moment Conn To Beam Webabdul khaderNo ratings yet

- Chequered DesignDocument2 pagesChequered DesignSaravana N100% (1)

- Magnified Moment Calculation For Circular Slender ColumnsDocument12 pagesMagnified Moment Calculation For Circular Slender ColumnsAli AkbarNo ratings yet

- Design of two-way reinforced concrete slabDocument15 pagesDesign of two-way reinforced concrete slabMohammed Saleem Syed KhaderNo ratings yet

- Pile Cap Design at AbutmentDocument4 pagesPile Cap Design at AbutmentAzwani Abdullah100% (1)

- Anchoring Bolt Calculations As Per HILTI ManualDocument2 pagesAnchoring Bolt Calculations As Per HILTI Manualmoganna73No ratings yet

- Crane Runway Beam Design - Crane Load CalculationDocument6 pagesCrane Runway Beam Design - Crane Load CalculationAlex MolinaNo ratings yet

- Culvert Precast Top Cover - ECV-CAL-005BDocument18 pagesCulvert Precast Top Cover - ECV-CAL-005Bsidiq7No ratings yet

- PURLIN - DESIGN - AS - PER - IS - CODE LatestDocument22 pagesPURLIN - DESIGN - AS - PER - IS - CODE Latestnitin chaudharyNo ratings yet

- Monorail Design Lateral LoadDocument46 pagesMonorail Design Lateral Loadshangz1511No ratings yet

- Composite Beam DesignDocument4 pagesComposite Beam DesignSunil PulikkalNo ratings yet

- Base Plate Design in LSM by IS Code Revision 2Document24 pagesBase Plate Design in LSM by IS Code Revision 2Structural SpreadsheetsNo ratings yet

- Hilti Calculation ExamplesDocument10 pagesHilti Calculation ExamplesNgoc TruongNo ratings yet

- Design of Open Well StaircaseDocument2 pagesDesign of Open Well StaircaseAnish Neupane100% (1)

- Bolted Connection Angle Brace TensionDocument2 pagesBolted Connection Angle Brace TensionRajib MaharjanNo ratings yet

- Concrete Pull Out Check PDFDocument1 pageConcrete Pull Out Check PDFMaliki MuhammedNo ratings yet

- Design of Foundation for Column Load of 561 kNDocument7 pagesDesign of Foundation for Column Load of 561 kNB Paari VallalNo ratings yet

- Design of Base PlateDocument3 pagesDesign of Base Plateravi4paperNo ratings yet

- Anchored Sheet Pile Wall DesignDocument7 pagesAnchored Sheet Pile Wall Designmahmoud meslehNo ratings yet

- Base Plate Design SummaryDocument3 pagesBase Plate Design SummarySơn Nguyễn-LêNo ratings yet

- Deflection Limits As Per Is800-2007Document1 pageDeflection Limits As Per Is800-2007maheshbandhamNo ratings yet

- Grade Slab DesignDocument6 pagesGrade Slab DesignMALAY MRIDHANo ratings yet

- Design calculations for skin plate and stiffener of pier and piercapDocument4 pagesDesign calculations for skin plate and stiffener of pier and piercapraghuveer11No ratings yet

- Pedestal DesignDocument2 pagesPedestal DesignRamadanNo ratings yet

- Beam - Column Steel SpliceDocument20 pagesBeam - Column Steel SpliceAnsh SharmaNo ratings yet

- Steel to concrete connection design summaryDocument12 pagesSteel to concrete connection design summaryCSEC Uganda Ltd.No ratings yet

- Plate Girder DesignDocument109 pagesPlate Girder Designhasib100% (3)

- PurlinDocument1 pagePurlinCe WinNo ratings yet

- TRITECH DESIGN OF CORBEL AND BEARING PLATEDocument2 pagesTRITECH DESIGN OF CORBEL AND BEARING PLATEsuman_civilNo ratings yet

- Steel Beam Design As Per AISC ASDDocument2 pagesSteel Beam Design As Per AISC ASDKov Chanthy100% (1)

- Slab Base Connection.Document29 pagesSlab Base Connection.Darshan PanchalNo ratings yet

- Beam COlumDocument2 pagesBeam COlumprateeksuperNo ratings yet

- Design Calculation Of: Base Plate and Anchor BoltDocument4 pagesDesign Calculation Of: Base Plate and Anchor Bolthanuman sharma0% (1)

- Base PlateDocument6 pagesBase PlateJigarNo ratings yet

- Ext Finplate ConnecDocument78 pagesExt Finplate Connechary9100No ratings yet

- Beam To Beam Connection (Shear Only) - 1 RowDocument30 pagesBeam To Beam Connection (Shear Only) - 1 RowChangHangWingNo ratings yet

- Seismic and wind load calculations for vessel support structureDocument3 pagesSeismic and wind load calculations for vessel support structurecordajohnNo ratings yet

- Report BoltDocument1 pageReport BoltMong is not hereNo ratings yet

- Design of Moment and Shear Connections (boltedDocument4 pagesDesign of Moment and Shear Connections (boltedAmit Ghosh67% (3)

- Beam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesDocument13 pagesBeam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesVenkatesha Hebbar100% (1)

- Beam To Beam Connection (Shear Only) - 2 RowDocument45 pagesBeam To Beam Connection (Shear Only) - 2 RowChangHangWingNo ratings yet

- AddendumDocument4 pagesAddendumJoe NadakkalanNo ratings yet

- End Plate Connection (Both Side Flush) - IS800 - 2007 - 2020.04.22Document11 pagesEnd Plate Connection (Both Side Flush) - IS800 - 2007 - 2020.04.22MANOJNo ratings yet

- Revised Risk Assessment-Concrete Coring-1Document5 pagesRevised Risk Assessment-Concrete Coring-1riyazkader82% (11)

- Steel Water Tank Failure CalsDocument11 pagesSteel Water Tank Failure Calsriyazkader100% (1)

- Splice Length For CFRP RebarsDocument8 pagesSplice Length For CFRP RebarsriyazkaderNo ratings yet

- TSS 45 / 250 sheet specifications for aluminium and steel roofingDocument1 pageTSS 45 / 250 sheet specifications for aluminium and steel roofingriyazkaderNo ratings yet

- Comflor Composite Floor Deck Brochure UKDocument32 pagesComflor Composite Floor Deck Brochure UKAma DavidescuNo ratings yet

- Seismic Design of RC Structures Using UBC - ACI ProvisionsDocument281 pagesSeismic Design of RC Structures Using UBC - ACI ProvisionsMuhammad Saqib Abrar93% (15)

- Rayees House A4Document1 pageRayees House A4riyazkaderNo ratings yet

- PDS Sikawrap 900CDocument4 pagesPDS Sikawrap 900CriyazkaderNo ratings yet

- Hilti Hit-Re-500 PDFDocument68 pagesHilti Hit-Re-500 PDFSumanta BhayaNo ratings yet

- Dubai Wind Code GuideDocument25 pagesDubai Wind Code GuideEdin LissicaNo ratings yet

- Structural ReportDocument48 pagesStructural ReportriyazkaderNo ratings yet

- Comprehensive Guide to Implementing Estidama in Abu Dhabi CityDocument16 pagesComprehensive Guide to Implementing Estidama in Abu Dhabi CityriyazkaderNo ratings yet

- General Requirements For Alloy and Stainless Steel PipeDocument11 pagesGeneral Requirements For Alloy and Stainless Steel Pipergi178No ratings yet

- Liam Smith ResumeDocument1 pageLiam Smith Resumeapi-340130782No ratings yet

- Killeshal Lintels SpecificationDocument4 pagesKilleshal Lintels Specificationgdug27No ratings yet

- ChE 108A Syllabus PDFDocument3 pagesChE 108A Syllabus PDFnadimNo ratings yet

- Cosmet Presentation2Document62 pagesCosmet Presentation2taghdirimNo ratings yet

- CV - Zat WinarkoDocument5 pagesCV - Zat WinarkoAndika PratamaNo ratings yet

- Fall 2021 Master Course MemoDocument205 pagesFall 2021 Master Course MemoIbrahim MoazzamNo ratings yet

- Project PPT FinalDocument8 pagesProject PPT Finalsayandh spNo ratings yet

- Lesson S02C03-Moncarz P Et Al. (2000)Document5 pagesLesson S02C03-Moncarz P Et Al. (2000)gonzaloNo ratings yet

- Live Line WashingDocument18 pagesLive Line WashingAsad KhanNo ratings yet

- Tesla TransformersDocument4 pagesTesla TransformersBADRI VENKATESHNo ratings yet

- Engineering Risk Survey Reports - An Insight For UnderwritersDocument14 pagesEngineering Risk Survey Reports - An Insight For UnderwritersAli Mahgoub Ali TahaNo ratings yet

- Sen Answer Class Test 1Document14 pagesSen Answer Class Test 1zayankhan368369No ratings yet

- Mechatronics, Codes, Logic GatesDocument22 pagesMechatronics, Codes, Logic GatesAfolabi peterNo ratings yet

- Nafems Benchmark AerospaceDocument57 pagesNafems Benchmark Aerospacegarystevensoz0% (1)

- ES.0.06.0021-C - Compilation and Handover of Project DossierDocument34 pagesES.0.06.0021-C - Compilation and Handover of Project DossierHamid Khan100% (5)

- Engineering GroutsDocument4 pagesEngineering GroutsfairmatechemicalNo ratings yet

- 2-STOREY RESIDENTIAL BUILDING SPECIFICATIONSDocument11 pages2-STOREY RESIDENTIAL BUILDING SPECIFICATIONSTrisha Casiño88% (16)

- Engineering Optimization, 2nd Ed, Wiley (2006), 0471558141Document681 pagesEngineering Optimization, 2nd Ed, Wiley (2006), 0471558141Shivani GuptaNo ratings yet

- February 2017Document52 pagesFebruary 2017Alfred LamNo ratings yet

- DBRDocument36 pagesDBRMudit VermaNo ratings yet

- ANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 17Document1 pageANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 17visanuNo ratings yet

- Sandcrete Blocks Production ProcessDocument12 pagesSandcrete Blocks Production Processpraisejah moyoNo ratings yet

- HIT-RE 500 Epoxy Injection Mortar SystemDocument3 pagesHIT-RE 500 Epoxy Injection Mortar Systemdeanz_75No ratings yet

- Thermal comfort & passive design reading listDocument2 pagesThermal comfort & passive design reading listHarshil SafiNo ratings yet

- M Jayakumar Paper (17142691331)Document12 pagesM Jayakumar Paper (17142691331)N V DhandapaniNo ratings yet

- VSL News 1997 1Document16 pagesVSL News 1997 1DrPadipat ChaemmangkangNo ratings yet

- Glf-whp02-Epcic4 Exhibit H App h1Document7 pagesGlf-whp02-Epcic4 Exhibit H App h1Pete RueangchimNo ratings yet

- Section 260573 - Electrical Systems Analysis PartDocument7 pagesSection 260573 - Electrical Systems Analysis PartBoxer099No ratings yet

- Unza Provisional Loan Awads 2022 2023 Academic YearDocument37 pagesUnza Provisional Loan Awads 2022 2023 Academic Yearfabbyzulu5No ratings yet