Professional Documents

Culture Documents

Steela-'07: Duplex Stainless A Review After DSS Held in Grado

Uploaded by

Vinay MaisuriyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steela-'07: Duplex Stainless A Review After DSS Held in Grado

Uploaded by

Vinay MaisuriyaCopyright:

Available Formats

Materials Technology

Duplex Stainless steela- a Review after DSS '07 held in Grado

Jacques Charles

ARCELOR MITTAL, Stainless R&D General Manager, 5-7, rue Luigi Cherubini, 93210 La Plaine Saint-Denis Cdx, France;

jacques.charles@arcelormittal.com

Duplex stainless have always been an exiting area of interest for researchers, stainless steel producers, fabricators and end users. They

present very diversified technical challenges and simultaneously attractive in-service properties at excellent cost/properties ratios,

particularly in critical markets including oil and gas, chemical industry, pulp and paper industry, water systems, desalination plants, pollution

control equipments, chemical tankers, etc. This explains why although they still remain a marginal production in the stainless steel business

(less than 1%) dedicated international conferences have been organised since about 25 years. The purpose of this paper is to present a

review of the 100 scientific contributions presented during the latest international duplex stainless steel conference witch took place in

Grado, Italy, on 18-20 June 2007. The main topics concerned microstructure and mechanical properties, weldability, corrosion resistance

and in-service properties. The "standard" duplex stainless steels, Le. the 2304, 2205, and the family of 2507 (Cu,W,oo.) grades were

confirmed as very valuable grades with outstanding performances proven in more than 20 years successful in-service applications. New

grades including the so-called lean duplex dedicated to volume oriented markets (possible replacement of 304/316 grades) and some

"niche" grades dedicated to very specific markets were presented. It was pointed out that the duplex grades start to be well established

products particularly suitable for corrosion resistance applications. They show a two-digit yearly growth thanks to the production of new

grades and production ranges (coils and bars) targeting the replacement of the more costly 300 series including 304 but also rusty carbon

steel in e.g. structural application.

Keywords: Duplex Stainless Steel, Markets and Applications, Chemistries, Metallurgy, Mechanical Properties, Corrosion Resistance

Properties, Weldability.

DOl: 10.2374/SRI08SP063-79-2008-455; submitted on 7 March 2008, accepted on 14 March 2008

Introduction and cost savings partially obtained due to the favourable

mechanical properties were expected. New codes for

The first international duplex conferences (St duplex grades had to be established. The potential growth

Louis/DSA/82 and The HaguelNL/86) were mainly of the grades was clearly emphasized. All this partially

focused on "scientific" aspects like phase precipitations explained the extremely wide audience of the

(structures, kinetics), corrosion resistance, mechanical BEAUNE'91 conference.

properties. The world wide industrial production in that The York'94, Maestricht'97 and Venice'2000 con-

time was almost marginal and standardization still had to ferences were also successful conferences with increasing

be implemented. The main applications concerned the oil return of information on practical experiences [2-3]. Most

and gas Industry. of the applications still concerned quarto-plates and tubing.

The conference in Beaune/France in 1991 was the first The first lean duplex grades appeared.

duplex conference with a mix of scientific and market This paper is a review of the scientific and technical

focus. New grades with increased nitrogen additions were contributions presented at the latest International Duplex

presented [1]. Duplex grades gained in structure stability, Stainless Steel Conference held in Grado, Italy, on 26-28

weldability and corrosion resistance properties. New June 2007. With about 300 attendees and 100 con-

standards were proposed. The duplex family included the tributions the conference appeared to be an excellent mix

popular 2205 grades with increased nitrogen additions of outstanding scientific contributions and technical

(0.16/0.l8%N instead of 0.12/0.15%N) and optimized Mo presentations covering field experiences in many areas of

contents. PREN values were proposed between 33 and 36 applications.

with a most common value of 34/35. Sigma free grades

were recommended as well as a minimum Mo level of 3%.

Grade 2304 was already developed but for marginal Stainless Steel Production and Consumption

applications. Several super duplex grades were also

promoted - SAF 2507, DR 52N+, Zeron 100... - for the The worldwide yearly crude steel production for flat

most severe applications including off-shore. Those super stainless steels has been booming at an average growth of

duplex grades were also redesigned before the 6% since more than 50 years. Nevertheless, stainless steel

BEAUNE'91 conference in order to have a PREN value production is less than 1% of that of carbon steel [4], the

minimum of 40 and a nitrogen level minimum of 0.25 %. 304 grade being the most widely used. Today's biggest

The grades were mainly produced with EAF + VOD or geographic area of stainless consumption is Europe while

AOD and continuous casting devices. First extensive for the future most of the growth is expected to take place

applications were reported as well as new areas of in Asia. Production capacities are booming mainly in

developments. The duplex grades won the end-users' trust China and a similar rise is expected to come in India. Asia

steel research int. 79 (2008) No.6 455

Materials Technology

which has since many years imported a part of its demand material price. As a result, a rise of several thousands of

will soon be able to export stainless steel due to possible euros per ton has been observed for the 300 series prices

overcapacities. The booming demand in Asia particularly within a few years. Of course, ferritic steels are almost not

in China and a certain lack of regulations made it possible affected by those effects. Replacement of 304 and 316

to develop new grades with less alloying elements. China grades by ferritic grades is nowadays the cost saving

and India are the countries where the new 200 series were solution. This concerns particularly thin gauge

developed. More recently China has used more than 1 applications since ferritics are difficult to weld in thicker

million of tons of those new grades which are not subject sections.

to any specific norm [5].

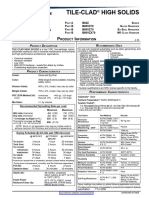

Austenitics remains the most popular grades thanks to

their unique combination of high ductility, high potential ~""'£'''''~ 304L

8000

of strengthening, weldability, toughness even at extra-low '~_316L

7000 Ni Mo Cr

temperatures and of course corrosion resistance. Ferritics 1 6 7 0,8

2101

_ _ 2304

represent about 25% of the total production. Due to 6000 2 10 17 1

........ 2205

3 14 35 1,5

welding aspects and toughness properties, they are 5000 4 30 40 1,5 _2507

restricted to thinner gauges even if they are often the cost 5 52 42 1,5 430

4000 439

saving grades. Duplex grades cover about 1% of the total 445

production [5]. 3000 --.434

_444

2000

" '.',,~

_ _ 204201

Duplex Stainless Steels - Market Applications 1000

175Cu

Most of the duplex grades in service are 2205 hot rolled 151 Cu

products. In the recent past strong demand and

developments have extended to cold finished flat products Figure 1. Evolution of raw material costs for stainless steel

and hot finished long products (rebar). The worldwide production from January through May 2007, in US$/ton.

production of duplex grades represents nowadays about

200 000 t, i.e. less than 1% of the total stainless steel

production although the duplex production has grown by

more than 100% in the latest decade. Most of the

production concerns the so-called quarto plates (i.e. plates

of more than 2000 mm width more than 6mm thickness).

For those products weight savings are often obtained

taking advantage of their advanced mechanical properties.

Most of the applications utilize the excellent corrosion

resistance properties, e.g. in the process industry (chemical,

petrochemical, off-shore, chemical tankers, pulp and paper

industry, pollution control equipments-FGD-, desalination,

sea-water applications...). In those applications 2205

grades have always been very competitive compared to the o 4 8 12 16 20 24 28 32 36 40

317 (LMN) and 904 grades due to their reduced nickel Cr eqUivalent

Cr% + Mo% + 1,5 Si% + 0,5 Nb% + 5V% + 3 AI%

content and favourable high mechanical properties

compared to austenitics, which make it possible to reduce

thicknesses (quarto plates). Figure 2. Schaeffler diagram illustrating the areas of stability of

Superduplex grades (2507 Cu,W) represent about 10% stainless steel microstuctures.

of the total duplex volume and are designed to replace

6Mo austenitic grades in the most severe applications. Although the Ni price has recently been declining,

Lean duplexes including the 2304 and 2101 grades duplex grades start to be very cost competitive answers for

contribute to slightly more than 10% of the total duplex thicker gauges. Replacements of 316 grades by 2205

production. duplex grades are now to be considered: cheaper material

The booming market is extending to products recently but much better corrosion resistance properties and high

developed, i.e. new grades including lean duplex and new mechanical properties! The same results are observed for

production ranges (coils and bars). The lean duplex grades 2304 duplex versus 304 and 316. And the new lean

are expected to replace 304/316 in volume markets. If coil duplexes of 2101 type are even less alloyed in the

production can be achieved at high productivity and expensive elements Ni and Mo. This provides new

quality, duplex consumption will grow very fast. Another powerful driving forces for a further increased use of

potential booming market could be duplex for rebar. duplex grades in new applications.

Stainless Families and Alloying Costs Duplex Stainless Steels - Grades

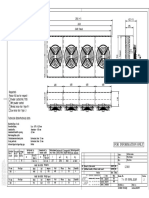

The recent evolutions of raw material costs, particularly Although the Schaeffler diagram (Figure 2) is mainly

Ni, have a drastic impact on 304 and 316 alloy surcharges used for welded structures, it is very useful to roughly

(Figure 1). They are nowadays higher than the base illustrate the areas of stability of the different stainless

456 steel research int. 79 (2008) No.6

Materials Technology

microstructures. Between the austenitic and the ferritic %N

N solubility limit

areas, we obtain a mixed ferrite + austenite microstructure: 0.40

the duplex area. Most of the duplex industrial grades have

.i Stability of T ~

a typical 50%ferrite/ 50%austenite microstructure. The 0.35 i not guaranteed ~ ~

three classical families of duplex grades are plotted in the i (Ms transiti~l'

Schaeffler diagram: the 2304 Mo free grades, the standard 0.30 i ~~

: ~

duplex type 2205 and the superduplex grades of 2507 type. : ~

As observed, it is almost impossible to develop duplex 0.25

grades having less than 20%Cr without possible formation

of martensite. Those grades that have an austenite/ferrite 0.20 ....'... ...

:r? , . "'N'standard duplex

....

First developments

Stability of a

microstructure even after quenching may undergo an ~. • 25Cr duplex difficultto achieve

0.15 • ~r. 32205 (intermetalliett

austenite/martensite transformation when plastic

deformation occurs. 0.10

With the extreme volatility of alloying element costs

(Figure 1) new grades have been introduced in the market 0.05

i 31803

(Table 1). The newly developed grades are on both sides ··32~04 4462

of the standard 2205 grade. The first family of grades 43$

concerns the so-called lean duplex, having less Mo and Ni o 25 30 35 Cr + Mo (%)

additions. Their phase stability may be achieved thanks to

Figure 3. Newly designed duplex grades with increased nitrogen

supplementary alloying of manganese, another austenitic content.

stabilizing element. These new grades also have an

increased nitrogen content since nitrogen additions (extra

low cost element) are known to improve the austenite and possible partial replacement of exclusive Mo additions

stability of the grades and localised corrosion resistance by mixed Mo+W additions. These types of alloying seem

properties (Figure 3). The main target of those grades is a to contribute to stabilise the respective grade, providing

partial replacement of 316 and even 304 austenitic grades less sensitivity to intergranular phase precipitations on

depending upon their properties related to the chemistry of heating. This concerns mostly the very high Mo content

the alloy. Some of those grades still have high Mo duplex grades.

contents combined with Ni additions.

When using the word "lean" for duplex grades we Microstructure Stability

should restrict our definition to almost Mo free grades and

nickel content lower than 3%. Grade 32003 is obviously Figure 4 schematically shows the phases and types of

less expensive in alloying elements than the 2205 .grade precipitations that may occur in duplex grades. Phase

but more expensive than the 2304. It should not be precipitations are clearly related to the Mo, Cr and W

considered as a lean duplex. additions. Alloying of Cr, Mo, W makes the grades more

On the other hand, some new more alloyed grades have prone to transform from the ferritic phase to intermetallic

been introduced as well. This concerns alloys having phases (sigma, chi ..), nitrides, carbides Or even, at lower

mostly higher corrosion resistance and structure stability temperature, to the alpha prime microstructures (Spinodal

than the 2507 type grades. They are often called decomposition). With copper additions complementary

hyperduplex grades. The driving forces are higher Cr precipitations of epsilon-Cu may occur in the 600/300°C

additions with simultaneously increased nitrogen additions range (Figure 5).

Table 1. Typical chemical compositions (in wt.%) of duplex stainless steels in comparison to the 300 series.

I FAMILY I USAI EURONORM~ OtherS~PRENWI

304L 18

300 316L

904LN

1.4307

1.4401

1.4339

18

17

20

°

2

4

9

11

25

1

1

1 °°

1,5 0,1

18

24

33

18

24

35

24

35

Standard

DUPLEX

S 32304

S 32205

S 32750

1.4362

1.4462

1.4410

23

22

25

°

3

3,5

4

6

7

1

1

1

0,13

0,17

0,27

23

32

37

25

35

41

25

35

41

(1996) S 32760 1.4501 25 3,8 7 1 0,7 0,27 0,7W 38 42 43

S 32520 1.4507 25 3,5 7 1 1,5 0,25 37 41 41

S 31500 18,5 2,7 5 1 0,1 27 29 29

S 32101 1.4162

New

S 32001

S 32003

21

20

20

°

0,3

1,7

1,5

1,7

3,5

5

5

2

0,3

0,2

0,15

0,15

21

21

26

24

23

28

24

23

28

DUPLEX

S 31260 27 3 7 1 0,5 0,16 0,3W 37 39 40

(EX)

S 39274 25 3 7 1 0,6 0,27 2W 35 39 42

S 32906 1.4362 29 2 6 1 0,4 36 42 42

S 32707 27 5 6,5 1 0,4 44 49 49

PRE =%Cr + 3.3%Mo ; PREN(W) =%Cr + 3.3%Mo + 16%N + (3.3(0.5%W)).

steel research int. 79 (2008) No.6 457

Materials Technology

MO,W,Si annealing temperatures produce higher ferrite contents and

1000·C ---~t'icarbide,Cr N nitride HAZ lower toughness [13].

1800·F , a phase

Cr ' Cr2 N nitride Step cooling, for example at 700°C, with or without

Mo ' X phase mechanical deformation, can lead to the precipitation of

W ' Y2 phase

Si ' M23 C6 carbide numerous small acicular austenite grains (gamma two),

, R Phase presenting a {Ill h//{11O} a Kurdjumov-Sachs relation-

••-- 7t phase ship. At lower temperatures an even finer structure may be

/' ' & phase (Cu)

Cr, Mo, Cu, ~ '. ~' ~h. ase formed ({l23} a habit plane with a Nishiyama-Wasserman

300·C ~hase ... orientation) [1].

600·F

Cr, Mo, Cu, W

Time High temperature precipitations. For the most

alloying duplex grades it has been confirmed that sigma

Figure 4. Typical phase precipitations which may occur in duplex phase issued from an eutectoid decomposition of austenite

grades. is the most common brittle phase observed. Its typical

chemical composition is 60Fe30Cr7M03Ni (2205). The

1800 sigma phase precipitates with the y2 phase, which is an

a Solidification

Possible primary austenitic phase having a lower PREN value than the

1600

carbides. nitrides matrix, typically 36 instead of 42 for a superduplex grade.

P

1400

1200

t The chi phase is often observed as an intermediate

precipitation before transforming into the sigma phase.

Sigma and Chi phases have a strong embrittlement

a ~ yl

...

:Q)

effect while y2 deteriorates the average corrosion

~ 1000 resistance properties of the respective grade.

~ 800 a ~ a+y3; a ~ y2 Models based on Avrami's equation are now available

E

{E. a ~

X. ~ cr+y3 ; G to predict the microstructure after both continuous and

600 SecondarY nitrides. carbo isothermal heat treatments of industrial grades. Typical

minimum cooling rates of 0.3°C/s are requested to avoid

400 sigma phase precipitations in a 2205 duplex alloy [14].

200

W additions are known to stabilise the sigma phase at

high temperatures. W containing grades require higher

0 - - - - - - ' 1 Y ~ Martensite (lean temperatures for solution annealing treatments. Some

30 20 10 %Cr duplex with defonnation

papers also underline the benefit of W additions in order to

a 10 20 %Ni

improve the phase stability of the duplex grade. After

Figure 5. Pseudo-binary phase diagram of the duplex grades long-term isothermal treatment the amount of sigma phase

2205/2507. is clearly reduced when comparing a Mo containing grade

with an equivalent Mo+W alloying where a part of the Mo

1000 is replaced by W additions. This seems to result from

900

r slower diffusion of big W atoms. Furthermore,

--- -------

Cr2N ,~ a-Phase

800 precipitation of the significant phases seems to be more

.... ~M2t:6 x-Phase

U 700 intragranular. Nevertheless, when looking at the first steps

0

...::s

(1)

600 of intermetallic formation, no clear evidence of W

additions is found, i.e. the first precipitations appear after

...

~ 500

the same holding time. As a result, no clear benefits of W

(1)

0.. \.~5·C- Embrittlemen additions on structure stability of duplex grades are

S

~

400

- observed.

On the contrary, the simultaneous increase in Cr (to

300

29%), decrease in Mo (2% instead of 3.5-4% ) and

increase in nitrogen (to 0.4%) is a good way to develop

2 6 20 60 180 600 1800 superduplex grades with higher structure stability [15]

time [min] (SAF 2906). The DP28W grade of Sumitomo has a similar

philosophy (27Cr, IMo, 2W, 0.35N) but with mixed W

Figure 6. TTT diagram of 2205 duplex steel. and Mo additions.

Newly developed "hyperduplexes", with PRENW

higher than 45, combine very high Cr+Mo+W additions

Most of the duplex industrial grades solidify in the with significant nitrogen additions (up to 0.4%). One

ferritic mode and undergo a partial transformation from example is the UNS 32707 grade (SAF2707) with 27% Cr

ferrite to austenite when cooling down. The volume and 5% Mo and another one is the UNS 39274 DP3W

fractions of austenite/ferrite are clearly linked to the grade (25% Cr, 3.3% Mo, 2.1% W). For those grades high

composition and temperature. (Thermocalc model is useful solution annealing temperatures are needed and they are

for such investigations). As a result, the room temperature more suitable for thinner gauges.

microstructures and properties are closely linked to the Cr-N and carbides (M7C3 , M23C6) are also expected to

solution annealing temperature, i.e. higher solution form during high temperature treatments (Figure 6). Clear

458 steel research int. 79 (2008) No.6

Materials Technology

evidences have been observed. Nevertheless, the Phase precipitations in the 550/300120oC range with

detrimental effects of sigma/chi phase precipitations in the ferrite hardening effects. At lower temperatures diffusion

superduplex grades as well as 2205 grades seem to mechanisms are slowing down and consequently the

annihilate the effect from nitides/carbides precipitations in formation of precipitates needs more time and finer

most of the cases. On the contrary, thermal cycles at very microstructures are generally found, which makes optical

high temperatures (> 1300°C), which may increase the investigations and phase identifications more difficult.

volume fraction of ferrite, followed by fast cooling Since the solubility of nitrogen in ferritic grains

treatments plus possible intermediate reheating (typical of decreases with temperature, nitrides precipitates generally

the HAZ of multipass welds) may cause significant occur at the ferrite/ferrite boundaries. Some complex

nitrides precipitations. This effect is due to excess nitrogen intermetallic phases like R, 1t, G, might also be formed

in ferritic grains and lack of time for austenite particularly in the Mo containing grades.

transformation and nitrogen diffusion [1, 16]. Carbides The most popular transformation is the Spinodal

precipitations are generally of secondary importance. decomposition of the ferrite into a' - demixing of the

For the less alloyed grades, i.e. Mo free grades, ferrite into two phase with poor and high chromium

sigma/chi phase precipitations need much more holding contents on a very small scale. This transformation is

time (several 10 hours) and nitrides precipitations, known as the 475°C transformation (it occurs mainly

particularly in the newly designed grades with higher between 475 and 280°C). A subsequent hardening and

nitrogen contents, which may be the main reason for embrittlement of the ferrite is observed. This explains why

inferior corrosion and toughness properties when heated in most of the applications are restricted to temperatures

the 600/850°C range. Brittle behaviour has been reported lower than 250°C. Superduplex grades with 25%Cr are

but for holding times by far exceeding the normal very sensitive to this phenomenon. 2205 grades are also

industrial treatments. sensitive but much less than the 2304 grade without Mo

The Mo-free duplex grades can be regarded as very although their Cr content of 22% is less than the 23% of

stable microstructure under standard heat treatments the 2304. The clear effect of Mo in this transformation is

including solution annealing treatments. Air cooling can not completely understood. Wand Cu additions have also

even be considered for some applications and very thick specific effects.

products for the solution annealed and water cooled CU-E particles may precipitate in the ferrite grains after

conditions. In those lean duplex grades (2101) nitrides heat treatment in the 550/300°C temperature range. A

precipitations have been found after a holding time of hardening effect can be obtained.

45min in the 6501750°C range. This explains why The Mo free grades seem to be less prone to low

toughness properties worsen and values less than 50J are temperature hardening. Holding times of about 10h are

observed in those conditions [16]. Typical microstructures necessary to find a' precipitation. For the lower alloyed

of duplex stainless steels observed after several heat grades (lean duplexes) martensitic transformation may

treatments are presented in Figure 7. occur to a large extent under plastic deformation [16].

(a) (c)

(d) (e) (f)

Figure 7. Duplex stainless steels after heat treatments: (a) Steel 2507 [8], ferrite and recrystallized austenite. (b) Steel 2507, 920°C, 10 min [9].

(c) and (d) Coral kind three-dimensional sigma phase precipitations [12]. (e) Steel 2507, 475°C, 100 h (11), TEM. (f) Steel 2205, 850°C, 1 h.

steel research int. 79 (2008) NO.6 459

Materials Technology

~ 16 r--------------------.

300 ~ 14 '=::::~~~I!!!!!!_=----------l

e; I

....

250 ~=12 •

t-------------"'jlilll.:,-------~

5: 200

i\ 8=10 t - - - - - - - - i 2205

..

'"

'"

ell

=

.:: 150

:\ ,-----

2205

938°e

.g~ 8 938°e

850oe......"'--------~..----------1

:1:j 6 7500e

~

e= l\ "\-: 850 0e

'3 4

E-<

100

~ 750 ~

0e

..E! Dissolution of sigma-phase

----~J;_---1

0e

50 Annealing temperature 1050

~~. ~2

0 "'0=

o 2345678 9 o 2 3 4

Intermetallic phase content [%1 Time [min]

(a) (b)

Plastic Strain Control • Coffin-Manson Curve (2fJ'C)

S3275~ • 20WC

Aep = u.3% 300 OIl 30WC

~ & 400°C

~

...-a

~

200

* 475°C

.... 500°C

550 •

-<

'"

'"

~ 40

S32750 Samples

10'

o 2000 4000 6000 8000

Number of Cycles, N 1000 10000

Number of Cycles to Failure, Nr

(c) (d)

Figure 8. (a) Effects of sigma phase precipitation on toughness properties of 2205 grade. (b) Annealing time and sigma phase dissolution

of 2205 grade. (c) and (d) fatigue crack propagation of 2507 grade.

250 I M"Yf, urit, in th.. ~ I.. "t 4H, .,.t.. , i7n ...

%

Toughness properties at -100·C 90

Irl?~~~ical

200 85

,tlllnl..YI

.,....,.. -rt TI

--

80 II I

.;e

~

150 75 A 11 UR45N

Industeel

() »: . /"...

70

~ Im~roved

;, 100 we dabilltv

U 60

~

1/

/' Ferrite ~ 70%

50

50

Cooling rate

0 40 7n 40 60 Rn 100 (CIs)

UR45N UR45NLF High heat input Low heat input

Figure 9. Improved low temperature toughness properties and improved weldability of 22Cr duplex steel after appropriate chemistry and

heat treatment.

Microstructure and Mechanical Properties The influence of those phase transformations on low

cycle fatigue tests was also presented (Figure 8c and 8d).

Several papers presented the links between mechanical Results included heat treatments in the low temperature

properties and microstructure. This includes the effect of range (Spinodal decomposition). It is concluded that

heat treatments and phase precipitations on mechanical duplex grades, including the 2507 superduplex grade, are,

properties [10, 12, 13, 16-18]. It is confirmed that for the in the solution annealed condition, characterized by high

2205 and 2507 grades only a few percentages of sigma fatigue crack propagation resistance with crack

phase (1-2%) drastically deteriorate the toughness of the propagation micro-mechanisms that are mainly ductile.

grades even if the tensile properties are less affected. Precipitations and heat treatments decrease the fatigue

Heat treatments of 5 minutes in the 1035/ 1050°C range crack propagation resistance and increase the fatigue crack

for the 2205 duplex grade are enough to restore the growth. The surface morphology is strongly affected.

austenite/ferrite microstructure. Lower heating tempera- Cleavage is commonly observed in the presence of

tures need longer holding time (Figure 8a and 8b). improper ferrite/austenite microstructure [19-23]. Smaller

460 steel research int. 79 (2008) No.6

Materials Technology

grain sizes improve the crack propagation behaviour. TEM Yield

I 13%Cr

investigations were presented and mechanisms discussed. Strength

One of the authors even observed martensitic

transformation of the austenite in a 2507 alloy.

-

Some papers also investigated the stress distribution in

---

the 2304, 2205 and 2507 alloys. Elastoplastic behaviour of

both phases a -y were presented by using X-rays and

neutron diffraction methods [18,22].

For the Mo free duplex grades, including the 2101 grade,

nitride precipitates occurred after 20 minutes in the

6001750°C range. Toughness values lower than 50J were

reported in such conditions

One of the most interesting topics discussed in Grado Corrosion

Resistance

conference was the improvement of low temperature

toughness properties of duplex alloys by appropriate

Figure 10. Ranking of the austenite and duplex stainless steels in

chemistry and heat treatment presented by Industeel. As a regard to mechanical and corrosion resistance properties.

result very high toughness can be obtained in both base

metal and welded joint at -lOO°C. Furthermore, the very

unfavourable welding parameters of former 22Cr duplex Kvaerner [4] pointed out the possible benefits of the use

grades completely disappear; excellent mechanical and of lean duplex steel in structural applications for platforms.

corrosion resistant properties of welded structures can be Pipe racks, pipe supports, architectural walls, insulation

obtained very easily (Figure 9). claddings, cable trays could be typical applications where

carbon steel is replaced by lean duplexes. Typical cost

savings by 20 to 40% are considered when material costs

Applications and welding plus corrosion resistant coatings are taken

into account Aluminium stairs and ladders are also

Oil and Gas. Several extended papers issued from Oil proposed to be made of lean duplex. In most of those

& Gas companies (Total, Statoil, Shell... ) [26.29] applications the existing 316 steel should be replaced by a

underline the very satisfactory behaviour of 22 and 25Cr lean duplex. Special care should nevertheless be taken of

duplexes which have been experienced since more than 25 the material selection taking into account the in-service

years in a large set of applications, i.e. top side, sub sea conditions since among the lean duplex grades a wide

piping, manifolds, umbilical components, wells applica- range of chemical compositions are proposed (PREN from

tions, fire systems, etc. 23 to 28).

Some failures have been observed. Most of them are A paper by Butting [33] provided technical information

related to unintended service conditions including poor concerning longitudinally welded pipe products (made

design, high local stresses, overloaded conditions, from strips) of both 2101 and 2003 grades. Girth welds

unexpected microstructure defects (sigma phase), local have also been produced successfully. It is concluded that

saturated brine solutions (evaporation/condensation lean duplexes can meet the specifications of 13%Cr steels

phenomenon's associated with high temperature), and for welded pipes (Figure 10) and that their corrosion

some HISC cases. resistance is superior to that of martensitic grades.

In order to avoid HISC phenomena, the DNV RP Fl12 Differences in corrosion resistance properties of the

document has been prepared as well as possible duplex grades are observed and closely linked to the

implementations. Clearly HISC results from a source of chemistry of the grades.

atomic hydrogen (generally cathodic protection by

sacrificial electrodes), high local stresses (overload Desalination and severe chloride containing environ-

phenomena associated with stress concentration factors ments. 1. Peultier [34] from Industeel presented an

like surface irregularities) and possible improper overview of the utilisations of duplex grades in

microstructures (sigma phase precipitations, high ferrite desalination plants. It is concluded that recently some

contents in HAZ or welds, .. ).[30-31]. Castings and forged engineering companies have completely shifted from

products with big grain sizes seem to be more sensitive to austenitic to duplex grades. 2205 grade is the cost saving

HISC phenomena. material bringing weight reductions and low maintenance

A new improved test method for qualification of costs due to itsr excellent corrosion resistance properties.

stainless steels exposed to HISC under cathodic protection More recently 2304 kind material has been introduced for

in seawater was proposed [31]. The two key elements that the less severe conditions.

have to be controlled to obtain a specific hydrogen level For the most severe conditions the classical superduplex

are the stress concentration factor and the net section stress is to be considered. The new "hyperduplex" grades seem

per yield stress. Of course, the most effective solution is to to offer improved properties [35-37] (Figure 11).

decrease the risk of hydrogen pick-up, and special care Linkages resulting from both pitting/crevice and stress

should be forwarded to the conditions of cathodic corrosion phenomena have been reported in many

protection (avoid too cathodic conditions). industries dealing with hot concentrated saline solutions.

Some interrelations in regard to crevice corrosion One typical case is the corrosion associated to brine solu-

phenomena were also discussed [32]. tions/salt deposits resulting from sea water evaporation (sea

steel research int. 79 (2008) NO.6 461

Materials Technology

_1r--------:-----"""T'---, proven to be of positive influence, as well as avoiding

~

w phase transformations, lower temperatures and moderately

~ ·\IDP3V'4 oxidising conditions.

~ 0.8 25~r Extensive tests were performed with a modified drop

J!l \ OS'S evaporation test that in the case of duplex 22Cr and 25Cr

'\

~ 0.6 220r \, grades subjects the material to wetting by sea water

OSS\ ~ (offshore platform). It was found that 70°C is the threshold

iii

:e 0.4 • temperature when local applied stresses are in the

G)

'0

~ 0.2 ,.....~"""""''"''''<£I'.'".,

e

\

....

'-. magnitude of 90% of the yield stress (at the temperature

investigated), see Figure 12. The critical temperature for

coating duplex products in offshore applications could

=

ii: 0 L . - _........_--...::~'.LL.c...c..tI.:...LLLLJj~"'_J

then be revised! In most of the cases microplastic

deformations are observed and as a result design

considerations and appropriate welding parameters are of

o 20 40 60 80

key importance. Of course, in closed loops with control of

Temperature (deg.C) the free oxygen, higher temperatures are feasible.

Figure 11. Pitting corrosion resistance of duplex grades versus

temperature [35]. Pollution control equipments / FGD. Extensive data

concerning the behaviour of stainless steels in FGD

scrubber conditions were presented by Peultier [42]. Guide

-

:::: 32506

50 C Half-Imm est. maps for material selection charts including chloride and

fluoride contents, pH, temperature were provided. It is

-e100000

5Cr3Mo

uplex

,

clearly confirmed that 2205 duplex grade behave much

better than the 317LN grade and is applicable in medium

severe environments (up to 30000 ppm chlorides at 55°C

and pH 6). The more corrosive conditions require

superduplex grades preferentially with Cu additions ( UNS

1000 32520) or even 6Mo super austenitic grades (80°C

applications).

530400 For such applications Ni based filler materials have been

successfully used to weld superduplex. Peultier provided a

very extensive list of projects where the stainless steels

10 L..-_-'-_....;.L.._----I_ _.L..-_....I-_....J

and in most cases duplex alloys were selected. Richard's

2 4 6 8 10 12 14 paper [43] clearly confirmed Industeel R&D results since

pH

he reported a 20-year success story with using 25Cu

superduplex grade in an Indiana power station (Figure 13).

22 CrOSS 25 CrSOSS

T(OC) Building and construction. Due to their cost advan-

Stress Stress Result Stress Stress Result

(MPa) (% (JO.2) (MPa) (% (JO.2) tages when considering weight savings (as a consequence

110 418 88 Fail 471 88 Fail of the high mechanical strength) and maintenance cost

110 395 83 445

savings (21/23%Cr providing better corrosion resistance

Fail 83 Fail

than 304 grades), lean duplexes are more and more

105 - - - 494 92 Fail considered for structural applications. Typically the Eiffel

100 335 70 Pass 494 92 Fail Tower should have been built up from lean duplex (e.g.

90 452 92 Fail 508 92 Fail

2304). At least 30% weight savings, tons of painting,

millions of hours for maintenance could be expected. The

80 - - - 507 90 Fail same story can be considered for the Golden Gate Bridge

70 461 90 Pass 518 90 Pass of San Francisco but 2205 duplex should then be

considered for marine environments purposes. Recently,

Figure 12. Behaviour of duplex stainless steel grades in brine the Millennium Bridge in York was designed and built in

solutions. Influence of pH and salt concentration [38] (top) and 2205 duplex. In front of the Guggenheim museum in

influence of temperature and applied stress [39] (bottom). Bilbao a 2304 footbridge was erected. Several Asian

applications are also reported.

Reinforced duplex bars are now specified for corrosion

water in contact with heated tubes). Wetting/heating cycles free bridges even in marine environments. Duplex grade

and/or drop evaporation tests have been developed. Some 2205 has shown no pitting corrosion and a completely

experiments were also conducted in autoclaves. Obviously passive behaviour over more than 900mV polarisation (reI.

damage results from complex interactions between to OCP) in Ca(OH)2 , pH 12.6, NaCl saturated solutions

chemistry, microstructure, temperature, local potential, whereas austenitic steel with 2.5% Mo suffered from

level of oxygen and level of stresses. SCC starts in the pitting [44-45]. The market for duplex reinforced bars is

microplastic deformation zones. Higher PREN values have evaluated to millions of tons!

462 steel research int. 79 (2008) NO.6

Materials Technology

Experimental work has confirmed that MATERIAL OVERVIEW

duplex grades can be used in the most (w.r.t. Chromium Content), at 120/1300C, and 15-30ppm CI

Potential -v- % Reduction Of Area

critical cases for design and construction :g 90

(orthotropic decks 1 Messina, Soreboelt

bridges). Cost calculations for solid duplex

< 80

(5 70

bridges compared to carbon steel result in :5 60

an increase of the erection and building t;::;, 50

costs (including the welds) by 20% [46-47]. -g 40

F

Savings are expected from lower 0:: 30

maintenance costs. ~

o 20 A

More recent investigations confirm the

10

advantages of stainless steel in fire

conditions. Higher temperatures can be o

-400 -200 o 200

400 600 800 1000 1200

accepted without damages as well as wider Potential mV

safety margins. Having 30 minutes instead -+- A 12% Cr --C 18.5% Cr

--E 25% Cr --<J- F 25% Cr

of 20 minutes to escape a burning building --"-814.5% Cr

can make the difference! Once again,

duplex grades offer cost saving solutions <3 1800,....---------......".............................-""'T.ll"""""""":"---=----,

Cl • 15ppm Chloride

[48]. ~ 1500 • 100ppm

~ • 1000ppm Chloride

Other Applications. Other interesting III 1200 A 10000ppm

successful duplex applications were

> -- --Power (15ppm Chloride)

~ gOO· Poly. (1000ppm Chloride)

reported at the Grado conference. For some

of them 20/30 years of positive experience .flo 600 Test Environment:

••

130C ; 8PPM Dissolved .... ~

are available. The pulp and paper industry iii oxygen

~

is obviously one of them. Digester, pulp c 300 •

storage tanks, drums, bleaching ~ o ! _ -.~ L- -1

equipments, paper machines are made of

duplex steels. The use of lean duplex is

g' -300 Ep =0.64(PREN)-

== =O.47(PREN)2 - 3.75(PREN)-205

Ep

I

more and more considered for the less c:: -600 Jl==========::::i:::::;="'=::;=L...-_-_-_--1

corrosive conditions. This includes the o 5 10 15 20 25 30 35 40 45 ~

PREN (% Cr + 3.3 %Mo +16%N)

utilisation of lean duplex in liquor tanks

and suction rolls [2, 3, 49]. Interesting Figure 12 continued. Influence of deformation and potential [40] (top) and effects

machining properties for the lean 2101 of chloride contents and PREN [41] (bottom).

duplex grade were reported by Bergkvist

[50].

Urea plants are a very specific market for

duplex grades even having 50%ferrite!

Specific grades have been developed for

the urea-carbamate stripper and condenser.

The austenitic steel 25Cr22Ni2Mo can be

replaced by highly alloyed duplex grades

[36-38].

In the end, one of the most versatile and

successful application of duplex grades is

found in chemical tankers. The 2205 alloy

is now the standard grade, able to transport

most chemicals [51]. For the less corrosive

applications (barges) 2304 is now also

considered.

Duplex stainless steels have also been

tested in more complex chemical industries,

55°C

e.g. the uses of super-duplex steels in F-<50ppm 1-_ _-----,- ,--- _ _----, ---. ,--- _ _----1

organic solutions [52]. pH 60000

6

Other Topics

5

The subject matters presented above are 4

only a part of all conference papers. Most

papers were of good quality, particularly

the presentations on the so-called Figure 13. Material selection chart for FGD scrubbersystems [42].

steel research into 79 (2008) No.6 463

Materials Technology

complementary products fabrication and to some aspects Grado, Italy. Special gratitude also goes to the whole

the welding sessions. conference team.

Conclusions References

Without doubt creatrvity is still prevailing and new [I] J. Charles and S. Bernhardson: The duplex stainless steels: materials

grades and applications are emerging. Among them are the to meet your needs. Duplex Stainless Steels '91 Conference, Beaune,

France, pp 3-48.

so-called lean duplexes targeting to replace the austenitic [2] J. Charles: Why and where duplex stainless steels. Duplex Stainless

steels 304 and 316. The Ni price increase is the best Steel '97 Conf., Maastricht, the Netherlands, pp 29-42.

argument to modify the habits! The cost savings become [3] 1. Charles: 10 years later, obviously duplex grades in industrial

very attractive although more activities have to be started applications look like a success story. Duplex Stainless Steels 2000

Conference, Venice, Italy, pp 1-12.

by the stainless steel producers to reduce production costs

[4] O. Doble, T. Havn: Lean Duplex Stainless Steel for structural

and increase availability. More investigations are also applications. Duplex Stainless Steels '07 Conf., Grado, Italy.

needed to clarify the true properties of each grade and [5] J. Charles: Past, present and future of duplex stainless steels.

optimise material selection. Among the lean duplex grades Duplex Stainless Steels'07 Conf., Grado, Italy.

the PREN value can move from 22 to 32 [53], which [6] J.C. Gagnepain, P. Soulignac: Why duplex usages will continue to

grow? Duplex Stainless Steels'07 Conf., Grado, Italy.

means that the range is wider that that between 304 and [7] D. S. Bergstrom, J. 1. Dunn, D. R. Hasek: Benchmarking of duplex

316 grades. Negative effects of very low Ni additions stainless steels vs. conventional stainless steel grades. Duplex

when considering crevice propagation and slightly Stainless Steels'07 Conf., Grado, Italy.

negative effects of Mn additions on the pitting corrosion [8] B. Holmberg, M. Liljas: Consequences on welding procedures when

are reported in the literature. It is still to clarify how doe changing material from austenitic to duplex stainless steel. Duplex

Stainless Steels'07 Conf., Grado, Italy.

lean duplex steels behave in solutions containing small [9] P. Ferro, A. Tiziani, F. Bonollo, M. Bulla: Influence of post-

amounts of chlorides in the 50/90°C temperature range. welding heat treatments on corrosion properties of duplex and

Are the grades totally immune to corrosion? superduplex stainless steels - a comparison between furnace and

Without doubt, when properly specified, the com- induction heat treatment. Duplex Stainless Steels'07 Conf., Grado,

promise between high strength, improved corrosion resis- Italy.

[10] V. Di Cocco, E. Franzese, F. Iacoviello, S.Natali: Heat treatment

tance and low alloying elements content must be a strong influence on the crack propagation in a 25Cr 7Ni superduplex

incentive for success. Huge market applications are tar- stainless steel. Duplex Stainless Steels'07 Conf., Grado, Italy.

geted and a two-digit growth is expected for duplex steels [II] A. F. Arams, S. Herenu, S. Degallaix, F. Lovey: Temperature

in the future. If thin gauges are available, a further strong influence on the cyclic behaviour of aged and unaged super duplex

stainless steels. Duplex Stainless Steels'07 Conf., Grado, Italy.

increase of the demand is expected since most of the actual

[12] O. Strorz, A. Ibach, M. Pohl: Morphology of sigma phase and its

existing applications cover the heavy plate applications effects on the mechanical behaviour of duplex-steels. Duplex

(> 6 mm.). For the most critical conditions some Stainless Steels'07 Conf., Grado, Italy.

"hyperduplexes" have been recently designed. They are [13] L. Maines, A. Molinari, F. Colombari, P. Burlando: The effect of

considered for "niche" markets, mainly for seamless pipes. solution annealing temperature on toughness and microstructure of a

329A duplex stainless steel. Duplex Stainless Steels'07 Conf.,

After years, the positive advantages regarding corrosion Grado, Italy.

resistance but also and mainly structure stability, of [14] P. Ferro, R. Cervo, F. Bonollo, R. Bertelli: Set up and

nitrogen applications has been confirmed. The newly implementation of a numerical model of simulation of heat

developed duplex grades have nitrogen contents close to treatment of duplex stainless steels. Duplex Stainless Steels'07

the solubility limit. No real negative effects on mechanical Conf., Grado, Italy.

[IS] J. 0 Nilsson, G. Chai: The physical metallurgy of duplex stainless

properties have been reported, instead, improvements of steel. Duplex Stainless Steels'07 Conf., Grado, Italy.

the HAZ microstructure have been found. [16] I. Calliari, M. Zanesco, E. Ramous, R. Bertelli: Microstructure and

The newly designed duplex grades of the 2205 family properties modifications after isothermal aging of a low nickel DSS.

present improved microstructure stability, which makes Duplex Stainless Steels'07 Conf., Grado, Italy.

[17] I. Calliari, E. Ramous, G. Rebuffi, M. Zanesco, G. Straffelini:

these steels appropriate for lower temperature applications

Investigation on the secondary phases effects on a 2205 DSS,

(even -100°C for welded structures), and a wider range of fracture toughness. Duplex Stainless Steels'07 Conf., Grado, Italy.

heat input can be considered. [18] R. Dakhlaoui, C. Braham, A. Baczmanski, S. Wronski, K.

Finally positive field experiences concerning the Wierbanoski, E.C. Olivier Analysis of phase's mechanical

classical 2205 and 2507 (Cu,W) grades, over several behaviour of duplex stainless steels by X-ray and neutron

diffraction. Duplex Stainless Steels'07 Conf., Grado, Italy.

decades, in most of the corrosive environments, have been [19] M.G. Moscato, M.C.Marinelli, S. Degallaix, I. Alvarez-Armas:

presented and have confirmed the research work and Short crack initiation during low-cycle fatigue in UNS 32750

convictions of the duplex pioneers. duplex stainless steel plate. Duplex Stainless Steels'07 Conf., Grado,

Italy.

Acknowledgement [20] S. Sieurin, R. Sandstrom, E.M. Westin, M. Liljas: Fracture

toughness of welded commercial duplex stainless steel. Duplex

Stainless Steels'07 Conf., Grado, Italy.

This paper was prepared to be presented and published [21] O. Hechler, M. Feldman et al.: Fatigue of welded details made of

at the Stainless Steel Conference & Expo event which took duplex stainless steel. Duplex Stainless Steels '07 Conf., Grado,

place in Maastricht - 2007. The author is grateful to Italy.

[22] L. Ward, B. Gideon, D. Carr et al.: Residual stress determina-tion of

Stainless Steel World Journal for accepting to publish the

duplex stainless steel welds and their susceptibility to intergranular

papers in the Revue Francaise de la Metallurgie and to corrosion. Duplex Stainless Steels'07 Conf., Grado, Italy.

Prof. W. Nicodemi which gave to the author the honour to [23] V. Vignal, D. Kempf, H. Pelletier, J. Peultier: Micro-mechanical

co-chair the Duplex 2007 International Conference held in behaviour of duplex stainless steels; effects of the microstructure on

464 steel research into 79 (2008) No.6

Materials Technology

the surface microstrains and local stress-strain laws. Duplex [39] G. Hinds, A. Turnbull: Stress Corrosion cracking of duplex stainless

Stainless Steels'07 Conf., Grado, Italy. steels in evaporative conditions. Duplex Stainless Steels '07 Conf.,

[24] F. Fanica, B. Bonnefois, J. C. Gagnepain: Welding duplex stainless Grado, Italy.

steels : recent improvements developments. Duplex Stainless [40] J. R. Saithala, J. D. Atkinson: Stress Corrosion behaviour of duplex

Steels'07 Conf., Grado, Italy. stainless steels in dilute chloride solutions at 130°C. Duplex

[25] M. Serriere, A. Fanica, B. Bonnefois, J. C. Gagnepain: Mechanical Stainless Steels'07 Conf., Grado, Italy.

and corrosion properties of superduplex UNS 32520 after PWHT. [41] J. R. Saithala, J. D. Atkinson: Effects of temperature and chloride

Duplex Stainless Steels'07 Conf., Grado, Italy. concentration on the pitting behaviour of zeron 100, 2205,and

[26] K. A. Johansson, O. Strandmyr, G. E. Eie, O. Hagerup: 25 years Ferallium alloy 255 duplex stainless steels. Duplex Stainless

with duplex, from Tommeliten to Gjoea. Duplex Stainless Steels'07 Steels'07 Conf, Grado, Italy.

Conf, Grado, Italy. [42] J. Peultier, J. C. Gagnepain, P. Soulignac: Duplex and superduplex

[27] T. Cassagne, F. Busschaert: Experience with duplex stainless steels stainless steel grades for wet desulfurisation systems. Duplex

in oil and gas production. Duplex Stainless Steels'07 Conf., Grado, Stainless Steels'07 Conf., Grado, Italy.

Italy. [43] R. L. Richard: 20+ of successful FGD experience with superduplex

[28] L. Marken, G. Rorvik, I.M. Kulbotten: Duplex and superduplex (UNS32550)at the Gibson generation station. Duplex Stainless

stainless steel in Norwegian petroleum industry. Duplex Stainless Steels'07 Conf., Grado, Italy.

Steels'07 Conf, Grado, Italy. [44] T. Sourisseau, E. Chauveau, B. Demelin, C. Bourgin: A comparison

[29] S. Coelho, I. Abud, C. Barbosa, R. Centeno: Corrosion resistant of the performance of 1.4362 and 1.4404 stainless steel grades for

alloys for ultra deep water petroleum production application. concrete reinforcement. Duplex Stainless Steels'07 Conf., Grado,

Duplex Stainless Steels'07 Conf., Grado, Italy. Italy.

[30] I. Hannah, S. Paterson: Reducing risk of hydrogen induced stress [45] M. J. Correira, M. M. Salta, I. T. E. Fonseca, J. Teleggdi: Corrosion

cracking (HISC) in duplex stainless steel for subsea applications. resistance of duplex stainless steels in Ca(OH)2 saturated solutions.

Duplex Stainless Steels'07 Conf, Grado, Italy. Duplex Stainless Steels'07 Conf, Grado, Italy.

[31] R. Johnsen, B. Nyhus, S. Wastberg: New improved method for [46] A. Fanica, E. Maiorana: UNS S 32205 for bridge construction: an

HISC testing of stainless steels under cathodic protection. Duplex experience of application. Duplex Stainless Steels'07 Conf., Grado,

Stainless Steels'07 Conf, Grado, Italy. Italy.

[32] E. E. Skavas, S. Karlsen, S.C.A. Sekne, T. G. Eggen: Crevice [47] G. Zili, F. Fattrini, E. Maiorana: Application of duplex stainlesss

corrosion of 25Cr duplex tubes in subsea umbilicals. Duplex steel for welded bridge construction in aggressive environment.

Stainless Steels'07 Conf., Grado, Italy. Duplex Stainless Steels'07 Conf., Grado, Italy.

[33] L. Rommerskirchen, S. Lemken, R. Hoffmann: Lean duplex grades [48] R. Bertelli, R. Cristel: Stainless steel fire resistance: low nickel DSS

as longitudinally welded pipes for linepipes in the oil and gas preliminary results. Duplex Stainless Steels'07 Conf., Grado, Italy.

industry. Duplex Stainless Steels'07 Conf., Grado, Italy. [49] D. Eyzop ,J. Sjostrom, O. Kallgren: 304SRG : a growing market for

[34] S. Jacques, J. Peultier, P. Soulignac: Desalination plants - why paper mill suction rolls. Duplex Stainless Steels '07 Conf., Grado,

using duplex stainless steels. Duplex Stainless Steels'07 Conf., Italy.

Grado, Italy. [50] C. Bergkvist, J. Olsson: machining in the new duplex grade LDX

[35] m. yamashhita, s. matsumoto, n. hirohata: Corrosion resistance and 2101-easier than expected. Duplex Stainless Steels'07 Conf. Grado,

properties of duplex stainless steels. Duplex Stainless Steels'07 Italy.

Conf., Grado, Italy. [51] S. Jacques, G. Hagi: "Tour Pomerol" chemical tanker: eight years

[36] m. I. nyman, u. kivisakk, m. holmquist, k. goransson: Performances experience with duplex EN 1.4462. Duplex Stainless Steels'07

of SAF2707HD (UNS32707) in severe chloride containing Conf., Grado, Italy.

environments. Duplex Stainless Steels'07 Conf., Grado, Italy. [52] A. J. Invernizzi, L. Benedittiss, P. Trasalti: Corrosion behaviour of

[37] P. Stenvall, M. Holmquist: Weld properties of Sandvik 2707HD. duplex SAF 2507 in aquous acid organic solutions. Duplex Stainless

Duplex Stainless Steels'07 Conf., Grado, Italy. Steels'07 Conf., Grado, Italy.

[38] Y. Kobayashi, N. Koide: Corrosion resistance of duplex stainless [53] L. Peguet, A. Gauguin: Pitting and crevice corrosion behaviour of

steels in hypochlorite solutions. Duplex Stainless Steels'07 Conf, ferritic and duplex stainless steels in hot chloride environments.

Grado, Italy. Duplex Stainless Steels'07 Conf., Grado, Italy.

steel research int. 79 (2008) No.6 465

You might also like

- Technical Notes On Duplex SSDocument22 pagesTechnical Notes On Duplex SSBhyrappaNo ratings yet

- Past Present and Future of The Duplex Stainless SteelsDocument10 pagesPast Present and Future of The Duplex Stainless SteelsbayumahardikaNo ratings yet

- Hyper Duplex in Europe Sswsup1005 - Duplex - ChaterDocument4 pagesHyper Duplex in Europe Sswsup1005 - Duplex - ChaterThinh NguyenNo ratings yet

- Duplex Stainless Steels, A Review After Dss '07 Held in GradoDocument22 pagesDuplex Stainless Steels, A Review After Dss '07 Held in Gradojose.figueroa@foseco.comNo ratings yet

- D153 PSSC2010RWhiteDocument17 pagesD153 PSSC2010RWhiteJamesNo ratings yet

- Wear Analysis of PVD-coated Twist Drills Under MQL: Marlon José Cardoso, Milton Luiz Polli Giuseppe PintaudeDocument6 pagesWear Analysis of PVD-coated Twist Drills Under MQL: Marlon José Cardoso, Milton Luiz Polli Giuseppe PintaudePintaudeNo ratings yet

- Welding Duplex Stainless Steels - A Review of Currernt RecommendationsDocument12 pagesWelding Duplex Stainless Steels - A Review of Currernt RecommendationsTrushar Parmar100% (1)

- Pub 139 Copper Nickel Welding and Fabrication PDFDocument32 pagesPub 139 Copper Nickel Welding and Fabrication PDFG.SWAMI100% (1)

- Cladding & Overlay - Ni InstituteDocument24 pagesCladding & Overlay - Ni Institutesajid aslamNo ratings yet

- Millennium Steel 2022 Published Article - Nancy Badoo and Jit PatelDocument7 pagesMillennium Steel 2022 Published Article - Nancy Badoo and Jit PatelimetallurgyNo ratings yet

- Duplex Stainless Steel: A Successful Growth StoryDocument5 pagesDuplex Stainless Steel: A Successful Growth StoryBelle CervantesNo ratings yet

- Choice of Specifications and Design Codes For Duplex Stainless SteelsDocument12 pagesChoice of Specifications and Design Codes For Duplex Stainless SteelsRonald Leyva GiraldoNo ratings yet

- Applications of ADI in High Strength Thin Wall Automotive PartsDocument6 pagesApplications of ADI in High Strength Thin Wall Automotive PartsalgobozkurtNo ratings yet

- IBP1081 - 19 Seamless Line Pipes For Challenging Offshore ApplicationsDocument10 pagesIBP1081 - 19 Seamless Line Pipes For Challenging Offshore ApplicationsMarcelo Varejão CasarinNo ratings yet

- Steel Ladle Calderys Brochure A4Document22 pagesSteel Ladle Calderys Brochure A4Mitone Diaz100% (1)

- DM-Intro 15.0 L02 Introduction To WBDocument68 pagesDM-Intro 15.0 L02 Introduction To WBafnene1No ratings yet

- Kobe SteelDocument13 pagesKobe SteelmilalaNo ratings yet

- High Quality Products For Welding and CladdingDocument25 pagesHigh Quality Products For Welding and Claddingsanketpavi21100% (1)

- MSF 618-619 591Document4 pagesMSF 618-619 591Barak VinklerNo ratings yet

- Saer 5974 PDFDocument31 pagesSaer 5974 PDFZhiguo YangNo ratings yet

- EEW Clad Steel PipesDocument4 pagesEEW Clad Steel PipesstevenNo ratings yet

- The Last Defence Against Corrosion Alloy 945 and 945XDocument3 pagesThe Last Defence Against Corrosion Alloy 945 and 945XVelissarios DemetriouNo ratings yet

- Welding News 03-08Document6 pagesWelding News 03-08skisharkNo ratings yet

- Microstructural Characterization and Production of High Yield Strength Rebar-Mansutti-DanieliDocument7 pagesMicrostructural Characterization and Production of High Yield Strength Rebar-Mansutti-DanieliSergio RonchiNo ratings yet

- Zecor PDFDocument7 pagesZecor PDFjavoidea696526100% (1)

- RoofDek Structural Roof Decking and Trays BrochureDocument24 pagesRoofDek Structural Roof Decking and Trays Brochuresiddharth vekariyaNo ratings yet

- A Duplex Stainless Steel 2205Document8 pagesA Duplex Stainless Steel 2205AboMuhmadSr.No ratings yet

- Metals: Formulation of Sustainable Water-Based Cutting Fluids With Polyol Esters For Machining Titanium AlloysDocument11 pagesMetals: Formulation of Sustainable Water-Based Cutting Fluids With Polyol Esters For Machining Titanium AlloysMenoddin shaikhNo ratings yet

- Metallurgical Benefits of Vanadium Microalloying in Producing High Strength Seismic Grade RebarDocument12 pagesMetallurgical Benefits of Vanadium Microalloying in Producing High Strength Seismic Grade RebarUlises Quintana CarhuanchoNo ratings yet

- Material Product Data Sheet Chromium Carbide - 20 % Nickel Chromium PowdersDocument4 pagesMaterial Product Data Sheet Chromium Carbide - 20 % Nickel Chromium PowdersJesus D. Gutierrez G.No ratings yet

- PVD Coatings For Thread Tapping of Austempered Ductile Iron PDFDocument10 pagesPVD Coatings For Thread Tapping of Austempered Ductile Iron PDFFlorin MilasNo ratings yet

- Pfisterer SefagDocument20 pagesPfisterer SefagJordan Riley100% (1)

- Ssw11xx Urea GemacoDocument5 pagesSsw11xx Urea GemacoYudhistira Perdana PutraNo ratings yet

- North American Galvanizing Status and OpportunitiesDocument16 pagesNorth American Galvanizing Status and OpportunitiesFrank GoodwinNo ratings yet

- Pintura Epoxica Sherwin Willians Hoja SeguridadDocument4 pagesPintura Epoxica Sherwin Willians Hoja Seguridad1No ratings yet

- Welding of 2205 Duplex Stainless Steel PipesDocument5 pagesWelding of 2205 Duplex Stainless Steel PipesMarcelo Varejão CasarinNo ratings yet

- CuniDocument32 pagesCunikampit100% (1)

- OSNA10 Sheathing MTL Group EN 2019Document6 pagesOSNA10 Sheathing MTL Group EN 2019David RobsonNo ratings yet

- Dev Corrosion Abrasion Resisitant Overlay MenonCook 012415 PDFDocument19 pagesDev Corrosion Abrasion Resisitant Overlay MenonCook 012415 PDFunknown1711No ratings yet

- Latest Trends in Welding Processes and Consumables BY M. P. Dhanuka GEE Limited Thane - 400 064Document50 pagesLatest Trends in Welding Processes and Consumables BY M. P. Dhanuka GEE Limited Thane - 400 064Aayush PandeyNo ratings yet

- Corrosion Protection For Cold-Formed Structural STDocument8 pagesCorrosion Protection For Cold-Formed Structural STethiwaNo ratings yet

- New Separators For Industrial and Specialty Lead Acid BatteriesDocument6 pagesNew Separators For Industrial and Specialty Lead Acid BatteriesCustomer Tech Support / Product Development Sales/CCT Dept. AECPLNo ratings yet

- Mobil DTE™ 700 Series Mobil DTE™ 700 Series Mobil DTE™ 700 Series Mobil DTE™ 700 SeriesDocument4 pagesMobil DTE™ 700 Series Mobil DTE™ 700 Series Mobil DTE™ 700 Series Mobil DTE™ 700 SeriesAbu AlbumNo ratings yet

- High Performance: Properties & General DataDocument4 pagesHigh Performance: Properties & General DataRaghNo ratings yet

- Erdemir 1 - Tribological and Solid Lubrificant Coatings PDFDocument9 pagesErdemir 1 - Tribological and Solid Lubrificant Coatings PDFMÔNICA SUEDE S. SILVANo ratings yet

- Nickel Aluminium Bronze: A Reconsideration For Valve ManufactureDocument4 pagesNickel Aluminium Bronze: A Reconsideration For Valve ManufactureFred Duarte CaldeiraNo ratings yet

- Properties and Welding Procedure For Grade 91 Alloy Steel: Siddharth Pant and Swati BhardwajDocument6 pagesProperties and Welding Procedure For Grade 91 Alloy Steel: Siddharth Pant and Swati BhardwajArvind ShuklaNo ratings yet

- Everything You Need to Know About Duplex Stainless SteelsDocument4 pagesEverything You Need to Know About Duplex Stainless SteelsAndy PhoenixNo ratings yet

- Automotive PDFDocument24 pagesAutomotive PDFbathinsreenivasNo ratings yet

- Flat-Roofing Specificationguide Jan16Document16 pagesFlat-Roofing Specificationguide Jan16Mohammed HammadNo ratings yet

- AL-Nafeay 2021 IOP Conf. Ser. Mater. Sci. Eng. 1094 012141Document22 pagesAL-Nafeay 2021 IOP Conf. Ser. Mater. Sci. Eng. 1094 012141hassan ghorbaniNo ratings yet

- Production Technology Ch21Document16 pagesProduction Technology Ch21Nimmagadda BharathNo ratings yet

- GALV - Cut Edge ProtectionDocument5 pagesGALV - Cut Edge ProtectionHarry Aldous100% (1)

- Pages From SCTT31-2Document1 pagePages From SCTT31-2Anh Quoc VuNo ratings yet

- MBIE - Grade 500E Reinforcing Steel - Good PracticeDocument8 pagesMBIE - Grade 500E Reinforcing Steel - Good PracticeNelson ChinNo ratings yet

- 1978 - Friction Wear and Corrosion of Laves-Hardened Nickel Alloy Hardsurfacing in SodiumDocument9 pages1978 - Friction Wear and Corrosion of Laves-Hardened Nickel Alloy Hardsurfacing in SodiumDrenkensteinNo ratings yet

- Finite Element Indentation Analysis of AutomotiveDocument7 pagesFinite Element Indentation Analysis of AutomotiveytabakovNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- 39 MicrostructureDocument7 pages39 MicrostructureVinay MaisuriyaNo ratings yet

- Assignment 3 PDFDocument3 pagesAssignment 3 PDFVinay MaisuriyaNo ratings yet

- Gas Turbine Combustion Chamber TypesDocument14 pagesGas Turbine Combustion Chamber TypesVinay MaisuriyaNo ratings yet

- Draught PDFDocument30 pagesDraught PDFVinay MaisuriyaNo ratings yet

- Renewable Energy Sources For Caribbean Territories and SIDS: OTECDocument42 pagesRenewable Energy Sources For Caribbean Territories and SIDS: OTECVinay MaisuriyaNo ratings yet

- Economics of Power Generation: Prepared By: Bhavin MehtaDocument21 pagesEconomics of Power Generation: Prepared By: Bhavin MehtaVinay MaisuriyaNo ratings yet

- Economics of Power Generation: Prepared By: Bhavin MehtaDocument21 pagesEconomics of Power Generation: Prepared By: Bhavin MehtaVinay MaisuriyaNo ratings yet

- SolarDocument13 pagesSolarVinay Maisuriya0% (1)

- Solaranglesandgeometry 9-12 PDFDocument32 pagesSolaranglesandgeometry 9-12 PDFVinay MaisuriyaNo ratings yet

- WindDocument61 pagesWindVinay MaisuriyaNo ratings yet

- Wind Energy PDFDocument42 pagesWind Energy PDFAnonymous oUoJ4A8xNo ratings yet

- Solar Energy & Its Measurement: Chapter - 1Document35 pagesSolar Energy & Its Measurement: Chapter - 1Vinay MaisuriyaNo ratings yet

- European Steel and Alloy Grades: G-Nicr50Nb (2.4680)Document2 pagesEuropean Steel and Alloy Grades: G-Nicr50Nb (2.4680)farshid KarpasandNo ratings yet

- The Reactivity SeriesDocument25 pagesThe Reactivity SeriesMUHAMMAD DANIYAL KANDANo ratings yet

- List of Jewelry Manufacture ToolsDocument2 pagesList of Jewelry Manufacture ToolsMellisa AllenNo ratings yet

- Astm F3125-18Document13 pagesAstm F3125-18HeiderHuertaNo ratings yet

- Well Completion For Severe Corrosive OilDocument35 pagesWell Completion For Severe Corrosive OilAniekan SabastineNo ratings yet

- Green Sand CastingDocument14 pagesGreen Sand Castingkarthick rajaNo ratings yet

- GD KT Pro-0276-0407 #Sus #Abs #v1Document92 pagesGD KT Pro-0276-0407 #Sus #Abs #v1vikasindiaNo ratings yet

- TPS Extended Surface Tubes 2018Document32 pagesTPS Extended Surface Tubes 2018Aarti ChameNo ratings yet

- MSS SP 25 Standard Marking System For Valves Fittings Flanges and Unions PDFDocument27 pagesMSS SP 25 Standard Marking System For Valves Fittings Flanges and Unions PDFTinuoye Folusho OmotayoNo ratings yet

- Astm A572Document4 pagesAstm A572udaykiranorange100% (2)

- Investment CastingDocument14 pagesInvestment CastingAkshaj NevgiNo ratings yet

- #15 Adhesion Test Report (3M VHB APT & Alpolic Panels)Document5 pages#15 Adhesion Test Report (3M VHB APT & Alpolic Panels)Senthil KumarNo ratings yet

- Hot Rolled Round Steel BarsDocument20 pagesHot Rolled Round Steel BarsNomoNo ratings yet

- 7 SteelDocument6 pages7 SteelIssaNo ratings yet

- Astm B 150Document6 pagesAstm B 150arifin rizalNo ratings yet

- FittingDocument16 pagesFittingLALIT 318No ratings yet

- 2430 295 423 U 5 100 Max 2565 U 5 2400 FinnedDocument1 page2430 295 423 U 5 100 Max 2565 U 5 2400 Finnedignatius domenicoNo ratings yet

- Lecture Casting InSteelCon 2007Document8 pagesLecture Casting InSteelCon 2007radynasrNo ratings yet

- Weight Calculations - Steel Tube - Thyssenkrupp AerospaceDocument4 pagesWeight Calculations - Steel Tube - Thyssenkrupp AerospacewinasharNo ratings yet

- SSW-Q1R Class 2Document2 pagesSSW-Q1R Class 2mohsen_267No ratings yet

- Alloy Steel Casting PartsDocument3 pagesAlloy Steel Casting Parts奥世迈拓No ratings yet

- Grade c300Document1 pageGrade c300grezmosNo ratings yet

- Implant Materials - Wrought 18 - Chromiickel - 2.5 - Molybdenum Stainless Steel.5 - Molybdenum Stainless SteelDocument32 pagesImplant Materials - Wrought 18 - Chromiickel - 2.5 - Molybdenum Stainless Steel.5 - Molybdenum Stainless SteelGagan BajpaiNo ratings yet

- PT. Tekenomiks Indonesia: 05357110 PT - Kalimantan Prima Persada - SangattaDocument2 pagesPT. Tekenomiks Indonesia: 05357110 PT - Kalimantan Prima Persada - SangattaReksiNo ratings yet

- Metalurgia GeneralDocument538 pagesMetalurgia Generalmarcos100% (2)

- Price History: Tables and ChartsDocument16 pagesPrice History: Tables and ChartsAmir Mahmoud Mahdavi AbhariNo ratings yet

- HovedkatalogccDocument352 pagesHovedkatalogccibraheemNo ratings yet

- Standard Welded Wire Mesh For Concrete ReinforcementDocument3 pagesStandard Welded Wire Mesh For Concrete Reinforcementmarksantana100% (2)

- Section 05505 METAL FABRICATIONS PDFDocument13 pagesSection 05505 METAL FABRICATIONS PDFIm ChinithNo ratings yet

- Lack of Fusion in Welded Joints: Pretty Long and Narrow and RejectableDocument20 pagesLack of Fusion in Welded Joints: Pretty Long and Narrow and RejectableSamira MahmoodiNo ratings yet