Professional Documents

Culture Documents

b203g-f NX2525 201608

Uploaded by

Alexandre SouzaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

b203g-f NX2525 201608

Uploaded by

Alexandre SouzaCopyright:

Available Formats

TOOLS NEWS FLASH 2016.

8 Update

B203G-F

Cermet Grade for Steel and Cast Iron

NX2525

Added chipbreakers for negative inserts.

NX2525 has highly hardened Ti compound

particles within it's microstructure therefore

the grade has both excellent wear and

fracture resistance properties.

Micro-Structure of NX2525

Application

Breaker Name Cross Section

and Features

Shape Geometry

Mild Steel Nose

FY First recommendation for finish cutting of mild steel

Finish Cutting

3 15°

Double sided chipbreaker.

ap (mm)

2

Effectively controls adhesive chips.

Suitable for mild steel finishing. 1 Flank

0.2

0 0.1 0.2 0.3 0.4 15°

f (mm/rev)

Mild Steel Nose

SY First recommendation for light cutting of mild steel 4

10°

Double sided chipbreaker. 3

ap (mm)

Effectively controls adhesive chips. 2

Suitable for mild steel light cutting. 1

Flank

0.2

Light Cutting

0 0.1 0.3 0.5 10°

f (mm/rev)

Carbon Steel • Alloy Steel Nose

SA Alternative chipbreaker for light cutting of carbon steel 4 0.3

25°

and alloy steel 3

ap (mm)

10°

Double sided chipbreaker. 2

Superior chip control at small depth of cuts. Flank

1

25° 0.34

Covers copying and back turning with wavy edge. 0 0.1 0.3 0.5

Recommended for work material in the 200 ─ 300HB range. f (mm/rev) 8°

Recommended Cutting Conditions (mm)

vc f

Work Material Hardness Cutting Mode Breaker (m/min) (mm/rev) ap

P

Finish Cutting FY 280 ─ 405 0.09 ─ 0.23 0.20 ─ 0.80

Mild Steel

≤ 180HB

(SS400, S10C etc.)

Light Cutting SY 255 ─ 370 0.16 ─ 0.33 0.50 ─ 1.20

Carbon Steel • Alloy Steel

180 ─ 280HB Light Cutting SA 190 ─ 275 0.10 ─ 0.40 0.30 ─ 2.00

(S45C, SCM440 etc.)

Inserts

a Negative Inserts

Stock Stock Stock

Shape Order Number Shape Order Number Shape Order Number

NX2525 NX2525 NX2525

FY CNMG120404-FY a FY TNMG160404-FY a SA WNMG080404-SA a

CNMG120408-FY a TNMG160408-FY a WNMG080408-SA a

Finish Cutting Finish Cutting Light Cutting

SY CNMG120404-SY a SY TNMG160404-SY a

CNMG120408-SY a TNMG160408-SY a

Light Cutting Light Cutting

SA CNMG120404-SA a SA TNMG160404-SA a

CNMG120408-SA a TNMG160408-SA a

Light Cutting Light Cutting

FY DNMG150404-FY a SA VNMG160404-SA a

DNMG150408-FY a VNMG160408-SA a

Finish Cutting Light Cutting

SY DNMG150404-SY a FY WNMG080404-FY a

DNMG150408-SY a WNMG080408-FY a

Light Cutting Finish Cutting

SA DNMG150404-SA a SY WNMG080404-SY a

DNMG150408-SA a WNMG080408-SY a

Light Cutting Light Cutting

a : Inventory maintained in Japan.

For Your Safety

aDon't handle inserts and chips without gloves. aPlease machine within the recommended application range and exchange expired tools with new ones in advance of breakage. aPlease use safety

covers and wear safety glasses. aWhen using compounded cutting oils, please take fire precautions. aWhen attaching inserts or spare parts, please use only the correct wrench or driver. aWhen using

rotating tools, please make a trial run to check run-out, vibration and abnormal sounds etc.

MITSUBISHI MATERIALS CORPORATION

Overseas Sales Dept, Asian Region

KFC bldg., 8F, 1-6-1 Yokoami, Sumida-ku, Tokyo 130-0015, Japan

TEL +81-3-5819-8771 FAX +81-3-5819-8774

Overseas Sales Dept, European & American Region

KFC bldg., 8F, 1-6-1 Yokoami, Sumida-ku, Tokyo 130-0015, Japan

TEL +81-3-5819-8772 FAX +81-3-5819-8774

http://www.mitsubishicarbide.com/en/

(Tools specifications subject to change without notice.)

EXP-13-E011

2016.7.E( - )

You might also like

- td4n e PDFDocument8 pagestd4n e PDFAlexandre SouzaNo ratings yet

- B231e VFR EnglishDocument32 pagesB231e VFR EnglishAlexandre SouzaNo ratings yet

- Composite p715g PDFDocument44 pagesComposite p715g PDFAlexandre SouzaNo ratings yet

- KORLOYDocument12 pagesKORLOYAlexandre SouzaNo ratings yet

- WWX400 ProductProfile MMBRDocument11 pagesWWX400 ProductProfile MMBRAlexandre SouzaNo ratings yet

- B169e VF2WB EnglishDocument4 pagesB169e VF2WB EnglishAlexandre SouzaNo ratings yet

- Pushing The Boundaries of Steel Machining.: ISO Insert Series For Steel TurningDocument24 pagesPushing The Boundaries of Steel Machining.: ISO Insert Series For Steel TurningAlexandre SouzaNo ratings yet

- Ahx B195GDocument32 pagesAhx B195GAlexandre SouzaNo ratings yet

- b205g - MS Plus - 201601Document44 pagesb205g - MS Plus - 201601Alexandre SouzaNo ratings yet

- b197g Vq-Smart Miracle 201311 SigmaDocument40 pagesb197g Vq-Smart Miracle 201311 SigmaAlexandre SouzaNo ratings yet

- b205g - MS Plus - 201601Document32 pagesb205g - MS Plus - 201601Alexandre SouzaNo ratings yet

- Ahx B195GDocument32 pagesAhx B195GAlexandre SouzaNo ratings yet

- b205g - MS Plus - 201601Document32 pagesb205g - MS Plus - 201601Alexandre SouzaNo ratings yet

- Bedame b140g-f GY 1 Edge Insert 201611Document2 pagesBedame b140g-f GY 1 Edge Insert 201611Alexandre SouzaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Pipe Standash Byp PomDocument96 pagesPipe Standash Byp Pomallouche_abdNo ratings yet

- Stainleess Steel SpecificationDocument11 pagesStainleess Steel SpecificationcysautsNo ratings yet

- Working With Boron Steel NovDec 2005Document4 pagesWorking With Boron Steel NovDec 2005Hugo MoraisNo ratings yet

- Boca Do Lobo CatalogueDocument152 pagesBoca Do Lobo CatalogueJames JaraNo ratings yet

- ARP1317Document18 pagesARP1317Oottuparambil Krishnakumar RamakrishnanNo ratings yet

- Mayuresh21 CVDocument3 pagesMayuresh21 CVAmolsarode99No ratings yet

- ASM - ExtrusionDocument605 pagesASM - ExtrusionPablo Vásquez100% (2)

- Aws-5 18Document42 pagesAws-5 18Nick McalpinNo ratings yet

- Aluminium GMAW GuideDocument32 pagesAluminium GMAW GuideDaniel Salinas100% (2)

- Chapter Five: Tools Classification and Design of ToolsDocument61 pagesChapter Five: Tools Classification and Design of ToolsTemuNo ratings yet

- AstmDocument8 pagesAstmdiego rodriguezNo ratings yet

- WOWLibrary Preheating of Materials ConsumablesDocument4 pagesWOWLibrary Preheating of Materials ConsumableshreerNo ratings yet

- Lesson 3 - Covered Electrodes For Welding Mild Steels PDFDocument1 pageLesson 3 - Covered Electrodes For Welding Mild Steels PDFMelissa MurrayNo ratings yet

- 2008-96 CanaleDocument53 pages2008-96 CanaleАнна КокоеваNo ratings yet

- 17798AMPDocument1 page17798AMPsouravNo ratings yet

- Vulcan LIBS Analyser For QA QC - 2Document6 pagesVulcan LIBS Analyser For QA QC - 2Trần Văn LộcNo ratings yet

- Saej 125 V 001Document11 pagesSaej 125 V 001Glauco SantosNo ratings yet

- PRE4122 Exercise No. 4 Imperfections in SolidsDocument9 pagesPRE4122 Exercise No. 4 Imperfections in SolidsعبداللهأحمدNo ratings yet

- Design and Analysis of Aluminium 6082-T6 PistonDocument9 pagesDesign and Analysis of Aluminium 6082-T6 PistonIJIRSTNo ratings yet

- Applied Physical Metallurgy Sixth EditionDocument597 pagesApplied Physical Metallurgy Sixth EditionT.c. Ertuğrul Sağlık67% (6)

- Theoretical Assessment For The Mixing Properties of Almg Liquid Alloys at 1073KDocument9 pagesTheoretical Assessment For The Mixing Properties of Almg Liquid Alloys at 1073KShayista AhmadNo ratings yet

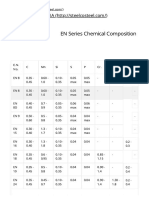

- En Series Chemical CompositionDocument3 pagesEn Series Chemical CompositionAyanBiswas22No ratings yet

- Aluminium 6061 & 7075Document2 pagesAluminium 6061 & 7075Anoj pahathkumburaNo ratings yet

- Precious Palladium Aluminium Based Alloy With High Hardness and WorkabilityDocument9 pagesPrecious Palladium Aluminium Based Alloy With High Hardness and WorkabilityhyyziaNo ratings yet

- High Temperature Solution Nitriding and Low Temperature Nitriding of AISI 316 Effect On Pitting Potential and Crevice Corrosion Performance 2018 AppliDocument8 pagesHigh Temperature Solution Nitriding and Low Temperature Nitriding of AISI 316 Effect On Pitting Potential and Crevice Corrosion Performance 2018 AppliFerdinandoBorgesNo ratings yet

- Material Datasheet Cuzn30Document2 pagesMaterial Datasheet Cuzn30alex94kgNo ratings yet

- Attachment 1 DLT 5017-2007Document67 pagesAttachment 1 DLT 5017-2007Andi Baso Temalala STNo ratings yet

- บทที่ 3 Heat treatmentDocument24 pagesบทที่ 3 Heat treatmentParas gurungNo ratings yet

- Material Characterization Assignment 1Document4 pagesMaterial Characterization Assignment 1Elango SureshNo ratings yet