Professional Documents

Culture Documents

Welding Guideline

Uploaded by

shazanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Guideline

Uploaded by

shazanCopyright:

Available Formats

APPENDIX – B

Extract from AWS D 1.1. 1992

SAFE PRACTICES

(Non-mandatory Information)

(This Appendix is not a part of ANSI/AWS D1.1-92, Structural Welding Code-

Steel, but is included for information purposes only)

This appendix covers many of the basic elements of safety general to arc

welding processes. It includes many, but not all of the safety aspects related to

structural welding. The hazards that may be encountered and the practices

that will minimize personal injury and property damage are reviewed here.

J1 Electrical Hazards

Electric shock can kill. However, it can be avoided. Live electrical parts should

not be touched. Read and understand the manufacturer’s instructions and

recommended safe practices. Faulty installation, improper grounding, and

incorrect operation and maintenance of electrical equipment are all sources of

danger.

All electrical equipment and the work pieces should be grounded. A separate

connection is required to ground the workpiece. The work lead should not be

mistaken for a ground connection.

To prevent shock, the work area, equipment, and clothing should be kept dry at

all times. Dry gloves and rubber soled shoes should be worn. The welder

should stand on a dry board or insulated platform.

Cables and connectors should be kept in good condition. Worn, damaged, or

bare cables should not be used. In case of electric shock, the power should be

turned off immediately. If the rescuer must resort to pulling the victim from the

live contact, nonconducting materials should be used. A physician should be

called and CPR continued until breathing has been restored, or until a

physician has arrived. See references 8,7 and 10

J2 Fumes and Gases

Many welding, cutting and allied processes produce fumes and gases which

may be harmful to one’s health. Fumes and solid particles originate from

welding consumables, the base metal, and any coating present on the base

metal. Gases are produced during the welding process or may be produced by

the effects of process radiation on the surrounding environment. Everyone

associated with the welding operation should acquaint themselves with the

effects of these fumes and gases.

You might also like

- Welding for Off-Road Beginners: This Book Includes - Welding for Beginners in Fabrication & Off-Road WeldingFrom EverandWelding for Off-Road Beginners: This Book Includes - Welding for Beginners in Fabrication & Off-Road WeldingRating: 5 out of 5 stars5/5 (2)

- Lincoln Kubota WeldDocument56 pagesLincoln Kubota WeldashielanieNo ratings yet

- Vantage 500 Cummins 500Document54 pagesVantage 500 Cummins 500Bladimir Jesus Vasquez AlaveNo ratings yet

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Lincoln Vantage 300 K2409-1 11310 Operator's ManualDocument57 pagesLincoln Vantage 300 K2409-1 11310 Operator's ManualJean Munoz100% (1)

- AEC 200-4C: Solid State Spoolgun & Control Operation and Parts ManualDocument12 pagesAEC 200-4C: Solid State Spoolgun & Control Operation and Parts ManualdzzmikeNo ratings yet

- Seismic Calculation IS 1893 - RSMDocument3 pagesSeismic Calculation IS 1893 - RSMshazanNo ratings yet

- 9-237 Welding Theory and ApplicationDocument762 pages9-237 Welding Theory and ApplicationDelia GarcíaNo ratings yet

- Gasket Selection GuideDocument6 pagesGasket Selection GuiderezaNo ratings yet

- Mig 250c ManualDocument18 pagesMig 250c ManualBondan PratamaNo ratings yet

- Power Wave455m 10942 10957Document165 pagesPower Wave455m 10942 10957Jaime ArreolaNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- EWISDocument41 pagesEWISAbiyot Aderie100% (2)

- Lincoln AC-225 Arc Welder ManualDocument68 pagesLincoln AC-225 Arc Welder ManualWarhammer1375% (4)

- Checking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumberDocument1 pageChecking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumbershazanNo ratings yet

- Weld CalculationsDocument12 pagesWeld Calculationshakr5100% (1)

- Lecture2 (Petrochemical)Document12 pagesLecture2 (Petrochemical)ToniAndiwijaya100% (1)

- U Stamp - KK Form - SampleDocument5 pagesU Stamp - KK Form - SampleshazanNo ratings yet

- LT7 Tractor Operator Manual IM279Document88 pagesLT7 Tractor Operator Manual IM279Waldo AtNo ratings yet

- Aotai ARC 400 3 Phase 440V 60HzDocument39 pagesAotai ARC 400 3 Phase 440V 60Hzmaverick kitaro0% (1)

- Electric Shock Can Kill YouDocument6 pagesElectric Shock Can Kill YoutemterNo ratings yet

- Aotai MIG250C Operating ManualDocument25 pagesAotai MIG250C Operating Manualmaverick kitaroNo ratings yet

- Lincoln ManualDocument108 pagesLincoln ManualosamaNo ratings yet

- Lincoln CV400 PDFDocument15 pagesLincoln CV400 PDFosamaNo ratings yet

- D300K 33 Operators Manual NEWDocument34 pagesD300K 33 Operators Manual NEWvitrolaNo ratings yet

- Im642 PDFDocument58 pagesIm642 PDFCarlos PadillaNo ratings yet

- Hobart Handler 140 Manual 15165Document48 pagesHobart Handler 140 Manual 15165hovno2002No ratings yet

- Invertec V300Document117 pagesInvertec V300r_cristiNo ratings yet

- VRTEX 360 Virtual Welding TrainerDocument65 pagesVRTEX 360 Virtual Welding TrainerMarius PopaNo ratings yet

- Cruiser: Operator'S ManualDocument54 pagesCruiser: Operator'S ManualJaime ArreolaNo ratings yet

- Invertec STT PDFDocument145 pagesInvertec STT PDFAltai OspanNo ratings yet

- Invertec STT II: Operator'S ManualDocument38 pagesInvertec STT II: Operator'S ManualajuciniNo ratings yet

- LGK-100/120/160/200/300IGBT: Operator'S ManualDocument25 pagesLGK-100/120/160/200/300IGBT: Operator'S ManualMaurizioNo ratings yet

- SVM199Document145 pagesSVM199tesaurusNo ratings yet

- Maxsa 10 Controller: Operator'S ManualDocument48 pagesMaxsa 10 Controller: Operator'S ManualJaime ArreolaNo ratings yet

- HDSD Mig OTC DM350 PDFDocument72 pagesHDSD Mig OTC DM350 PDFHOryshorNo ratings yet

- Lincoln DC 1500 ManualDocument23 pagesLincoln DC 1500 ManualCOCHINITO123No ratings yet

- RNC Commissioning Guide 01-01 Safety InformationDocument14 pagesRNC Commissioning Guide 01-01 Safety InformationMohsenNo ratings yet

- Powerwave Acdc 1000 11124, 11226Document74 pagesPowerwave Acdc 1000 11124, 11226Jaime ArreolaNo ratings yet

- IFR 101 ManualDocument28 pagesIFR 101 ManualsunhuynhNo ratings yet

- Safety Precautions - Read Before Using: 1-1. Symbol UsageDocument2 pagesSafety Precautions - Read Before Using: 1-1. Symbol UsageMario E. MorenoNo ratings yet

- SKD-BN200 Series - ManualDocument11 pagesSKD-BN200 Series - ManualChung LeNo ratings yet

- Teromatec 400 English Manual PDFDocument24 pagesTeromatec 400 English Manual PDFex-2156100% (1)

- Invertec V250Document118 pagesInvertec V250Sergiu BadalutaNo ratings yet

- Arc Welding Electrical HazardsDocument2 pagesArc Welding Electrical HazardsZeeshan BajwaNo ratings yet

- Power Wave I400.Document57 pagesPower Wave I400.Jose LopezNo ratings yet

- BODYDocument3 pagesBODYSean Kenneth RosarosoNo ratings yet

- A Saw I I Series Operating ManualDocument34 pagesA Saw I I Series Operating ManualPascu AurelNo ratings yet

- Precautions: 1.1 Safety WarningDocument4 pagesPrecautions: 1.1 Safety WarningAngel BorsaniNo ratings yet

- 00 DM-350 Manual P10322-1Document72 pages00 DM-350 Manual P10322-1André Moura100% (1)

- Invertec 200 260 400tDocument16 pagesInvertec 200 260 400tJxyz QwNo ratings yet

- Smaw Facilitator'S Guide: Opening Notes FOR THE TeacherDocument62 pagesSmaw Facilitator'S Guide: Opening Notes FOR THE TeacherAJ AcuñaNo ratings yet

- Ronch 160arc DV 200arc DV User Manual PDFDocument36 pagesRonch 160arc DV 200arc DV User Manual PDFHenry JaraNo ratings yet

- Tig Mig Plasma OkDocument83 pagesTig Mig Plasma Okspwajeeh50% (2)

- Health and Safety in WeldingDocument46 pagesHealth and Safety in Weldingegn2007No ratings yet

- Harmee TooDocument26 pagesHarmee TooBirbirsa BetieNo ratings yet

- Operation Manual HLJDocument45 pagesOperation Manual HLJjoegrantosNo ratings yet

- Welding Safety Best PracticesDocument3 pagesWelding Safety Best PracticesLeni KusumawatiNo ratings yet

- Arc Welding: Electric ShockDocument5 pagesArc Welding: Electric ShockNamdeo YengadeNo ratings yet

- Skd-Be512l Skd-Be519l Skd-Be512lf Skd-Be517lf Skd-Be512p Skd-Be519p Skd-Be512pf Skd-Be517pfDocument16 pagesSkd-Be512l Skd-Be519l Skd-Be512lf Skd-Be517lf Skd-Be512p Skd-Be519p Skd-Be512pf Skd-Be517pfPrasathNo ratings yet

- Flextec ™ 450 CE: Operator'S ManualDocument32 pagesFlextec ™ 450 CE: Operator'S ManualLuis ErnestoNo ratings yet

- Army WeldingDocument757 pagesArmy WeldingKenn FerroNo ratings yet

- Electricity Unplugged: A Beginner's Guide to Electrical SafetyFrom EverandElectricity Unplugged: A Beginner's Guide to Electrical SafetyNo ratings yet

- Flange Details & DrawingsDocument338 pagesFlange Details & DrawingsshazanNo ratings yet

- Cleat Summary Excel SheetDocument4 pagesCleat Summary Excel SheetshazanNo ratings yet

- Clearance CalculationDocument12 pagesClearance CalculationshazanNo ratings yet

- Clearance Calculation For Skirt OpeningDocument3 pagesClearance Calculation For Skirt OpeningshazanNo ratings yet

- Static Equipment A Look Inside The How and Why of SpecificationDocument19 pagesStatic Equipment A Look Inside The How and Why of SpecificationshazanNo ratings yet

- Welding EngineeringDocument1 pageWelding EngineeringshazanNo ratings yet

- Test Flange TypeDocument1 pageTest Flange TypeshazanNo ratings yet

- Manhole MH PDFDocument1 pageManhole MH PDFshazanNo ratings yet

- Midrex Case StudyDocument1 pageMidrex Case StudyshazanNo ratings yet

- Flange GeometryDocument1 pageFlange GeometryshazanNo ratings yet

- MN-V-02 Sump - NozDocument1 pageMN-V-02 Sump - NozshazanNo ratings yet

- Training Course ASMEDocument2 pagesTraining Course ASMEshazan100% (1)

- Test Ring1 ModelDocument1 pageTest Ring1 ModelshazanNo ratings yet

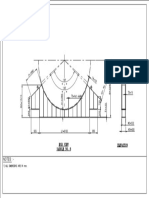

- Saddle DrawingDocument1 pageSaddle DrawingshazanNo ratings yet

- MN-V-02 M-01 - NozDocument1 pageMN-V-02 M-01 - NozshazanNo ratings yet