Professional Documents

Culture Documents

Zeron 100hs Wirelines To Api9a Rev1

Uploaded by

hesam abbaszadehOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zeron 100hs Wirelines To Api9a Rev1

Uploaded by

hesam abbaszadehCopyright:

Available Formats

API 9A/ISP10425 - 2003: Steel wire ropes for the petroleum and natural gas industries -

Minimum requirements and terms for acceptance.

ZERON 100HS slickline is often required to comply with API 9A/ISO 14025 as being the standard

recommended by the industry. API covers carbon steel ropes with a reference to other materials but with little

detail. ZERON 100HS on the other hand is a single strand Super Duplex stainless steel wireline so inevitably

there are some differences.

Below are the main areas where ZERON 100HS is to the technical requirements of the standard.

Material.

ZERON 100HS is a super duplex stainless steel which has outstanding strength and corrosion resistance. The

product is a single strand wireline with high strength, as shown below.

Diameter (inch) 0.092 0.108 0.125 0.140 0.160

Breaking load 1920 2500 3300 4050 5150

(lbf)

The wires do not contain any welds.

The wire is bare, uncoated and is lubricated with Metashield 610S.

The wires are Eddy current tested.

Tolerance on Diameter

Diameter (inch) 0.092 0.108 0.125 0.140 0.160

Tolerance +/-0.001 +/- 0.001 +/- 0.001 +/- 0.002 +/- 0.002

(inch)

Torsion test

It is unusual for a stainless steel wire to have significant torsions from a torsion test on an 8” gauge length. The

torsions do not show a significant degradation in service as do the carbon steel wires. Typical torsion test values

are as follows.

Diameter (inch) 0.092 0.108 0.125 0.140 0.160

Typical 4 4 3 3 3

Torsions

www.websterandhorsfall.co.uk info@websterandhorsfall.co.uk sales@websterandhorsfall.co.uk

You might also like

- Electric-Resistance-Welded Carbon and Alloy Steel Mechanical TubingDocument20 pagesElectric-Resistance-Welded Carbon and Alloy Steel Mechanical TubingMohamad ShafeyNo ratings yet

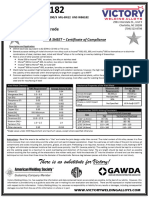

- NI-182 Victory ENICRFE-3 Electrode Data SheetDocument1 pageNI-182 Victory ENICRFE-3 Electrode Data SheetgianNo ratings yet

- 409 Data SheetDocument2 pages409 Data SheetMatthieuNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Technical DataDocument17 pagesTechnical Datat_syamprasadNo ratings yet

- Water Level Indicator Circuit Using Bipolar Junction TransistorFrom EverandWater Level Indicator Circuit Using Bipolar Junction TransistorRating: 4.5 out of 5 stars4.5/5 (7)

- Stainless Steel Grade Composition ChartDocument8 pagesStainless Steel Grade Composition ChartZaveri SagarNo ratings yet

- Aps Bluescope Asnzs3678 G250 PlateDocument2 pagesAps Bluescope Asnzs3678 G250 PlateMuhammad Adam PratamaNo ratings yet

- Product Manual: BarrettDocument52 pagesProduct Manual: Barrettbrajendra1020No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- AlloyDocument1 pageAlloyenemesio_85No ratings yet

- Stainless Steel For Potable Water Treatment Plants PWTP Guidelines PDFDocument8 pagesStainless Steel For Potable Water Treatment Plants PWTP Guidelines PDFAsgard SanchezNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- 3 Slickline CapabilitiesDocument14 pages3 Slickline CapabilitiesHedi ChhidiNo ratings yet

- KST 309LDocument1 pageKST 309LTharman SupramaniamNo ratings yet

- Stainless Steel For Potable Water Treatment Plants (PWTP) : by RE Avery, S. Lamb, C.A. Powell and A.H. TuthillDocument8 pagesStainless Steel For Potable Water Treatment Plants (PWTP) : by RE Avery, S. Lamb, C.A. Powell and A.H. TuthillAkash GundaleNo ratings yet

- Alambron CHQDocument4 pagesAlambron CHQJavier GranadosNo ratings yet

- Cavitalloy: Technical Data Sheet Cored Welding WireDocument1 pageCavitalloy: Technical Data Sheet Cored Welding WireMAURO MORESCONo ratings yet

- AS/NZS 3678 - 300 XLERPLATE Steel: General Description Australian StandardsDocument2 pagesAS/NZS 3678 - 300 XLERPLATE Steel: General Description Australian StandardsAdamNo ratings yet

- Turbaloy 310 (SS-310) Data SheetDocument1 pageTurbaloy 310 (SS-310) Data SheetcandraNo ratings yet

- Electrode SsDocument29 pagesElectrode SsEbrahim Abdelhady ElmekaweyNo ratings yet

- Mat Const Grade UNS C% MN% P% S% Si% Tensile Yield Point: Contact UsDocument1 pageMat Const Grade UNS C% MN% P% S% Si% Tensile Yield Point: Contact UsPOOL MASTERNo ratings yet

- Aluminum Bronze A2 Welding Wire and Rod: Cert # 05-R0925Document1 pageAluminum Bronze A2 Welding Wire and Rod: Cert # 05-R0925Valli RajuNo ratings yet

- Stainless Steel Grade Composition ChartDocument8 pagesStainless Steel Grade Composition Chart23OtterNo ratings yet

- SS 430, Type 430, WNR 1.4016, UNS S43000, AISI 430, ASTM 430, Grade 430, AFNOR Z8C-17Document3 pagesSS 430, Type 430, WNR 1.4016, UNS S43000, AISI 430, ASTM 430, Grade 430, AFNOR Z8C-17Harish AmpoluNo ratings yet

- AISI 52100 Chrome Steel Data Sheet: Simply Bearings LTD Authorised Precision Ball and Roller Distributors in The UKDocument1 pageAISI 52100 Chrome Steel Data Sheet: Simply Bearings LTD Authorised Precision Ball and Roller Distributors in The UKZehNo ratings yet

- 409 Stainless Steel PDFDocument2 pages409 Stainless Steel PDFDang Thanh TuanNo ratings yet

- Lead FreeDocument6 pagesLead FreeJithin Mathew0% (1)

- Tata Ductile Iron PipeDocument8 pagesTata Ductile Iron PipeAniket NimkarNo ratings yet

- Tubing TestDocument16 pagesTubing Testbenergy84100% (1)

- ASTM A325: ScopeDocument2 pagesASTM A325: ScopetylerstearnsNo ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel WeldingcfcshakerNo ratings yet

- 1 Wire Ropes, Elements and DefinitionsDocument6 pages1 Wire Ropes, Elements and DefinitionsDiego RodriguezNo ratings yet

- ISO 9001 AS 9100 Revision A: Usw Alloy Designation AND Description Data SheetDocument1 pageISO 9001 AS 9100 Revision A: Usw Alloy Designation AND Description Data Sheetbunky bunkoNo ratings yet

- 4500 ER High Pressure Retrievable ProbeDocument3 pages4500 ER High Pressure Retrievable ProbeshyamNo ratings yet

- Product Description Wire RodDocument3 pagesProduct Description Wire RodEngr Farrukh RehanNo ratings yet

- Aluminium Cladding For Pipe Insulation - HaomeiDocument2 pagesAluminium Cladding For Pipe Insulation - HaomeiHaytham ElsayedNo ratings yet

- Alloy 625 Wire & Rod: U.S. Alloy CoDocument1 pageAlloy 625 Wire & Rod: U.S. Alloy CowinstonsequeiraNo ratings yet

- SS Tubing (Wall Thickness)Document1 pageSS Tubing (Wall Thickness)hisaj4uNo ratings yet

- Carbon Hollow BarDocument3 pagesCarbon Hollow Barscrane@No ratings yet

- 230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505Document1 page230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505mohamed AdelNo ratings yet

- Rail Specification S & CorrosionDocument94 pagesRail Specification S & CorrosionGowthami Priya HanumuthuNo ratings yet

- Welding Stainless SteelDocument4 pagesWelding Stainless SteelJohan ZraghozNo ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel Weldingkdsenipah6667No ratings yet

- Alloy Steel Castings Table 1Document16 pagesAlloy Steel Castings Table 1takumi_zNo ratings yet

- Kaiser Aluminum Soft Alloy Tube PDFDocument31 pagesKaiser Aluminum Soft Alloy Tube PDFgerrzen64No ratings yet

- Bus Conductor Design and ApplicationsDocument70 pagesBus Conductor Design and ApplicationsJithinNo ratings yet

- 409 Data BulletinDocument12 pages409 Data BulletinWilliam PaivaNo ratings yet

- Aluminium Bronze To Bs 1400: Ab2Document1 pageAluminium Bronze To Bs 1400: Ab2Tirta BudiawanNo ratings yet

- Catalogo de Ejes CromsteelDocument20 pagesCatalogo de Ejes CromsteelJhonFerneyBohorquezSaldarriagaNo ratings yet

- Metals For Bus BarsDocument19 pagesMetals For Bus BarsYuttapong SupattaravongNo ratings yet

- ER4000Document2 pagesER4000deini13No ratings yet

- Flexible Conduit Systems enDocument15 pagesFlexible Conduit Systems enSam ANo ratings yet

- Kaiser Aluminum Shapes Soft Alloy PDFDocument18 pagesKaiser Aluminum Shapes Soft Alloy PDFgerrzen64No ratings yet

- Feeding Bottles: Printing Inks ForDocument4 pagesFeeding Bottles: Printing Inks Forhesam abbaszadehNo ratings yet

- Auxiliaries Pad TI GB 0622Document8 pagesAuxiliaries Pad TI GB 0622hesam abbaszadehNo ratings yet

- Tampa Tex TPX: Field of ApplicationDocument4 pagesTampa Tex TPX: Field of Applicationhesam abbaszadehNo ratings yet

- AS Food Packaging, One of TheDocument25 pagesAS Food Packaging, One of Thehesam abbaszadehNo ratings yet

- Pad Printing: High Performance Inks ForDocument7 pagesPad Printing: High Performance Inks Forhesam abbaszadehNo ratings yet

- Catering Collectin Disposable Pearl Plate V2Document2 pagesCatering Collectin Disposable Pearl Plate V2hesam abbaszadehNo ratings yet

- Oil Well Blowout Simulator: BackgroundDocument3 pagesOil Well Blowout Simulator: Backgroundhesam abbaszadehNo ratings yet

- Medium Truck Mounted Wireline Unit With Hydraulic Power Pack or PTODocument1 pageMedium Truck Mounted Wireline Unit With Hydraulic Power Pack or PTOhesam abbaszadehNo ratings yet

- La Minar 600 SpecificationDocument4 pagesLa Minar 600 Specificationhesam abbaszadehNo ratings yet

- HHF-1300-partsDocument44 pagesHHF-1300-partshesam abbaszadeh100% (1)

- Trailer Design Guideline V3 2014 ConfettiDocument28 pagesTrailer Design Guideline V3 2014 Confettihesam abbaszadehNo ratings yet

- Ws Wireline UnitDocument1 pageWs Wireline Unithesam abbaszadehNo ratings yet

- Slickline and Strand CareDocument10 pagesSlickline and Strand Carehesam abbaszadehNo ratings yet

- API Spec 9ADocument1 pageAPI Spec 9Ahesam abbaszadehNo ratings yet

- Wireline Advisory Wilco PDFDocument5 pagesWireline Advisory Wilco PDFhesam abbaszadehNo ratings yet

- Ansys Student Brochure PDFDocument2 pagesAnsys Student Brochure PDFhesam abbaszadehNo ratings yet

- API Spec 8C - Specification For Drilling and Production Hoisting Equipment (PSL 1 and PSL 2)Document6 pagesAPI Spec 8C - Specification For Drilling and Production Hoisting Equipment (PSL 1 and PSL 2)hesam abbaszadehNo ratings yet

- 1M65 Lathe UniversalDocument7 pages1M65 Lathe Universalhesam abbaszadehNo ratings yet