Professional Documents

Culture Documents

Principles of Pattern Making

Uploaded by

Alex TsegayeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Principles of Pattern Making

Uploaded by

Alex TsegayeCopyright:

Available Formats

Subject: Principles of Pattern Making

Unit 1: Introduction to pattern making

Quadrant 1 – E-Text

Learning Objectives

The learning objectives of this unit are to:

Match a tool to their function for drafting patterns.

Identify the different weights of muslin and paper.

Discuss the importance of the dart.

Discuss the importance of math in all aspects of the production process.

Use workroom related terms accurately when communicating with associates.

Define production terms and the associate’s tasks related to the terms.

1.1 Pattern Making Methods

Drafting

Drafting is a method of pattern making in which the body measurement are taken accurately.

Ease, is then added for easy body movement.

Pattern are made based on calculations and step by step instructions.

Drafting:

Can be done with only measurements.

It Assists in creating various designs.

It Requires a Model or Dress Form to take measurements.

Some measurement can be found by using the calculation, when all the measurements are

not available.

It is widely used in the readymade garment industry, and

Can make use of computer applications.

Drafting:

Requires many calculations.

The fit can be seen only during test fit.

Is time consuming.

1.2 Draping

This is a pattern making technique in which the muslin fabric or similar fabric of the original

garment put directly on the dress form to make the patterns.

The fabric is adjusted for fit, dart, ease and design(like gathers, pleats etc) and outline of the

garment parts is traced to make the patterns.

Draping:

Is easy no calculation required.

Allows the fit to be seen without stitching.

Is best suited for contour fit garment.

Does not require body measurements.

Is used by most of designers.

Draping:

Requires a dress form for every customer.

Requires the model to stand till the draping is over. This can take a long time.

1.3 Knockoff

The knockoff method:

Is useful if you want to reproduce the garment with same fit.

Does not require pattern making skills.

In this method:

Garment parts are copied into patterns.

Garments are ironed and folded into half and place on the flat table and seam lines are

traced. Then necessary seam allowances and marks added later.

The knockoff method:

Is easy to make patterns.

Can achieve similar fits.

In the knockoff method garments with Darts is difficult to knock off. Today many manufacturers

developed the Apparel CAD System.

Some of the developers are:

- Optitex

- Gerber

- Lectra

- Pad

- Tucktech

- Pad

- Investronica

1.4 Digitizer

With the digitizer patterns can be digitized with the help of mouse. All the pattern marking like

Grainline, Notches, pockets can be marked while digitizing. Nested digitized can be done for

graded patterns.

The pattern development system helps to make the flat patterns on computers. It helps to make

the patterns, Check the patterns, Adding Seam allowances, marking notches, Walking the pieces,

Grading etc. Today many developers are offering 3D Virtual stitching.

1.5 3D Virtual Sampling

3D body scanners are used to scan the models. Then the models are imported in virtual sampling

application. Preset models are also available. The models measurements are adjusted if required.

The patterns are placed in position and stitching lines defined. The simulators virtually stitch the

garment. The fabric properties can be adjusted. The required fabric designs can be rendered and

many fabric design combination rendered easily.

Garment fitting can be seen for the same.

1.6 Marker Making System

The Marker Making System helps to make the markers.

Automarker save lot of time to the operator and help to increase the efficiency.

1.7 Plotters

Plotters help to print the patterns in real size. The marker also plot in real size and used for

cutting.

1.8 3D Body Scanner

A 3D body scanner used to scan the body and converting into digital format. This enables many

measurements to be taken accurately. It has a light-emitting device that can produce scans

accurate to 1/16”.

1.9 Pattern Making Terminology And Principles

Pattern making requires a number of tools that help during the pattern making process. This

includes an awl, compass, French curve, Hip curve ruler, square, muslin, notcher, pattern making

paper, mechanical pencils, pins, push pins, ruler transparent, scissors or shears, measuring tape,

and tracing wheel.

The awl is a Pointed tool with a wooden handle. Used to pierce small holes such as to indicate

apex, Pocket markings etc.

The compass is a tool consisting of two rods, one sharply pointed and the other equipped with a

drawing end; Compasses are available in various sizes to draw circles of different measurements.

It is used for making ruffles and circular skirts.

The French curve is A plastic curve shape device used to draw curve lines like armhole and neck

shapes.

The Hip curve ruler is a wooden / Plastic / metal curved shaped ruler. The Edges are marked

with measurements. It is mostly used to draw the hip shape of the skirt and Pant. It can be used to

draw slight curve shape like Hemline etc.

The L square is A wooden / metal / plastic ruler with one side longer than the other. It is used to

make perpendicular lines.

Muslin is a plain weave fabric used for test fit the garment. Available in light, medium and heavy

weights.

The Notcher is a hand punching tool which produces a 1/16” (0.2 cm) nick in pattern. Used to

establish notches at the outer edge of seam when pattern is completed.

White or Brown coloured paper available in a variety of width and weights. Light weight papers

are used while drafting and thicker papers are used for sloppers.

Some papers available with dot at 1” interval for easy marking and drawing parallel and

perpendicular lines.

Mechanical pencils are used to draw patterns. Normally 4H lead is used for pattern making.

Size 17 pins are used to pin the fabrics.

Push pins are used to pin the pattern on the table.

The transparent ruler is a see through scale used to mark parallel lines.

The scissors or shears is a cutting device, used for cutting paper and fabric. Normally 6” to 9”

used.

Measuring tape is Plastic coated very flexible 60” long and has metal tips at the ends. These are

mostly marked both Inches and centimeters.

A tracing wheel is a pointed wheel at one end and wooden or plastic handle in the other end. It is

used to transfer pattern marking.

Metric pattern master is a see through plastic tool useful for marking parallel lines, giving seam

allowances and draw bias lines.

1.10 Pattern Terminology

1.11 Conclusion

To summarize, this course, in this unit you have been given an overview of pattern making

techniques.

You might also like

- Registrable and Non-Registrable Adverse ClaimsDocument18 pagesRegistrable and Non-Registrable Adverse ClaimsJacob Castro100% (1)

- Module 4 - Lesson 1 Pattern DraftingDocument22 pagesModule 4 - Lesson 1 Pattern Draftingabby moral0% (1)

- Permanently End Premature EjaculationDocument198 pagesPermanently End Premature EjaculationZachary Leow100% (5)

- Garment Construction - Amina CreationsDocument74 pagesGarment Construction - Amina Creationspoonam_ranee3934100% (2)

- Pattern MakingDocument10 pagesPattern MakingChaitanya Krishna100% (1)

- Draping AssignmentDocument18 pagesDraping AssignmentGunjan Maan100% (1)

- Principles of FittingDocument7 pagesPrinciples of FittingOmer Farooq100% (4)

- Pattern Making TechniquesDocument68 pagesPattern Making Techniquesarunkadve100% (4)

- Q4 SLM in GARMENTS GRADE 10 FINALDocument32 pagesQ4 SLM in GARMENTS GRADE 10 FINALD Garcia100% (3)

- Industrial Pattern MakingDocument17 pagesIndustrial Pattern MakingKathirrveluSubramainanNo ratings yet

- Pattern Making TerminologyDocument2 pagesPattern Making Terminologymaya_muth100% (1)

- Garment Construction DFDDocument138 pagesGarment Construction DFDANOOGA50% (4)

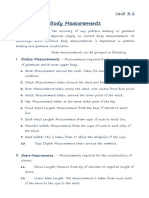

- Body Measurements: Unit 3.1Document3 pagesBody Measurements: Unit 3.1maya_muth100% (1)

- Pattern Chptr-2Document18 pagesPattern Chptr-2Ratul HasanNo ratings yet

- Gored Skirt Pattern DraftingDocument3 pagesGored Skirt Pattern DraftingJeff50% (2)

- Basics of Garment Construction PDFDocument18 pagesBasics of Garment Construction PDFvik1987100% (1)

- Blouse DraftingDocument19 pagesBlouse Draftingkiran_y286% (7)

- Pattern Making and DrapingDocument4 pagesPattern Making and DrapingYashvi JainNo ratings yet

- Garments CBCDocument63 pagesGarments CBCMphilipTNo ratings yet

- Y2 Module 1 Drafting and Cutting Pattern For Ladies' Casual Apparel Part 1Document84 pagesY2 Module 1 Drafting and Cutting Pattern For Ladies' Casual Apparel Part 1jeyan b100% (3)

- Las Math 2 Q3 Week 1Document6 pagesLas Math 2 Q3 Week 1Honeyjo Nette100% (7)

- Fashion DesignDocument134 pagesFashion Designnaonikino67% (9)

- Taking Body Measurement Pattern DraftingDocument17 pagesTaking Body Measurement Pattern DraftingEp-ep Pie BonzNo ratings yet

- Introduction To DrapingDocument32 pagesIntroduction To DrapingFinding Something100% (1)

- Pattern Drafting Grading CurDocument44 pagesPattern Drafting Grading Curmahendran50% (2)

- Clothing Construction PATTERNMAKINGDocument11 pagesClothing Construction PATTERNMAKINGAlexandra FernandezNo ratings yet

- Lesson 4: Drafting Basic / Block Pattern of Sleeping GarmentDocument44 pagesLesson 4: Drafting Basic / Block Pattern of Sleeping Garmentadelfa100% (6)

- Pattern Making InstructionsDocument16 pagesPattern Making InstructionsVania Yulita100% (3)

- Drafting A Princess Line Dress Pattern From The Basic Bodice Block OriginalDocument12 pagesDrafting A Princess Line Dress Pattern From The Basic Bodice Block OriginalNikoletta KourtakiNo ratings yet

- Pattern Making Guidelines and Kids BlockDocument134 pagesPattern Making Guidelines and Kids Blocka k67% (3)

- Draping PPT 151212104203 PDFDocument17 pagesDraping PPT 151212104203 PDFHancé PacheoNo ratings yet

- Tailoring-12 QUARTER 3 LO 1 DRAFT AND CUT PATTERN FOR BLAZERDocument12 pagesTailoring-12 QUARTER 3 LO 1 DRAFT AND CUT PATTERN FOR BLAZERKim Charlotte Balicat-Rojo Manzori100% (1)

- Apparel Design Management Day 2Document46 pagesApparel Design Management Day 2tiarany awaliaNo ratings yet

- DartsDocument13 pagesDartsPhoenix Griffith100% (1)

- Module - I Introduction To Sewing MachineDocument5 pagesModule - I Introduction To Sewing Machineanurag6866100% (1)

- Pattern Making SoftwareDocument2 pagesPattern Making Softwareinama33100% (1)

- Cases Torts 7-29-17 DigestDocument1 pageCases Torts 7-29-17 Digestczabina fatima delicaNo ratings yet

- Tailoring: Department of EducationDocument14 pagesTailoring: Department of EducationCarl Laura Climaco100% (3)

- Professional Pattern Grading For Women's, Men's, and Children's ApparelDocument265 pagesProfessional Pattern Grading For Women's, Men's, and Children's Apparelkiran narayan100% (1)

- Teach Yourself Stitch Craft and Dressmaking Volume IV: Pattern Drafting for Men and Practice Drafts - Trying your hand at drafting shirtsFrom EverandTeach Yourself Stitch Craft and Dressmaking Volume IV: Pattern Drafting for Men and Practice Drafts - Trying your hand at drafting shirtsNo ratings yet

- Head TheoryDocument17 pagesHead TheoryRaina varshney100% (1)

- Fashion REDUCING FULLNESS (Reduce Size)Document5 pagesFashion REDUCING FULLNESS (Reduce Size)Caphas Kaptain100% (1)

- Dart ManipulationDocument13 pagesDart ManipulationHarshita Sipani100% (2)

- Different Kinds of SkirtDocument15 pagesDifferent Kinds of SkirtKenneth MoralesNo ratings yet

- Drafting Pattern For Blouse and Skirt and SleeveDocument27 pagesDrafting Pattern For Blouse and Skirt and SleeveMedelyn Mhed Gadon FatallaNo ratings yet

- TorqueArm PDFDocument186 pagesTorqueArm PDFanush_swaminathanNo ratings yet

- Dressmaking NCII Draft The Basic Block PatternDocument17 pagesDressmaking NCII Draft The Basic Block PatternBe MotivatedNo ratings yet

- Pattern Making IntroductionDocument26 pagesPattern Making Introductionsonamanand2008100% (1)

- Dressmaking: Quarter 3 - Module 1 Produce Children's DressDocument30 pagesDressmaking: Quarter 3 - Module 1 Produce Children's DressIlerh Dave MiñanoNo ratings yet

- Fashion Draping: The Art of ClothingDocument8 pagesFashion Draping: The Art of Clothingmaya_muthNo ratings yet

- Project Plan For Childrens WearDocument6 pagesProject Plan For Childrens WearMary Jane Repaja Canaya68% (19)

- Taking Body Measurement by Precy NasisDocument2 pagesTaking Body Measurement by Precy NasisJay Cast100% (2)

- Students Notes - AFD - I Year - 02 - Tools & Equipment Used in Garment MakingDocument8 pagesStudents Notes - AFD - I Year - 02 - Tools & Equipment Used in Garment Makingmaya_muthNo ratings yet

- Dressmaking: Quarter 3 - Module 4 Produce Children's DressDocument12 pagesDressmaking: Quarter 3 - Module 4 Produce Children's DressIlerh Dave MiñanoNo ratings yet

- TLE10 - HE - Q1-Mod1 - Dressmaking - Draft and Cut Pattern For Ladies' Skirt - v3Document22 pagesTLE10 - HE - Q1-Mod1 - Dressmaking - Draft and Cut Pattern For Ladies' Skirt - v3MERCADER, ERICKA J100% (3)

- 01 - Basics of Pattern Making - 01Document17 pages01 - Basics of Pattern Making - 01maya_muthNo ratings yet

- 8 Head TheoryDocument21 pages8 Head TheoryAnand Dubey50% (2)

- Types of Pockets...Document5 pagesTypes of Pockets...Jorita Manayon100% (1)

- Principleof DesignDocument31 pagesPrincipleof DesignJay CastNo ratings yet

- How To Take Body Measurements For Dress MakingDocument9 pagesHow To Take Body Measurements For Dress Makingyasin husen100% (1)

- Lay-Up FabricDocument5 pagesLay-Up Fabrictom100% (1)

- Garment Construction ProcessesDocument4 pagesGarment Construction ProcessesMaria ElizabethNo ratings yet

- Important Topics of Pattern Making: UNIT-2:: Pattern Drafting Ready-To-Wear ClothingDocument47 pagesImportant Topics of Pattern Making: UNIT-2:: Pattern Drafting Ready-To-Wear ClothingISHITANo ratings yet

- Fashion Research PaperDocument78 pagesFashion Research PapervstyleinNo ratings yet

- Brochure For New HiresDocument11 pagesBrochure For New HiresroseNo ratings yet

- A Daily Miracle2Document1 pageA Daily Miracle2LizZelencichNo ratings yet

- Chapter 1Document25 pagesChapter 1Aditya PardasaneyNo ratings yet

- Simile ListDocument3 pagesSimile ListFiona SohNo ratings yet

- Orthodox Pebbles Raising of LazarusDocument29 pagesOrthodox Pebbles Raising of LazarusMonica DavidNo ratings yet

- NEGRETE vs. COURT OF FIRST INSTANCE OF MARINDUQUEDocument1 pageNEGRETE vs. COURT OF FIRST INSTANCE OF MARINDUQUELeo TumaganNo ratings yet

- Alamat NG BatangasDocument2 pagesAlamat NG BatangasGiennon Arth LimNo ratings yet

- Kumpulan Soal UPDocument16 pagesKumpulan Soal UPTriono SusantoNo ratings yet

- Pechay Camote Buchi - Aug7Document36 pagesPechay Camote Buchi - Aug7Rockie Alibio JuanicoNo ratings yet

- ICT Authority Legal NoticeDocument13 pagesICT Authority Legal NoticeICT AUTHORITYNo ratings yet

- Arendi v. GoogleDocument16 pagesArendi v. GooglePriorSmartNo ratings yet

- Emilio Aguinaldo: The First Philippine Republic The Malolos CongressDocument3 pagesEmilio Aguinaldo: The First Philippine Republic The Malolos CongressLIEZLE ANN EROYNo ratings yet

- Cropanzano, Mitchell - Social Exchange Theory PDFDocument28 pagesCropanzano, Mitchell - Social Exchange Theory PDFNikolina B.No ratings yet

- Chapter 1: Introduction Aviation Industry: Mini Project On Vistara AirlinesDocument84 pagesChapter 1: Introduction Aviation Industry: Mini Project On Vistara Airlinesselvaraj rapakaNo ratings yet

- CLASSIFICATION OF COSTS: Manufacturing: Subhash Sahu (Cs Executive Student of Jaipur Chapter)Document85 pagesCLASSIFICATION OF COSTS: Manufacturing: Subhash Sahu (Cs Executive Student of Jaipur Chapter)shubhamNo ratings yet

- Examples of Literacy Narrative Thesis StatementDocument6 pagesExamples of Literacy Narrative Thesis Statementzxtccvgld100% (2)

- Family Advent Devotions 1Document3 pagesFamily Advent Devotions 1collingdalenazNo ratings yet

- Law Sample QuestionDocument2 pagesLaw Sample QuestionknmodiNo ratings yet

- Kinematic Tool-Path Smoothing For 6-Axis Industrial Machining RobotsDocument10 pagesKinematic Tool-Path Smoothing For 6-Axis Industrial Machining RobotsToniolo LucaNo ratings yet

- Al-Arafah Islami Bank Limited: Prepared For: Prepared By: MavericksDocument18 pagesAl-Arafah Islami Bank Limited: Prepared For: Prepared By: MavericksToabur RahmanNo ratings yet

- Unit 2 Listening SkillDocument7 pagesUnit 2 Listening SkillSbgacc SojitraNo ratings yet

- Annual 2005Document128 pagesAnnual 2005KarredeLeonNo ratings yet

- Republic of The Philippines: Paulene V. Silvestre Personal DevelopmentDocument3 pagesRepublic of The Philippines: Paulene V. Silvestre Personal DevelopmentPau SilvestreNo ratings yet

- Introduction - Types and ApproachesDocument88 pagesIntroduction - Types and ApproachesAritra DeyNo ratings yet

- Listening Test Sweeney Todd, Chapter 4: 1 C. Zwyssig-KliemDocument3 pagesListening Test Sweeney Todd, Chapter 4: 1 C. Zwyssig-KliemCarole Zwyssig-KliemNo ratings yet