Professional Documents

Culture Documents

BMI-WI-5711-14 Ball Valve 2in-900# Manufacturing Process Rev.0

Uploaded by

MacelCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BMI-WI-5711-14 Ball Valve 2in-900# Manufacturing Process Rev.0

Uploaded by

MacelCopyright:

Available Formats

WORKING INSTRUCTION

BMI-WI-5711-14 Ball Valve 2in ANSI Class 900

Manufacturing Process

Revision No. : 0

Effective Date: August 27, 2015

Prepared By Reviewed By Approved by

Signature

Name Abdurrahman Maricel L. Lobis Lee Ka King

Designation Production Manager Operations Manager Managing Director

Date 12.08.2015 20.08.2015 25.08.2015

Ball Valve 2in ANSI Class 900

Doc. ID No. REVISION

WI-5711-14 0

Manufacturing Process

DATE PAGE

27.08.15 1 OF 11

1.0 Purpose

The purpose of this procedure is to provide the manufacturing process in the production of

Ball Valve Size 2in ANSI Class rating 900.

2.0 Scope

This procedure covers the inspection, machining, assembly, testing of Ball Valve 2in

ANSI Class 900. All process of manufacturing are based on API 6D, ASME B16.34 and

API 578.

3.0 Specification

PRODUCT SPECIFICATION:

Type: Ball Valve Stem Material: A105+3 mill ENP

Size: 2” Seat Material: PEEK

Rating: 900# Packing & Seal Material: Graphite / Viton

Connection: Flange RF Temperature Rating: 320 to 1900 F

Style: Bolted Body Operator: Lever Operated

Seating Arrangement: Trunnion Additional Design Features:

Body Material: ASTM A105 Cavity Relief, Fire safe Design, Anti-Static,

Replaceable ball and seat

Ball Material: ASTM A105 + 3 mill ENP Stainless Steel nameplate

4.0 Responsibility

4.1 Engineering Team

Prepares the bill of material and drawing structure logic.

4.2 Production Manager

Monitors and controls the production process that is carried out by the operator

4.3 Quality Manager

Approves finished products by confirming specifications; conducting visual and

measurement tests; returning products for re-work; confirming re-work

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY Page 1

Ball Valve 2in ANSI Class 900

Doc. ID No. REVISION

WI-5711-14 0

Manufacturing Process

DATE PAGE

27.08.15 2 OF 11

4.4 Quality Inspector

Doing inspection and approved incoming materials by confirming specifications,

conducting visual and measurement test.

Doing inspection during in-process production by confirming specification by

conducting visual and measurement tests, communicating required adjustments to

production manager.

4.5 Machine Operators

Operates the machines as per approved engineering drawing.

5.0 Material Receive

5.1 Receiving of Raw Material

Logistic coordinator checks the materials received against the supplier’s packing

slip and against a copy of the BMI’s purchase order to verify that the correct items

have been shipped. The quantity of the shipment is verified in the same manner.

Logistic coordinator inspects the general condition of the material to determine

whether any external damage was incurred during shipment. Endorsed the materials

received to QC Inspector for Material Inspection.

Refer to QSP-563-01 Verification of Purchased Product & Activities for details.

5.2 Inspection of Raw Material

QC Inspector inspects the incoming materials as endorsed by logistic coordinator for

inspection. QC Inspector examines and inspects the material according to inspection

specifications and perform test according to documented testing methods.

Refer to BMI-WI-563-02 Raw Material Acceptance Procedure for details.

6.0 Fabrication Process

6.1 Cutting Process

With approved drawing released by Engineering, production manager gives the

dimension and length of the raw material that is needed.

Upon received the required length and dimension the operator will cut the raw

material accordingly and will be checked and verified by QC Inspector. Refer to

BMI-WI-5711-01 Cutting Machine Operation for details.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY Page 2

Ball Valve 2in ANSI Class 900

Doc. ID No. REVISION

WI-5711-14 0

Manufacturing Process

DATE PAGE

27.08.15 3 OF 11

6.2 Machining – Lathe Process

6.2.1 Machine operator shall Inspect equipment before use, for damage parts and

cords.

6.2.2 Prepare all lathe chisel and the measuring instrument to be used.

6.2.3 Check whether the material re-entry in the machining tolerance for or not and

use chuck 4.

6.2.4 Setting 1 :

Post a raw material in the lathe chuck

Setting using a dial indicator on the diameter of the raw material

If the material is already center, material ready for machining

6.2.5 Process (Body and Bonnet)

6.2.5.1 Facing surface of the body and bonnet raw material, appropriate

dimensions in the drawing

6.2.5.2 Facing surface of the outer and inner diameter of body and bonnet

raw material, appropriate dimensions as per the drawing provided

by Engineering Department.

6.2.5.2.1 Body Process

Grooving surface for gasket as per engineering

drawing.

6.2.5.2.2 Bonnet Process

Facing surface with a faster speed for the

manufacture of RF,if RTJ follow the drawing

regarding countour

Grooving outer and inner diameter for bonnet as per

engineering drawing.

6.2.5.3 For class 300, 600 and so on, do facing the rear flange except class

150

6.2.5.4 Finish process

Materials / components are declared fit to be

submitted or proceed to the next process

6.2.6 Setting 2 :

Release the material,reverse and put raw material in the lathe chuck

Setting using a dial indicator on the diameter of the raw material

If the material is already center, material ready for machining

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY Page 3

Ball Valve 2in ANSI Class 900

Doc. ID No. REVISION

WI-5711-14 0

Manufacturing Process

DATE PAGE

27.08.15 4 OF 11

6.2.7 Process 2 :

6.2.7.1 Facing surface of the body and bonnet raw material, appropriate

dimensions in the drawing

6.2.7.2 Facing surface of the outer and inner diameter of body and bonnet

raw material, appropriate dimensions as per the drawing provided

by Engineering Department.

6.2.7.2.1 Body Process

Grooving surface for gasket as per engineering

drawing.

6.2.7.2.2 Bonnet Process

Facing outer and grooving for o- ring housing as per

engineering drawing.

6.2.7.3 Finish process.

Materials / components are declared fit to be

submitted or proceed to the next process

6.2.8 Switch off the machine and reset all guards to a fully closed position.

6.2.9 Place all tools used back where they belong.

6.2.10 Leave the machine in safe, clean and tidy state.

6.3 Drilling, Milling & Tapping

6.3.1 Machine operator shall Inspect equipment before use, for damage parts and

cords.

6.3.2 Preparation

Prepare drill and measuring devices to be used

Use vice clamping for holding the body and bonnet.

6.3.3 Setting 1 :

6.3.3.1 Place the body and bonnet in vertical position for vice clamping to

hold.

6.3.3.2 Set the center of the diameter of the body and bonnet using

centrofix.

6.3.4 Process

6.3.4.1 Create the program of CNC milling for drill, milling and tapping

for the body and bonnet. Follow the dimensions as per engineering

drawing.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY Page 4

Ball Valve 2in ANSI Class 900

Doc. ID No. REVISION

WI-5711-14 0

Manufacturing Process

DATE PAGE

27.08.15 5 OF 11

6.3.5 Finish Process.

Materials / components are declared fit to be submitted or proceed to the

next process

6.3.6 Same setting as 6.3.3 and process as 6.3.4.

6.3.7 Setting 3: Setting-up trunnion

6.3.7.1 Place the valve body in horizontal position for vice clamping to

hold the body.

6.3.7.2 Set the center of the body using centrofix.

6.3.8 Repeat process 6.3.4.

6.3.9 Finish Process.

6.3.10 Switch off the machine and reset all guards to a fully closed position.

6.3.11 Place all tools used back where they belong.

6.3.12 Leave the machine in safe, clean and tidy state.

7.0 Marking

Valve body is marked as required in QSP-A5-01 Control of the Application &

Removal of API Monogram. Identification markings below are marked on the valve

body:

1) Manufacturers name

2) Material

3) Rating

4) Size

8.0 Assembly Process

Note: Before performing the assembly work, clean the working area, ensure that there are

no iron filings, rust, welding slag, and other debris inside the valve. Keep all valve parts

and the working area clean all throughout the assembly process. The working area must be

padded with any soft material or mat. Do not allow the valve body, its components, or any

of its assembled parts to have direct contact with the ground.

Be careful with the lifting and moving of the ball valve’s components. Excessive

force applied to the assembly may damage or deform the valve, its related parts, and its

components which may cause the ball valve to malfunction.

8.1 Refer to the General Assembly drawing to assemble the valve.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY Page 5

Ball Valve 2in ANSI Class 900

Doc. ID No. REVISION

WI-5711-14 0

Manufacturing Process

DATE PAGE

27.08.15 6 OF 11

8.2 Assemble the O-ring and spring into its corresponding location in the valve seat.

Fit this assembly inside the valve body section. Assemble the O-ring and spring

into the valve seat then fit this assembly into the body cap section. Place the

remaining O-ring and gasket inside the cap section.

8.3 Place the ball inside the valve body section. Connect the assembled body cap

section and secure it with stud and nut. Tighten the bolts with a torque as specified

in Table 1.

8.4 Place the antistatic components in their position located at the lower stem trunnion

and fit them into the bottom part of the valve body. Make sure that head of the

lower stem trunnion enters the hole underneath the ball inside the valve body.

Insert the stem bearing into the lower trunnion and into the valve body.

8.5 Place the gasket and O-ring into the lower cover then fit the lower cover into the

bottom of the valve body. Secure this into the valve body and screw bolt and screw

nut and tighten it.

8.6 Secure the key into the keyway of the upper stem and fit this into the stop of the

upper stem and fit this into the top of the valve body. Make sure that its head is

properly connected to the ball. Place the stem bearing into the upper stem and

continuously into the valve body.

8.7 Place the O-rings and back-up ring into the stem retainer. Fit the stem retainer into

the head of upper stem and continuously into the valve body.

8.8 Place the cut ring into the upper stem and continuously into the top valve body.

8.9 Insert the O-ring, back-up ring gasket and packing into the gland flange. Fit the

gland flange into the head of the upper stem and mount it on the top of the valve

body. Secure it with stud bolts and tighten.

8.10 Insert the keys into the keyway of the upper stem. Place the operator correctly into

the top of the valve stem which should come in contact with the top of the valve

body.

8.11 Use the bolt and nut to tighten the operator and gland flange.

8.12Screw the sealant fittings and the drain plug into their corresponding location in

the valve bodies and tighten it.

8.13Make the valve actuate once or twice by rotating the driving device to ensure the

accuracy and reliability of the valve. Finally, rotate the valve at fully open position.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY Page 6

Ball Valve 2in ANSI Class 900

Doc. ID No. REVISION

WI-5711-14 0

Manufacturing Process

DATE PAGE

27.08.15 7 OF 11

9.0 Inspection and Test

9.1 Dimensional Inspection

Dimensions shall be inspected in accordance with the drawings and specified values.

Face to face tolerance for Ball valve 2”-900# is ±2mm.

9.2 Visual Inspection

9.2.1 Machined faces and all surfaces are free from flaws or unevenness on

finished surfaces.

9.2.2 The fluid passage is finished appropriately and free from foreign debris.

9.2.3 Angles and corners the dimensions of which are not specified in the

drawings and standards are chamfered and rounded appropriately.

9.2.4 The nominal pressure, nominal diameter, and other necessary

information should be properly indicated on the body surface and label.

9.2.5 The flow direction shall be properly indicated when restricted.

9.2.6 Bore should be unobstructed when valve is in full open position.

9.3 Pressure Test

9.3.1 Shell Test

With the valve kept half open, fill the body with water and apply test pressure

shown in Table 1. Make sure that the connections are tight then use leak detector

spray on all body joins & body surfaces to ensure zero leakage and all parts are

free from leakage.

Table 1. Shell Test

Shell Material Class 900 Time Duration

A105 3356 psi 2 mins

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY Page 7

Ball Valve 2in ANSI Class 900

Doc. ID No. REVISION

WI-5711-14 0

Manufacturing Process

DATE PAGE

27.08.15 8 OF 11

9.3.2 High Pressure Valve Seat Test

With the valve closed fully, test in both directions, one direction at a time at

pressure given in Table 2. Use bubble test to ensure zero leakage.

Table 2. High Pressure Valve Seat Test

Size Class 900 Time Duration

2in 2489 psi 2 mins

9.3.3 Low Pressure Valve Seat Test (Gas)

With the valve closed fully, test in both directions, one direction at a time at

pressure of 0.6Mpag. Use Bubble test to ensure zero leakage. An acceptance

criterion for closure test is 0 leakages.

10 Finishing Process

10.1 Name plating

Refer to QSP-A5-01 Control of Application & Removal API Monogram.

10.2 Cleaning and Anti-rust coating

The interior of the valve is to be sprayed or coated with rust preventative oil to

prevent rust and corrosion during transit and storage.

10.3 Painting

Please refer to BMI-WI-5711-01 Painting Procedure.

11 Final Inspection

11.1 Paint Check

a. The paint check shall be made after the above-mentioned tests have been

completed.

b. Check that finished coat is free from peeling, unevenness, blistering, etc.

c. Specification and color shall be in accordance with customer specifications. Unless

otherwise not specified.

11.2 Ensure that all marking and tagging are correct.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY Page 8

Ball Valve 2in ANSI Class 900

Doc. ID No. REVISION

WI-5711-14 0

Manufacturing Process

DATE PAGE

27.08.15 9 OF 11

11.3 Body finish of casting/forging to be physically inspected.

12 Packing/Storage

Please refer to BMI-WI-5761-02 Preservation of API 6D Products and BMI-WI-5762-01

Packaging Instruction.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY Page 9

Ball Valve 2in ANSI Class 900

Doc. ID No. REVISION

WI-5711-14 0

Manufacturing Process

DATE PAGE

27.08.15 10 OF 11

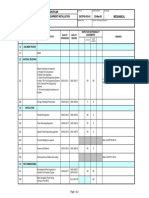

JOB ORDER

(Operation Manager)

SHOP ORDER

(Production/PPIC)

DESIGN&DRAWING

(Engineering Team)

Drawing NO

& BOM

YES

MATERIAL REQUISITION

(Production)

YES

NO PURCHASE REQUISITION PURSHASE ORDER

Stock

(Logistics) (Purchasing)

YES

RELEASE MATERIAL YES QC RECEIVING MATERIAL

(Logistics) verified (Logistics & QC)

NO

Machining Work

Instruction

MACHINING PROCESS

(Production)

a) Cutting b) Lathe

c) Milling d) Marking

YES

INSPECTION NO NO REJECTED

REWORK

(Quality Control) (Scrap)

NCR

(QC Inspector)

A

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY Page 10

Ball Valve 2in ANSI Class 900

Doc. ID No. REVISION

WI-5711-14 0

Manufacturing Process

DATE PAGE

27.08.15 11 OF 11

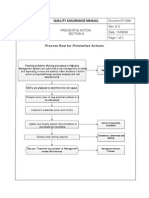

YES Assembly

Procedure

ASSEMBLY

(Production)

YES

INSPECTION NO NO REJECTED

REWORK

(Quality Control) (Scrap/Rejected Area)

NCR

YES

(QC Inspector)

Hydrotest

HYDROTEST Procedure

(Production)

NO

INSPECTION REPAIR

(Quality Control) (Production) NCR

(QC Inspector)

YES Painting

Procedure

PAINTING

(Production)

NO

FINAL

REPAIR

INSPECTION

(Production) NCR

(Quality Control)

(QC Inspector)

YES

Preservation of

PRESERVATION Product Procedure

(Logistics)

STORAGE

(Ware House Area)

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY Page 11

You might also like

- Internal Quality Audit ProcedureDocument2 pagesInternal Quality Audit ProceduremahendraNo ratings yet

- ICM Certification (P) LTD.: STANDARD: - ISO 9001: 2015 Audit ReportDocument18 pagesICM Certification (P) LTD.: STANDARD: - ISO 9001: 2015 Audit ReportRohit AttriNo ratings yet

- 8.5.1 Corrective Action FormDocument1 page8.5.1 Corrective Action FormvishvendanNo ratings yet

- QM1 Quality Manual R9 (ISO 9001 - 2015)Document27 pagesQM1 Quality Manual R9 (ISO 9001 - 2015)paulNo ratings yet

- Preventing Quality IssuesDocument5 pagesPreventing Quality IssuesVivek VNo ratings yet

- Butterworth Feedmill SDN BHD: Toolbox Meeting RecordsDocument1 pageButterworth Feedmill SDN BHD: Toolbox Meeting RecordsNurul NatashaNo ratings yet

- Contract Review FormatDocument1 pageContract Review Formatsuresh kumarNo ratings yet

- Supplier Audit Checklist Optimizes Risk ManagementDocument13 pagesSupplier Audit Checklist Optimizes Risk ManagementPrakash kumarTripathiNo ratings yet

- Standard Auditing Checklist: General Questions Job ConditionsDocument2 pagesStandard Auditing Checklist: General Questions Job ConditionsBharathNo ratings yet

- Objective and Programme of YEAR 2023Document8 pagesObjective and Programme of YEAR 2023hse bsjNo ratings yet

- Quality Procedure: NS-EN ISO 9001-2008 - Certificate No 1221Document5 pagesQuality Procedure: NS-EN ISO 9001-2008 - Certificate No 1221vsnaiduqcNo ratings yet

- Customer Specific Formatting and Validation ReportDocument1 pageCustomer Specific Formatting and Validation ReportHarjeet SinghNo ratings yet

- BMI WI 5711 01 Cutting ProcedureDocument3 pagesBMI WI 5711 01 Cutting ProcedureMacelNo ratings yet

- Proposal For - TPI For Oxygen Generator - BVQS - Ver02 (EN)Document11 pagesProposal For - TPI For Oxygen Generator - BVQS - Ver02 (EN)Asan IbrahimNo ratings yet

- OHS Internal Audit ProcedureDocument5 pagesOHS Internal Audit ProcedurekamranNo ratings yet

- Control of Monitoring & Measuring DevicesDocument10 pagesControl of Monitoring & Measuring DevicesRamesh mudunuriNo ratings yet

- Internal Audit Observation ReportDocument2 pagesInternal Audit Observation Reportsenk197100% (1)

- FOF-InP-010 Base Inspection - Operations and Dispatch Check List Rev. 1Document3 pagesFOF-InP-010 Base Inspection - Operations and Dispatch Check List Rev. 1dnana100% (1)

- Tri Star Ind: Non - Conformance ReportDocument3 pagesTri Star Ind: Non - Conformance Reportvines7831No ratings yet

- Welders Continuity Log: Name Welder ID ProcessDocument4 pagesWelders Continuity Log: Name Welder ID ProcessMacelNo ratings yet

- 1 SATIP-B-019-01 Portable Fire Protection Equip-Rev 1Document2 pages1 SATIP-B-019-01 Portable Fire Protection Equip-Rev 1JithuJohnNo ratings yet

- Internal audit checklist for MR, CIP, training and customer complaintsDocument3 pagesInternal audit checklist for MR, CIP, training and customer complaintsganrashNo ratings yet

- Production Scheduling OptimizationDocument9 pagesProduction Scheduling OptimizationRohini GadhaweNo ratings yet

- Customer Satisfaction Survey ProcedureDocument1 pageCustomer Satisfaction Survey ProcedureAnkur GuptaNo ratings yet

- Supplier Assesment MaxionDocument23 pagesSupplier Assesment Maxionesivaks2000No ratings yet

- QP-5 Rev.0-RDocument14 pagesQP-5 Rev.0-RvsnaiduqcNo ratings yet

- F MR 13 Internal Audit ScheduleDocument6 pagesF MR 13 Internal Audit ScheduleRohtash fastnerNo ratings yet

- Sharma Enterprises: Contingency Plan For Business ContinuityDocument1 pageSharma Enterprises: Contingency Plan For Business ContinuitytriveshNo ratings yet

- Blank A3 PPS Ver2Document2 pagesBlank A3 PPS Ver2Lpitt56No ratings yet

- Internal Qualified Auditor ListDocument1 pageInternal Qualified Auditor ListvictorNo ratings yet

- Planning Procedure Quality SystemDocument4 pagesPlanning Procedure Quality SystemMacelNo ratings yet

- Quality Procedure: TrainingDocument7 pagesQuality Procedure: TrainingvsnaiduqcNo ratings yet

- ROF QP 007 Internal AuditingDocument5 pagesROF QP 007 Internal AuditingISO ConsultancyNo ratings yet

- DBMS Lab Manual AmendmentsDocument1 pageDBMS Lab Manual AmendmentsThaddeus MooreNo ratings yet

- MARATHAN MOTOR SOP Recruitment ProcedureDocument4 pagesMARATHAN MOTOR SOP Recruitment Procedurerishi gautamNo ratings yet

- IATF 16949 Audit Status & Importance TrackerDocument5 pagesIATF 16949 Audit Status & Importance TrackerUlhas Kavathekar0% (1)

- Global Engineering Standard: Crimp Verification Report Process DefinitionDocument25 pagesGlobal Engineering Standard: Crimp Verification Report Process DefinitionRodrigo TorresNo ratings yet

- Prepared by Approved by Department Status Saurabh Kumar Praguman Verma Biw VqaDocument2 pagesPrepared by Approved by Department Status Saurabh Kumar Praguman Verma Biw VqaScientific KingNo ratings yet

- Quality inspection plan for dyed and printed finished fabricDocument3 pagesQuality inspection plan for dyed and printed finished fabricITOPS TeamNo ratings yet

- MM/COP/HR/F/08 - Mahabal Metals Staff Induction Training RecordsDocument3 pagesMM/COP/HR/F/08 - Mahabal Metals Staff Induction Training RecordsNitin KambleNo ratings yet

- Employee Training LogDocument1 pageEmployee Training Logjt2328No ratings yet

- Heat Treatment - Furnace TreatmentDocument19 pagesHeat Treatment - Furnace Treatmentkumar QANo ratings yet

- Quality Assurance Manual Process FlowDocument2 pagesQuality Assurance Manual Process FlowNgonidzashe ZvarevasheNo ratings yet

- EOHSP 01 Identification Evaluation of AspectsDocument5 pagesEOHSP 01 Identification Evaluation of Aspectsjulio_salas_59No ratings yet

- F-05 Corrective Action FormDocument1 pageF-05 Corrective Action Formsuhara hussainNo ratings yet

- GSB-Form-58 Non Conforming Report (NCR)Document1 pageGSB-Form-58 Non Conforming Report (NCR)Made GileeNo ratings yet

- QAP K-HouseDocument4 pagesQAP K-HouseAbhinash TamangNo ratings yet

- DS-09-01 R0 Communication During ChangeDocument1 pageDS-09-01 R0 Communication During ChangeDhinakaranNo ratings yet

- ISO 9001:2000 IN A NUTSHELL (First Revision)Document5 pagesISO 9001:2000 IN A NUTSHELL (First Revision)nallasivam v100% (1)

- 390018-Lito Garcia Junio-Production Team LeaderDocument3 pages390018-Lito Garcia Junio-Production Team LeaderATKNo ratings yet

- Sop 091-15Document2 pagesSop 091-15m_armoutiNo ratings yet

- Gate & Globe PDFDocument0 pagesGate & Globe PDFZoebairNo ratings yet

- Die Inward Inspection ReportDocument2 pagesDie Inward Inspection ReportRahul DevkateNo ratings yet

- D - 14k - 3 - Delta Checklist ISO 14001-2015 - 20150917 - Short - EnglDocument9 pagesD - 14k - 3 - Delta Checklist ISO 14001-2015 - 20150917 - Short - EnglPRASAD SHETTYNo ratings yet

- Efwe 2 e 4 GF 1 W 3Document1 pageEfwe 2 e 4 GF 1 W 3BALACHANDAR SNo ratings yet

- 01a.supplier Evaluation Form For Raw Material & VendorDocument3 pages01a.supplier Evaluation Form For Raw Material & VendorPurchase RG FibrotechNo ratings yet

- Internal Audit PlanDocument1 pageInternal Audit PlanAgisNo ratings yet

- Control of Records: I. Table of ContentsDocument5 pagesControl of Records: I. Table of ContentsRehan SabirNo ratings yet

- Human Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveFrom EverandHuman Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveNo ratings yet

- METHOD STATEMENT For Roll-Up Doors InstallationDocument16 pagesMETHOD STATEMENT For Roll-Up Doors Installationmoytabura96100% (2)

- Iso 9001Document29 pagesIso 9001Macel100% (1)

- 160811143045Document53 pages160811143045Кари МедNo ratings yet

- Casting Methods Tools & ProcessDocument6 pagesCasting Methods Tools & ProcessMacelNo ratings yet

- MPS.2015.07.01 Ball Valve 4in 150LbDocument11 pagesMPS.2015.07.01 Ball Valve 4in 150LbMacelNo ratings yet

- ISA 75.19.01 Hydrostatic Testing of Control ValveDocument34 pagesISA 75.19.01 Hydrostatic Testing of Control ValveZacLiew100% (5)

- API 6A Conformance AssessmentDocument2 pagesAPI 6A Conformance AssessmentMacelNo ratings yet

- Metallurgical Test Certificate: Doc. No. R-QC.11 Nov.12Document2 pagesMetallurgical Test Certificate: Doc. No. R-QC.11 Nov.12MacelNo ratings yet

- Welders Continuity Log: Name Welder ID ProcessDocument4 pagesWelders Continuity Log: Name Welder ID ProcessMacelNo ratings yet

- MPS.2016.02 Ball Valve 4in 300Lb PDFDocument11 pagesMPS.2016.02 Ball Valve 4in 300Lb PDFMacelNo ratings yet

- Manufacturing Ball ValvesDocument12 pagesManufacturing Ball ValvesMacel100% (1)

- BMI WI 5762 03 Crane Safety UsageDocument8 pagesBMI WI 5762 03 Crane Safety UsageMacel100% (1)

- Delrin 500 Material Test Report PO50Document2 pagesDelrin 500 Material Test Report PO50Macel100% (1)

- Perfomance Target FormDocument1 pagePerfomance Target FormMacelNo ratings yet

- Written SpecificationDocument3 pagesWritten SpecificationMacelNo ratings yet

- Backlight VerificationDocument1 pageBacklight VerificationMacelNo ratings yet

- Factory Acceptance Testing Guideline Process - NoRestrictionDocument16 pagesFactory Acceptance Testing Guideline Process - NoRestrictionhamed51060No ratings yet

- Ball Valve - VnumberDocument3 pagesBall Valve - VnumberMacelNo ratings yet

- Failure Mode Department/Area Equipment: Top Contributors ParetoDocument1 pageFailure Mode Department/Area Equipment: Top Contributors ParetoMacelNo ratings yet

- Introduction To Internal AuditsDocument33 pagesIntroduction To Internal AuditsMacelNo ratings yet

- BMI-WI-5711 - API6D Valve Marking - Rev Draft 03Document6 pagesBMI-WI-5711 - API6D Valve Marking - Rev Draft 03Macel100% (1)

- BMI WI 5711 02 Lathe Operation Rev.1Document3 pagesBMI WI 5711 02 Lathe Operation Rev.1MacelNo ratings yet

- Production PlanningDocument1 pageProduction PlanningMacelNo ratings yet

- BMI WI 5711 01 Cutting ProcedureDocument3 pagesBMI WI 5711 01 Cutting ProcedureMacelNo ratings yet

- BMI WI 563 01 Raw Material AcceptanceDocument22 pagesBMI WI 563 01 Raw Material AcceptanceMacel100% (1)

- QSP 510 01 Contract ReviewDocument9 pagesQSP 510 01 Contract ReviewMacel100% (1)

- QSP 4322-01 Personnel Competence and TrainingDocument8 pagesQSP 4322-01 Personnel Competence and TrainingMacel100% (2)

- NDE-Penetrant TestDocument2 pagesNDE-Penetrant TestCandy KendeeNo ratings yet

- Planning Procedure Quality SystemDocument4 pagesPlanning Procedure Quality SystemMacelNo ratings yet

- QSP-5762-01 Storage and AssessmentDocument27 pagesQSP-5762-01 Storage and AssessmentMacel100% (1)

- Tutorial 1Document2 pagesTutorial 1eddy50% (2)

- Filtration EquipmentsDocument29 pagesFiltration EquipmentsharijayaramNo ratings yet

- Hot Plate-Stirr User ManualDocument32 pagesHot Plate-Stirr User ManualLuz ContrerasNo ratings yet

- EBS e PDFDocument92 pagesEBS e PDFRowan Cornelius100% (2)

- Murakami - Analysis of Stress Intensity Factors of Modes I, II and III For Inclined Surface Cracks of Arbitrary ShapeDocument14 pagesMurakami - Analysis of Stress Intensity Factors of Modes I, II and III For Inclined Surface Cracks of Arbitrary ShapeDavid C HouserNo ratings yet

- The Vital Role of Quantum Cryptography in IoT Network SecurityDocument15 pagesThe Vital Role of Quantum Cryptography in IoT Network SecurityAllanki Sanyasi RaoNo ratings yet

- Weekly Home Learning Plan - KindergartenDocument3 pagesWeekly Home Learning Plan - KindergartenMae Escobin BetonggaNo ratings yet

- Safety Assessment For External Short Circuit of Li-Ion Battery inDocument15 pagesSafety Assessment For External Short Circuit of Li-Ion Battery inpcNo ratings yet

- CCS - View Topic - Enable Timer1 Interrupt in Another ISRDocument4 pagesCCS - View Topic - Enable Timer1 Interrupt in Another ISRapi-3755810100% (2)

- DC Characteristics of A MOS Transistor (MOSFET) : Created in COMSOL Multiphysics 5.3Document20 pagesDC Characteristics of A MOS Transistor (MOSFET) : Created in COMSOL Multiphysics 5.3Anika TabassumNo ratings yet

- Chapter 3Document6 pagesChapter 3Sheldon BazingaNo ratings yet

- Cloud Load Balancing Overview - Google CloudDocument1 pageCloud Load Balancing Overview - Google CloudnnaemekenNo ratings yet

- Computer Basics Study GuideDocument11 pagesComputer Basics Study GuidePrerak DedhiaNo ratings yet

- Universal JointDocument17 pagesUniversal Jointakmalzuhri96No ratings yet

- Relat EstoquecsDocument32 pagesRelat EstoquecsAlissonNo ratings yet

- Presentation GLDocument18 pagesPresentation GLAris NurrochmanNo ratings yet

- Experiments On Partial Replacement of Coconut Shell As Coarse Aggregate in ConcreteDocument10 pagesExperiments On Partial Replacement of Coconut Shell As Coarse Aggregate in ConcreteIJIRSTNo ratings yet

- Types of ImplicatureDocument4 pagesTypes of ImplicatureSaman Khan100% (3)

- Math 7-Q4-Module-3Document16 pagesMath 7-Q4-Module-3Jeson GaiteraNo ratings yet

- SBJ Series: Summing Junction Boxes For 2, 3, or 4 Load CellsDocument1 pageSBJ Series: Summing Junction Boxes For 2, 3, or 4 Load CellsJAcobNo ratings yet

- The preparation, dyeing and finishing of cotton knit goodsDocument67 pagesThe preparation, dyeing and finishing of cotton knit goods郭哲宏100% (1)

- Landslides and Engineered Slopes - Chen 2008 PDFDocument2,170 pagesLandslides and Engineered Slopes - Chen 2008 PDFLupu Daniel100% (2)

- Preparation of Sample For AnalysisDocument27 pagesPreparation of Sample For Analysisapi-26215965100% (2)

- MATLAB Image Processing Toolbox Basic IntroductionDocument10 pagesMATLAB Image Processing Toolbox Basic IntroductionHilbertNo ratings yet

- Cathodic Disbondment Test of Pipeline Coatings (Attached Cell Method)Document4 pagesCathodic Disbondment Test of Pipeline Coatings (Attached Cell Method)Alex OliveiraNo ratings yet

- Helios PDF HandshakeDocument2 pagesHelios PDF HandshakemilivojNo ratings yet

- Seismic Analysis of Gravity Dams: A Comparative Study Using A Progressive MethodologyDocument8 pagesSeismic Analysis of Gravity Dams: A Comparative Study Using A Progressive MethodologyMirza Waqar BaigNo ratings yet

- FP35 Hearing Aid Analyzer TrainingDocument85 pagesFP35 Hearing Aid Analyzer TrainingPamela Tamara Fernández EscobarNo ratings yet

- Math M P3 2013 QuestionDocument6 pagesMath M P3 2013 QuestionMasnah HussenNo ratings yet

- 4.0L Cec System: 1988 Jeep CherokeeDocument17 pages4.0L Cec System: 1988 Jeep CherokeefredericdiNo ratings yet