Professional Documents

Culture Documents

Plastic Welding Machine Construction Site PE Up To OD 1200mm PN 12.5 SDR 13.6 2017

Uploaded by

Nararya Muh Pratito AndityaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plastic Welding Machine Construction Site PE Up To OD 1200mm PN 12.5 SDR 13.6 2017

Uploaded by

Nararya Muh Pratito AndityaCopyright:

Available Formats

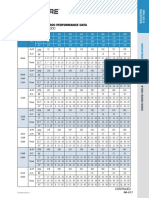

Table for PE

Basis: DVS data sheets 2207, 2208 - State 2016

Field of application: 8000 (from 07/2000 until 05/2009)

10000 (from 07/2000) / 12000 (from 07/2000)

1 bar on pressure gauge: 463 N (Effective surface of cylinder: 4626 mm² / 7,17 inch²)

The heating element temperature is 220° C ± 10° C / 428° F ± 18° F.

The change-over time should be kept as low as possible.

The joining pressure build-up time should be recognized as maximum value and may be underrun by up to 50%.

You must add the motion pressure of the welding machine to the indicated bead-up and cooling pressure in each case!

The maximum pressure of the welding machine is to be observed.

These cooling times are only valid under the following conditions:

• Welding connection is produced under workshop conditions

• Removal from the welding machine and temporary storage until complete cooling time elapses

only cause minor strain for the welding connection

All information without guarantee

P (N/mm²)

bead-up heat-up change- pressure cooling

0,15 (PE) over build-up pressure in

welding area

Tdesired temperature

0,01 in welding area

time

pipe SDR bead-up circular heat-up max. pressure welding cooling time for special

degree pressure bead time change- build-up pressure ambient temperature cooling

(s) height over time time < 15°C 15-25°C > 25°C time

(s) min. < 59°F 59-77°F > 77°F

[mm] [bar] [mm] [min:s] [s] [s] [bar] [min:s] [min:s] [min:s] [min:s]

DA 450

11,0 41 5 1,5 01:50 8 8 5 08:48 11:06 14:18 07:24

13,8 33 7 2 02:18 9 9 7 10:39 13:33 17:41 09:02

17,2 26 8 2 02:52 9 10 8 12:51 16:27 21:49 10:58

21,5 21 10 2,5 03:35 11 12 10 15:47 20:09 26:51 13:26

25,5 17,6 12 2,5 04:15 12 14 12 18:39 23:34 31:26 15:43

26,7 17 12 3 04:27 12 14 12 19:31 24:38 32:50 16:27

33,1 13,6 15 3 05:31 15 17 15 24:10 30:27 40:23 20:31

40,9 11 18 3,5 06:49 17 21 18 29:42 37:36 49:48 25:24

50,3 9 21 4 08:23 20 25 21 36:13 46:16 61:22 31:11

61,5 7,4 25 4 10:15 23 31 25 44:03 56:21 74:48 37:54

DA 500

12,3 41 7 2 02:03 8 8 7 09:42 12:15 15:52 08:10

15,3 33 8 2 02:33 9 9 8 11:37 14:50 19:30 09:53

19,1 26 10 2,5 03:11 10 11 10 14:04 18:05 24:07 12:03

23,9 21 12 2,5 03:59 11 13 12 17:30 22:12 29:36 14:48

28,4 17,6 14 3 04:44 13 15 14 20:45 26:11 34:50 17:32

29,7 17 15 3 04:57 13 16 15 21:41 27:22 36:22 18:21

36,8 13,6 18 3 06:08 16 19 18 26:51 33:49 44:46 22:52

45,4 11 22 3,5 07:34 19 23 22 32:49 41:45 55:20 28:10

56,0 9 26 4 09:20 21 28 26 40:12 51:24 68:12 34:36

68,3 7,4 31 4 11:23 25 34 31 48:49 62:28 82:58 41:59

10.05.2017 Working Instructions WIDOS 10000 - 12000 (8000 until 05.2009)

Table for PE

Basis: DVS data sheets 2207, 2208 - State 2016

Field of application: 8000 (from 07/2000 until 05/2009)

10000 (from 07/2000) / 12000 (from 07/2000)

1 bar on pressure gauge: 463 N (Effective surface of cylinder: 4626 mm² / 7,17 inch²)

The heating element temperature is 220° C ± 10° C / 428° F ± 18° F.

The change-over time should be kept as low as possible.

The joining pressure build-up time should be recognized as maximum value and may be underrun by up to 50%.

You must add the motion pressure of the welding machine to the indicated bead-up and cooling pressure in each case!

The maximum pressure of the welding machine is to be observed.

These cooling times are only valid under the following conditions:

• Welding connection is produced under workshop conditions

• Removal from the welding machine and temporary storage until complete cooling time elapses

only cause minor strain for the welding connection

All information without guarantee

P (N/mm²)

bead-up heat-up change- pressure cooling

0,15 (PE) over build-up pressure in

welding area

Tdesired temperature

0,01 in welding area

time

pipe SDR bead-up circular heat-up max. pressure welding cooling time for special

degree pressure bead time change- build-up pressure ambient temperature cooling

(s) height over time time < 15°C 15-25°C > 25°C time

(s) min. < 59°F 59-77°F > 77°F

[mm] [bar] [mm] [min:s] [s] [s] [bar] [min:s] [min:s] [min:s] [min:s]

DA 560

13,7 41 8 2 02:17 8 9 8 10:36 13:27 17:34 08:58

17,2 33 10 2 02:52 9 10 10 12:51 16:27 21:49 10:58

21,4 26 12 2,5 03:34 11 12 12 15:43 20:03 26:45 13:22

26,7 21 15 3 04:27 12 14 15 19:31 24:38 32:50 16:27

31,7 17,6 18 3 05:17 14 17 18 23:09 29:11 38:44 19:38

33,2 17 18 3 05:32 15 17 18 24:14 30:33 40:31 20:35

41,2 13,6 22 3,5 06:52 17 21 22 29:54 37:53 50:10 25:35

50,8 11 27 4 08:28 20 25 27 36:34 46:43 61:58 31:29

62,5 9 32 4 10:25 23 31 32 44:45 57:15 76:00 38:30

75,8 7,4 38 4,5 12:38 26 35 38 54:04 69:13 91:58 46:29

DA 630

15,4 41 10 2 02:34 9 9 10 11:41 14:55 19:38 09:57

19,3 33 12 2,5 03:13 10 11 12 14:13 18:15 24:21 12:10

24,1 26 15 2,5 2,5 11 13 15 17:39 22:22 29:50 14:55

30,0 21 19 3 3 13 16 19 21:55 27:38 36:44 18:33

35,7 17,6 22 3 05:57 16 18 22 26:03 32:49 43:28 22:10

37,4 17 23 3,5 06:14 16 19 23 27:17 34:22 45:30 23:15

46,3 13,6 28 3,5 07:43 19 23 28 33:26 42:35 56:27 28:43

57,2 11 34 4 09:32 22 29 34 41:02 52:29 69:38 35:19

62,5 9 37 4 10:25 23 31 37 44:45 57:15 76:00 38:30

85,1 7,4 48 4,5 14:11 29 35 48 60:34 77:35 103:07 52:04

10.05.2017 Working Instructions WIDOS 10000 - 12000 (8000 until 05.2009)

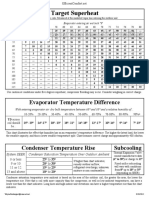

Table for PE

Basis: DVS data sheets 2207, 2208 - State 2016

Field of application: 8000 (from 07/2000 until 05/2009)

10000 (from 07/2000) / 12000 (from 07/2000)

1 bar on pressure gauge: 463 N (Effective surface of cylinder: 4626 mm² / 7,17 inch²)

The heating element temperature is 220° C ± 10° C / 428° F ± 18° F.

The change-over time should be kept as low as possible.

The joining pressure build-up time should be recognized as maximum value and may be underrun by up to 50%.

You must add the motion pressure of the welding machine to the indicated bead-up and cooling pressure in each case!

The maximum pressure of the welding machine is to be observed.

These cooling times are only valid under the following conditions:

• Welding connection is produced under workshop conditions

• Removal from the welding machine and temporary storage until complete cooling time elapses

only cause minor strain for the welding connection

All information without guarantee

P (N/mm²)

bead-up heat-up change- pressure cooling

0,15 (PE) over build-up pressure in

welding area

Tdesired temperature

0,01 in welding area

time

pipe SDR bead-up circular heat-up max. pressure welding cooling time for special

degree pressure bead time change- build-up pressure ambient temperature cooling

(s) height over time time < 15°C 15-25°C > 25°C time

(s) min. < 59°F 59-77°F > 77°F

[mm] [bar] [mm] [min:s] [s] [s] [bar] [min:s] [min:s] [min:s] [min:s]

DA 710

17,4 41 13 2 02:54 10 10 13 12:58 16:38 22:03 11:05

21,8 33 16 2,5 03:38 11 12 16 16:00 20:24 27:12 13:36

27,2 26 19 3 04:32 12 15 19 19:52 25:05 33:25 16:46

33,9 21 24 3 05:39 15 18 24 24:45 31:11 41:20 21:02

40,2 17,6 28 3,5 06:42 17 20 28 29:13 36:57 48:56 24:58

42,1 17 29 3,5 07:01 18 21 29 30:32 38:42 51:17 26:08

52,2 13,6 35 4 08:42 21 26 35 37:32 47:59 63:38 32:19

64,5 11 43 4 10:45 24 32 43 46:09 59:03 78:24 39:42

78,9 9 51 4,5 13:09 27 35 51 56:14 72:01 95:41 48:20

95,9 7,4 60 5 15:59 31 35 60 68:08 87:19 116:05 58:32

DA 800

19,6 41 16 2,5 03:16 10 11 16 14:26 18:31 24:41 12:21

24,5 33 20 2,5 04:05 12 13 20 17:56 22:43 30:17 15:09

30,6 26 24 3 05:06 14 16 24 22:21 28:11 37:26 18:56

38,1 21 30 3,5 06:21 16 20 30 27:46 35:01 46:21 23:41

45,3 17,6 35 3,5 07:33 19 23 35 32:45 41:40 55:13 28:06

47,4 17 37 3,5 07:54 19 24 37 34:12 43:36 57:48 29:24

58,8 13,6 45 4 09:48 22 29 45 42:10 53:55 71:34 36:17

72,7 11 54 4,5 12:07 26 35 54 51:53 66:26 88:14 44:37

88,9 9 65 4,5 14:49 30 35 65 63:14 81:01 107:41 54:20

108,1 7,4 77 5 18:01 35 35 77 76:40 98:17 130:43 65:52

10.05.2017 Working Instructions WIDOS 10000 - 12000 (8000 until 05.2009)

Table for PE

Basis: DVS data sheets 2207, 2208 - State 2016

Field of application: 8000 (from 07/2000 until 05/2009)

10000 (from 07/2000) / 12000 (from 07/2000)

1 bar on pressure gauge: 463 N (Effective surface of cylinder: 4626 mm² / 7,17 inch²)

The heating element temperature is 220° C ± 10° C / 428° F ± 18° F.

The change-over time should be kept as low as possible.

The joining pressure build-up time should be recognized as maximum value and may be underrun by up to 50%.

You must add the motion pressure of the welding machine to the indicated bead-up and cooling pressure in each case!

The maximum pressure of the welding machine is to be observed.

These cooling times are only valid under the following conditions:

• Welding connection is produced under workshop conditions

• Removal from the welding machine and temporary storage until complete cooling time elapses

only cause minor strain for the welding connection

All information without guarantee

P (N/mm²)

bead-up heat-up change- pressure cooling

0,15 (PE) over build-up pressure in

welding area

Tdesired temperature

0,01 in welding area

time

pipe SDR bead-up circular heat-up max. pressure welding cooling time for special

degree pressure bead time change- build-up pressure ambient temperature cooling

(s) height over time time < 15°C 15-25°C > 25°C time

(s) min. < 59°F 59-77°F > 77°F

[mm] [bar] [mm] [min:s] [s] [s] [bar] [min:s] [min:s] [min:s] [min:s]

DA 900

12,5 13,6 12 2 02:05 8 8 12 09:49 12:26 16:06 08:17

22,0 41 20 2,5 03:40 11 12 20 16:09 20:34 27:26 13:43

27,6 33 25 3 04:36 13 15 25 20:10 25:27 33:53 17:01

34,4 26 31 3 05:44 15 18 31 25:07 31:38 41:56 21:21

42,9 21 38 3,5 07:09 18 22 38 31:05 39:27 52:16 26:38

51,0 17,6 45 4 08:30 20 26 45 36:42 46:54 62:12 31:36

53,3 17 46 4 08:53 21 27 46 38:19 48:58 64:58 32:59

66,2 13,6 57 4 11:02 24 33 57 47:20 60:35 80:26 40:43

81,8 11 69 4,5 13:38 28 35 69 58:16 74:37 99:10 50:05

100,0 9 82 5 16:40 32 35 82 71:00 91:00 121:00 61:00

121,6 7,4 97 5,5 20:16 35 35 97 86:07 110:26 146:55 73:58

DA 1000

24,5 41 25 2,5 04:05 12 13 25 17:56 22:43 30:17 15:09

30,6 33 31 3 05:06 14 16 31 22:21 28:11 37:26 18:56

38,2 26 38 3,5 06:22 16 20 38 27:50 35:06 46:29 23:44

47,7 21 47 3,5 07:57 19 24 47 34:24 43:53 58:10 29:35

56,7 17,6 55 4 09:27 22 28 55 40:41 52:02 69:02 35:01

59,3 17 57 4 09:53 22 30 57 42:31 54:22 72:10 36:35

73,5 13,6 70 4,5 12:15 26 35 70 52:27 67:09 89:12 45:06

90,9 11 85 5 15:09 30 35 85 64:38 82:49 110:05 55:32

111,1 9 101 5,5 18:31 35 35 101 78:46 100:59 134:19 67:40

135,1 7,4 119 6 22:31 35 35 119 95:34 122:35 163:07 82:04

10.05.2017 Working Instructions WIDOS 10000 - 12000 (8000 until 05.2009)

Table for PE

Basis: DVS data sheets 2207, 2208 - State 2016

Field of application: 8000 (from 07/2000 until 05/2009)

10000 (from 07/2000) / 12000 (from 07/2000)

1 bar on pressure gauge: 463 N (Effective surface of cylinder: 4626 mm² / 7,17 inch²)

The heating element temperature is 220° C ± 10° C / 428° F ± 18° F.

The change-over time should be kept as low as possible.

The joining pressure build-up time should be recognized as maximum value and may be underrun by up to 50%.

You must add the motion pressure of the welding machine to the indicated bead-up and cooling pressure in each case!

The maximum pressure of the welding machine is to be observed.

These cooling times are only valid under the following conditions:

• Welding connection is produced under workshop conditions

• Removal from the welding machine and temporary storage until complete cooling time elapses

only cause minor strain for the welding connection

All information without guarantee

P (N/mm²)

bead-up heat-up change- pressure cooling

0,15 (PE) over build-up pressure in

welding area

Tdesired temperature

0,01 in welding area

time

pipe SDR bead-up circular heat-up max. pressure welding cooling time for special

degree pressure bead time change- build-up pressure ambient temperature cooling

(s) height over time time < 15°C 15-25°C > 25°C time

(s) min. < 59°F 59-77°F > 77°F

[mm] [bar] [mm] [min:s] [s] [s] [bar] [min:s] [min:s] [min:s] [min:s]

DA 1200

29,4 41 36 3 04:54 13 16 36 21:28 27:05 36:01 18:10

36,7 33 44 3 06:07 16 19 44 26:47 33:44 44:39 22:49

45,9 26 54 3,5 07:39 19 23 54 33:10 42:13 55:57 28:29

57,2 21 67 4 09:32 22 29 67 41:02 52:29 69:38 35:19

68,0 17,6 79 4 11:20 24 34 79 48:36 62:12 82:36 41:48

70,6 17 82 4,5 11:46 25 35 82 50:25 64:32 85:43 43:22

88,2 17 100 4,5 14:42 30 35 100 62:44 80:23 106:50 53:55

109,1 11 122 5 18:11 35 35 122 77:22 99:11 131:55 66:28

133,3 9 145 6 22:13 35 35 145 94:19 120:58 160:58 80:59

162,2 7,4 172 6,5 27:02 35 35 172 114:32 146:59 195:38 98:19

10.05.2017 Working Instructions WIDOS 10000 - 12000 (8000 until 05.2009)

You might also like

- SHOABA PROJECT DUCT PRESSURE DROP ANALYSISDocument6 pagesSHOABA PROJECT DUCT PRESSURE DROP ANALYSISmohamedNo ratings yet

- Model 4100 Performance Data 231Document8 pagesModel 4100 Performance Data 231MIGUELNo ratings yet

- Temperature and heating rate data from muffle furnace annealing experimentDocument7 pagesTemperature and heating rate data from muffle furnace annealing experimentMohamed HarisNo ratings yet

- Polystyrene Processing GuideDocument4 pagesPolystyrene Processing GuidemadogodNo ratings yet

- Softening Point of Bitumen PDFDocument8 pagesSoftening Point of Bitumen PDFbishry ahamedNo ratings yet

- Experiment Four: Refrigerator SystemDocument4 pagesExperiment Four: Refrigerator Systemahmed jemalNo ratings yet

- Ice Build CalcsDocument7 pagesIce Build Calcsrc@alfrioNo ratings yet

- Model: ZR250KCE-TWD: Technical DataDocument9 pagesModel: ZR250KCE-TWD: Technical DataBalaji DhandapaniNo ratings yet

- Thesis SalineDocument25 pagesThesis SalineSaikiran PuliNo ratings yet

- Data Set Modul 3Document40 pagesData Set Modul 3Mariani SinagaNo ratings yet

- Zr160kce TFDDocument9 pagesZr160kce TFDmuthuveerNo ratings yet

- Dryer Performance MonitoringDocument3 pagesDryer Performance Monitoringdilip matalNo ratings yet

- Model: ZR190KCE-TFD: Technical DataDocument9 pagesModel: ZR190KCE-TFD: Technical DataBalaji DhandapaniNo ratings yet

- Zr190kce TFDDocument9 pagesZr190kce TFDnaser712No ratings yet

- Table For PP: The Data in The Colored, Labeled Arrays Are Interpolated, No Garantee, Based On DVS 2207 Part 11Document3 pagesTable For PP: The Data in The Colored, Labeled Arrays Are Interpolated, No Garantee, Based On DVS 2207 Part 11Haseeb ZahidNo ratings yet

- Zr125kce TFDDocument9 pagesZr125kce TFDmuthuveerNo ratings yet

- Project: Plot 68 Amghara SITE: Kuwait Ac Unit: Pacu 01 General DataDocument1 pageProject: Plot 68 Amghara SITE: Kuwait Ac Unit: Pacu 01 General DataSajidNo ratings yet

- TN102A NTCSensorsDocument1 pageTN102A NTCSensorsFrank Lenin Ortiz GalarzaNo ratings yet

- Mathematical ConversionsDocument155 pagesMathematical ConversionsSudheesh KNo ratings yet

- Technical Data Sheet for B38G CompressorDocument4 pagesTechnical Data Sheet for B38G CompressorIssouf Tidiane TRAORENo ratings yet

- Jan 2022-CLB20403 Results Exp 1-Exp 4 Group 6Document10 pagesJan 2022-CLB20403 Results Exp 1-Exp 4 Group 6Ahmad DanialNo ratings yet

- 2wt Arita Ci Bfly VLV Uni Flanged MalaysiaDocument2 pages2wt Arita Ci Bfly VLV Uni Flanged MalaysiaannaomarNo ratings yet

- Experiment # 09: ObjectDocument9 pagesExperiment # 09: ObjectRiazNo ratings yet

- Rating Chart For NTM SeriesDocument1 pageRating Chart For NTM Series2ravikanthNo ratings yet

- Tabla de Soldadura PT1200 DVSDocument7 pagesTabla de Soldadura PT1200 DVSAlejandro PizarroNo ratings yet

- Tabla de Soldadura PT1200 DVS PDFDocument7 pagesTabla de Soldadura PT1200 DVS PDFAlejandro PizarroNo ratings yet

- 3 Zuata 16Document1 page3 Zuata 16Miguel BetancourtNo ratings yet

- Pipe Size CalculationDocument28 pagesPipe Size CalculationAnonymous Iev5ggSR100% (1)

- BS EN 1092 PN16 Flange Dimensions - Roy MechDocument4 pagesBS EN 1092 PN16 Flange Dimensions - Roy MechpriyankaNo ratings yet

- Charging and TD Chart PlusDocument1 pageCharging and TD Chart PlusFaquruddin AliNo ratings yet

- Megacard CorporationDocument6 pagesMegacard CorporationJanit SethiNo ratings yet

- RDC 01-16 Cálculo Queda de Tensão - AdmDocument5 pagesRDC 01-16 Cálculo Queda de Tensão - AdmPaulo Vitor Agrissi AmorimNo ratings yet

- Experiment Four: Refrigerator SystemDocument4 pagesExperiment Four: Refrigerator Systemahmed jemalNo ratings yet

- Experiment No.: 16 Title: Thermal Performance of Solar Water Heater Aim: Heating and Cooling Performance of Flat Plate Solar Collector Instruments UsedDocument2 pagesExperiment No.: 16 Title: Thermal Performance of Solar Water Heater Aim: Heating and Cooling Performance of Flat Plate Solar Collector Instruments UsedAngsuman PhukanNo ratings yet

- Experiment No.: 16 Title: Thermal Performance of Solar Water Heater Aim: Heating and Cooling Performance of Flat Plate Solar Collector Instruments UsedDocument2 pagesExperiment No.: 16 Title: Thermal Performance of Solar Water Heater Aim: Heating and Cooling Performance of Flat Plate Solar Collector Instruments UsedAngsuman PhukanNo ratings yet

- Pile CapacityDocument3 pagesPile CapacityEYBER ALEXANDER GARNICA TRUJILLONo ratings yet

- Butterfly Valve DatasheetDocument2 pagesButterfly Valve DatasheetKanthan DevanNo ratings yet

- K RAIN KVF NozzlesDocument2 pagesK RAIN KVF NozzlesManoj DoshiNo ratings yet

- 359 Bus ScheduleDocument2 pages359 Bus ScheduleSaadiq El-HaqqNo ratings yet

- Surface Tension and Vapour Pressure ExperimentDocument3 pagesSurface Tension and Vapour Pressure ExperimentHazel Gornez OcaNo ratings yet

- Copeland Scroll Digital: F-Line Air-Cooled Condensing UnitsDocument2 pagesCopeland Scroll Digital: F-Line Air-Cooled Condensing UnitsAbdiel MartínezNo ratings yet

- Danfoss GLY80RDa R134a 115 60Document5 pagesDanfoss GLY80RDa R134a 115 60arnold1994No ratings yet

- Data Chiller 4 After SequencingDocument72 pagesData Chiller 4 After Sequencingsalad garamNo ratings yet

- Ficha Zuata VR300Document1 pageFicha Zuata VR300Oswaldo HernandezNo ratings yet

- Techno Canada Gauge Survey ReportDocument6 pagesTechno Canada Gauge Survey ReportAAKASHNo ratings yet

- 07 - Dew Point and RH Table PDFDocument3 pages07 - Dew Point and RH Table PDFvinod singhNo ratings yet

- TopLine Katalog Original EnglDocument36 pagesTopLine Katalog Original EnglAnonymous KB3AksTpBNo ratings yet

- MeetingDocument1 pageMeetingzdravkoNo ratings yet

- Danfoss GU45TG R134a 200 50Document5 pagesDanfoss GU45TG R134a 200 50Dadan KurniaNo ratings yet

- Main - Vaccine Refrigerator Freezer Temperature Chart TemplateDocument1 pageMain - Vaccine Refrigerator Freezer Temperature Chart TemplateMaan SantiagoNo ratings yet

- 30 JulyDocument16 pages30 JulyRohit KumarNo ratings yet

- Teakai s11189811Document9 pagesTeakai s11189811Teakai TuariiNo ratings yet

- Copeland ZBD30KCE-TFD scroll compressor specsDocument6 pagesCopeland ZBD30KCE-TFD scroll compressor specsarpac tecnologiaNo ratings yet

- 4.0 Experimental ProcedureDocument9 pages4.0 Experimental ProcedureSyazwan MansorNo ratings yet

- Final FRDocument13 pagesFinal FRChris Thel MayNo ratings yet

- Elapsed Time Sample Number Notes T1 (°C) T2 (°C) T3 (°C)Document17 pagesElapsed Time Sample Number Notes T1 (°C) T2 (°C) T3 (°C)christianNo ratings yet

- Darelbeida AshraeDocument2 pagesDarelbeida AshraeSmail MiloudiNo ratings yet

- Respon Time Farmasi Agustus 2022 AkhirDocument30 pagesRespon Time Farmasi Agustus 2022 AkhirRahman Pazha UtomoNo ratings yet

- Jesus according to Scripture: Restoring the Portrait from the GospelsFrom EverandJesus according to Scripture: Restoring the Portrait from the GospelsRating: 5 out of 5 stars5/5 (2)

- Hdpe Design ConsiderationsDocument22 pagesHdpe Design ConsiderationsOscar Gonzales SotoNo ratings yet

- Asian Games Road RestrictionDocument1 pageAsian Games Road RestrictionNararya Muh Pratito AndityaNo ratings yet

- Liebherr Casing Oscillator Deep Foundation enDocument4 pagesLiebherr Casing Oscillator Deep Foundation enNararya Muh Pratito Anditya100% (1)

- Radius Towe Crane-Layout2Document1 pageRadius Towe Crane-Layout2Nararya Muh Pratito AndityaNo ratings yet

- Assembly of LG PDFDocument6 pagesAssembly of LG PDFNararya Muh Pratito AndityaNo ratings yet

- Reactive Power Compensation: Presented By: Ari Nugraheni Chairy Wahyu WinantiDocument28 pagesReactive Power Compensation: Presented By: Ari Nugraheni Chairy Wahyu WinantiNararya Muh Pratito AndityaNo ratings yet

- Expansion Joint Asphaltic PlugDocument21 pagesExpansion Joint Asphaltic PlugNararya Muh Pratito AndityaNo ratings yet

- Hydraulic Crawler Crane: - Maximum 200-Ton Lifting Capacity: - Long Reach (Long Boom Specs)Document35 pagesHydraulic Crawler Crane: - Maximum 200-Ton Lifting Capacity: - Long Reach (Long Boom Specs)mszahmedNo ratings yet

- Air-Pollution-Meteorology UNIT IIDocument91 pagesAir-Pollution-Meteorology UNIT IIDR. Ramesh ChandragiriNo ratings yet

- Refrigeration Cycle Assignment QuestionsDocument3 pagesRefrigeration Cycle Assignment QuestionsAnonymous GGtvR65MRNo ratings yet

- 68 0312Document140 pages68 0312vaglohrdNo ratings yet

- Sea and Land BreezesDocument5 pagesSea and Land BreezesrosermaNo ratings yet

- HVAC Calculation Control Bldg. (System-01)Document21 pagesHVAC Calculation Control Bldg. (System-01)VIREN GOHILNo ratings yet

- Psychrometry For Air ConditioningDocument59 pagesPsychrometry For Air ConditioningPraveenkumar KashyabNo ratings yet

- Presentation On Psychrometry and Air Conditioning UpdatedDocument103 pagesPresentation On Psychrometry and Air Conditioning UpdatedJoshua Phillip Austero FederisNo ratings yet

- How air conditioners and refrigerators work efficientlyDocument4 pagesHow air conditioners and refrigerators work efficientlysanjay975No ratings yet

- 2021-Sakhri-New Passive Thermal Comfort System Using Three Renewable - Wind Tower-SC and GAHEDocument18 pages2021-Sakhri-New Passive Thermal Comfort System Using Three Renewable - Wind Tower-SC and GAHEraviNo ratings yet

- Split Type Air Conditioner Specifications and Installation ManualDocument34 pagesSplit Type Air Conditioner Specifications and Installation ManualMihaela CaciumarciucNo ratings yet

- Product Data: Features/BenefitsDocument100 pagesProduct Data: Features/BenefitsAustin Dillon50% (2)

- 4 SEA 3 Bulk Cargo Operation PDFDocument23 pages4 SEA 3 Bulk Cargo Operation PDFChadAclanParas100% (2)

- Tecumseh 2003Document18 pagesTecumseh 2003willcarl obandoNo ratings yet

- Dew PointDocument9 pagesDew PointTruong van TruongNo ratings yet

- ACMV TrainingDocument227 pagesACMV Traininghbitho100% (3)

- Ultracool Flow Diagram and Component IdentificationDocument1 pageUltracool Flow Diagram and Component IdentificationAjayNo ratings yet

- AHRI Certifi Ed: Why Certify With AHRI?Document2 pagesAHRI Certifi Ed: Why Certify With AHRI?Benjamin BriceñoNo ratings yet

- Data Sheet - DX Air Cooled - ASR 682 A - GERMANYDocument1 pageData Sheet - DX Air Cooled - ASR 682 A - GERMANYLilac SongNo ratings yet

- Air Conditioning DefinitionsDocument29 pagesAir Conditioning DefinitionsRay RavelNo ratings yet

- Ashrae Chart PDFDocument2 pagesAshrae Chart PDFChatchai MikeNo ratings yet

- Topic 7 Practice PacketDocument46 pagesTopic 7 Practice Packetsg 85No ratings yet

- UTCIWBGTDocument4 pagesUTCIWBGTDiego Bruno Villarroel100% (1)

- Cooling LoadDocument39 pagesCooling LoadMohtasham NaeemNo ratings yet

- UNIT 5 Changes of StateDocument6 pagesUNIT 5 Changes of StatePham Van Tin B1909842No ratings yet

- Marine MeteorologyDocument49 pagesMarine MeteorologyMahdi Bordbar100% (12)

- Lab 10 - Humidity and Weather Patterns 2021Document4 pagesLab 10 - Humidity and Weather Patterns 2021juanNo ratings yet

- TERMOHIDRAULIKA CEVNIH SISTEMA KOTLOVA NA BLOKOVIMA B1 I B2 TERMOELEKTRANE „NIKOLA TESLA B” _ THERMALHYDRAULICS OF TUBE SYSTEMS IN STEAM BOILERS AT UNITS B1 AND B2 OF THERMAL POWER PLANT „NIKOLA TESLA B“Document10 pagesTERMOHIDRAULIKA CEVNIH SISTEMA KOTLOVA NA BLOKOVIMA B1 I B2 TERMOELEKTRANE „NIKOLA TESLA B” _ THERMALHYDRAULICS OF TUBE SYSTEMS IN STEAM BOILERS AT UNITS B1 AND B2 OF THERMAL POWER PLANT „NIKOLA TESLA B“Nikola MilovanovićNo ratings yet

- Weather and HydrologyDocument18 pagesWeather and HydrologyStephanie Joy CabahugNo ratings yet

- Heating and cooling load calculationsDocument23 pagesHeating and cooling load calculationsIsrael MuhiNo ratings yet