Professional Documents

Culture Documents

How To Make A Babbitting Mandrel

Uploaded by

Jason BowmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How To Make A Babbitting Mandrel

Uploaded by

Jason BowmanCopyright:

Available Formats

How to Make a Babbitting Mandrel

for your Little Giant Powerhammer

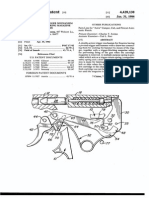

Using a mandrel, or dummy shaft, allows collars to be used to stop the fow of the molten babbitt (see photo).

Also, keyways in the actual main shaft present a problem when pouring babbitt, and the weight of the

fywheel interferes with the babbitting process. Using a mandrel eliminates the problems of trying to use the

actual main shaft.

Size of Hammer 25 LB 50 LB 100 LB

Diameter of Shaft 1 5/8” 2” 2 ½”

Length of Shaft 20” 26” 30”

Obtain the correct size of cold rolled steel from your local metal supplier. Polish the mandrel to ensure there

are no burrs on it.

To prevent the hot babbitt from running out of the bearing cavity, collars must be placed on the end of each

bearing, in conjunction with damming compound.

*WARNING* Only use damming compound meant for this purpose; the brand we sell is Moldpak. Do not use

substitutes that may have moisture content, as this can result in steam pockets that will cause the hot babbitt

to bubble out.

Place collars on shaft as shown in photo. To make collars for a 100 LB mandrel, turn a piece of stock to 2 ½”

inside diameter by approximately 4 ¼” outside diameter, and approximately 1 ½” thick. Use damming

compound between collar and bearing upright.

Collar for 25 LB Mandrel...........................................$9.00 each

Collar for 50 LB Mandrel...........................................$10.50 each

Babbittrite Damming Compound (2 LB)..........................$42.00

Babbitt (per pound).......................................................$7.90

You might also like

- Rebuild ManualDocument55 pagesRebuild Manualaccujack0% (1)

- Cesaroni Propellant SDSDocument7 pagesCesaroni Propellant SDSKaustubhNo ratings yet

- MD-Blue-Pipe Fitting and Flange ToolsDocument12 pagesMD-Blue-Pipe Fitting and Flange Toolssandii123No ratings yet

- Frosty T Burner Build: All The Ratios Are Derived From The Pipe IameterDocument4 pagesFrosty T Burner Build: All The Ratios Are Derived From The Pipe IameterKain402No ratings yet

- 71-77 Dies AccessoriesDocument7 pages71-77 Dies Accessoriesradio-chaserNo ratings yet

- NAA .32 ACP专利 PDFDocument8 pagesNAA .32 ACP专利 PDFJin SongNo ratings yet

- Indestructible Corner Clamp (Jig) For Welding ProjectsDocument1 pageIndestructible Corner Clamp (Jig) For Welding ProjectsTomas Tom MlNo ratings yet

- Old Model B392-OM1Document9 pagesOld Model B392-OM1Just4HimNo ratings yet

- Four Facet Drill Grinding JigDocument20 pagesFour Facet Drill Grinding Jigian_newNo ratings yet

- Lost-Wax Bronzes by Robyn ErbeDocument66 pagesLost-Wax Bronzes by Robyn Erbebr0nzeyNo ratings yet

- Making The Keats Angle Plate From CastingsDocument15 pagesMaking The Keats Angle Plate From CastingsJohn SmithNo ratings yet

- Diy Case AnnealerDocument9 pagesDiy Case AnnealergrelfodNo ratings yet

- Tube Rolling MachineDocument4 pagesTube Rolling MachinePushpa Mohan RajNo ratings yet

- How To Formulate Parkerizing SolutionDocument3 pagesHow To Formulate Parkerizing SolutionOtter1zNo ratings yet

- Corbin 2-Die Set For Reloading PressDocument1 pageCorbin 2-Die Set For Reloading PressÁdám MajorNo ratings yet

- Easy To Build CNC Mill Stepper Motor and Driver Ci - (Wazhua - Com)Document15 pagesEasy To Build CNC Mill Stepper Motor and Driver Ci - (Wazhua - Com)Kashif MirzaNo ratings yet

- Shellholder Cross ReferenceDocument9 pagesShellholder Cross ReferenceIM_JohnnyVNo ratings yet

- Tricking Out Asian 9x20 LatheDocument48 pagesTricking Out Asian 9x20 Lathearanicki8587No ratings yet

- Tap-Drill Chart Recommend Tap Drill To Use For 75% Depth of ThreadDocument1 pageTap-Drill Chart Recommend Tap Drill To Use For 75% Depth of ThreadPliskinAJNo ratings yet

- ACESORIOScatalog PDFDocument80 pagesACESORIOScatalog PDFlmelmelmeNo ratings yet

- Some Interesting Projects in FoundryDocument59 pagesSome Interesting Projects in FoundrySneha KritiNo ratings yet

- True Centrifugal CastingDocument6 pagesTrue Centrifugal Castingmuhammadasrafazmi0% (1)

- Stress relieving steel at 650°C for 1 hour removes 90% internal stressesDocument4 pagesStress relieving steel at 650°C for 1 hour removes 90% internal stressesAshish BoraNo ratings yet

- Foundry Tools Guide for Sand MouldingDocument5 pagesFoundry Tools Guide for Sand MouldingChristian VicenteNo ratings yet

- EDM Electrode Material Properties and SelectionDocument6 pagesEDM Electrode Material Properties and Selectionomer21No ratings yet

- How To Weld Aluminum - 13 Steps (With Pictures) - WikiHowDocument4 pagesHow To Weld Aluminum - 13 Steps (With Pictures) - WikiHowprajneshNo ratings yet

- LaserDocument29 pagesLaserGaurav YadavNo ratings yet

- How To Weld - TIG WeldingDocument14 pagesHow To Weld - TIG Weldingjumpupdnbdj100% (1)

- TungstenDocument49 pagesTungstenahmed samyNo ratings yet

- Negrini Hard Gun Cases CatalogDocument10 pagesNegrini Hard Gun Cases CatalognegrinicasesNo ratings yet

- Acoustic Tractor Beam: 35 Steps (With Pictures) PDFDocument38 pagesAcoustic Tractor Beam: 35 Steps (With Pictures) PDFAmirNo ratings yet

- Drill Press LatheDocument13 pagesDrill Press Latheboon1961No ratings yet

- Blackened and Antiqued Hard..Document6 pagesBlackened and Antiqued Hard..Robin Hughes100% (1)

- AFRICAN OX-CART DESIGNDocument62 pagesAFRICAN OX-CART DESIGNreissmachinistNo ratings yet

- Yeomans Multimachine LatheDocument4 pagesYeomans Multimachine LatheDianaSuarezNo ratings yet

- 44 Special: History, Ballistics & Loads of the Legendary Revolver RoundDocument5 pages44 Special: History, Ballistics & Loads of the Legendary Revolver RoundRonnie RensburgNo ratings yet

- The Rose Engine Lathe: Its History Development, and Modern UseDocument71 pagesThe Rose Engine Lathe: Its History Development, and Modern UseWolfgangNo ratings yet

- Broaching Operations Guide for Rotary BroachingDocument2 pagesBroaching Operations Guide for Rotary BroachingpeterNo ratings yet

- 742 ML10 Screwcutting LatheDocument5 pages742 ML10 Screwcutting LatheSimon GuardNo ratings yet

- Us 4207797Document7 pagesUs 4207797fghdfjerNo ratings yet

- Ruger 22-45 Parts PicturesDocument4 pagesRuger 22-45 Parts Picturesapi-3840428No ratings yet

- Mill Keyways On LatheDocument1 pageMill Keyways On LatheJim100% (3)

- Web QCGBDocument19 pagesWeb QCGBpramponiNo ratings yet

- Bench Lathe 3 in 1 (Lathe - Sander - Grinder/Sharpener)Document16 pagesBench Lathe 3 in 1 (Lathe - Sander - Grinder/Sharpener)Jd DiazNo ratings yet

- Series 7 Lathes: Technical Support Explaining Changewheel Sets For Lathes With Changewheel Driven LeadscrewsDocument8 pagesSeries 7 Lathes: Technical Support Explaining Changewheel Sets For Lathes With Changewheel Driven LeadscrewsTomas MalyNo ratings yet

- Conservation of a Japanese TsubaDocument10 pagesConservation of a Japanese Tsubaaalv2003No ratings yet

- Center LatheDocument33 pagesCenter LathejohnNo ratings yet

- Casting Tree Design PlatinumDocument5 pagesCasting Tree Design Platinumkumud_kediaNo ratings yet

- Handi Instr TwobDocument13 pagesHandi Instr TwobnotjustsomeoneNo ratings yet

- MD Profiler Instruction ManualDocument11 pagesMD Profiler Instruction ManualTatiana Trenogina100% (1)

- Toolmakers Microscope MeasurementsDocument7 pagesToolmakers Microscope MeasurementsskumarNo ratings yet

- Instructions For Making "Home-Made" Ballistic GelatinDocument3 pagesInstructions For Making "Home-Made" Ballistic Gelatinbrowar444No ratings yet

- Sharpening SystemDocument17 pagesSharpening Systemmarius_danila8736No ratings yet

- Reverse Electroplating of SilverDocument2 pagesReverse Electroplating of SilverMohammad Umer AsgherNo ratings yet

- SphericalturninglathetoolDocument14 pagesSphericalturninglathetoolFrenchwolf420No ratings yet

- Functional Composite Materials: Manufacturing Technology and Experimental ApplicationFrom EverandFunctional Composite Materials: Manufacturing Technology and Experimental ApplicationNo ratings yet

- A Treatise on Staff Making and Pivoting: Containing Complete Directions for Making and Fitting New Staffs from the Raw MaterialFrom EverandA Treatise on Staff Making and Pivoting: Containing Complete Directions for Making and Fitting New Staffs from the Raw MaterialNo ratings yet

- Hammer Spec. SheetDocument1 pageHammer Spec. SheetJason BowmanNo ratings yet

- Beth Forge 1891 Steam Hammer 250000 LbsDocument2 pagesBeth Forge 1891 Steam Hammer 250000 LbsJason BowmanNo ratings yet

- Bob Engnath On QsteelqDocument6 pagesBob Engnath On QsteelqJason BowmanNo ratings yet

- Pattern MakingDocument407 pagesPattern MakingJason BowmanNo ratings yet

- Waldorf, D.C. - The Art of Making Primitive Bows and Arrows (1985)Document53 pagesWaldorf, D.C. - The Art of Making Primitive Bows and Arrows (1985)live4love360No ratings yet

- 250 LB FoundationDocument1 page250 LB FoundationJason BowmanNo ratings yet

- 3563 PDFDocument16 pages3563 PDFdfirmo4925No ratings yet

- Procedures in Experimental Physics, Strong 1938Document652 pagesProcedures in Experimental Physics, Strong 1938JonNo ratings yet

- Anyang BrochureDocument8 pagesAnyang BrochureJason BowmanNo ratings yet

- Erie Single Frame Forging Hammers Bulletin 404Document8 pagesErie Single Frame Forging Hammers Bulletin 404Jason Bowman0% (1)

- How To Drill and Rifle A BarrelDocument2 pagesHow To Drill and Rifle A BarrelJason BowmanNo ratings yet

- Buffalo Ironworker ManualDocument11 pagesBuffalo Ironworker ManualJason BowmanNo ratings yet

- Accurate Reloading GuideDocument406 pagesAccurate Reloading GuideLilo Stitch88% (16)

- KOLee Tool Grinder Owners ManualDocument139 pagesKOLee Tool Grinder Owners ManualJason Bowman100% (3)

- Machine ForgingDocument121 pagesMachine ForgingJason BowmanNo ratings yet

- 1936 - How To Cut Screw Threads in The Lathe - Bulletin 36ADocument24 pages1936 - How To Cut Screw Threads in The Lathe - Bulletin 36AJason Bowman100% (1)

- The Modern Rifle Barrel Action Book Publishers 1999 HoffmanDocument60 pagesThe Modern Rifle Barrel Action Book Publishers 1999 Hoffmanfredd3039No ratings yet

- Making Rifle BarrelsDocument64 pagesMaking Rifle BarrelsJames Steele96% (27)

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- MODEL G0727 Vertical/Horizontal Benchtop Mill: Owner'S ManualDocument48 pagesMODEL G0727 Vertical/Horizontal Benchtop Mill: Owner'S ManualJason BowmanNo ratings yet

- The Machine Gun Volume 1 by George M. ChinnDocument712 pagesThe Machine Gun Volume 1 by George M. Chinnh762x39100% (9)

- Handgun Accuracy OvernightDocument13 pagesHandgun Accuracy OvernightJason Bowman100% (5)

- How To Shoot The US Army Rifle IDocument132 pagesHow To Shoot The US Army Rifle Ideolexrex100% (12)

- 1936 - How To Cut Screw Threads in The Lathe - Bulletin 36ADocument24 pages1936 - How To Cut Screw Threads in The Lathe - Bulletin 36AJason Bowman100% (1)