Professional Documents

Culture Documents

GIKEN Aux Pilerjetsystem

Uploaded by

PHÁT NGUYỄN THẾCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GIKEN Aux Pilerjetsystem

Uploaded by

PHÁT NGUYỄN THẾCopyright:

Available Formats

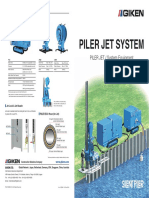

System Equipment

Piler Jet Piler Jet Reel

PILER JET SYSTEM

PJ4 JR28 JR29 PILER JET / System Equipment

Water Flow 60-600 L/min (adjustable via rpm) Water Flow Max. 700 L/min Water Flow Max. 700 L/min

Pressure 0.1-10 MPa (adjustable via rpm) Water Pressure Max. 14.7 MPa Water Pressure Max. 14.7 MPa

Power Source* Silent Piler Power Unit Mass 820 kg Mass 1250 kg

(EU300 J4 / K4 / G3)

Buffer Water Tank Capacity 2100 L

Generator for Water Pump (optional)** 25KVA

Moving Speed 1.4km/h (Remote Control)

Mass 4500 kg (including generator)

3800 kg (excluding generator)

*Piler Jet power supply must be from Silent Piler Power Unit.

**When generator is not installed, another water pump power source is required.

Panel mounted socket for screw terminals (63A/125A, 5P, 9h, 50-60Hz) is equipped.

The Jet Reel is mounted atop

the Silent Piler to feed the Jet

Jet Lock & Jet Nozzle Hose to the sheet pile.

Jet Lock is welded onto the sheet pile toe to fix a Jet Nozzle

in place with a Lock Pin. Piler ECO (Jet) Hose

1st Layer: Anti-abrasive rubber to

prevent external damage

2nd Layer:

Jet Nozzle External Rubber Layer

3rd Layer:

Metallic Wire Mesh Belts

Jet Lock

4th Layer:

Aramid Fiber Layer

5th Layer:

Metallic Wire Mesh Belts

Lock Pin

6th Layer: Internal Rubber Layer

The above specifications are subject to alteration without prior notice.

Construction Solutions Company www.giken.com

GIKEN LTD. Global Network : Japan, USA, UK, Germany, Singapore, China

International Business Department

3948-1 Nunoshida, Kochi-shi, Kochi 781-5195, Japan For more contact information, please visit:

Tel. : +81-(0)88-846-2980 Fax : +81-(0)88-826-5288 http://www.giken.com/en/contactus/groupcompanies

Email : international@giken.com

© 2017GIKEN LTD. All Rights Reserved. Ver 1.0EN01 / 23 Jun 2017

Highly Efficient Integrated Water Jetting System for the Press-in Method

Press-in with Water Jetting Functions of Piler Jet

When the pile is statically loaded during pile installation into Piler Jet water jetter is simultaneously operated and powered with the Silent Piler

granular soil, distribution of the soil stresses forms stress isobars and is controlled by the radio controller unit.

called "pressure bulbs" at the pile base area. As the base Water discharge pressure and water flow of the Piler Jet can be automatically

stiffness of a jacked pile increases with magnitude of the static controlled in accordance with the Silent Piler needs. Thus, the pile installation

loading, it may negatively affects the pile installation. Leading can be optimized with minimum water usage and disturbance to the surrounding

interlocks contain soil particles from previous installation, which soil. Radio Controller

are compacted during subsequent pile installation resulting in

greater interlock resistance.

Water jetting lubricates the pile surface and temporarily and ● Environmental Protection

locally loosens and softens the surrounding ground by increasing Press-in

1. The automated system minimizes water usage and disturbance to the

pore water pressure. Thus, the base resistance, skin friction and with Water Jetting surrounding soil.

interlock resistance are reduced during pile installation. Water Standard Press-in

2. With a particulate matter separator, the water pump allows untreated

jetting is an effective driving assistance method to overcome

0 25 50 freshwater for jetting purposes.

dense soil conditions. SPT N Value

3. As the Piler Jet is powered by the Silent Piler Power Unit, it does not require

Characteristics of Piler Jet System an independent power source. Therefore, environmental burden can be

The Silent Piler and Piler Jet are integrated to form a system with a common power unit to optimize the jetting parameters with minimized.

Inner Water Pump with a centrifugal

minimum environmental impact.

separator to remove solid impurities

Water Intake System

● Safety External Filter

1. Jet Nozzles and Jet Locks are designed with a safety function which

allows reverse water flushes in case of detachment from the pile. This

fail-safe system prevents the water jet hose from spiraling out of Piler Jet Reel Power Unit Piler Jet

control even if the jet nozzle or Jet Lock detaches from the pile. (common power source) (including a buffer water tank)

Dual Fail-safe Systems

Piler ECO (Jet) Hose

Silent Piler

Detachment of Jet Nozzle Detachment of Jet Lock

2. The Piler ECO (Jet) Hose is developed exclusively as a water hose

inserted into the ground with a pile. Therefore, it is extremely durable

with high anti-abrasivity and tensile strength.

パイラーエコホース

Piler ECO (Jet) Hose Normal High Pressure

Water Hose

Piler Stage

Jet Nozzle and Jet Lock

Water Pump

Endurance Testing:after Endurance Testing:after Main Components of Piler Jet System

2,000 trials of normal usage 1,000 trials of normal usage End Flush

You might also like

- PILER JET / System EquipmentDocument2 pagesPILER JET / System EquipmentVetriselvan ArumugamNo ratings yet

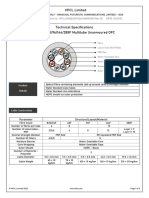

- Line Item 11 To 17 # Datasheet - 8F, 12F, 24F, 48F, 96F, 144F, 288F Duct MTUA SS PE BKDocument3 pagesLine Item 11 To 17 # Datasheet - 8F, 12F, 24F, 48F, 96F, 144F, 288F Duct MTUA SS PE BKSadiqNo ratings yet

- Line Item 18 To 24 # Datasheet - 8F, 12F, 24F, 48F, 96F, 144F, 288F D MTA SS PE BKDocument3 pagesLine Item 18 To 24 # Datasheet - 8F, 12F, 24F, 48F, 96F, 144F, 288F D MTA SS PE BKSadiqNo ratings yet

- Schedule of Technical Data: To: PLNDocument3 pagesSchedule of Technical Data: To: PLNLifran HamidNo ratings yet

- Construction and Dimensions of Power CablesDocument2 pagesConstruction and Dimensions of Power CablesCarlos Martínez del MonteNo ratings yet

- MI-MM Compactador Desechos Sólidos TECH IOL 1200EMRDocument17 pagesMI-MM Compactador Desechos Sólidos TECH IOL 1200EMRArturo suzan arvizuNo ratings yet

- STD INQ 0538 PT. Sinarmonas IndustriesDocument2 pagesSTD INQ 0538 PT. Sinarmonas IndustriesHavid ViqriNo ratings yet

- Technical Report GPE 221213204 - Master Tehnical ReportDocument1 pageTechnical Report GPE 221213204 - Master Tehnical Reportcecep hadyanNo ratings yet

- NEW ZTTDocument1 pageNEW ZTTmandar.linkedinNo ratings yet

- Line Item 36 To 42 # Datasheet - 8F, 12F, 24F, 48F, 96F, 144F, 288F MT FIG.8 SS PE BKDocument4 pagesLine Item 36 To 42 # Datasheet - 8F, 12F, 24F, 48F, 96F, 144F, 288F MT FIG.8 SS PE BKSadiqNo ratings yet

- Lv-168 Prozeal Infra Engineering Pvt. Ltd. Rev-01Document32 pagesLv-168 Prozeal Infra Engineering Pvt. Ltd. Rev-01Chaturbhai Hadiyal0% (1)

- EU Data Sheet Chainflex CF896Document6 pagesEU Data Sheet Chainflex CF896vfernandezNo ratings yet

- Netpack NP 350: Vertical Form, Fill and Seal MachineDocument2 pagesNetpack NP 350: Vertical Form, Fill and Seal MachineJuan OrtegaNo ratings yet

- Katalog Kabelej Dlya Kranov FujikuraDocument22 pagesKatalog Kabelej Dlya Kranov Fujikuraachmad maulanaNo ratings yet

- Technical Data Sheet: Straight Male Receptacle For SMT Slide Type - Reel of 400Document6 pagesTechnical Data Sheet: Straight Male Receptacle For SMT Slide Type - Reel of 400agus gatelNo ratings yet

- High Voltage Brochure 8pg Version 5 Celum Rev08102022Document8 pagesHigh Voltage Brochure 8pg Version 5 Celum Rev08102022Ferran MunyósNo ratings yet

- Cto Underground HuaweiDocument8 pagesCto Underground HuaweiJose QuinteroNo ratings yet

- NormaDocument6 pagesNormanicolasNo ratings yet

- Hydac Filter ElementsDocument30 pagesHydac Filter Elementsatorresh090675No ratings yet

- Leg450 500 htf7000 JB SRDocument1 pageLeg450 500 htf7000 JB SRzgpnuaaNo ratings yet

- Vitec Equipments PVT LTD Filename: Spreader Beam CalculationDocument48 pagesVitec Equipments PVT LTD Filename: Spreader Beam CalculationDarshan PanchalNo ratings yet

- 04 Psi Pikotek R 2018 enDocument14 pages04 Psi Pikotek R 2018 enAlejandro MartinezNo ratings yet

- Shreyans K. 44 Market SurveyDocument3 pagesShreyans K. 44 Market SurveyNeha KatariaNo ratings yet

- Solar Frame Aluminium To PlasticDocument29 pagesSolar Frame Aluminium To PlasticManoj YadavNo ratings yet

- FIBERGUARD 500 Dome ClosureDocument4 pagesFIBERGUARD 500 Dome ClosureTurinto MarjonoNo ratings yet

- 001-2. Fast ConnectorDocument4 pages001-2. Fast ConnectorHebert SánchezNo ratings yet

- Cable Termination Instruction 11kV Terminations 3 Core XLPE EPRDocument11 pagesCable Termination Instruction 11kV Terminations 3 Core XLPE EPRdeepu kumar100% (1)

- TEST REPORT Good SenseDocument1 pageTEST REPORT Good SenseAnastasia ErlitaNo ratings yet

- Process and Product Audit Check ListDocument5 pagesProcess and Product Audit Check ListRudrappa VeerabhadrappaNo ratings yet

- HIS MF sp481 Twin Turbo With g2 Connector Technical Data SheetDocument3 pagesHIS MF sp481 Twin Turbo With g2 Connector Technical Data SheetRodolfo Chavez NavarroNo ratings yet

- Loose Tube: Opsycom KP 6728 Duct Dielectric Loose Tube Optical CableDocument3 pagesLoose Tube: Opsycom KP 6728 Duct Dielectric Loose Tube Optical CableAhmed GhoneemNo ratings yet

- Overdenture Brochure ENGDocument10 pagesOverdenture Brochure ENGEmanuel RosuNo ratings yet

- PSF - EslonDocument12 pagesPSF - EslonanglangNo ratings yet

- BM-16 Optical Fiber Fusion Splicer - Precise Fiber Splicing MachineDocument1 pageBM-16 Optical Fiber Fusion Splicer - Precise Fiber Splicing MachineHanshu SharmaNo ratings yet

- Minixtend Loose Tube Cables, 12-144 Fibers: Features and BenefitsDocument3 pagesMinixtend Loose Tube Cables, 12-144 Fibers: Features and Benefitsnaxo6296No ratings yet

- Technical Note-Jacking SystemDocument5 pagesTechnical Note-Jacking SystemABNERNo ratings yet

- EU Data Sheet Chainflex CF113.DDocument12 pagesEU Data Sheet Chainflex CF113.DvfernandezNo ratings yet

- Electronic Bartacking and Button Attaching MachineDocument42 pagesElectronic Bartacking and Button Attaching Machineabu7omar-1No ratings yet

- ZTT Duct Cable 20-109788-2-ADocument8 pagesZTT Duct Cable 20-109788-2-AVictor DoyoganNo ratings yet

- Q.PEAK-G5 295-310: Q.Antum Solar ModuleDocument2 pagesQ.PEAK-G5 295-310: Q.Antum Solar ModuleEhsan RohaniNo ratings yet

- Insulation Sheath Xlpe Lead Voltage 127 / 220 / 245 KV Short-CircuitDocument1 pageInsulation Sheath Xlpe Lead Voltage 127 / 220 / 245 KV Short-CircuitMena KamelNo ratings yet

- Signal Fire Fiber Fusion Splicer AI-7 and AI-8Document23 pagesSignal Fire Fiber Fusion Splicer AI-7 and AI-8Thiaago LiraNo ratings yet

- L-Mesh Composite Mesh Brochure 20may17Document2 pagesL-Mesh Composite Mesh Brochure 20may17atharmediciveNo ratings yet

- MIL-C-83489 Spec for Nylon Cloth Coated with Radio Frequency Sealable UrethaneDocument17 pagesMIL-C-83489 Spec for Nylon Cloth Coated with Radio Frequency Sealable UrethaneprateekNo ratings yet

- 78 8114 7419 2 PDFDocument20 pages78 8114 7419 2 PDFAnibal RengifoNo ratings yet

- Discharge RodDocument1 pageDischarge Rodravi chandra mavuriNo ratings yet

- Foc Data Sheet-U M CablesDocument4 pagesFoc Data Sheet-U M CablesKAVIYARASAN SNo ratings yet

- FTP - FR - MT26 - 18 - 30 - 3X150 - MM2 - Al - PE - NOR - NR (1) - EnglishDocument5 pagesFTP - FR - MT26 - 18 - 30 - 3X150 - MM2 - Al - PE - NOR - NR (1) - EnglishapranaguptaNo ratings yet

- Ahu Dos Pisos-Uma-01-Dm1-0710bDocument8 pagesAhu Dos Pisos-Uma-01-Dm1-0710bSicologo CimeNo ratings yet

- 24F - 48F DJ ADSS Specs 600 MTRDocument2 pages24F - 48F DJ ADSS Specs 600 MTRJose GonzalesNo ratings yet

- FiberHome FHOC-DAL-190-48B1.3Document8 pagesFiberHome FHOC-DAL-190-48B1.3Victor BenavidesNo ratings yet

- Product Manual (AI-8C)Document25 pagesProduct Manual (AI-8C)Esteban PiñeraNo ratings yet

- 4260 Wattson Engineering AWDocument4 pages4260 Wattson Engineering AWemdadNo ratings yet

- ZTT Ficha Tecnica FFOODocument12 pagesZTT Ficha Tecnica FFOOJosé Luis Franco Calderón BartraNo ratings yet

- Newtex Z-Flex Silver P-202 Technical Data SheetDocument2 pagesNewtex Z-Flex Silver P-202 Technical Data SheetJhonatan ArboledaNo ratings yet

- Atlas Copco Rock Drilling Tools: Quantum Leap® HammersDocument2 pagesAtlas Copco Rock Drilling Tools: Quantum Leap® HammersitangNo ratings yet

- Loose Tube FiberSolutionsCatalog p48-54Document7 pagesLoose Tube FiberSolutionsCatalog p48-54Agus YulfizarNo ratings yet

- CONDUCTOR FASE - Constructions - 20005701 - 2500Document1 pageCONDUCTOR FASE - Constructions - 20005701 - 2500cbayon.satelNo ratings yet

- Technical Manual: ExcavatorDocument129 pagesTechnical Manual: ExcavatorPHÁT NGUYỄN THẾ100% (1)

- 390F UENR64560001 Hydraulic Circuit REVDocument11 pages390F UENR64560001 Hydraulic Circuit REVPHÁT NGUYỄN THẾNo ratings yet

- Sk210-8 Engine Starter Do Not WorkDocument1 pageSk210-8 Engine Starter Do Not WorkPHÁT NGUYỄN THẾNo ratings yet

- Basic Hydraulic Oil Flow For Curent Model of Kobelco CraneDocument79 pagesBasic Hydraulic Oil Flow For Curent Model of Kobelco CranePHÁT NGUYỄN THẾ100% (2)

- Komatsu Construction ICT 163-E-02Document6 pagesKomatsu Construction ICT 163-E-02edotecNo ratings yet

- Press Sensor ChangeDocument1 pagePress Sensor ChangePHÁT NGUYỄN THẾNo ratings yet

- KOMTRAX BrochureDocument8 pagesKOMTRAX BrochurePHÁT NGUYỄN THẾNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document35 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Eduardo SantanaNo ratings yet

- Manitou 180 ATJ (EURO 3) Electric CircuitDocument11 pagesManitou 180 ATJ (EURO 3) Electric CircuitPHÁT NGUYỄN THẾNo ratings yet

- PC240 PC290 Apr2011Document1 pagePC240 PC290 Apr2011PHÁT NGUYỄN THẾNo ratings yet

- MARK 8 X-Mode New Starting ModeDocument1 pageMARK 8 X-Mode New Starting ModePHÁT NGUYỄN THẾNo ratings yet

- Sk115 Sk235sr-1e - sk170 Sk480-6e Auto Idle Stop Time AdjustDocument2 pagesSk115 Sk235sr-1e - sk170 Sk480-6e Auto Idle Stop Time AdjustPHÁT NGUYỄN THẾ0% (1)

- Principle of Synchcronous MotorDocument3 pagesPrinciple of Synchcronous MotorPHÁT NGUYỄN THẾNo ratings yet

- BM800HD 2F BrochureDocument8 pagesBM800HD 2F BrochurePHÁT NGUYỄN THẾNo ratings yet

- Subject: Page 1 of 57Document57 pagesSubject: Page 1 of 57PHÁT NGUYỄN THẾNo ratings yet

- E Service InstructionsDocument17 pagesE Service InstructionsPHÁT NGUYỄN THẾ0% (1)

- E3170015BDocument44 pagesE3170015BPHÁT NGUYỄN THẾ100% (1)

- Subject: Page 1 of 17Document17 pagesSubject: Page 1 of 17PHÁT NGUYỄN THẾ100% (1)

- Subject: Page 1 of 17Document17 pagesSubject: Page 1 of 17PHÁT NGUYỄN THẾ100% (1)

- Subject: Page 1 of 8Document8 pagesSubject: Page 1 of 8PHÁT NGUYỄN THẾ100% (1)

- KOMATSU Excavator Detail ExplainingDocument6 pagesKOMATSU Excavator Detail ExplainingPHÁT NGUYỄN THẾNo ratings yet

- Subject: Page 1 of 7Document7 pagesSubject: Page 1 of 7PHÁT NGUYỄN THẾNo ratings yet

- 151-09 - E KomatsuDocument6 pages151-09 - E Komatsuthierrylindo100% (8)

- Torque Conveter TA22-42E Training TextDocument8 pagesTorque Conveter TA22-42E Training TextPHÁT NGUYỄN THẾNo ratings yet

- EskavatorDocument6 pagesEskavatorYasri AcciNo ratings yet

- EskavatorDocument6 pagesEskavatorYasri AcciNo ratings yet

- KOMATSU Excavator Detail ExplainingDocument6 pagesKOMATSU Excavator Detail ExplainingPHÁT NGUYỄN THẾNo ratings yet

- KOMATSU Excavator Detail ExplainingDocument8 pagesKOMATSU Excavator Detail ExplainingPHÁT NGUYỄN THẾNo ratings yet

- EskavatorDocument6 pagesEskavatorYasri AcciNo ratings yet

- EskavatorDocument6 pagesEskavatorYasri AcciNo ratings yet

- Catálogo Manómetros ASHCROFT PDFDocument282 pagesCatálogo Manómetros ASHCROFT PDFAnonymous tFhBRsNo ratings yet

- Embedded Systems Online TestingDocument6 pagesEmbedded Systems Online TestingPuspala ManojkumarNo ratings yet

- Rt37m5538s8hl User Manual HLDocument92 pagesRt37m5538s8hl User Manual HLpandian002No ratings yet

- Fire Fighting Works Bill of QuantityDocument341 pagesFire Fighting Works Bill of QuantityMuhammad Afzal100% (1)

- DONGFENG DFA1063DJ10/14 Light Truck Spare Parts Catalog Less than 40 CharactersDocument352 pagesDONGFENG DFA1063DJ10/14 Light Truck Spare Parts Catalog Less than 40 CharactersWeifang PowerNo ratings yet

- VDI2221Document8 pagesVDI2221hansen_golsvokNo ratings yet

- BROCO Standard Line Series Electrical Fittings and Accessories Price ListDocument14 pagesBROCO Standard Line Series Electrical Fittings and Accessories Price ListKiyahNo ratings yet

- DIY Filament Extruder Kit v2 - Store of WH HuangDocument5 pagesDIY Filament Extruder Kit v2 - Store of WH Huangeduardo toscanoNo ratings yet

- Gold Mining TechniquesDocument3 pagesGold Mining TechniquesDanielleNo ratings yet

- Lambda Americas Inc. power supply derating curvesDocument2 pagesLambda Americas Inc. power supply derating curvesnithinsmathew2004No ratings yet

- .bd-BCMEA Member InfoDocument5 pages.bd-BCMEA Member InfoManGoNo ratings yet

- Ac System Parts Id SK-KD 19Document89 pagesAc System Parts Id SK-KD 19Louise LucassicNo ratings yet

- Hot-rolled steel sheet standard covers chemical compositionDocument7 pagesHot-rolled steel sheet standard covers chemical compositionsiens2304No ratings yet

- "Fluidized Bed Industry Benchmarking: A Five-Year Review" by Jack Fuller and Matthew RobinsonDocument16 pages"Fluidized Bed Industry Benchmarking: A Five-Year Review" by Jack Fuller and Matthew RobinsonThe International Research Center for Energy and Economic Development (ICEED)No ratings yet

- JPT Review Notes for Master Plumber Board Exam PrepDocument108 pagesJPT Review Notes for Master Plumber Board Exam Prepcajaro100% (1)

- Profile MJCDocument18 pagesProfile MJCsahaNo ratings yet

- Nilkamal FormworkDocument23 pagesNilkamal FormworkRahul AgarwalNo ratings yet

- Life Cycle of Civil Engineering ProjectsDocument28 pagesLife Cycle of Civil Engineering ProjectsMarvin Bryant MedinaNo ratings yet

- Topic 1 - Intro Ai: ITS662 - Intelligent Systems DevelopmentDocument13 pagesTopic 1 - Intro Ai: ITS662 - Intelligent Systems DevelopmentZaabaIbnuAhmadNo ratings yet

- 5182 Aluminium: Take-Away FactsDocument5 pages5182 Aluminium: Take-Away FactsshakeerNo ratings yet

- Microstructure and Mechanical Properties of X80/X100 Grade Plates and PipesDocument6 pagesMicrostructure and Mechanical Properties of X80/X100 Grade Plates and PipesallswellelleNo ratings yet

- DeaeratorDocument4 pagesDeaeratorAnonymous NFoZJKYNo ratings yet

- Salary Guide for Creative, Architecture & Design ProfessionsDocument1 pageSalary Guide for Creative, Architecture & Design ProfessionssaaNo ratings yet

- Drilling Dynamics Sensors Opt BR PDFDocument16 pagesDrilling Dynamics Sensors Opt BR PDFhamed1725No ratings yet

- Installation Wiring Diagram for SD119 Series Smoke DetectorsDocument2 pagesInstallation Wiring Diagram for SD119 Series Smoke DetectorsVictor PatsiNo ratings yet

- FINISHINGDocument26 pagesFINISHINGNeha SinghNo ratings yet

- Trelleborg Confor Impact Foam EnglishDocument2 pagesTrelleborg Confor Impact Foam EnglishchoopoNo ratings yet

- AeroShell Turbine Oil 500 PDFDocument2 pagesAeroShell Turbine Oil 500 PDFAnonymous oAbjbl4HNo ratings yet

- Ena Solar Inverter GT-ManualDocument32 pagesEna Solar Inverter GT-ManualRob DuthieNo ratings yet

- The Drawing Club - Master The Art of Drawing Characters From Life (2014)Document147 pagesThe Drawing Club - Master The Art of Drawing Characters From Life (2014)Ronald Meza Puentes100% (5)