Professional Documents

Culture Documents

Astm E11

Uploaded by

Ivan AlanizOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm E11

Uploaded by

Ivan AlanizCopyright:

Available Formats

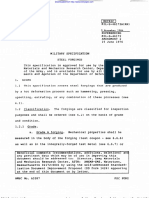

Designation: E 11 – 09

Standard Specification for

Woven Wire Test Sieve Cloth and Test Sieves1

This standard is issued under the fixed designation E 11; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope E 2427 Test Method for Acceptance by Performance Test-

1.1 This document specifies the technical requirements for; ing of U.S. Standard Test Sieves

the woven wire test sieve cloth (sieve cloth) used in test sieves, 2.2 Federal Standard:

the construction of test sieves, standard and non-standard test Fed. Std. No. 123 Marking for Shipment (Civil Agencies)3

sieve frame sizes, and test procedures used to inspect sieve 2.3 Military Standard:

cloth and the test sieves. This Specification applies to test MIL-STD-129 Marking for Shipment and Storage3

sieves manufactured with sieve cloth having a nominal aper- 2.4 ISO Standard:

ture size ranging from 125 millimeters (mm) down to 20 ISO 3310-1 Test Sieves—Technical Requirements and Test-

micrometers (µm). ing – Part 1: Test Sieves of Metal Wire Cloth4

1.2 Additional reference information can be found in Speci- 3. Terminology

fications E 161, E 323, E 2016, and in Test Methods C 430 and

E 2427. 3.1 Definitions:

1.3 The values stated in SI units shall be considered 3.1.1 aperture—the dimension defining an opening in a

standard for the dimensions of the sieve cloth openings and the screening surface.

wire diameters used in the sieve cloth. The values stated in 3.1.2 crimp—the corrugation in the warp and shute wire, or

inch-pound units shall be considered standard with regard to both. The crimp in the wires is formed either during the

the sieve frames, pans, and covers. weaving process, or with a crimping machine prior to weaving.

1.4 This standard does not purport to address all of the If formed during the weaving process, the tension existing

safety concerns, if any, associated with its use. It is the between the warp and shute wires fundamentally determines

responsibility of the user of this standard to establish appro- the respective amount or depth of crimp, which locks the wires

priate safety and health practices and determine the applica- in place, and in part establishes the firmness of the sieve cloth.

bility of regulatory limitations prior to use. 3.1.3 firmness—a subjective term referring to the planar

rigidity of sieve cloth (as a roll good, not mounted in a test

2. Referenced Documents sieve frame), established by the tensile strength of the material,

2.1 ASTM Standards:2 the relationship of the mesh to wire diameters, the type of

C 430 Test Method for Fineness of Hydraulic Cement by weave, and amount of crimp in the wires. The absence of

the 45-µm (No. 325) Sieve firmness in sieve cloth is termed sleaziness.

E 161 Specification for Precision Electroformed Sieves 3.1.4 matched test sieve—a test sieve that reproduces the

E 323 Specification for Perforated-Plate Sieves for Testing performance results of another test sieve within user defined

Purposes limits for a designated material (for information only and may

E 1638 Terminology Relating to Sieves, Sieving Methods not be in compliance with this Specification).

and Screening Media 3.1.5 mesh—the number of wires or openings per linear

E 2016 Specification for Industrial Woven Wire Cloth inch (25.4 mm) counted from the center of any wire to a point

exactly 1 in. (25.4 mm) distant, including the fractional

distance between either thereof.

3.1.6 plain weave—sieve cloth in which the warp wires and

--``,,`,`,,````,`,`,`````,,``-`-`,,`,,`,`,,`---

1

This specification is under the jurisdiction of ASTM Committee E29 on Particle

and Spray Characterization and is the direct responsibility of Subcommittee E29.01 shute wires pass over one and under one in both directions.

on Sieves, Sieving Methods, and Screening Media.

Current edition approved May 1, 2009. Published June 2009. Originally

3

approved in 1925. Last previous edition approved in 2004 as E 11 – 04. Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.dodssp.daps.mil.

4

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International

Provided by IHS under license with ASTM

1Licensee=Praxair Inc/5903738101, User=Cabriales, Rodolfo

No reproduction or networking permitted without license from IHS Not for Resale, 10/09/2009 10:40:25 MDT

E 11 – 09

3.1.7 shute wires—the wires running the short way of, or 5. Sieve Cloth Requirements

across the cloth as woven (also referred to as the shoot, fill, or 5.1 The sieve cloth used in test sieves shall meet the

weft wires). requirements of Table 1 and shall be designated Specification

3.1.8 sieve—an apparatus for the purpose of sieving, con- E 11 Sieve Cloth. The number of inspected apertures shall be

sisting of a separating media mounted in a frame. in accordance with Table 1 (Column 7). Sieve cloth conform-

3.1.9 sieve cloth—woven wire cloth conforming to this ing to this specification shall be woven from stainless steel,

specification. brass, or bronze. Sieve cloth with openings greater than or

3.1.10 test sieve (wire cloth)—a sieve manufactured by equal to 75 micrometers shall be woven using a plain weave.

mounting sieve cloth in a frame, designed for use in particle For sieve cloth with openings equal to or less than 63

size analysis by sieving. micrometers the sieve cloth may be supplied using a twill

3.1.11 compliance test sieve—a test sieve manufactured weave. The sieve cloth shall not be coated or plated.

using sieve cloth which has been inspected prior to being 5.2 All measurements of openings and wire diameters shall

mounted in the sieve frame; and that meets the requirements of be made along the midpoints of the openings as shown in Fig.

Table 1 in part based on the standard deviation of the required 1.

number of sample openings per 100 square feet of sieve cloth 5.3 There shall be no punctures or obvious defects in the

(column 7) not exceeding the maximum allowable for a sieve cloth.

confidence level of 66% (column 8). 5.4 Test sieves can be supplied based on different levels of

3.1.12 inspection test sieve—a test sieve manufactured us- confidence as Compliance Sieves, Inspection Sieves, and

ing sieve cloth which has been inspected after being mounted Calibration Sieves. Calibration sieves have had at least twice as

in the sieve frame; and that meets the requirements of Table 1 many openings measured as Inspection sieves.

in part based on the standard deviation of the required number 5.5 Each test sieve must be examined and found to be free

of sample openings in the test sieve (column 9) not exceeding of manufacturing defects.

the maximum allowable for a confidence level of 99% (column

10). 6. Technical Requirements

3.1.13 calibration test sieve—a test sieve manufactured

using sieve cloth which has been inspected after being mounted 6.1 Opening Sizes, Tolerances, and Standard Deviation:

in the sieve frame; and that meets the requirements of Table 1 6.1.1 Four tolerances shall be applied: the variation for

in part based on the standard deviation of the required number average opening (Y), the maximum variation (X), the maximum

of sample openings in the test sieve (column 11) not exceeding standard deviation and the wire diameter. The opening toler-

the maximum allowable for a confidence level of 99.73% ances apply to the opening sizes, measured on the midpoint of

(column 12). the opening (see Fig. 1), and applied separately in both the

3.1.14 twill weave—sieve cloth in which the warp wires and warp and shute directions.

shute wires pass over two and under two wires in both 6.1.2 The average opening size shall not exceed the sieve

directions. designation by more than 6Y (Table 1, Column 4):

3.1.15 warp wires—the wires running the long way of the w0.98

Y 5 27 1 1.6 (1)

cloth as woven.

3.2 Additional terms can be found in Terminology E 1638. where Y and w are expressed in micrometers.

6.1.3 The maximum opening size measured shall not exceed

4. Ordering Information the nominal opening size w (Table 1, Column 1), by more than

4.1 Orders for items under this specification should include X (Table 1, Column 5):

the following information as required: 2~w0.75!

4.1.1 Description of item(s) (Test Sieve or Sieve Cloth), X5 3 1 4w0.25 (2)

4.1.2 ASTM E 11 designation and year of issue,

where X and w are expressed in micrometers.

--``,,`,`,,````,`,`,`````,,``-`-`,,`,,`,`,,`---

4.1.3 Quantity of each item, and

4.1.4 Sieve designation (Table 1, Standard Column 1, Al- 6.1.4 The intermediate value Z shall be stated as follows:

ternate Column 2). Z 5 ~X 1 Y! / 2 (3)

4.2 Test sieves in standard circular frame: 6.1.5 The maximum standard deviation is calculated based

4.2.1 Nominal sieve frame diameter (see Table 2), and on the Gaussian normal distribution curve, where the area

4.2.2 Nominal sieve frame height (see Table 2). under the curve to the maximum value X minus the area under

4.3 For sieve cloth not in frames or in nonstandard frames: the curve to the intermediate value Z, is equal to this critical

4.3.1 Sieve cloth designation, and area between (w + Z) and (w + X) not exceeding more than 5 %

4.3.2 Description of nonstandard frame. of the openings (see Appendix X2). The resulting tolerances

4.4 For U.S. Government purchases, if supplementary re- for sigma are given in Table 1 for Compliance sieve cloth

quirements apply: (Column 8).

4.4.1 Compatible sieve pans and covers, and 6.1.5.1 In order to increase the probability or acceptance

4.4.2 Special requirements (specific type of metal for sieve confidence level from 66 % at one-sigma to Xs, specifically

cloth and frames, test sieve designation and or matched sieves 99 % (2.58s) and 99.73 % (3s) for Inspection and Calibration

for example). sieves respectively, these maximum standard deviation values

Copyright ASTM International

Provided by IHS under license with ASTM

2Licensee=Praxair Inc/5903738101, User=Cabriales, Rodolfo

No reproduction or networking permitted without license from IHS Not for Resale, 10/09/2009 10:40:25 MDT

E 11 – 09

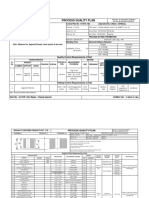

TABLE 1 Nominal Dimensions and Permissible Variations for Sieve Cloth and Compliance, Inspection and Calibration Test Sieves

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) (12) (13) (14) (15)

Permissible Range

Sieve Designation Nominal 6Y +X Resulting Compliance Sieves Inspection Sieves Calibration Sieves

Typical of Choice

Sieve Variation Maximum Maximum

Wire

Opening for Average Variation Individual Sample Maximum Sample Maximum Sample Maximum

Standard Alternative (in.) Opening for Opening Opening Openings Standard Openings Standard Openings Standard Diameter Min Max

per 100 ft2 Deviation per Sieve Deviation per Sieve Deviation

millimeter inches millimeter millimeter millimeter millimeter

125 5 in. 5 3.66 4.51 129.51 20 – all – all – 8 6.8 9.2

106 4.24 in. 4.24 3.12 3.99 109.99 20 – all – all – 6.3 5.4 7.2

100 4 in. 4 2.94 3.82 103.82 20 – all – all – 6.3 5.4 7.2

90 31⁄2 in. 3.5 2.65 3.53 93.53 20 – all – all – 6.3 5.4 7.2

75 3 in. 3 2.22 3.09 78.09 20 – all – all – 6.3 5.4 7.2

63 21⁄2 in. 2.5 1.87 2.71 65.71 20 – all – all – 5.6 4.8 6.4

53 2.12 in. 2.12 1.58 2.39 55.39 20 – all . all – 5 4.3 5.8

50 2 in. 2 1.49 2.29 52.29 20 – all – all – 5 4.3 5.8

45 13⁄4 in. 1.75 1.35 2.12 47.12 20 . all – all – 4.5 3.8 5.2

37.5 11⁄2 in. 1.5 1.13 1.85 39.35 20 1.374 all – all – 4.5 3.8 5.2

31.5 11⁄4 in. 1.25 0.95 1.63 33.13 20 1.066 all – all – 4 3.4 4.6

26.5 1.06 in. 1.06 0.802 1.44 27.94 20 0.869 15 0.584 all – 3.55 3 4.1

25 1.00 in. 1 0.758 1.38 26.38 20 0.823 15 0.553 all – 3.55 3 4.1

22.4 7⁄8 in. 0.875 0.681 1.27 23.67 150 0.734 15 0.493 all – 3.55 3 4.1

19 3⁄4 in. 0.750 0.579 1.13 20.13 150 0.622 15 0.418 30 0.446 3.15 2.7 3.5

16 5⁄8 in. 0.625 0.490 0.99 16.99 150 0.527 15 0.354 30 0.378 3.15 2.7 3.6

13.2 0.530 in. 0.530 0.406 0.86 14.06 150 0 441 15 0.296 30 0.316 2.8 2.4 3.2

12.5 1⁄2 in. 0.500 0.385 0.83 13.33 150 0.421 15 0.283 30 0.302 2.5 2.1 2.9

11.2 7⁄16 in. 0.438 0.346 0.77 11.97 150 0.382 15 0.256 30 0.274 2.5 2.1 2.9

9.5 3⁄8 in. 0.375 0.295 0.68 10.18 150 0.330 15 0.222 30 0.237 2.24 1.9 2.6

8 5⁄16 in. 0.312 0.249 0.60 8.60 150 0.284 15 0.191 30 0.204 2 1.7 2.3

6.7 0.265 in. 0.265 0.210 0.53 7.23 150 0.245 15 0.164 30 0.175 1.8 1.5 2.1

6.3 1⁄4 in. 0.250 0.197 0.51 6.81 150 0.233 15 0.157 30 0.167 1.8 1.5 2.1

5.6 No. 31⁄2 0.223 0.176 0.47 6.07 150 0.211 15 0.142 30 0.151 1.6 1.3 1.9

4.75 No. 4 0.187 0.150 0.41 5.16 150 0.182 15 0.123 30 0.131 1.6 1.3 1.9

4 No. 5 0.157 0.127 0.37 4.37 150 0.161 15 0.108 30 0.115 1.4 1.2 1.7

3.35 No. 6 0.132 0.107 0.32 3.67 200 0.138 20 0.097 40 0.103 1.25 1.06 1.5

2.8 No. 7 0.110 0.090 0.29 3.09 200 0.121 20 0.085 40 0.090 1.12 0.95 1.3

2.36 No. 8 0.0937 0.076 0.25 2.61 200 0.104 20 0.073 40 0.077 1 0.85 1.15

2 No. 10 0.0787 0.065 0.23 2.23 250 0.094 25 0.068 50 0.072 0.9 0.77 1.04

1.7 No. 12 0.0661 0.056 0.20 1.90 250 0.081 25 0.059 50 0.062 0.8 0.68 0.92

1.4 No. 14 0.0555 0.046 0.18 1.58 400 0.071 40 0.055 80 0.057 0.71 0.6 0.82

1.18 No. 16 0.0469 0.040 0.16 1.34 400 0.063 40 0.049 80 0.051 0.63 0.54 0.72

1 No. 18 0.0394 0.034 0.14 1.14 400 0.055 40 0.042 80 0.044 0.56 0.48 0.64

micrometer inches micrometer micrometer micrometer micrometer

850 No. 20 0.0331 29.1 127 977 400 48.76 40 37.73 80 39.36 0.5 0.43 0.58

710 No. 25 0.0278 24.7 112 822 500 42.63 50 33.82 100 35.14 0.45 0.38 0.52

600 No. 30 0.0234 21.2 101 701 500 38.00 50 30.14 100 31.32 0.4 0.34 0.46

500 No. 35 0.0197 18.0 89 589 600 33.23 60 26.85 120 27.82 0.315 0.27 0.36

425 No. 40 0.0165 15.5 81 506 600 29.95 60 24.20 120 25.08 0.28 0.24 0.32

355 No. 45 0.0139 13.3 72 427 800 26.45 80 21.95 160 22.64 0.224 0.19 0.26

300 No. 50 0.0117 11.5 65 365 800 23.70 80 19.66 160 20.29 0.2 0.17 0.23

250 No. 60 0.0098 9.9 58 308 800 21.02 80 17.44 160 17.99 0.16 0.13 0.19

212 No. 70 0.0083 8.7 52 264 800 18.79 80 15.59 160 16.08 0.14 0.12 0.17

180 No. 80 0.0070 7.6 47 227 1000 16.85 100 14.24 200 14.65 0.125 0.106 0.15

150 No. 100 0.0059 6.6 43 193 1000 15.30 100 12.93 200 13.30 0.1 0.085 0.115

125 No. 120 0.0049 5.8 38 163 1000 13.51 100 11.41 200 11.74 0.09 0.077 0.104

--``,,`,`,,````,`,`,`````,,``-`-`,,`,,`,`,,`---

106 No. 140 0.0041 5.2 35 141 1000 12.39 100 10.47 200 10.77 0.071 0.06 0.082

90 No. 170 0.0035 4.6 32 122 1000 11.27 100 9.53 200 9.80 0.063 0.054 0.072

75 No. 200 0.0029 4.1 29 104 1000 10.23 100 8.64 250 9.02 0.05 0.043 0.058

63 No. 230 0.0025 3.7 26 89 1000 9.18 100 7.76 250 8.09 0.045 0.038 0.052

53 No. 270 0.0021 3.4 24 77 1000 8.44 100 7.13 250 7.44 0.036 0.031 0.041

45 No. 325 0.0017 3.1 22 67 1000 7.76 100 6.56 250 6.84 0.032 0.027 0.037

38 No. 400 0.0015 2.9 20 58 1000 7.09 100 5.99 300 6.31 0.03 0.024 0.035

32 No. 450 0.0012 2.7 18 50 1000 6.42 100 5.42 300 5.71 0.028 0.023 0.033

25 No. 500 0.0010 2.5 16 41 1000 5.71 100 4.82 300 5.06 0.025 0.021 0.029

20 No. 635 0.0008 2.3 15 35 1000 5.33 100 4.51 300 4.75 0.02 0.017 0.023

Column 3—These numbers are only approximate but are in use for reference; the sieve shall be identified by the standard designation in millimeters or micrometers.

Columns 9 and 11—See Annex A1, which specifies that all openings will be inspected for test sieves having 15 openings or less.

Columns 9 and 11 - These number of sample openings are based on an 89 diameter test sieve.

Copyright ASTM International

Provided by IHS under license with ASTM

3Licensee=Praxair Inc/5903738101, User=Cabriales, Rodolfo

No reproduction or networking permitted without license from IHS Not for Resale, 10/09/2009 10:40:25 MDT

E 11 – 09

TABLE 2 Dimensions of Standard Frames 6.1.6.2 The sample standard deviation s is calculated from

Nominal Mean Diameter, in. (mm) Typical FrameA the measurement of the number of apertures, n as listed in

Diameter, Nominal Height, Table 1 (Column 8 for sieve cloth, Column 10 for Inspection

in. Inside at TopB Outside on Skirt

in. (mm) Sieves, and Column 12 for Calibration Sieve), using the

3 3.000 + 0.030/−0.000 3.000 + 0.000/−0.030 11⁄4 (32) FHC following equation:

(76 + 0.76/ −0.00) (76 + 0.00/ −0.76) 5⁄8 (16) HH

8

6.000 + 0.030/−0.000

(152 + 0.76/ −0.00)

8.000 + 0.030/−0.000

6.000 + 0.000/−0.030

(152 + 0.00/ −0.76)

8.000 + 0.000/−0.030)

13⁄4 (45) FH

1 (25) HH

2 (50) FH

s5 Π1 n

( ~wi – w!2

n – 1 r51 (7)

(203 + 0.76/ −0.00 (203 + 0.00/ −0.76) 1 (25) HH 6.2 Wire Diameters:

10 10.000 + 0.030/−0.000 10.000 + 0.000/−0.030 3 (76) FH

6.2.1 The nominal wire diameters given in Table 1, Column

(254 + 0.76/ −0.00) (254 + 0.00/ −0.76) 11⁄2 (38) HH

12 12.000 + 0.030/−0.000 12.000 + 0.000/−0.030 31⁄4 (83) FH 13 are typical.

(305 + 0.76/ −0.00) (305 + 0.00/ −0.76) 13⁄8 (50) IH 6.2.2 The wires in a test sieve or sieve cloth shall fall

15⁄8 (41) HH

between the range of choice (d min and d max ) given in Table

A

Frame height meaasured from top of frame to top of sieve cloth. 1, Column 14 and 15, respectively. It is recognized that

B

Measured 0.2 in. (5 mm) below the top of the frame.

C

FH = full height; HH = half height; IH = intermediate height. mechanical deformation of the wire occurs during weaving,

and therefore the diameter measured after weaving may be

different than the nominal wire diameter.

6.2.3 The wires shall be crimped in such a manner that the

cloth exhibits firmness, as agreed between the user and the

supplier, as applied to roll goods.

6.3 Test Sieve Frames:

6.3.1 General Requirements—Frames for test sieves shall

be constructed in such a manner to be rigid. The sieve cloth

shall be mounted on a frame without distortion, looseness, or

waviness. The method used to attach the sieve cloth to the

frame shall be done so the material being sieved will not

become caught in the joint between the sieve cloth and the

frame.

6.3.2 Standard Frames—Sieve frames shall be circular.

Typical frame sizes are 3 in., 6 in., 8 in., 10 in., and 12 in.

diameter (or 76, 152, 203, 254, or 305 mm). Tolerances for

dimensions of test sieve frames are given in Table 2. Other

frame sizes may be used. Frames shall be made of a noncor-

FIG. 1 Aperture Size

rosive material such as brass or stainless steel. The bottom of

the frame shall be constructed so as to provide an easy sliding

or nesting fit with any sieve frame of the same nominal

are determined by dividing sigma by a correction or K-factor. diameter conforming to the specified dimensions.

These K-factors are determined based on approximation to a 6.3.3 The joint or fillet at the point where the sieve cloth and

Chi-square distribution for the sample variance as follows: frame meet will provide a minimum clear sieving surface with

K 5 1 1 Xs / =2~n – 1! (4) a diameter equal to the nominal diameter, less 0.5 in. (13 mm).

6.3.4 Nonstandard Frames—Other sieve frames may be

6.1.5.2 The applicable resulting K-factors (see Appendix

square, rectangular, circular, or non-metal. The frame may

X3) are then applied and the maximum standard deviation

have the sieve cloth permanently attached, or it may be

tolerances are determined as follows:

designed so the sieve cloth is replaceable. The provisions of

sx 5 sigma / K (5) section 6.3.1 apply.

6.1.5.3 The resulting tolerances are given in Table 1 for

Inspection Sieves (Column 10) and for Calibration Sieves 7. Test Sieve and Sieve Cloth Documentation and

(Column 12). Certification

6.1.6 The actual standard deviation of the openings in the 7.1 Documentation of the measurement of the openings in

warp and weft directions, when taken separately, shall not the sieve cloth must assure that the test sieve is traceable and

exceed the values shown in Table 1 for each type. If the number certifiable. All test sieve certificates must be traceable by the

of sample openings is less than 15, the maximum standard test sieve serial number. Inspection and Calibration sieves must

deviation is not evaluated. also include the date, name and signature of the person

certifying to the test sieve quality.

6.1.6.1 The population standard deviation s is obtained by

7.2 Test sieves may be supplied as Compliance, Inspection

measuring all of the full openings N found in the test sieve and

or Calibration Sieves.

is calculated from the following equation:

7.2.1 A Compliance sieve certificate shall state that the test

s5 Π1 N

( ~wi – w!2

N i51 (6)

sieve has been manufactured with sieve cloth that has been

inspected and found to be in compliance with the requirements

--``,,`,`,,````,`,`,`````,,``-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

4Licensee=Praxair Inc/5903738101, User=Cabriales, Rodolfo

No reproduction or networking permitted without license from IHS Not for Resale, 10/09/2009 10:40:25 MDT

E 11 – 09

of Specification E 11. The Certificate does not require any 8.1.1 “Test Sieve,”

statistical documentation. 8.1.2 The “ASTM E 11” designation,

7.2.2 An Inspection sieve certificate shall state at a mini- 8.1.3 Name of the manufacturer or distributor,

mum the value for the average aperture size, separately in both 8.1.4 Test sieve designation from Table 1, Column 1, and

the warp and shute direction of the sieve cloth. A Certificate 8.1.5 Alternate test sieve designation from Table 1, Column

with this inspection data must be supplied. 2 (optional).

7.2.3 A Calibration sieve certificate shall state at a minimum 8.1.6 Each test sieve shall have a unique serial number

the number of aperture and wire diameters measured, the permanently marked onto the sieve frame, skirt or nameplate.

average aperture size, standard deviation and average wire

8.1.7 The test sieve may also be labeled with the Grade

diameter, separately in both the warp and shute directions of

designation.

the sieve cloth. A Certificate with this inspection data must be

supplied.

9. Keywords

8. Marking or Labeling of Test Sieves 9.1 aperture; calibration sieve; compliance sieve; inspection

8.1 Each Test Sieve supplied shall hear a label marked with sieve; opening; particle size; sieve; sieve analysis; sieve cloth;

the following information: sieve designation; test sieve; woven wire test sieve cloth

SUPPLEMENTARY REQUIREMENTS

The following supplementary requirements shall apply only when specified by the purchaser in the

contract or order.

S1. Responsibility for Inspection S2. Government Procurement

S1.1 Unless otherwise specified in the contract or purchase S2.1 Unless otherwise specified in the contract, the material

order, the producer is responsible for the performance of all shall be in packaged in accordance with the suppliers’ standard

inspection and test requirements specified herein. Except as practice that will be acceptable to the carrier at lowest rates.

otherwise specified in the contract or order, the producer may Containers and packing shall comply with the Uniform Freight

use his own or any other suitable facilities for the performance Classification rules or National Motor Classification rules.

of the inspections and tests requirements specified herein, Marking for shipment of such materials shall be in accordance

unless disapproved by the purchaser. The purchaser shall have

with Fed. Std. No. 123 for civil agencies, and MIL-STD-129

the right to perform any of the inspections and tests set forth in

for military agencies.

this specification where such inspections are deemed necessary

to ensure that materials meet the specification.

ANNEX

(Mandatory Information)

A1. PROCEDURE FOR INSPECTING SIEVE CLOTH AND TEST SIEVES

A1.1 Every opening in the sieve cloth or test sieve shall

have the same probability of being inspected for compliance

with the requirements shown in Table 1. For sieve cloth and

--``,,`,`,,````,`,`,`````,,``-`-`,,`,,`,`,,`---

NOTE—Apertures randomly spaced over the full diameter at irregular

intervals, measurement for warp and shute dimension, only one measure-

ment per aperture.

FIG. A1.2 Example for Crosswise Spot Check

FIG. A1.1 All Full Apertures Measure up to 15 Apertures

Copyright ASTM International

Provided by IHS under license with ASTM

5Licensee=Praxair Inc/5903738101, User=Cabriales, Rodolfo

No reproduction or networking permitted without license from IHS Not for Resale, 10/09/2009 10:40:25 MDT

E 11 – 09

A1.1.2 Inspect for oversize openings per tolerance X given

in Table 1 (Column 5); carefully and methodically examine the

appearance of all openings in order to detect oversize openings

for subsequent measurements. Openings in fine mesh sieves

are best viewed when magnified optically. In the optical

method, the minimum number of apertures examined shall be

in accordance with Table 1 (Columns 9 or 11) for sieves and

(Column 7) for sieve cloth. The magnifications listed in Table

A1.1 may be used. If any opening is found to be oversize by

more than tolerance X, the sieve cloth or test sieve is unac-

ceptable.

NOTE—Apertures randomly spaced over the full diameter at irregular A1.1.3 Determine the average opening size (w in millime-

intervals, measurements for both warp and shute dimensions shall be ters), and for apertures less than one millimeter, in microme-

made in any one aperture.

ters, the standard deviation and wire diameter. The measured

FIG. A1.3 Example for Diagonal Spot Check

openings shall be spaced over the full diameter of the test

sieve. Figs. A1.1 and A1.2 indicate options to measure the

individual openings in an 8 in. (203 mm) diameter test sieve.

The minimum number of openings to be measured, in both the

warp and shute direction, in an 8 in. diameter test sieve for

Inspection and Calibration grades are shown in Table 1,

Columns 9 or 11 respectively. For test sieve sizes other than the

8 in. diameter, the values shown in this table should be

modified in proportion to the sieving area. Determine the

average opening along the center line of the sieve cloth

separately in two directions, parallel to the warp and shute

wires respectively (See Figs. A1.2 and A1.3). If the sieve cloth

is a twill weave (openings less than or equal to 63 micrometer),

the configuration shall be as shown in Fig. A1.4 and the

measurements shall be made vertically, to the wire.

FIG. A1.4 Configuration of Twilled Weaves

A1.1.4 To determine the average opening in sieve cloth

refer to Table 1 for the minimum number of sample openings

to be measured. Calculate the standard deviation as per section

--``,,`,`,,````,`,`,`````,,``-`-`,,`,,`,`,,`---

test sieves having 15 openings or less, measure all full

6.1.6.2. If the wire diameter is measured separately, not at the

openings (see Fig. A1.1). For sieve cloth and test sieves having

same time the opening is measured, measure at least 10 wire

more than (15) openings, carry out the inspection using the

diameters, if available, in each direction.

following three procedures:

A1.1.1 Visually inspect the condition of the sieve cloth

against a uniformly illuminated background. If obvious devia- TABLE A1.1 Magnifying Power in Optical Method

tions from uniformity of appearance are found (weaving

Nominal Aperture Size 5 mm to 500 µm 500 to 250 µm 250 to 20 µm

defects, creases, wrinkles, etc.) the sieve cloth and/or test sieve Magnification 5 to 20 20 to 50 50 to 500

is unacceptable.

Copyright ASTM International

Provided by IHS under license with ASTM

6Licensee=Praxair Inc/5903738101, User=Cabriales, Rodolfo

No reproduction or networking permitted without license from IHS Not for Resale, 10/09/2009 10:40:25 MDT

E 11 – 09

APPENDIXES

(Nonmandatory Information)

--``,,`,`,,````,`,`,`````,,``-`-`,,`,,`,`,,`---

X1. DETERMINATION OF THE STANDARD DEVIATION ON AVERAGE APERTURE SIZE

The standard deviation is calculated using equations as illustrated by the following two examples.

X1.1 Example 1 X1.2 Example 2

X1.1.1 Test for Inspection Grade sieve (n = 25, nominal X1.2.1 Test for Calibration Grade sieve (n = 50, nominal

aperture size w = 2 mm): aperture size w = 2 mm):

wi ni ni 3 w i –) – )2 – )2 wi ni ni 3 w i –) – )2 – )2

(wi – w (wi – w n 3 (wi – w (wi – w (wi – w n 3 (wi – w

1.812 0 0.000 –0.132 0.017 0.000 1.812 0 0.000 –0.187 0.035 0.000

1.859 3 5.577 –0.085 0.007 0.021 1.859 2 3.718 –0.140 0.020 0.039

1.906 5 9.530 –0.038 0.001 0.007 1.906 4 7.624 –0.093 0.009 0.035

1.953 11 21.483 0.009 0.000 0.001 1.953 9 17.577 –0.046 0.002 0.019

2.000 6 12.000 0.056 0.003 0.019 2.000 20 40.000 0.001 0.000 0.000

2.047 0 0.000 0.103 0.011 0.000 2.047 10 20.470 0.048 0.002 0.023

2.094 0 0.000 0.150 0.023 0.000 2.094 3 6.282 0.095 0.009 0.027

2.141 0 0.000 0.197 0.039 0.000 2.141 2 4.282 0.142 0.020 0.040

2.188 0 0.000 0.244 0.060 0.000 2.188 0 0.000 0.189 0.036 0.000

n= 25 48.590 0.049 n= 50 99.953 0.183

n n

( ni – w i

r51

( ni – w i

r51

w5 n w5 n

48.590 99.953

w 5 25 5 1.944 mm w 5 50 5 1.999 mm

s5 Π1 n

( ~wi – w!2

n Р1 i51 s5 Π1 n

( ~wi – w!2

n – 1 i51

s5 Π1

24 3 0.049 5 0.045 mm s5 Π1

49 3 0.183 5 0.061 mm

X1.1.2 Standard deviation ss = 0.045 shall be compared X1.2.2 Standard deviation ss = 0.061 shall be compared

with the value of sx = 0.070 given in Table 1, column 10. with the value of sx = 0.072 given in Table 1, column 12.

Copyright ASTM International

Provided by IHS under license with ASTM

7Licensee=Praxair Inc/5903738101, User=Cabriales, Rodolfo

No reproduction or networking permitted without license from IHS Not for Resale, 10/09/2009 10:40:25 MDT

E 11 – 09

X2. CRITICAL AREA OF NORMAL DISTRIBUTION CURVE

--``,,`,`,,````,`,`,`````,,``-`-`,,`,,`,`,,`---

FIG. X2.1 Critical Area of Normal Distribution Curve

X3. K-FACTORS

TABLE X3.1 K Factors

Xs K-factors

Samples

n 2.58 3.00

99% 99.73%

15 1.49 1.57

20 1.42 1.49

25 1.37 1.43

30 1.34 1.39

40 1.29 1.34

50 1.26 1.30

60 1.24 1.28

80 1.21 1.24

100 1.18 1.21

120 1.17 1.19

160 1.14 1.17

200 1.13 1.15

250 1.12 1.13

300 1.11 1.12

Reference: Courtesy of Professor Aridaman K. Jain, New Jersey Institute of

Technology, 2008. The acceptance confidence levels 2.58 and 3.00 are conser-

vative as applied to the inspection of sieves, and the large sample K-factors are

derived by using the normal distribution as an approximation to a Chi-square

distribution for the sample variance.

Copyright ASTM International

Provided by IHS under license with ASTM

8Licensee=Praxair Inc/5903738101, User=Cabriales, Rodolfo

No reproduction or networking permitted without license from IHS Not for Resale, 10/09/2009 10:40:25 MDT

E 11 – 09

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

--``,,`,`,,````,`,`,`````,,``-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

9Licensee=Praxair Inc/5903738101, User=Cabriales, Rodolfo

No reproduction or networking permitted without license from IHS Not for Resale, 10/09/2009 10:40:25 MDT

You might also like

- Astm E11-16Document11 pagesAstm E11-16Said MohamedNo ratings yet

- Norma Astm E11Document12 pagesNorma Astm E11Luis Chircca100% (2)

- D2168 21269Document6 pagesD2168 21269D IZomer Oyola-Guzmán100% (1)

- D244Document8 pagesD244samuelNo ratings yet

- Relative Density (Specific Gravity) and Absorption of Coarse AggregateDocument5 pagesRelative Density (Specific Gravity) and Absorption of Coarse AggregateMuhammad Taimur KhanNo ratings yet

- D4221 1518350-1Document4 pagesD4221 1518350-1Joseph Marriott AndersonNo ratings yet

- E177 16066Document9 pagesE177 16066CJPATAGANNo ratings yet

- Automated Extraction of Asphalt Binder From Asphalt MixturesDocument6 pagesAutomated Extraction of Asphalt Binder From Asphalt MixturesJose Luis Contreras RamaycunaNo ratings yet

- Astm D698Document11 pagesAstm D698Mohamed Reda Hussein SengarNo ratings yet

- D-5240 Boulder AggregateDocument3 pagesD-5240 Boulder AggregateUmesh KumarNo ratings yet

- Astm D1558Document3 pagesAstm D1558johan lopez100% (1)

- Astm C 87Document4 pagesAstm C 87mickyfelixNo ratings yet

- ASTM D4402 - D4402M-15 (Reapproved 2022)Document4 pagesASTM D4402 - D4402M-15 (Reapproved 2022)anant1123550% (2)

- Preparing Rock Core As Cylindrical Test Specimens and Verifying Conformance To Dimensional and Shape TolerancesDocument13 pagesPreparing Rock Core As Cylindrical Test Specimens and Verifying Conformance To Dimensional and Shape Tolerancesdeivy ardila100% (2)

- D653 27514 PDFDocument50 pagesD653 27514 PDFJUAN CAMILO VIVARES GÓMEZNo ratings yet

- Description and Identification of Soils (Visual-Manual Procedures)Document13 pagesDescription and Identification of Soils (Visual-Manual Procedures)Inti Glls GmnkNo ratings yet

- Astm D1140 PDFDocument4 pagesAstm D1140 PDFcatalina_tudosa0% (1)

- D7012 19774Document9 pagesD7012 19774christian moncayoNo ratings yet

- D 4867 - D 4867M - 04Document5 pagesD 4867 - D 4867M - 04Luisinho Alvarez ChávezNo ratings yet

- Minimum Requirements For Agencies Testing and Inspecting Road and Paving MaterialsDocument7 pagesMinimum Requirements For Agencies Testing and Inspecting Road and Paving Materialsاحمد علي احمدNo ratings yet

- Astm D4253-2016Document14 pagesAstm D4253-2016Javier Burgos ÐiedrichsNo ratings yet

- D7013D7013M 15Document6 pagesD7013D7013M 15Carlos Guillermo Somoza Alvarenga100% (1)

- Astm D7380 - 15Document3 pagesAstm D7380 - 15guyii86No ratings yet

- D4753 19711 PDFDocument6 pagesD4753 19711 PDFeduardo bonillaNo ratings yet

- D 1557 - 12e1Document14 pagesD 1557 - 12e1Anonymous ctjoMs100% (1)

- Astm D4254-2016Document9 pagesAstm D4254-2016Javier Burgos Ðiedrichs100% (1)

- Astm d5519Document10 pagesAstm d5519Jony Gutiérrez Abanto100% (1)

- Calibration of Laboratory Mechanical-Rammer Soil Compactors: Standard Practices ForDocument6 pagesCalibration of Laboratory Mechanical-Rammer Soil Compactors: Standard Practices ForAbid HussainNo ratings yet

- Astm d6938Document10 pagesAstm d6938elexdosNo ratings yet

- Astm D 2726 - 2014Document4 pagesAstm D 2726 - 2014NazarethNo ratings yet

- Astm D7263 PDFDocument7 pagesAstm D7263 PDFMuhammad AsifNo ratings yet

- Sand Equivalent Value of Soils and Fine Aggregate: Standard Test Method ForDocument10 pagesSand Equivalent Value of Soils and Fine Aggregate: Standard Test Method Formuqeem khan100% (2)

- Astm d4253Document15 pagesAstm d4253Ruddy EspejoNo ratings yet

- Astm C136-19Document5 pagesAstm C136-19bestoon RamadhanNo ratings yet

- Astm C490Document5 pagesAstm C490Horacio ApolayoNo ratings yet

- C566 PDFDocument3 pagesC566 PDFNaura RasyidaNo ratings yet

- Particle-Size Distribution (Gradation) of Soils Using Sieve AnalysisDocument34 pagesParticle-Size Distribution (Gradation) of Soils Using Sieve AnalysisJP SALDAÑANo ratings yet

- Particle-Size Distribution (Gradation) of Fine-Grained Soils Using The Sedimentation (Hydrometer) AnalysisDocument26 pagesParticle-Size Distribution (Gradation) of Fine-Grained Soils Using The Sedimentation (Hydrometer) Analysisjuan pablo100% (1)

- C1140 PDFDocument3 pagesC1140 PDFMyriam Carrera100% (2)

- Water Content of Soil and Rock in Place by Nuclear Methods (Shallow Depth)Document5 pagesWater Content of Soil and Rock in Place by Nuclear Methods (Shallow Depth)Brenda HVNo ratings yet

- Moisture Lnduced Damage: Resistance of Compactad Asphalt Mixture ToDocument8 pagesMoisture Lnduced Damage: Resistance of Compactad Asphalt Mixture ToGabith Quispe ApazaNo ratings yet

- Astm C702 C702M 11Document12 pagesAstm C702 C702M 11Jhaiiler ZlatanNo ratings yet

- Bulk Specific Gravity and Density of Non-Absorptive Compacted Asphalt MixturesDocument4 pagesBulk Specific Gravity and Density of Non-Absorptive Compacted Asphalt MixturesKev SantiagoNo ratings yet

- D76D76M-11 Standard Specification For Tensile Testing Machines For Textiles PDFDocument7 pagesD76D76M-11 Standard Specification For Tensile Testing Machines For Textiles PDFJAVIERNo ratings yet

- Uncompacted Void Content of Fine Aggregate (As Influenced by Particle Shape, Surface Texture, and Grading)Document5 pagesUncompacted Void Content of Fine Aggregate (As Influenced by Particle Shape, Surface Texture, and Grading)Oscar LopezNo ratings yet

- Astm D 4944Document4 pagesAstm D 4944Au C. GacotNo ratings yet

- ASTM D5821 - Standard Test Method For Determining The Percentage of Fractured Particles in Coarse AggregateDocument6 pagesASTM D5821 - Standard Test Method For Determining The Percentage of Fractured Particles in Coarse AggregateGG0% (1)

- Astm E11-13Document9 pagesAstm E11-13Ian Turgo Cabang BangNo ratings yet

- Astm D 6913Document34 pagesAstm D 6913safak kahramanNo ratings yet

- ASTM D6026 - Significant DigitsDocument5 pagesASTM D6026 - Significant Digitsrrb_92100% (1)

- C50 Standard Practice For Sampling, Sample Preparation, Packaging, and Marking of Lime and Limestone ProductsDocument9 pagesC50 Standard Practice For Sampling, Sample Preparation, Packaging, and Marking of Lime and Limestone ProductsEder Dávila100% (1)

- Astm D2726 - 10Document4 pagesAstm D2726 - 10Black GokuNo ratings yet

- Astm E11-13Document9 pagesAstm E11-13OmarMageedNo ratings yet

- Astm E11 - 13Document9 pagesAstm E11 - 13Ali Saleh Saad AL-isawiNo ratings yet

- E11-15 Standard Specification For Woven Wire Test Sieve Cloth and Test SievesDocument9 pagesE11-15 Standard Specification For Woven Wire Test Sieve Cloth and Test SievesJosé Luis Celis TejadaNo ratings yet

- Astm e 11 - 16Document11 pagesAstm e 11 - 16Mạnh XuânNo ratings yet

- E-Cld-6002 - Astm E11Document9 pagesE-Cld-6002 - Astm E11claudiaortizlozaNo ratings yet

- Astm E11 13 PDFDocument9 pagesAstm E11 13 PDFSyv Consultores Asociados100% (2)

- Astm E11Document9 pagesAstm E11Michel BohorquezNo ratings yet

- Woven Wire Test Sieve Cloth and Test Sieves: Standard Specification ForDocument12 pagesWoven Wire Test Sieve Cloth and Test Sieves: Standard Specification ForEliasTalaAllcaNo ratings yet

- Astm F 722 PDFDocument11 pagesAstm F 722 PDFIvan AlanizNo ratings yet

- Astm F 1545Document8 pagesAstm F 1545Ivan Alaniz100% (2)

- C014M PDFDocument4 pagesC014M PDFleo_pio_ochoaNo ratings yet

- A 0732 98 Fundicion Acero C & Aleado CoDocument6 pagesA 0732 98 Fundicion Acero C & Aleado CoIvan AlanizNo ratings yet

- Astm G 88 - 90Document5 pagesAstm G 88 - 90Ivan AlanizNo ratings yet

- A 0709 01 PL Estructural C & Hsla TempladaDocument8 pagesA 0709 01 PL Estructural C & Hsla TempladaIvan AlanizNo ratings yet

- Determining The Susceptibility of Stainless Steels and Related Nickel-Chromium-Iron Alloys To Stress-Corrosion Cracking in Polythionic AcidsDocument3 pagesDetermining The Susceptibility of Stainless Steels and Related Nickel-Chromium-Iron Alloys To Stress-Corrosion Cracking in Polythionic AcidsIvan AlanizNo ratings yet

- Astm F 1183Document4 pagesAstm F 1183Ivan AlanizNo ratings yet

- Astm G 88 PDFDocument27 pagesAstm G 88 PDFIvan AlanizNo ratings yet

- C13330 PDFDocument2 pagesC13330 PDFJose VasquezNo ratings yet

- Astm A 714 (1999) PDFDocument8 pagesAstm A 714 (1999) PDFnisha_khanNo ratings yet

- A 0734 97 PL Recipientes Aleado Hsla TempladaDocument2 pagesA 0734 97 PL Recipientes Aleado Hsla TempladaIvan AlanizNo ratings yet

- A 0723 99 Forja Acero Aleado Alta PresionDocument4 pagesA 0723 99 Forja Acero Aleado Alta PresionIvan AlanizNo ratings yet

- A 0703 01 Fundicion Acero Presion Requisitos GDocument14 pagesA 0703 01 Fundicion Acero Presion Requisitos GIvan AlanizNo ratings yet

- A 0841 01 PL Recipiente TMCPDocument6 pagesA 0841 01 PL Recipiente TMCPIvan AlanizNo ratings yet

- A 0841 01 PL Recipiente TMCPDocument6 pagesA 0841 01 PL Recipiente TMCPIvan AlanizNo ratings yet

- A833-1996-OCR-Standard Practice For Indentation Hardness of Metallic Materials by Comparison Hardness Testers PDFDocument2 pagesA833-1996-OCR-Standard Practice For Indentation Hardness of Metallic Materials by Comparison Hardness Testers PDFMohamed Ahmed MaherNo ratings yet

- A 0898 01 Inspeccion Ut Pulsoeco Perfil EstructuralDocument3 pagesA 0898 01 Inspeccion Ut Pulsoeco Perfil EstructuralIvan AlanizNo ratings yet

- A 0829 00 PL Acero Estructural AleadoDocument4 pagesA 0829 00 PL Acero Estructural AleadoIvan AlanizNo ratings yet

- A 0830 00 PL Estructural Acero X ComposicionDocument4 pagesA 0830 00 PL Estructural Acero X ComposicionIvan AlanizNo ratings yet

- A 0808 00 Acero Estructural Microa TenazDocument2 pagesA 0808 00 Acero Estructural Microa TenazIvan AlanizNo ratings yet

- A 0832 99 PL Recipiente CR Mo VDocument4 pagesA 0832 99 PL Recipiente CR Mo VIvan AlanizNo ratings yet

- A 0913 01 Perfil Estructural Hsla DuroDocument4 pagesA 0913 01 Perfil Estructural Hsla DuroIvan AlanizNo ratings yet

- A 0822 00 Tubin Acero C Sistema HidraulicoDocument3 pagesA 0822 00 Tubin Acero C Sistema HidraulicoIvan AlanizNo ratings yet

- A800-2001-OCR-Standard Practice For Steel Casting, Austenitic Alloy, Estimating Ferrite Content Thereof PDFDocument6 pagesA800-2001-OCR-Standard Practice For Steel Casting, Austenitic Alloy, Estimating Ferrite Content Thereof PDFMohamed Ahmed MaherNo ratings yet

- A 0941 01 Terminologia Aleacion Inoxidable FerroaDocument7 pagesA 0941 01 Terminologia Aleacion Inoxidable FerroaIvan AlanizNo ratings yet

- A 0815 01 Conexion Tuberia Inox PDFDocument7 pagesA 0815 01 Conexion Tuberia Inox PDFIvan AlanizNo ratings yet

- A 999 PDFDocument10 pagesA 999 PDFmilecsaNo ratings yet

- A 0967 01 Pasivacion Partes Acero InoxDocument7 pagesA 0967 01 Pasivacion Partes Acero InoxIvan AlanizNo ratings yet

- A 0945 00 PL Estructural Hsla Controlada SoldabilidadDocument3 pagesA 0945 00 PL Estructural Hsla Controlada SoldabilidadIvan AlanizNo ratings yet

- Asbestos Cement Pressure Pipes and Joints - Specification: Indian StandardDocument15 pagesAsbestos Cement Pressure Pipes and Joints - Specification: Indian StandardsuryatejaNo ratings yet

- Hypochloride Skid Punch List 27augDocument3 pagesHypochloride Skid Punch List 27augSiriepathi SeetharamanNo ratings yet

- Api 4 FDocument84 pagesApi 4 FDaniel Arturo Acosta AlvarezNo ratings yet

- HRSG Inspection ServicesDocument4 pagesHRSG Inspection Servicesvasilev_darkoNo ratings yet

- Crosshole Testing D6760-14.17145 PDFDocument7 pagesCrosshole Testing D6760-14.17145 PDFAndres100% (1)

- Atlas Machine & Supply, Inc Quality - ManualDocument26 pagesAtlas Machine & Supply, Inc Quality - ManualBo DoNo ratings yet

- Poster DIN EN 1090-1 ENG Final PDFDocument1 pagePoster DIN EN 1090-1 ENG Final PDFlth770310No ratings yet

- Production Control Plan 4111078Document10 pagesProduction Control Plan 4111078Yogesh PatilNo ratings yet

- Procurement of 07 Wellhead CompressorsDocument10 pagesProcurement of 07 Wellhead CompressorsMihirduttaNo ratings yet

- Wis 4 34 04 PDFDocument16 pagesWis 4 34 04 PDFNitinNo ratings yet

- Manual Arc Welding of Carbon Steel and AlloysDocument23 pagesManual Arc Welding of Carbon Steel and AlloysathulpcucekNo ratings yet

- Evidence PlanDocument7 pagesEvidence PlanJaypee AturoNo ratings yet

- Mechanical Engineer ResumeDocument17 pagesMechanical Engineer ResumegiasNo ratings yet

- Pipeline Tehnology Journal-1-2018 PDFDocument80 pagesPipeline Tehnology Journal-1-2018 PDFtaufiqsaidinNo ratings yet

- Charlte Hutchison Managing of Temporary Works Construction April 2018Document62 pagesCharlte Hutchison Managing of Temporary Works Construction April 2018Elsayed ElberryNo ratings yet

- Iec 61400 22 PDF FreeDocument59 pagesIec 61400 22 PDF FreeCliffordWellnerNo ratings yet

- WI-INSP-07 R2 Work Instruction-Inspection of PumpsDocument5 pagesWI-INSP-07 R2 Work Instruction-Inspection of PumpsRakesh MishraNo ratings yet

- 1 - REV Method Statement For Generator SetDocument13 pages1 - REV Method Statement For Generator SetAyda JohariNo ratings yet

- Steel Forgings Specification GuideDocument36 pagesSteel Forgings Specification GuidekarthiprojectsNo ratings yet

- Licensing Requirements for Concrete Testing Labs in MassachusettsDocument40 pagesLicensing Requirements for Concrete Testing Labs in MassachusettskghlkhglkghklNo ratings yet

- API 510 - Pressure Vessel Inspector Training - RINADocument3 pagesAPI 510 - Pressure Vessel Inspector Training - RINARajdeep SinghNo ratings yet

- Quality Assurance Manual For CpaDocument21 pagesQuality Assurance Manual For CpaJoan FranciscoNo ratings yet

- Checklist For SS TankDocument2 pagesChecklist For SS TankRanjan KumarNo ratings yet

- 28 - Hofmann - Trackpads Brochure - A4Document4 pages28 - Hofmann - Trackpads Brochure - A4Jorge Villalobos100% (1)

- Report WritingDocument6 pagesReport WritingPurushotham MPNo ratings yet

- Smart: NDE 4.0 in Manufacturing: Challenges and Opportunities For NDE in The 21st CenturyDocument10 pagesSmart: NDE 4.0 in Manufacturing: Challenges and Opportunities For NDE in The 21st CenturyHyujeii MceNo ratings yet

- Method Statement - GI ConduitDocument8 pagesMethod Statement - GI ConduitPrabhim NairNo ratings yet

- JGC Arabia LTD.: Drawin and Do UM NT Ransmi ADocument26 pagesJGC Arabia LTD.: Drawin and Do UM NT Ransmi AElezer BatchoNo ratings yet

- 52 Pac RBTDocument32 pages52 Pac RBTsoutrick BaruiNo ratings yet

- Title: Table of Contents Section: QM 0.1: Quality Manual As Per ICH GuidelinesDocument21 pagesTitle: Table of Contents Section: QM 0.1: Quality Manual As Per ICH GuidelinesbpharmbaNo ratings yet