Professional Documents

Culture Documents

Method Statement - Road Marking & Road Markers

Uploaded by

TAHER AMMARCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement - Road Marking & Road Markers

Uploaded by

TAHER AMMARCopyright:

Available Formats

METHOD STATEMENT

ROAD MARKING & ROAD MARKERS

Contents

1. Purpose

2. Scope of Work

3. Definitions

4. References

5. Materials & Tools

6. Plant & Equipment

7. HSSE

8. Prior Activities

9. Procedure

10.Responsibilities

TAHER AMMAR totytaher@yahoo.com Page 1

METHOD STATEMENT

1- Purpose

To ensure that all Road Marking and Signs are executed safely and in

accordance with the contract requirements and that all quality assurance/

control activities are conducted in a systematic manner, works are

inspected and conformance is verified and documented.

2- Scope of Work

a. This procedure is applicable to the following works associated with the

project.

b. This method statement outlines the procedures to be followed in

construction of Road Marking and Signs.

3- Definitions

CM Construction Manager

PE / SE Project Engineer / Site Engineer

CS Chief Surveyor

ITP Inspection Test Procedures

HSSE Heath ,Safety, Security, and Environmental

T.S. Technical Specifications

4- References

Contract – General &Special Conditions – BOQ – Approved Drawings –

Specifications - Shop drawings (Respectively).

Egyptian Code & British Standard (Otherwise Specified).

TAHER AMMAR totytaher@yahoo.com Page 2

METHOD STATEMENT

5- Materials & Tools

Warning tapes

Temporary signs

Safety Barriers

Traffic Cones

Grade Stakes

Road marking Paints (White and Yellow)

Soap Solution ( not detergent)

Cleaning Cloths, Roller Brushes, Paint Brushes, Permanent Tapes, fine

emery papers, etc.

6- Plant & Equipment

The major equipment used for this construction works includes, but are not

limits to the followings;

Pavement Marking Equipment

Process Monitoring Equipment

1. Portable environmental measuring devices for temperature

& humidity

2. Paint application rate computers

3. Electronic scales / bead bucket and stop watch for glass

bead application rate

4. Applicator speedometers, calibrated over range of

applicator speeds

5. Paint pressure and / or hydraulic/air pressure gauges

6. Wet film gauges

7. Bead application comparison plates.

TAHER AMMAR totytaher@yahoo.com Page 3

METHOD STATEMENT

Post-Application Measuring Equipment

1. Non-destructive eddy current device such as the Elcometer

and steel test plates for dry film thickness.

2. Retro reflectometers

3. Skid resistance testers.

7- HSSE

a. Approved safety plan procedures shall be strictly followed.

b. Where possible hazards may arise from filling activities, the necessary

safety measures will be taken to prevent accident or injury at all times.

This may include barriers, warning tape/ net, signage, watchman, and

proper lighting.

c. Where work upon existing services may be required, the necessary work

permits and safety equipment should be obtained prior to the activity

commencement.

d. HSSE officer will enforce that Personal Protective Equipment (such as

Respiratory mask, Safety Shoes, Face mask, Hard hats,,, etc.) be worn by

site personnel at all times during construction activities .

e. Prior to the commencement of any activities, the workforce will receive an

induction talk on the project site safety requirements. This induction talk

will include both activity safety issues, as well as general safety

requirements.

f. Safety engineer will ensure that Personal Protective Equipment is worn by

site personnel at all times during construction activities.

g. Plant and Equipment will be provided with back-up alarms, lights, and all

other applicable safety devices.

h. Proper access to the work area shall be maintained throughout the working

period.

TAHER AMMAR totytaher@yahoo.com Page 4

METHOD STATEMENT

8- Prior Activities

a. The Surveyor will locate and mark all Centerlines for all types .

b. Width and length for all types must be marked.

9- Procedure

A. Road Marking

1. Surfaces to be painted shall be prepared by removing

effervescence, chalk, dust, dirt, grease, oil and release agent and

roughening the surface with fine emery paper to remove glaze.

2. The Surveyor will locate and mark all main Outlines, Spots and

Coordinates for every type of marking and signs. These outlines

will be clearly marked using chalk lines and tapes.

3. Carefully mix and prepare paint materials in accordance with

manufacture direction.

4. Use suitable thinner approved by Paint manufacture and only

within recommended limits.

5. Using Roller Brush, a single coating of white color road marking

paint is applied on to the yellow rubber surface evenly.

6. While painting adjacent areas and installations shall be protected

by using of masking tape or other approved precautionary

measures.

7. When the white color paint is dried, a coat of Yellow Color road

marking paint is applied evenly on the top of the white surfaces.

8. When the single coat of Yellow Paint is dried, another final coat is

applied of Yellow Road Marking and let to dry.

9. Apply paint to an even and fine texture, leave no evidence of

rolling such as laps, irregularity in texture, skid marks.

10. Apply additional coat where under coats, stain or other condition

show in final coat.

TAHER AMMAR totytaher@yahoo.com Page 5

METHOD STATEMENT

B. Road Markers

1. Road markers are separate raised metallic or plastic or ceramic units fixed

on the road surface for the purpose of directing traffic according to the

required lane.

2. Apply a mass of material that is approximately three-quarters the size of

the stud to the hole.

3. When the typical stud application method is used, a stud is centered

2.54cm (1 inch) to 5.08cm (2 inches) above the road surface and dropped

onto the hole. With finger pressure only, the stud is pushed down to a

point where a slight bead.

4. The entire stud bottom should be supported by adhesive, and there should

be adhesive surrounding the stud. Be careful not to have excessive

adhesive in front of the stud.

5. The surface on which the lines or reflectors must be installed should be

clean and free from old markers or lines, and the surface must be dry and

free from any oils or lubricants. After ensuring the cleanliness of the

surface and its suitability for placing lines or markers, consistence of the

surface must be reviewed such that it must not be disintegrated or with

large cracks or any other defects which may minimize stability of the lines

or reflectors installed on it. Contractor must supply and install all the work

parts shown on the drawings of the special specifications with the

dimensions, machines and tools required for completing the works

according to requirements.

6. The markers must be fixed at the locations specified on the drawings such

that the distance between markers must not be less than half (0.5) meter

and not more than six (6) meters. For fixing units, holes are first must be

made on the asphalt after cleaning the whole surface, by a driller, the

diameter of the hole must be more than the reflector's stud diameter by

about two (2) to four (4) millimeters, and with a depth of more than the

length of the reflector stud by about two (2) to four (4) millimeters, after

TAHER AMMAR totytaher@yahoo.com Page 6

METHOD STATEMENT

that the hole is cleaned and filled with the adhesive used according to

manufacturer's recommendation. The reflectors are fixed by inserting the

fixing shaft to a depth of six (6) centimeters on the asphalt surface. The

fixing stud must be deformed or grooved to resist extraction.

7. The markers are fixed by an adhesive material composed of bituminous.

8. compound or epoxy resin manually mixed. The bituminous adhesive must

not contain rubber polymer, since the high temperature at cohesion may

lead to the adhesive disintegration. The compound must be tested and used

according to the manufacturer's recommendation. Adhesive must be

suitable for application in temperatures range between zero (0°C) to fifty

eight (85°C) degrees Celsius.

9. Equipment installing markers and lines must either be units mounted on

trucks or motor equipped units that the worker rides or manually driven

equipment according to the type of the markers or lines required.

Motorized units which are rode by the worker must be capable of working

in a speed not less than eight (8) Kilometer per hour, but the manual

equipment must be capable of maneuvering in such a way enough for

making the axes lines, lane lines, and side lines, and drawing triangular

pieces, turning lines, pedestrian lines, parking lines, arrows, symbols and

terms. All shapes and lines must be in compliance with the specifications.

10- Responsibilities

10.1 The CM will coordinate with PE / SE and ensure that the necessary

resources to implement the approved method statement and ITP have

been allocated to the task.

10.2 The PE / SE will ensure that the site preparation activities are conducted

according to the approved method statement and all in-situ tests

according to the ITP are implemented.

TAHER AMMAR totytaher@yahoo.com Page 7

METHOD STATEMENT

10.3 Quality Control Engineer will ensure that the materials being used are in

accordance to the project specifications, the approved method statement

and the ITP.

10.4 The HSSE officer along with his team will ensure implementation of all

HSSE procedures related to the nature of the works being carried out and

in accordance with the HSSE Plan.

10.5 The CS along with his team will ensure that all levels, coordinates and

stations are accordance with the approved drawings.

End of: Method Statement

ROAD MARKING & ROAD MARKERS

TAHER AMMAR totytaher@yahoo.com Page 8

You might also like

- Method Statement - ASPHALT CONCRETE WORKS PDFDocument10 pagesMethod Statement - ASPHALT CONCRETE WORKS PDFTAHER AMMAR100% (6)

- Road Markings SpecsDocument6 pagesRoad Markings SpecsMeFloth100% (1)

- Method Statement For Road MarkingDocument15 pagesMethod Statement For Road Markingeshwar75% (4)

- SHC 631 Submission of Revised Method Statement of Double Surface Dressing and Apply For Trial Section of Double Surface DressingDocument9 pagesSHC 631 Submission of Revised Method Statement of Double Surface Dressing and Apply For Trial Section of Double Surface DressingShekhar Mitra100% (1)

- Method Statement For AsphaltDocument10 pagesMethod Statement For AsphaltJer Fortz100% (3)

- T-4.196.224 Road MarkingDocument4 pagesT-4.196.224 Road MarkingYuvaraj PonrajNo ratings yet

- Method Statement Road ConstructionDocument12 pagesMethod Statement Road ConstructionMcDonald Wesley71% (7)

- Earthworks and road construction processesDocument5 pagesEarthworks and road construction processesmemekenya100% (3)

- 28 Ms For Asphalt Road WorksDocument16 pages28 Ms For Asphalt Road Worksprasath_subramanian97% (35)

- Method Statement For Road WorksDocument11 pagesMethod Statement For Road WorksArunKumar Chandrasekar100% (3)

- MS For Prime CoatDocument4 pagesMS For Prime CoatBalasubramanian Mahadevan100% (1)

- Method Statement-Road WorksDocument6 pagesMethod Statement-Road WorksahYing12078% (32)

- Method of Statement Road Drain RockDocument6 pagesMethod of Statement Road Drain RockAlister PangNo ratings yet

- Method Statement For Roadbase ConstructionDocument3 pagesMethod Statement For Roadbase ConstructionNordin Yunus93% (84)

- Method Statement For Road WorkDocument31 pagesMethod Statement For Road Workdinidu3priyankara3sa67% (3)

- Method of Statement For DBST Seal Coat UploadDocument10 pagesMethod of Statement For DBST Seal Coat UploadSandar100% (1)

- Method of Statement - Construction of Pipe CulvertsDocument18 pagesMethod of Statement - Construction of Pipe Culverts魏秦No ratings yet

- 203 - Roadway Excavation and Embankment (2012)Document12 pages203 - Roadway Excavation and Embankment (2012)lhikbaniNo ratings yet

- Method Statements of Road WorksDocument37 pagesMethod Statements of Road Workslmthunzi74% (43)

- Method Statement For Cement Stabilized SubbaseDocument9 pagesMethod Statement For Cement Stabilized Subbase石银雷0% (1)

- Gabion Construction Method StatementDocument3 pagesGabion Construction Method StatementIsaiah DongoNo ratings yet

- MOS For Road ConstructionDocument7 pagesMOS For Road ConstructionHussam WaleedNo ratings yet

- Method Statement For Asphalt Paving WorksDocument5 pagesMethod Statement For Asphalt Paving WorksGokulakrishnan Govindarajan100% (1)

- Method Statement Road ProjectDocument3 pagesMethod Statement Road ProjectMalitha Fernando67% (3)

- Method Statement For Drainage Work at VBC KG Titi Besi (CH 232457.551)Document7 pagesMethod Statement For Drainage Work at VBC KG Titi Besi (CH 232457.551)MAYMODERN STEELNo ratings yet

- Method Statement For Road and Paving WorkDocument32 pagesMethod Statement For Road and Paving WorkĐặng Quang Huy100% (7)

- Method Statement For Interlocking BlocksDocument3 pagesMethod Statement For Interlocking BlocksJaime Manalili LandinginNo ratings yet

- Method Statement For Construction For Sub-Base and Road Base WorksDocument20 pagesMethod Statement For Construction For Sub-Base and Road Base WorksBleep NewsNo ratings yet

- Method Statement For EarthworksDocument3 pagesMethod Statement For EarthworksNorendro KangjamNo ratings yet

- Double Seal Surface Treatment SummaryDocument4 pagesDouble Seal Surface Treatment Summarymemekenya100% (1)

- MS For Milling and Laying of Asphalt Wearing Course (60 70)Document19 pagesMS For Milling and Laying of Asphalt Wearing Course (60 70)RaheelHashmiNo ratings yet

- Ms-Road MarkingDocument7 pagesMs-Road Markingmoytabura9680% (5)

- Guardrail Installation ProcedureDocument5 pagesGuardrail Installation ProcedureThandabantu Magengelele50% (2)

- Method Statement For Roads WorksDocument39 pagesMethod Statement For Roads WorksAbdullahSharawiNo ratings yet

- Road and Parking Area Method StatementDocument22 pagesRoad and Parking Area Method StatementAmin KhanNo ratings yet

- Method Statement For Culvert ConstructionDocument2 pagesMethod Statement For Culvert ConstructionTAHER AMMAR100% (3)

- Method Statement-Hard Landscaping WorksDocument4 pagesMethod Statement-Hard Landscaping Worksbhupsjangir0% (1)

- Concrete Pavement Construction MethodDocument21 pagesConcrete Pavement Construction Methodjoshua Manggala100% (7)

- Method Statement For Concrete WorkDocument1 pageMethod Statement For Concrete WorkNo Green Blue100% (3)

- Method Statement Repair and Replacement of Road Asphalt Rev. 1Document12 pagesMethod Statement Repair and Replacement of Road Asphalt Rev. 1MG100% (3)

- Method Statement Sub Base & Road BaseDocument1 pageMethod Statement Sub Base & Road Basefyzalazry100% (3)

- Method Statement For Screeding WorksDocument5 pagesMethod Statement For Screeding WorksArunKumar Chandrasekar100% (2)

- Method Statement For Construction of EmbankmentDocument6 pagesMethod Statement For Construction of EmbankmentRabnawaz Imam100% (1)

- Programme of Works For Road WorksDocument2 pagesProgramme of Works For Road WorksEliphas Quabe IV50% (2)

- Method Statement Roadworks Acdc Lane-DraftDocument8 pagesMethod Statement Roadworks Acdc Lane-DraftDeqNo ratings yet

- Rigid Pavement MethodologyDocument3 pagesRigid Pavement MethodologyVibekananda MohantyNo ratings yet

- Concrete Works Method StatementDocument6 pagesConcrete Works Method StatementmemekenyaNo ratings yet

- Method Statement For Construction of Gabion ProtectionDocument18 pagesMethod Statement For Construction of Gabion Protectiondanilo m.sampaga95% (38)

- MMN Bina SDN BHD: Method Statement For Drainage WorksDocument6 pagesMMN Bina SDN BHD: Method Statement For Drainage WorksFosu DicksonNo ratings yet

- Maintenance of National Road No. 3 in CambodiaDocument20 pagesMaintenance of National Road No. 3 in Cambodiaroldski90% (10)

- Method of Statement For Interlocking Block and Curb StoneDocument4 pagesMethod of Statement For Interlocking Block and Curb StoneTAHER AMMAR100% (1)

- Method Statements For EarthworkDocument3 pagesMethod Statements For EarthworkBzy Bir Bikram Shrestha67% (3)

- Method Statement For EarthworksDocument4 pagesMethod Statement For EarthworksNur Ain98% (62)

- Method Statement For Construction of Road EmbankmentDocument9 pagesMethod Statement For Construction of Road EmbankmentAnonymous a3K3Wg100% (2)

- MS 158 - Method Statement For Sub-Grade Construction of Parallel RoadsDocument11 pagesMS 158 - Method Statement For Sub-Grade Construction of Parallel Roadsthushara100% (1)

- Method Statement For Road and Paving Works - Work ProcedureDocument20 pagesMethod Statement For Road and Paving Works - Work Procedurehysh890% (1)

- Method Statement - Road Marking & Road Markers: June 2018Document9 pagesMethod Statement - Road Marking & Road Markers: June 2018Ahmed GamalNo ratings yet

- Method Statement - Asphaltic Concrete Works: April 2018Document11 pagesMethod Statement - Asphaltic Concrete Works: April 2018Shahab Bashir KhanNo ratings yet

- Painting Procedure NG SystemsDocument6 pagesPainting Procedure NG SystemsTanveer Rajput EngrNo ratings yet

- Painting Methodology for Two-Storey BuildingDocument26 pagesPainting Methodology for Two-Storey BuildingFleight Vandollin0% (1)

- C29C29M (Bulk Density) PDFDocument4 pagesC29C29M (Bulk Density) PDFnickdash09No ratings yet

- ASTMDocument11 pagesASTMTAHER AMMARNo ratings yet

- Compressive Strength of Cylindrical Concrete Specimens: Standard Test Method ForDocument5 pagesCompressive Strength of Cylindrical Concrete Specimens: Standard Test Method ForHassan MokhtarNo ratings yet

- Making and Curing Concrete Test Specimens in The Field: Standard Practice ForDocument5 pagesMaking and Curing Concrete Test Specimens in The Field: Standard Practice ForHassan MokhtarNo ratings yet

- Gypsum Plasters: Standard Specification ForDocument4 pagesGypsum Plasters: Standard Specification ForGrato Jr SingcoNo ratings yet

- Scope of The Railway ProjectDocument35 pagesScope of The Railway ProjectTAHER AMMARNo ratings yet

- C22 PDFDocument2 pagesC22 PDFLW85100% (1)

- ASTM C40-04 Standard Test Method For Organic Impurities in Fine Aggregates For Concrete PDFDocument2 pagesASTM C40-04 Standard Test Method For Organic Impurities in Fine Aggregates For Concrete PDFmakhsmyNo ratings yet

- Technical Terms and ConditionsDocument42 pagesTechnical Terms and ConditionsTAHER AMMARNo ratings yet

- Astm C78Document3 pagesAstm C78avrajan100% (3)

- Astm C70Document3 pagesAstm C70avrajan100% (2)

- Astm C579Document2 pagesAstm C579Jony Gutiérrez AbantoNo ratings yet

- Technical SpecificationsDocument37 pagesTechnical SpecificationsTAHER AMMARNo ratings yet

- Dismantling of Existing RailwayDocument16 pagesDismantling of Existing RailwayTAHER AMMARNo ratings yet

- Maintenance StandardsDocument39 pagesMaintenance StandardsTAHER AMMARNo ratings yet

- Geodetic Reference SystemDocument8 pagesGeodetic Reference SystemTAHER AMMARNo ratings yet

- BS en 00933-6-2014Document26 pagesBS en 00933-6-2014TAHER AMMARNo ratings yet

- Contract Project PPPDocument44 pagesContract Project PPPTAHER AMMARNo ratings yet

- BS en 13231-1-2013Document34 pagesBS en 13231-1-2013TAHER AMMAR100% (3)

- B Técnicas FC - Anexo M - Sistema de Señalización y CTC English VersionDocument24 pagesB Técnicas FC - Anexo M - Sistema de Señalización y CTC English VersionZalfa AthallahNo ratings yet

- Construction Quality RequirementsDocument20 pagesConstruction Quality RequirementsTAHER AMMAR100% (2)

- BS en 00932-6-1999Document14 pagesBS en 00932-6-1999TAHER AMMARNo ratings yet

- BS - enDocument18 pagesBS - enTAHER AMMARNo ratings yet

- BS - enDocument22 pagesBS - enTAHER AMMARNo ratings yet

- Bs en 10346 2015 PDFDocument46 pagesBs en 10346 2015 PDFTito MuñozNo ratings yet

- BS - enDocument14 pagesBS - enTAHER AMMARNo ratings yet

- BS en 00933-5-1998 (2005)Document12 pagesBS en 00933-5-1998 (2005)TAHER AMMARNo ratings yet

- BS en 00932-3-1997 (2004)Document14 pagesBS en 00932-3-1997 (2004)TAHER AMMARNo ratings yet

- BS en 00933-1-2012Document22 pagesBS en 00933-1-2012TAHER AMMARNo ratings yet

- En 933 4 Flaskiness Shape PDFDocument14 pagesEn 933 4 Flaskiness Shape PDFracNo ratings yet

- Offices Summary GuidelinesDocument6 pagesOffices Summary GuidelinesGeorge StockburgerNo ratings yet

- 2.4 WP-XXX XX-XX PPE Policy (Final)Document5 pages2.4 WP-XXX XX-XX PPE Policy (Final)MarwotoNo ratings yet

- Oil Companies International Marine Forum Offshore Vessel Inspection Database (OVID)Document48 pagesOil Companies International Marine Forum Offshore Vessel Inspection Database (OVID)Norman SasongkoNo ratings yet

- Contact Center Services NC II AmendedDocument61 pagesContact Center Services NC II Amendedvictor50% (2)

- Acetic AnhydrideDocument8 pagesAcetic AnhydrideAsyraf SabriNo ratings yet

- Unit 002 Working Effective and Efficiently in An Engineering EnvironmentDocument3 pagesUnit 002 Working Effective and Efficiently in An Engineering EnvironmentThomas Brandon50% (2)

- Material Safety Data Sheet: 5-NitrovanillinDocument3 pagesMaterial Safety Data Sheet: 5-NitrovanillinjbarenasNo ratings yet

- MSDS - Diclean F-504-2Document4 pagesMSDS - Diclean F-504-2mariana100% (2)

- Molecular Sieves, 3A: Safety Data SheetDocument4 pagesMolecular Sieves, 3A: Safety Data SheetEmiZNo ratings yet

- Method Statement For Attending Fire Fighting Snag WorksDocument8 pagesMethod Statement For Attending Fire Fighting Snag Worksfawzar100% (1)

- Hilly Area ProcedureDocument59 pagesHilly Area ProcedurejohnNo ratings yet

- Humastar 200Document286 pagesHumastar 200Dinesh SreedharanNo ratings yet

- Commissioning Guidelines ION-IX Rev.1Document8 pagesCommissioning Guidelines ION-IX Rev.1Derick RoartyNo ratings yet

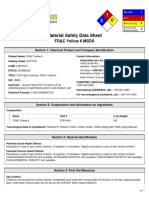

- FD&C Yellow 6 MSDS: Section 1: Chemical Product and Company IdentificationDocument5 pagesFD&C Yellow 6 MSDS: Section 1: Chemical Product and Company Identificationzubair1951No ratings yet

- Job Safety Analysis Foundation WorkDocument3 pagesJob Safety Analysis Foundation WorkMihirdutta75% (4)

- 0059 Lca Safety Inspection ChecklistDocument3 pages0059 Lca Safety Inspection ChecklistIvanna Celeste Duran RojasNo ratings yet

- Puzzle BookDocument109 pagesPuzzle BookFlorence ReidNo ratings yet

- JHA For Plumbing and Piping TradesDocument84 pagesJHA For Plumbing and Piping TradesKhurram Iqbal100% (2)

- VGO Safety Data SheetDocument7 pagesVGO Safety Data SheetMuhammad MasoodNo ratings yet

- (PPE) Awareness Training: Personal Protective EquipmentDocument11 pages(PPE) Awareness Training: Personal Protective EquipmentEmind Annamalai JPNagarNo ratings yet

- SSPL Polymers Technical Data Sheet for CRAY COAT 30-36 HVAC Duct Insulation CoatingDocument25 pagesSSPL Polymers Technical Data Sheet for CRAY COAT 30-36 HVAC Duct Insulation Coatingsmartayaz1987No ratings yet

- ALP Cultivator Users-GuideDocument27 pagesALP Cultivator Users-GuidePașala Mihai LucianNo ratings yet

- CG Aquaculture ExploratoryDocument7 pagesCG Aquaculture Exploratorymarilyn bristolNo ratings yet

- MOS For Hot Tapping Work PDFDocument20 pagesMOS For Hot Tapping Work PDFAho Chi- ShuenNo ratings yet

- 7 Global Golden Rules of Safety - Rule 7 - Vehicles, Mobile Equipment & Workplace - DraftDocument11 pages7 Global Golden Rules of Safety - Rule 7 - Vehicles, Mobile Equipment & Workplace - DraftPedro ViegasNo ratings yet

- K To 12 Commercial Cooking Techer's GuideDocument17 pagesK To 12 Commercial Cooking Techer's GuideHari Ng Sablay96% (27)

- 18CM0006 - Raik ConstructionDocument5 pages18CM0006 - Raik Constructionzab04148114No ratings yet

- Rashid Ullah HSE OfficerDocument3 pagesRashid Ullah HSE OfficerBilal Tahir GondalNo ratings yet

- Contractor Safety RequirementsDocument24 pagesContractor Safety RequirementseastNo ratings yet

- Safety in GSKDocument12 pagesSafety in GSKbaluchakpNo ratings yet