Professional Documents

Culture Documents

Technical Note No-02-A-Critical Steel Ratios in Concrete Structures

Uploaded by

HCStepOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Note No-02-A-Critical Steel Ratios in Concrete Structures

Uploaded by

HCStepCopyright:

Available Formats

Design Guidance Note

No. 2

Critical Steel Ratios for the Design of Reinforced Concrete Structures

Critical steel ratios should be used for the design of reinforced concrete elements that are subjected to high restraint, e.g. joint-

free construction or walls that are cast on large foundations. This paper describes the procedures for calculating critical steel

ratios. It highlights that these ratios are now approximately 3% to 6% higher than previous design guidance. It also stresses the

importance of controlling cracking due to restrained movement of mature concrete

CONTROL OF CRACKING BY REINFORCEMENT βcc and α are coefficients based on the age of concrete

Basic Principles Mature Concrete

Concrete tends to contract as its temperature drops from the The tensile strength of mature concrete is specified by EC22 as:

hydration peak to ambient. This contraction starts at early-age and

continues through to long-term. Shrinkage can also increase the fctm= 0.30(fck)0.67 for fck ≤ C50/60 (5a)

amount of contraction significantly. fctm= 2.12ln[1+(fck+8)/10] for fck > C50/60 (5b)

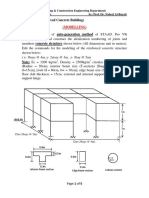

The basic principles for controlling cracking by reinforcement are where fctm = tensile strength of mature concrete

illustrated in Fig 1. If the concrete is restrained so that contraction fck = specified 28-day cylinder strength

cannot occur, tensile stress gradually builds up. When the tensile

stress exceeds the capacity of the concrete section, a crack occurs. CRITICAL STEEL RATIO

Movement at the crack relieves some of the stress but as the Probability of Cracking

contraction continues the stress also continues to build up. The

reinforcement will yield if it is weaker than the cracking force and all Uncontrolled cracking of concrete due to restrained movement can

future contraction movement will be concentrated at the crack. The result in wide cracks with serious structural implications. Therefore,

crackwidth will gradually increase with continued contraction (Fig 1a). the occurrence of this type of cracking should be designed to be

relatively improbable. The criterion suggested here is at least the

95% confidence limit, i.e., less than 1:20 failures.

Critical Steel Ratio for Early-Age Concrete

a. Too Little Reinforcement b. Enough Reinforcement

The early-age critical steel ratio, ρcrit, derived from Eqns (3) and (4)

Fig 1. Control of Cracking by Reinforcement1 is:

However, if the reinforcement is stronger than the cracking force, it ρcrit = fct,ea/fyk = 0.598fctm/fyk (6)

will remain elastic and a new crack will form at the next weakest

where fct,ea = early-age tensile strength of concrete

cross-section, as contraction increases. This process continues until

enough cracks have formed to absorb the total amount of contraction A full probability analysis, which accounts for variations in concrete

(Fig 1b). The cracking in the first model is uncontrolled, but it is tensile strength and the distribution of reinforcement yield strength, is

controlled in the second model. presented in C6603. The equation used in the C6603 analysis for the

concrete tensile strength is:

Fundamental Criteria

fct,ea = fct(3).kis.ks.ka (7)

The amount of reinforcement required to control cracking of concrete

2

is subject to two criteria, namely: where fct(3) = 3-day tensile strength in accordance with EC2

kis = factor for in-situ effects, including temperature rise

a. Controlling cracking by ensuring that the reinforcement does not

ks = factor for reduced tensile strength under sustained

yield and therefore distributes the cracks evenly.

loading

b. Limiting crackwidths to a specified value. ka = factor to allow for cracking at ages other than 3 days

Only the first criterion is discussed in this design guide. The The C6603 probability analysis shows that the values for critical steel

procedures for limiting crackwidths are described in a separate paper. ratios derived from Eqn (6) for early-age concrete are safe at

confidence levels better than 98%.

Control of Cracking by Reinforcement

Correction Factors for Mature Concrete

The ratio of reinforcement to control cracking can be derived from

first principles by making the strength of the reinforcement at least Alexander1 and C6603 suggest that a reduction factor of 0.8 be

equal to the strength of the concrete as follows: applied to fctm to allow for the reduction of concrete tensile strength

under sustained loading. The resulting critical steel ratio for mature

Reinforcement capacity, Fs= As.fs (1)

concrete derived from Eqns (3) and (5) is:

Uncracked concrete capacity, Fc= Ac.fct [1+ρ(αe –1)] (2)

ρ'crit = fct/fs = 0.8fctm/fyk (8)

Equating (1) and (2) and neglecting the term ρ(αe –1) as small gives,

Comparing the values derived from Eqn (8) with those derived from

As.fs = Ac.fct, which results in:

the full probability analysis presented in C6603 indicates that the Eqn

ρ = fct/fs (3) (8) values for mature concrete are safe at confidence levels better

than 98%.

where ρ = reinforcement ratio, As/Ac

fct = tensile strength of concrete DESIGN GUIDANCE

fs = yield strength of reinforcement

Critical Steel Ratios

αe = modular ratio

Values of the critical steel ratio for various concrete strengths derived

TENSILE STRENGTH OF CONCRETE

from Eqns (4) to (8) are shown in Table 1.

Early-Age Concrete

Design Process

The early-age (3-day) tensile strength, fct,ea, may be estimated from

The design process for elements subject to direct tension has been

Eqns (3.1) and (3.2) of EC22: namely:

consolidated into the flowchart shown in Fig 2. The flowchart shows

fct,ea = (βcc(t))α.fctm = 0.598fctm (4) that the risk of early-age cracking should be assessed first and once

this is proved to be satisfactory, then the risk of late-life cracking

where fctm = mean value of axial tensile strength of mature concrete should be assessed.

Hyder Consulting Page 1 of 3

PC File Ref: DesignGuidanceNoteNo-02-0A Issue 01: Jan-2007

Design Guidance Note No. 2 (contd)

Specified Strength Class, fck/fck,cube 28/35 35/45 40/50 50/60 60/75 70/85 80/95 90/105

Early-Age Tensile Strength, fct,ea = 0.592fctm 1.67 1.94 2.13 2.47 2.61 2.76 2.89 3.02

ρcrit = fct,ea/fyk 0.335% 0.389% 0.425% 0.494% 0.521% 0.552% 0.579% 0.604%

Late-Life Tensile Strength, fctm 2.80 3.25 3.55 4.13 4.35 4.61 4.84 5.04

ρ'crit = 0.8fctm/fyk 0.486% 0.565% 0.618% 0.717% 0.757% 0.802% 0.842% 0.877%

Table 1. Early-Age and Mature Concrete Tensile Strengths and Associated Critical Steel Ratios (better than 98% Fractiles)

Code requirements

Clients requirements Establish the requirements

• Durability

• Aesthetics for crack width

• Tightness class

Define allowable crack widths for

early age and long-term effects

Element

geometry Restraint

Assess the risk and

extent of early-age cracking

Concrete Casting

mix conditions

Cracking likely

Cracking

unlikely Check ρcrit using early-age tensile

Strength - increase if necessary

Crack width

Assess risk of

less than Calculate early-age crack width

late life cracking

specified

Crack width greater than specified

Check ρcrit using

late life tensile

Strength - increase Review options Review options

if necessary

Crack width OPTIONS

Calculate late

greater than

life crack width

specified Increase reinforcement

Reduce T1 by mix modification or cooling

Crack width

less than

Reduce αc and improve εctu by specification of

specified aggregate type

Reduce restraint by adjusting element size,

DESIGN pour sequence, movement joints

COMPLETE

Fig 2. Flowchart showing the Design Process for the Control of Early-Age and Late-Life Cracking in Concrete3

The key omission from current codes of practice or industry-standard 0.45%Ac ratio is generally thought to apply to structural tension

publications is where ρ is greater than ρcrit but less than ρ′crit. Then members such as hangers and not to members where the tensile

the cracks which were controlled for early-age contractions could stress arises from temperature or shrinkage contraction. Neither of

become uncontrolled for all further contraction movement. However, these ratios are related to the tensile strength of the concrete,

if ρ is greater than ρ′crit, new cracks form in addition to the original whereas Eqn (3) shows that it should be directly proportional to it.

ones and both old and new cracks are controlled. This omission

A comparison can also be made with the design of continuous

should be addressed by the publication of CIRIA Report C6603.

reinforced concrete pavements, for which the Highways Agency5

KEY QUESTIONS specifies 0.6% reinforcement in a single layer at the mid-depth. This

is similar to the critical steel ratio in Table 1 for typical UK concrete

The key questions raised by Alexander1 are summarised below.

strengths.

Are we misled by BS 8110?

Do We get a False Sense of Security from BS 8007?

In BS 81104, the only references to minimum reinforcement are

BS 80076 considers design to resist early-age contractions by using

0.13%bh in bending and 0.45%Ac in direct tension. The 0.13%bh

Eqn (3) to derive the critical steel ratio, with fy = 460 MPa, but it

ratio is significantly less than the Table 1 values. Furthermore, the

does not describe how the early-age tensile strength of concrete, fct,

Hyder Consulting Middle East Page 2 of 3

PC File Ref: DesignGuidanceNoteNo-02-0A Issue 01: Jan-2007

Design Guidance Note No. 2 (contd)

6

is established. However, for Grade 28/35 concrete, BS 8007 uses fct with uncontrolled cracking, but this may be due to the high ratios of

= 1.6 MPa, which leads to a critical steel ratio: steel provided to satisfy the 0.2 mm crackwidth criterion.

Nonetheless, it would be prudent to design for fck/fcu = 8/10 MPa

ρcrit = 1.6/460 = 0.35%

above the specified value to allow for mean strengths achieved on

The early-age analysis, based on Eqn (6), results in percentages in site.

the third row of Table 1 which are similar to BS 80076. However, the

A NEW DESIGN PHILOSOPHY?

analysis for mature concrete results in Table 1 values that are

approximately 40% higher than 80076. There is no new design philosophy. The Hyder approach in the

Middle East remains unchanged. This approach is to provide the

BS 80076 is written for reservoirs, i.e., tanks full of water.

minimum concrete thickness needed for satisfactory structural

Consequently, there should be small temperature variations and little

performance at ultimate limit state - the 250 mm thickness from BS

long-term shrinkage, indeed there is often long-term expansion due

81026 is usually a reasonable guess for basement walls. Crack

to the presence of water. It is assumed implicitly in BS80076 that

control reinforcement in accordance with this design guide should

subsequent contractions will be less than the relief of early-age

then be provided. Critical steel ratios are obtained from the third row

contractions by creep. The important behaviour of mature concrete

of Table 1 if early-age contractions are restrained or the fifth row if

in piled raft foundations, basements and similar structures is

the mature concrete will be restrained.

therefore ignored.

DESIGN GUIDANCE

Poor Guidance for Basements and Similar Structures?

Use the EC22 equations as modified below:

In the UK, British Standards 80076, 81027 and 81104 all contribute

relevant material, but even so piled raft foundations; basements and a. Calculate the early-age critical steel ratio, ρcrit, from Eqn (6):

similar structures are not properly covered. In particular, the

ρcrit = 0.598fctm/fyk (6)

importance of considering contraction in mature concrete is ignored.

Industry guides such as CIRIA reports 918 and 1399 similarly miss b. Calculate the late-life critical steel ratio, ρ'crit, from Eqn (8):

this important point. The minimum percentages of reinforcement in

ρ'crit = 0.8fctm/fyk (8)

mature concrete are shown in the fifth row of Table 1. It is evident

that they are much higher than current general practice. c. Design for concrete strengths fck/fcu = 8/10 MPa above the

specified value to allow for mean strengths achieved on site.

Good News from EC2?

REFERENCES

Clause 7.3.2 of EC22 includes a provision for minimum

reinforcement, “if crack control is required”. It presents a formula 1. Alexander, A J, ‘Why does our concrete still crack and leak?’, The

which reduces to Eqn (3) for rectangular sections in direct tension. Structural Engineer, 84, No 23/24, 5 Dec 2006

The full probability analysis presented in C6603 demonstrates that 2. EC2, EN 1992-1-1, ‘Eurocode 2 Design of concrete structures

critical steel ratios derived from Eqns (6) and (8) are safe at Part 1: General rules and rules for buildings’, British Standards

confidence levels better than 98% for early-age movements and Institution, 2004

late-life movements. Consequently, the EC22 equations are safe, 3. C660, ‘Early-age thermal crack control in concrete’, Report C660,

although Eqn (8) shows that EC22 may overestimate the critical steel Construction Industry Research and Information Association,

ratio for mature concrete by 25%, if the 0.8 reduction factor for Draft of report to be published Feb 2007

sustained loading is not used. 4. BS 8110-1, ‘Structural use of concrete, Part 1 Code of practice

for design and construction’, British Standards Institution, 1997

Why are Anderson’s1 Steel Ratios High?

5. ‘Design manual for roads and bridges’, V7, section 2, part 3,

The critical steel ratios derived by Anderson1 are approximately 28% notes on figure 2.5, Highways Agency

higher than those shown in Table 1. Anderson1 increases the 6. BS 8007, ‘Design of concrete structures for retaining aqueous

concrete tensile strength to change the value from mean to 95% liquids’, British Standards Institution, 1987

fractile. However, he neglects the reduction in concrete tensile 7. BS 8102, ‘Code of practice for protection of structures against

strength under sustained loading. C6602 suggests that a reduction water from the ground’, British Standards Institution, 1990

factor, ks = 0.8, be used for sustained loading for early-age 8. CIRIA 91, ‘Early-age thermal crack control in concrete (revised

movements. It also suggests that this be reduced to 0.6 for late-life edition)’, Report 91, Construction Industry Research and

movements. The lack of commensurate reduction factors in Information Association, 1992

Anderson’s1 paper probably explains the higher critical steel ratios. 9. CIRIA 139, ‘Water-resisting basement construction: a guide’,

Report 139, Construction Industry Research and Information

Do We have Problems with Current Hyder Designs?

Association, 1995

Current Hyder design practice is based on Eqn (3) using yield

strength, fy = 460 MPa, and the following equation for the early-age REVISION HISTORY

strength: Issue Description By Date

0.7

fct,ea= 0.12(fcu) (9)

A comparison between current Hyder practice and Table 1 indicates

that the Hyder values are 3-6% lower than those suggested in Table 0A Draft for comment AGMF Jan 2007

1. However, it appears that the 0.2 mm crackwidth design criterion

has resulted in steel ratios that are similar to those stipulated in

Table 1.

For example, the steel ratios provided for Grade 35/45 concrete for

Dubai Festival City vary from 0.47% for areas of low strain to 0.60-

0.90% for areas of high strain. This indicates that there should be

few problems associated with existing Hyder designs that use the

0.2 mm crackwidth criterion. Furthermore, in the Middle East, early-

age movements tend to dominate. The early-age load combination,

(high) contraction/(low) fct,ea, usually exceeds the late-life load

combination, (relatively low) contraction/(high) fctm.

Should We Design for a Maximum Concrete Strength?

Average compressive strength on site tends to be 8/10 MPa above

the specified minimum. This suggests that an upper limit should be

used for crack-control design. Table 1 indicates that the minimum

reinforcement ratio will be underestimated if the compressive

strength is too high. However, Hyder have had few problems to date

Hyder Consulting Middle East Page 3 of 3

PC File Ref: DesignGuidanceNoteNo-02-0A Issue 01: Jan-2007

You might also like

- Fatigue of Concrete Under Uniaxial Compression Cyclic LoadingDocument7 pagesFatigue of Concrete Under Uniaxial Compression Cyclic LoadingHCStepNo ratings yet

- Rio Tinto Standard DetailsDocument34 pagesRio Tinto Standard DetailsHCStepNo ratings yet

- Diff Equation 2 2011-Fall TheoryDocument48 pagesDiff Equation 2 2011-Fall TheoryAna CristacheNo ratings yet

- Slab Deflections: ST George Wharf Case StudyDocument3 pagesSlab Deflections: ST George Wharf Case StudyHayyan JarboueNo ratings yet

- Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002: (Draft Amendment No. 1 To IS 16700)Document6 pagesManak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002: (Draft Amendment No. 1 To IS 16700)Keyur Patel100% (1)

- Stiffness Modifiers As Per Is Code-Etabs ApplicationDocument2 pagesStiffness Modifiers As Per Is Code-Etabs ApplicationDjaber Boulaam100% (1)

- CVEN444-Dr. E. Sandt-StructuralConcreteDocument1,775 pagesCVEN444-Dr. E. Sandt-StructuralConcreteHero Djoni SNo ratings yet

- Analysis and Design of RC Tall Building Subjected To Wind and EarthquakeDocument10 pagesAnalysis and Design of RC Tall Building Subjected To Wind and EarthquakeAHSAN HABIB100% (1)

- IS1893 Lecture1Document41 pagesIS1893 Lecture1G.RameshNo ratings yet

- Effect of Backstay On 3B+G+20 Storey RC BuildingDocument5 pagesEffect of Backstay On 3B+G+20 Storey RC Buildingdharashah28No ratings yet

- Why Steel Reinforcement Is Needed in Concrete SlabsDocument2 pagesWhy Steel Reinforcement Is Needed in Concrete SlabsAuYongTheanSengNo ratings yet

- Analysis of G+30 Highrise Buildings by Using Etabs For Various Frame Sections in ZoneIV and ZoneV PDFDocument15 pagesAnalysis of G+30 Highrise Buildings by Using Etabs For Various Frame Sections in ZoneIV and ZoneV PDFK.ANISHNo ratings yet

- Backstay EffectDocument2 pagesBackstay EffectCHarlesghylonNo ratings yet

- FC-WCJ-18016-CSW6ST101-001 Cal - PDFDocument205 pagesFC-WCJ-18016-CSW6ST101-001 Cal - PDFSaravanan SKNo ratings yet

- Practical Application of Finite Element Analysis To The Design of Post-Tensioned and Reinforced Concrete FloorsDocument104 pagesPractical Application of Finite Element Analysis To The Design of Post-Tensioned and Reinforced Concrete FloorsSalam FaithNo ratings yet

- Residential Morcellement at Mon TresorDocument104 pagesResidential Morcellement at Mon TresorYannick HowNo ratings yet

- v375 Ebook Ebook Download Reinforced Concrete Structures Analysis and Design by David FanellaDocument7 pagesv375 Ebook Ebook Download Reinforced Concrete Structures Analysis and Design by David FanellaGandhi HammoudNo ratings yet

- Effect of Cracking On Corrosion of Steel in Concrete PDFDocument12 pagesEffect of Cracking On Corrosion of Steel in Concrete PDFSteve NolaNo ratings yet

- FanellaDocument4 pagesFanellamendoncajam100% (1)

- Staircase DesignDocument13 pagesStaircase DesignAbelbelachewNo ratings yet

- Unit No 3: Design of Reinforced Concrete SlabDocument29 pagesUnit No 3: Design of Reinforced Concrete SlabMapanguriSitoeNo ratings yet

- CV Sajoyan Haque Inditex Arup Nec CuetDocument2 pagesCV Sajoyan Haque Inditex Arup Nec CuetSajoyan HaqueNo ratings yet

- Ghid de Calcul Presiune Beton in CofrajeDocument59 pagesGhid de Calcul Presiune Beton in CofrajeArziv EstoNo ratings yet

- Monitoring Methods of Concrete From Early Age Strength Gain of Concrete A ReviewDocument8 pagesMonitoring Methods of Concrete From Early Age Strength Gain of Concrete A ReviewAmit Sharma IPS AcademyNo ratings yet

- Residential Bearing Wall Removal: What Is A Bearing Wall and What Does It Do?Document7 pagesResidential Bearing Wall Removal: What Is A Bearing Wall and What Does It Do?Hussein JaberNo ratings yet

- Responsibility For Controlling Slab CurlingDocument1 pageResponsibility For Controlling Slab CurlingProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNo ratings yet

- Ask The Engineer Proper Bedding For PVC Pressure PipeDocument5 pagesAsk The Engineer Proper Bedding For PVC Pressure PipeUnibellNo ratings yet

- Vertical Extensions Technical Challenges and Carbon ImpactDocument4 pagesVertical Extensions Technical Challenges and Carbon ImpactMyo Min ThuNo ratings yet

- Design of High-Rise Reinforced Concrete BuildingDocument142 pagesDesign of High-Rise Reinforced Concrete Buildingsk m hassanNo ratings yet

- List of Queries:: A Few General Queries On SAP2000/ETABS/SAFEDocument48 pagesList of Queries:: A Few General Queries On SAP2000/ETABS/SAFERohan Polekar100% (1)

- IS1893 Lecture7Document29 pagesIS1893 Lecture7ksshashidharNo ratings yet

- BPG Rationalising Flat SlabDocument4 pagesBPG Rationalising Flat SlabAlf HorsemanNo ratings yet

- 134 - As Struck Finishes PDFDocument2 pages134 - As Struck Finishes PDFJonathan KeoughNo ratings yet

- 2018-04-05 Structural Design Basis - R1 PDFDocument16 pages2018-04-05 Structural Design Basis - R1 PDFkiranNo ratings yet

- Stress-Strain Relationship For Reinforced Concrete in TensionDocument8 pagesStress-Strain Relationship For Reinforced Concrete in TensionManprit SinghNo ratings yet

- Shear Wall ModellingDocument42 pagesShear Wall ModellingGopalAdhikariNo ratings yet

- Experimental Study of Pervious ConcreteDocument7 pagesExperimental Study of Pervious ConcreteIJAERS JOURNALNo ratings yet

- Analysis and Design of Shear Wall With Various Openings CriteriaDocument5 pagesAnalysis and Design of Shear Wall With Various Openings CriteriaEditor IJTSRDNo ratings yet

- Chun Wo - Technical Note 005Document3 pagesChun Wo - Technical Note 005Paul KwongNo ratings yet

- Reinforced Concrete Building, Modelling, Analysis and Design by Staad-Pro (Example 3) by Prof. Dr. Nabeel Al-BayatiDocument5 pagesReinforced Concrete Building, Modelling, Analysis and Design by Staad-Pro (Example 3) by Prof. Dr. Nabeel Al-BayatiProfessor Dr. Nabeel Al-Bayati-Consultant Engineer50% (2)

- Earthquake Tips: Learning Earthquake Design and ConstructionDocument55 pagesEarthquake Tips: Learning Earthquake Design and ConstructionanikenskyywalkerNo ratings yet

- Dynamic Analysis of Multistoreyed Frame Shear Wall Building Considering SSIDocument50 pagesDynamic Analysis of Multistoreyed Frame Shear Wall Building Considering SSIEditor IJTSRD100% (1)

- ISE Technical Note 001Document1 pageISE Technical Note 001AlexZaNo ratings yet

- Specifications For Fills To Support Building FoundationsDocument5 pagesSpecifications For Fills To Support Building FoundationspnNo ratings yet

- S Kempton 1955Document18 pagesS Kempton 1955Paulo Vinícius MartinsNo ratings yet

- EQTip Full IITK PDFDocument71 pagesEQTip Full IITK PDFPooja100% (1)

- 1977-01 Pages 30-37 PDFDocument8 pages1977-01 Pages 30-37 PDFsamNo ratings yet

- Geotechnical Soil Property CorrelationsDocument4 pagesGeotechnical Soil Property CorrelationsmikeengineeringNo ratings yet

- LysmerDocument147 pagesLysmerHans OlmosNo ratings yet

- Use of Expanded Polystyrene in Road EmbankmentsDocument6 pagesUse of Expanded Polystyrene in Road EmbankmentsmikadituNo ratings yet

- High-Strength Concrete Columns: State of The Art: Repor Ted by Joint ACI-ASCE Committee 441Document13 pagesHigh-Strength Concrete Columns: State of The Art: Repor Ted by Joint ACI-ASCE Committee 441DIDIER ANGEL LOPEZ RINCONNo ratings yet

- Basic Pile Group BeahviourDocument160 pagesBasic Pile Group BeahviourSimon EdwardsNo ratings yet

- Analysis - ofBareFrame and Infilled Frame PDFDocument6 pagesAnalysis - ofBareFrame and Infilled Frame PDFagustinussetNo ratings yet

- 82 72Document8 pages82 72Chetan B ArkasaliNo ratings yet

- Expansion Joint - Technical Paper 2Document4 pagesExpansion Joint - Technical Paper 2Charles Orebola OresanwoNo ratings yet

- CFD Is 456 2000Document85 pagesCFD Is 456 2000Angel VargasNo ratings yet

- Unit 14 Design of Slender ColumnsDocument32 pagesUnit 14 Design of Slender ColumnsSh Jvon Sh JvonNo ratings yet

- Seismic Response Reduction Factor Evaluation For Irregular RC Structures IJERTV8IS010114Document5 pagesSeismic Response Reduction Factor Evaluation For Irregular RC Structures IJERTV8IS010114pandurang kadamNo ratings yet

- Probabilistic service life model of RC structures subjected to the combined effect of chloride-induced corrosion and cyclic loadingFrom EverandProbabilistic service life model of RC structures subjected to the combined effect of chloride-induced corrosion and cyclic loadingNo ratings yet

- A Correlation Study of Methods of Matrix Structural Analysis: Report to the 14th Meeting, Structures and Materials Panel Advisory Group for Aeronautical Research and Development, NATO, Paris, France, July 6, 1962From EverandA Correlation Study of Methods of Matrix Structural Analysis: Report to the 14th Meeting, Structures and Materials Panel Advisory Group for Aeronautical Research and Development, NATO, Paris, France, July 6, 1962Rating: 5 out of 5 stars5/5 (1)

- Design Wind Speed Maps For The CaribbeanDocument55 pagesDesign Wind Speed Maps For The CaribbeanHCStepNo ratings yet

- Natural Frequencies of Toroidal TanksDocument27 pagesNatural Frequencies of Toroidal TanksHCStepNo ratings yet

- Safety in Pressure TestingDocument14 pagesSafety in Pressure TestingHCStepNo ratings yet

- Maurer Tuned Mass and Viscous Dampers: Technical Information and ProductsDocument29 pagesMaurer Tuned Mass and Viscous Dampers: Technical Information and ProductsHCStepNo ratings yet

- Den Hartog Galloping Criterion Revisited A Non Classical CaseDocument4 pagesDen Hartog Galloping Criterion Revisited A Non Classical CaseHCStepNo ratings yet

- Aerodynamic Loads On Tall Buildings: Interactive DatabaseDocument11 pagesAerodynamic Loads On Tall Buildings: Interactive DatabaseHCStepNo ratings yet

- HFFB Vs HFPI ASCE Structures Congress May 18-21 2006 St. Louis Missouri USA 633 PDFDocument10 pagesHFFB Vs HFPI ASCE Structures Congress May 18-21 2006 St. Louis Missouri USA 633 PDFHCStepNo ratings yet

- Dynamic Watertightness Tests For Curtain WallingDocument4 pagesDynamic Watertightness Tests For Curtain WallingHCStepNo ratings yet

- Hilti CoringDocument32 pagesHilti CoringHCStepNo ratings yet

- CALCULATION of ACTUAL Concrete Shrinkage PCIA Journal ArticleDocument5 pagesCALCULATION of ACTUAL Concrete Shrinkage PCIA Journal ArticleHCStepNo ratings yet

- UFC Design of Building To Resist Progressive Collapse PDFDocument245 pagesUFC Design of Building To Resist Progressive Collapse PDFHCStepNo ratings yet

- Moses Mabhida Stadium PDFDocument4 pagesMoses Mabhida Stadium PDFHCStepNo ratings yet

- Quantum-ProblemSet 2Document5 pagesQuantum-ProblemSet 2Krishanu ChatterjeeNo ratings yet

- PatentDocument29 pagesPatentAbner BaltazarNo ratings yet

- WEG Regulador de Tensao Grt7 Th4 10040217 Manual Portugues BRDocument50 pagesWEG Regulador de Tensao Grt7 Th4 10040217 Manual Portugues BRJuan I. Meza Lozano100% (1)

- The Key To Predicting Emulsion Stability - Solid ContentDocument8 pagesThe Key To Predicting Emulsion Stability - Solid ContentLAURA CATALINA CARDENAS RODRIGUEZNo ratings yet

- Prof - I M - Idriss PDFDocument21 pagesProf - I M - Idriss PDFindahzzNo ratings yet

- Competency Test: Revision WorkshopDocument20 pagesCompetency Test: Revision Workshopapi-247132748No ratings yet

- Unit ConversionDocument21 pagesUnit ConversioninsidereaderNo ratings yet

- Chapter 8: Beam Analysis and Cross SectionsDocument17 pagesChapter 8: Beam Analysis and Cross SectionsShital ChaudhariNo ratings yet

- Quest For Zero-Point Energy: Engineering Principles For "Free Energy"Document5 pagesQuest For Zero-Point Energy: Engineering Principles For "Free Energy"Manish ShahNo ratings yet

- Vojt Ech Pleskot: Doctoral ThesisDocument116 pagesVojt Ech Pleskot: Doctoral ThesisMarina RotaruNo ratings yet

- CLAB1Document4 pagesCLAB1Mohammed GowharNo ratings yet

- Lecture 7 and 8 Transients and Control SystemDocument38 pagesLecture 7 and 8 Transients and Control SystemRaisul Haque RahatNo ratings yet

- Hydraulic Spring Stiffness Testing Machine: Nagre N.P., Bhosale M.S., Prof. Patil S.CDocument5 pagesHydraulic Spring Stiffness Testing Machine: Nagre N.P., Bhosale M.S., Prof. Patil S.CShivam MishraNo ratings yet

- X-Strata980: Rapid, Non-Destructive Coating Thickness Measurement and Elemental AnalysisDocument4 pagesX-Strata980: Rapid, Non-Destructive Coating Thickness Measurement and Elemental Analysisdejavu77No ratings yet

- Navier Stokes PDFDocument22 pagesNavier Stokes PDFKhirupasagar RavibaskarNo ratings yet

- Scaffolded and Highly Scaffolded Experimental Report For The Hydrogen Pop TestDocument4 pagesScaffolded and Highly Scaffolded Experimental Report For The Hydrogen Pop Testapi-326410597No ratings yet

- P Delta EffectDocument2 pagesP Delta EffectManjari ArasadaNo ratings yet

- Entropy and Free EnergyDocument7 pagesEntropy and Free EnergyNikka LopezNo ratings yet

- Introduction To Fuzzy SetsDocument26 pagesIntroduction To Fuzzy SetsAkshat SapraNo ratings yet

- Jarkko Kari - Cellular Automata: TutorialDocument294 pagesJarkko Kari - Cellular Automata: TutorialldkgfdNo ratings yet

- Waterfront Seismic Survey ReportDocument39 pagesWaterfront Seismic Survey ReportVis CharoonvisNo ratings yet

- Petrophysics Overview RMBDocument11 pagesPetrophysics Overview RMBwandaNo ratings yet

- Neuman and MorgensternDocument32 pagesNeuman and Morgensternvadim3108No ratings yet

- Time Current SelectivityDocument13 pagesTime Current SelectivityvodnjanacNo ratings yet

- ConclusionDocument4 pagesConclusionS Karan NagarNo ratings yet

- Fho5000 Series OtdrDocument12 pagesFho5000 Series OtdrRodolfo Victor Barrios CastilloNo ratings yet

- FLUENT - Tutorial - VOF - Horizontal Film BoilingDocument16 pagesFLUENT - Tutorial - VOF - Horizontal Film BoilingBrilliand Tegar VerlambangNo ratings yet

- Industrial Training at Traco Cables Company Limited: Cochin University College of Engineering KUTTANADU-637215Document30 pagesIndustrial Training at Traco Cables Company Limited: Cochin University College of Engineering KUTTANADU-637215Zain MughalNo ratings yet

- Corrosion Measurement Techniques in Steel ReinforcedDocument15 pagesCorrosion Measurement Techniques in Steel ReinforcedVidhun RavindranNo ratings yet