Professional Documents

Culture Documents

6 MF f485 Handout

Uploaded by

PranavSharmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6 MF f485 Handout

Uploaded by

PranavSharmaCopyright:

Available Formats

INSTRUCTION DIVISION

SECOND SEMESTER 2017-2018

COURSE HANDOUT (PART-II)

Date: 05/01/2018

In addition to Part-I (General Handout for all courses appended to the timetable), this portion

gives further specific details regarding the course.

Course Code : MF F485

Name of the Course : Sustainable Manufacturing

Instructor-In-Charge : PHANEENDRA KIRAN CHAGANTI

I. Scope and Objective of the Course

Growing awareness and concerns about climate change, energy security and natural resource

scarcity led by the rapid expansion of economic activity in the last two decades have put

government and business under immense pressure to optimize the natural resources, to increase

use of renewable energy and recycled material and to reduce the environmental effects involved

in the production and consumption of goods and services. The primary objective of this course is

to provide environmental, economical and social perspective of manufacturing processes,

systems and tooling including material, energy and toxicity analysis during the various phases of

product life cycle. A multidisciplinary approach will be undertaken. Collection and analysis of

real world data from industry will be encouraged.

II. Textbook

Required material will be supplied during lecture hours.

III. Reference books

1. D. Dornfeld (ed.), Green Manufacturing: Fundamentals and Applications, Springer, New

York, 2013.

2. Wen LI(ed), Efficiency of manufacturing process: Energy and Ecological perspective,

Springer, Australia, 2015.

3. David T Allen & David R Shonnard, Sustainable engineering, Pearson, India, 2015.

4. J Paulo Davim, Sustainable Manufacturing, Wiley, UK, 2010

5. Rob Thompson, Sustainable Materials, process and production, Thames & Hudson, 2013.

IV. Contents

Topic Learning Objective Number

of

Lectures

1. Introduction Overview, WEEE, triple bottom concept of environment, 2

economy and society

2. Sustainable manufacturing Driver and barriers to sustainable manufacturing, SM 5

stakeholders

implementation factors

3. Sustainable manufacturing Eco-innovation, design for environment, design for 5

design disposal, design for energy efficiency, design for material

efficiency, sustainable materials, sustainable energy

4. Sustainable practices and 5

Recycling, remanufacturing, reuse, resource efficiency,

matrices energy efficiency in machine tools and process chains

Strategic and operational evaluation of technologies using 5

5. Life cycle management

life cycle concept, MET analysis, environmental impact

and assessment assessment, various impact assessment models, life cycle

costing

5

6. End of life (EOL)

End-of-life strategies and product definition, reverse

strategies logistics, recycle, reuse and remanufacture

7. Sustainability framework 3

Elements and relationship

8. Sustainable business 4

Integrated product policy, sustainable product service

models systems, green factories

9 Waste minimizations 5

Lean and green, waste categorization, waste reduction

Case studies and practice on 3

Umberto

42

Total

V. Evaluation scheme and schedule

EC Component Duration Weightage Date, time Nature

NO (%)

1 Mid Exam 90min 30 9/3 CB

11.00-12.30PM

2 Seminar//Case study 20 OB

(Each chapter-

9components)

3 Project 10 OB

4 Comprehensive Exam 3hr 40 10/05 AN CB

V. Chamber consultation hour: To be announced in the class

VI. Notices concerning the course: All notices concerning the course will be displayed on CMS

notice board only

VII. Makeup Policy: Makeup will be permitted only in genuine medical cases with prior

permission.

Instructor-In Charge

MF F485

You might also like

- Sustainability and Green Life ENG3415 - Syllabus - MAS - NLH (60 Credit Version) 7-10-2015Document4 pagesSustainability and Green Life ENG3415 - Syllabus - MAS - NLH (60 Credit Version) 7-10-2015smithson JoeNo ratings yet

- Concepts and Applications in Sustainability CourseDocument2 pagesConcepts and Applications in Sustainability CourseNavneetNo ratings yet

- Environmentalcourse OutlineDocument8 pagesEnvironmentalcourse Outlinefikadubiruk87No ratings yet

- Chapter 1 EIADocument86 pagesChapter 1 EIAMUHAMMAD LUQMAN IZZUDDIN BIN SUHAIMINo ratings yet

- Issues, Challenges and Prospects of Sustainable ConsumptionDocument232 pagesIssues, Challenges and Prospects of Sustainable ConsumptionKrutika GoyalNo ratings yet

- NothingDocument5 pagesNothingisahhhNo ratings yet

- CSF CHME461 - Powder Technology - 2023Document6 pagesCSF CHME461 - Powder Technology - 2023Azamat ToktarovNo ratings yet

- Ifma S Sustainability Course TocDocument6 pagesIfma S Sustainability Course TocAbu Jamal Mohd FirdausNo ratings yet

- Managerial Economics Course HandoutDocument3 pagesManagerial Economics Course HandoutADITYA JAMAN VAGHASIANo ratings yet

- Plant Utilities and Maintenance CPB 20004 Prolog. Karte 00: Mohd Syazwan B Mohd GhazaliDocument10 pagesPlant Utilities and Maintenance CPB 20004 Prolog. Karte 00: Mohd Syazwan B Mohd GhazaliAdam BukhariNo ratings yet

- Clinical Restorations Course Prepares Dentistry StudentsDocument24 pagesClinical Restorations Course Prepares Dentistry StudentsDweenArt YoutubeNo ratings yet

- Course Produce Post Harvest ManagementDocument281 pagesCourse Produce Post Harvest ManagementAddisuNo ratings yet

- CHM222 Course CompactDocument3 pagesCHM222 Course CompactGlory UsoroNo ratings yet

- Scope and Sequence COST 2Document5 pagesScope and Sequence COST 2Earl Russell S PaulicanNo ratings yet

- Course Guide: RICS School of Built EnvironmentDocument11 pagesCourse Guide: RICS School of Built EnvironmentAjit SinghNo ratings yet

- KTEE401 Microeconomics 2 - 09 Aug 2018Document13 pagesKTEE401 Microeconomics 2 - 09 Aug 2018Văn Duy BùiNo ratings yet

- Instructional Manual in EA1 Introduction To Agricultural and Biosystems EngineeringDocument20 pagesInstructional Manual in EA1 Introduction To Agricultural and Biosystems EngineeringJohn Mark MalabananNo ratings yet

- Pharmaceutical EngineeringDocument7 pagesPharmaceutical EngineeringsalahNo ratings yet

- Maintenance Management - Course Outline (4) (AutoRecovered)Document3 pagesMaintenance Management - Course Outline (4) (AutoRecovered)Raju SainiNo ratings yet

- Sustainable Practices in Built Environment Course GuideDocument12 pagesSustainable Practices in Built Environment Course GuideAnkit GuptaNo ratings yet

- T6 Course Specifications GS400 New VersionDocument10 pagesT6 Course Specifications GS400 New Versionbachour58No ratings yet

- Assignment HandoutDocument9 pagesAssignment Handoutmrunali.donodeNo ratings yet

- Pollution Control and Effluent Treatment 03602267: Unit I Basics of Environmental PollutionDocument4 pagesPollution Control and Effluent Treatment 03602267: Unit I Basics of Environmental PollutionSMIT CHRISTIANNo ratings yet

- MANF 5317 Maintenance of Machinery Lecture NotesDocument76 pagesMANF 5317 Maintenance of Machinery Lecture Notesrobel metikuNo ratings yet

- Lab ModuleDocument92 pagesLab ModuleRajan SinnathambyNo ratings yet

- Natural Resource and Environmental EconomicsDocument2 pagesNatural Resource and Environmental EconomicsBereket AdmasuNo ratings yet

- 6092 Pure Chemistry Syllabus For O Level Exams in 2023Document34 pages6092 Pure Chemistry Syllabus For O Level Exams in 2023YU WEINo ratings yet

- Course Outlines PGD Chemistry EntrepreneurshipDocument17 pagesCourse Outlines PGD Chemistry EntrepreneurshipShahir AshuNo ratings yet

- Third MVE GuidebookDocument3 pagesThird MVE GuidebookmuhaNo ratings yet

- Sustainability Part 2 - UMDocument43 pagesSustainability Part 2 - UMJared AngNo ratings yet

- Course Outline For Analytical Chemistry3Document4 pagesCourse Outline For Analytical Chemistry3Ernest Kwabena AnointedNo ratings yet

- Renewable Energy CourseDocument6 pagesRenewable Energy CourseShj OunNo ratings yet

- MEE106: Manufacturing Processes and Plant Visits SyllabusDocument65 pagesMEE106: Manufacturing Processes and Plant Visits SyllabusRenante Dela Cruz BudomoNo ratings yet

- Industrial Pharmacy Course OverviewDocument21 pagesIndustrial Pharmacy Course Overviewhamam salih badriNo ratings yet

- - EET2011 Cơ sở quản lý năng lượng - Principles of Energy ManagementDocument5 pages- EET2011 Cơ sở quản lý năng lượng - Principles of Energy ManagementNam LeeNo ratings yet

- Annex 2 University of Mauritius Module CatalogueDocument4 pagesAnnex 2 University of Mauritius Module CatalogueDstormNo ratings yet

- General Chemistry ModuleDocument367 pagesGeneral Chemistry ModuleBirhaanu TolesaNo ratings yet

- 1. Learning Guide#24 HANT01A1Optom 2024Document58 pages1. Learning Guide#24 HANT01A1Optom 2024molotopotsoNo ratings yet

- Onboarding Session Learning Facilitators SUSTAINABILITY Session 1-2Document36 pagesOnboarding Session Learning Facilitators SUSTAINABILITY Session 1-2Fabian ChahinNo ratings yet

- Muhey PHD F2012Document287 pagesMuhey PHD F2012Kecil JosephNo ratings yet

- 2022 - ME - COURSE PACK (2022) - ReviewDocument19 pages2022 - ME - COURSE PACK (2022) - ReviewNatasha DassNo ratings yet

- Risk Management ModulesDocument25 pagesRisk Management ModulesDamian WayneNo ratings yet

- Env StudiesDocument11 pagesEnv StudiesArun NesamNo ratings yet

- CP 104 Module 1Document22 pagesCP 104 Module 1Vimbee Cefre Alipoon EresuelaNo ratings yet

- Course GuideDocument148 pagesCourse GuideEyob BezabehNo ratings yet

- AGRI 104 Module 1Document32 pagesAGRI 104 Module 1Vimbee Cefre Alipoon EresuelaNo ratings yet

- CET-0112.1-Chem-for-Engrs-Lab 2023 EditedDocument4 pagesCET-0112.1-Chem-for-Engrs-Lab 2023 EditedAxel Rose EvangelistaNo ratings yet

- Bernd Wagner, Stefan Enzler Material Flow Management Improving Cost Efficiency and Environmental Performance Sustainability and Innovation 2005Document212 pagesBernd Wagner, Stefan Enzler Material Flow Management Improving Cost Efficiency and Environmental Performance Sustainability and Innovation 2005Nader SalehiNo ratings yet

- Aec 403Document81 pagesAec 403Yahaya AdamuNo ratings yet

- Course Guide: RICS School of Built EnvironmentDocument11 pagesCourse Guide: RICS School of Built EnvironmentAnkit GuptaNo ratings yet

- L6 Sustainable Farming in The Environment 01092020Document4 pagesL6 Sustainable Farming in The Environment 01092020Eimear ReillyNo ratings yet

- S205 SA132 Industrial SanitationDocument3 pagesS205 SA132 Industrial Sanitationgerson floresNo ratings yet

- Asset Maintenance ManagementDocument92 pagesAsset Maintenance ManagementNanthini100% (1)

- CHEM108 BSEE S1 AY2324 - SyllabusDocument6 pagesCHEM108 BSEE S1 AY2324 - Syllabuszhao YingingNo ratings yet

- Course Outline: International Islamic University MalaysiaDocument6 pagesCourse Outline: International Islamic University MalaysiajojkoknoNo ratings yet

- 2009 Biology SyllabusDocument44 pages2009 Biology SyllabusImiosaNo ratings yet

- ECON101.602 Spring 2023 - Syllabus - Aamina AjazDocument5 pagesECON101.602 Spring 2023 - Syllabus - Aamina AjazAdam MahfouzNo ratings yet

- Life-Cycle Assessment of BiorefineriesFrom EverandLife-Cycle Assessment of BiorefineriesEdgard GnansounouNo ratings yet

- Ecosystem and Territorial Resilience: A Geoprospective ApproachFrom EverandEcosystem and Territorial Resilience: A Geoprospective ApproachEmmanuel GarbolinoNo ratings yet

- Intensification of Sorption Processes: Active and Passive MechanismsFrom EverandIntensification of Sorption Processes: Active and Passive MechanismsNo ratings yet

- Tybms Sem 5 CCPRDocument45 pagesTybms Sem 5 CCPROswin DsouzaNo ratings yet

- The Structural Engineer - August 2022 UPDATEDDocument36 pagesThe Structural Engineer - August 2022 UPDATEDES100% (1)

- Form-Q - Application For Quarry PermitDocument1 pageForm-Q - Application For Quarry PermitDebasish PradhanNo ratings yet

- BBEK4203 Principles of MacroeconomicsDocument20 pagesBBEK4203 Principles of MacroeconomicskiranaomomNo ratings yet

- E Studio 167Document26 pagesE Studio 167GabiNo ratings yet

- Domestic Ro Price List 2021Document6 pagesDomestic Ro Price List 2021den oneNo ratings yet

- الصراع التنظيمي وأثره...Document25 pagesالصراع التنظيمي وأثره...mohmod moohNo ratings yet

- Resume of Thomas Qiao SAP FICO (5yrs Version 4.7) : ProfileDocument3 pagesResume of Thomas Qiao SAP FICO (5yrs Version 4.7) : ProfileVenkata AraveetiNo ratings yet

- Natural DyeDocument21 pagesNatural Dyesanjay shettiNo ratings yet

- Communicating Corporate Social Responsibility: Perspectives and PracticeDocument26 pagesCommunicating Corporate Social Responsibility: Perspectives and PracticeAndiMuhammadIrwanNo ratings yet

- MasterCard Approves PAX Card ReaderDocument2 pagesMasterCard Approves PAX Card ReaderThinakaran RajamoorthiNo ratings yet

- Philippines Islands Judiciary Torrens System Title in Rem - BLP FoundationDocument2 pagesPhilippines Islands Judiciary Torrens System Title in Rem - BLP FoundationBLP CooperativeNo ratings yet

- MU - NACELLESURCAMION - ANG - E07.07 htb180Document73 pagesMU - NACELLESURCAMION - ANG - E07.07 htb180Marcin RombalskiNo ratings yet

- Knowledge Mgmt in BPO: Capturing & Sharing Valuable InsightsDocument3 pagesKnowledge Mgmt in BPO: Capturing & Sharing Valuable InsightsameetdegreatNo ratings yet

- BREAKING NEWS ROCKS SMALL TOWNDocument119 pagesBREAKING NEWS ROCKS SMALL TOWNКостя НеклюдовNo ratings yet

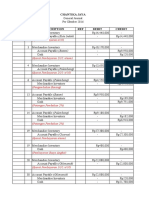

- PT Amar Sejahtera General LedgerDocument6 pagesPT Amar Sejahtera General LedgerRiska GintingNo ratings yet

- Integrated Farming System: A ReviewDocument12 pagesIntegrated Farming System: A ReviewIndian Journal of Veterinary and Animal Sciences RNo ratings yet

- To Revision of DDPMAS-2002: Centre For Military Airworthiness and Certification (CEMILAC)Document11 pagesTo Revision of DDPMAS-2002: Centre For Military Airworthiness and Certification (CEMILAC)Jatinder Singh100% (1)

- Municipal Tax Dispute Over Petroleum Refinery in PilillaDocument5 pagesMunicipal Tax Dispute Over Petroleum Refinery in PilillaDaphne Jade Estandarte PanesNo ratings yet

- Panasonic Th-42pd50u Chassis Gp8duDocument147 pagesPanasonic Th-42pd50u Chassis Gp8du02ury05No ratings yet

- China Identity Verification (FANTASY TECH)Document265 pagesChina Identity Verification (FANTASY TECH)Kamal Uddin100% (1)

- 2390A Series Spectrum AnalyzersDocument6 pages2390A Series Spectrum AnalyzersElizabeth FaulknerNo ratings yet

- Stare DecisisDocument7 pagesStare DecisisBirolal Jamatia100% (1)

- Impact of Digitalisation Online FinalDocument72 pagesImpact of Digitalisation Online FinalBanon KekeNo ratings yet

- PDF-6.2 The Pressurized Water ReactorDocument35 pagesPDF-6.2 The Pressurized Water ReactorJohn W HollandNo ratings yet

- Appendix 27 - CASH RECEIPTS REGISTERDocument1 pageAppendix 27 - CASH RECEIPTS REGISTERPau PerezNo ratings yet

- Dr. Mian Ashfaq Ali: Mechanical Vibrations ME-421Document14 pagesDr. Mian Ashfaq Ali: Mechanical Vibrations ME-421Talha MohsinNo ratings yet

- Ahmad Hassan Textile MillsDocument52 pagesAhmad Hassan Textile Millsmakymakymaky007100% (4)

- Banking Fundamentals QuizDocument5 pagesBanking Fundamentals QuizPhương Nghi LêNo ratings yet

- Dr. Shakuntala Misra National Rehabilitation University: Lucknow Faculty of LawDocument9 pagesDr. Shakuntala Misra National Rehabilitation University: Lucknow Faculty of LawVimal SinghNo ratings yet