Professional Documents

Culture Documents

Diesel Cycle

Uploaded by

Astrid Aisya0 ratings0% found this document useful (0 votes)

22 views16 pagesDC

Copyright

© © All Rights Reserved

Available Formats

ODP, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDC

Copyright:

© All Rights Reserved

Available Formats

Download as ODP, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views16 pagesDiesel Cycle

Uploaded by

Astrid AisyaDC

Copyright:

© All Rights Reserved

Available Formats

Download as ODP, PDF, TXT or read online from Scribd

You are on page 1of 16

Four-stroke cycle

Two- Stroke Cycle

THEORETICAL HEAT CYCLE

PRACTICAL CYCLES

Indicator Diagram

THERMAL EFFICIENCY

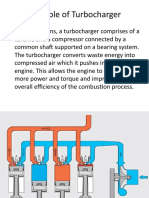

Exhaust gas turbocharging

arrangement

Fuel injection

INJECTION AND COMBUSTION

● Although the pressure in the cylinder at this point is likely to be

anything up to 200 bar, the fuel pressure at the atomizer will

be of the order of 1300–1800 bar.

● In the early days of airless injection many ingenious varieties

of combustion chamber were used, sometimes mainly to

reduce noise or smoke, or to ease starting; but often in part to

reduce, or to use modest, injection and combustion pressures.

Direct and Indirect Injection

Direct Injection

● Direct injection is what it says it is: the fuel is delivered directly

into a single combustion chamber formed in the cylinder space

atomization being achieved as the fuel issues from small drillings

in the nozzle tip.

● In the direct injection engine the fuel/air mixing is achieved by the

energy in the fuel spray propelling the droplets into the hot, dense

air. Additional mixing may be achieved by the orderly movement

of the air in the combustion chamber, which is called ‘air swirl’.

● Naturally aspirated engines usually have a degree of swirl and an

injection pressure of around 800 bar. Highly turbocharged engines

with four-valve heads have virtually no swirl, but have an injection

pressure of 1200–1800 bar to provide the mixing energy.

High Pressure, Noise, vibrate

Indirect Injection

● indirect injection is exploited, some high speed engines retain

a pre-chamber in the cylinder head into which fuel is injected

as a relatively coarse spray at low pressure, sometimes using

a single hole. Combustion is initiated in the pre-chamber, the

burning gases issuing through the throat of the chamber to act

on the piston.

● Fuel/air mixing is achieved by a very high air velocity in the

chamber, the air movement scouring the walls of the chamber

and promoting good heat transfer. Thus the wall can be very

hot-requiring heat resistant materials—but it can also absorb

too much heat from the air in the initial compression strokes

during starting and prevent ignition

poor starting, glow plugs

combination of the two systems

One engine designer, SEMT-Pielstick, achieved an

ingenious combination of the two systems by dividing the

pre-chamber between cylinder head and piston crown. At

TDC a stud on the piston enters the pre-chamber to provide

a restricted outlet. On the expansion stroke the restriction is

automatically removed and fuel economy comparable with

normal direct injection engines is attainable

INJECTOR

PUMP

Timing

You might also like

- TurbochargerDocument17 pagesTurbochargerAravindhRaj100% (1)

- 03 Principle of TurbochargerDocument19 pages03 Principle of TurbochargerSky RNo ratings yet

- Turbo Charger - ProjectDocument36 pagesTurbo Charger - ProjectSam Sams100% (2)

- Turbocharger Basics - What is a TurbochargerDocument18 pagesTurbocharger Basics - What is a TurbochargerShrwan Gyawali100% (3)

- Crude Oil Tank Mixer Data SheetDocument3 pagesCrude Oil Tank Mixer Data Sheetsiska bedegul100% (1)

- Turbocharger and Supercharger 2Document36 pagesTurbocharger and Supercharger 2shoaibNo ratings yet

- The Quest For 4th Generation Nuclear WeaponsDocument236 pagesThe Quest For 4th Generation Nuclear Weaponsgpduf100% (1)

- 4 Stroke Petrol EngineDocument11 pages4 Stroke Petrol EngineAnkit Joshi50% (4)

- Comparison of Diesel and Petrol EnginesFrom EverandComparison of Diesel and Petrol EnginesRating: 2.5 out of 5 stars2.5/5 (3)

- Four-Stroke, Four Cylinder Diesel Engine: BY Shubham Kulshrestha Atul Yadav Irfan KhanDocument27 pagesFour-Stroke, Four Cylinder Diesel Engine: BY Shubham Kulshrestha Atul Yadav Irfan KhanShubham Kulshrestha100% (1)

- Katzung Questions PDFDocument29 pagesKatzung Questions PDFChristian Solis100% (1)

- Combustion Chambers in CI EnginesDocument24 pagesCombustion Chambers in CI EnginesKLUniveristy100% (2)

- FM-23-85 60mm Mortar M19 1967Document174 pagesFM-23-85 60mm Mortar M19 1967rigal849No ratings yet

- Charge Air System by P.KDocument28 pagesCharge Air System by P.Kkr_abhijeet72356587100% (1)

- Turbochargers, Final Report of The SeminarDocument19 pagesTurbochargers, Final Report of The SeminarMuddukrishna C Shetty91% (22)

- Boiler BurnersDocument8 pagesBoiler BurnersAnoop VijayakumarNo ratings yet

- Diesel Engine and Steam BoilerDocument0 pagesDiesel Engine and Steam BoilerChathuranga ManukulaNo ratings yet

- Anthony F Molland - Stephen R Turnock - Dominic A Hudson-Ship Resistance and Propulsion - Practical Estimation of Ship Propulsive Power-Cambridge University Press (2011)Document563 pagesAnthony F Molland - Stephen R Turnock - Dominic A Hudson-Ship Resistance and Propulsion - Practical Estimation of Ship Propulsive Power-Cambridge University Press (2011)ghanbari8668100% (1)

- CH CH CH - CH CL CL N N: PolymerizationDocument40 pagesCH CH CH - CH CL CL N N: PolymerizationAkash YadavNo ratings yet

- Wartsila TurbochargerDocument51 pagesWartsila TurbochargerSambath kumarNo ratings yet

- Ship Manual Km-LabobarDocument262 pagesShip Manual Km-LabobarAstrid AisyaNo ratings yet

- Catalogo Herramientas CaterpillarDocument112 pagesCatalogo Herramientas CaterpillarJorge Perez100% (2)

- Intake ProcessDocument9 pagesIntake ProcessHizanorhuda ZurghibaNo ratings yet

- Camera Di CombustioneDocument29 pagesCamera Di CombustioneAsif S KhanNo ratings yet

- All Ablut Glowplugs BERUDocument16 pagesAll Ablut Glowplugs BERURoman AdamNo ratings yet

- Internal Combustion EngineDocument7 pagesInternal Combustion EngineLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLNo ratings yet

- TurbochargingDocument11 pagesTurbochargingtiamiyusefiu95No ratings yet

- Turbochargers: BY: Muddukrishna C Shetty USN:4AL08ME023Document25 pagesTurbochargers: BY: Muddukrishna C Shetty USN:4AL08ME023Vinod SubramaniamNo ratings yet

- Operating PrincipleDocument6 pagesOperating PrincipleGedan CristianNo ratings yet

- UNIT 1aiceDocument54 pagesUNIT 1aicemanikandanNo ratings yet

- Indirect Injection: ComponentsDocument6 pagesIndirect Injection: Components9966299828No ratings yet

- IC AssignmentDocument43 pagesIC AssignmentBoppudNo ratings yet

- Intercooler - WikipediaDocument6 pagesIntercooler - Wikipediashapoor_pouladiNo ratings yet

- Module 2 IcegtDocument26 pagesModule 2 IcegtHimanshuNo ratings yet

- 001 Turbo ChargerDocument26 pages001 Turbo ChargerfrankNo ratings yet

- IC Engines IIDocument57 pagesIC Engines IISahil SINGHNo ratings yet

- Bacem Laporan Combustion EngineDocument38 pagesBacem Laporan Combustion EngineRizky FajarNo ratings yet

- What Is Stratified Charge Engine?Document18 pagesWhat Is Stratified Charge Engine?ÅBin PÅulNo ratings yet

- Unit 1 B Ic EnginesDocument47 pagesUnit 1 B Ic Enginesoliyad teferiNo ratings yet

- Solution of Sheet 1 ICEDocument4 pagesSolution of Sheet 1 ICEMahmoud NaderNo ratings yet

- Sheet 1 ICEDocument5 pagesSheet 1 ICEHoàng LongNo ratings yet

- 1diesel Fuel SystemDocument40 pages1diesel Fuel SystemeyobNo ratings yet

- Wollo University: Kombolcha Institute of Technology Mechanical Engineering DepartmentDocument6 pagesWollo University: Kombolcha Institute of Technology Mechanical Engineering DepartmentMelie BackNo ratings yet

- Wollo University: Kombolcha Institute of Technology Mechanical Engineering DepartmentDocument6 pagesWollo University: Kombolcha Institute of Technology Mechanical Engineering DepartmentMeleseNo ratings yet

- Wollo University: Kombolcha Institute of Technology Mechanical Engineering DepartmentDocument6 pagesWollo University: Kombolcha Institute of Technology Mechanical Engineering DepartmentMelie BackNo ratings yet

- Performance Analysis and Fabrication On A Turbocharger in Two Stroke Single Cylinder Petrol EngineDocument8 pagesPerformance Analysis and Fabrication On A Turbocharger in Two Stroke Single Cylinder Petrol Engineashan19800217No ratings yet

- Final ReportDocument42 pagesFinal ReportNimish PandeNo ratings yet

- HowATurboWorks PDFDocument5 pagesHowATurboWorks PDFNikhil KanojiNo ratings yet

- GTE Combustion ChamberDocument33 pagesGTE Combustion ChamberTAMILSELVAM NALLUSAMYNo ratings yet

- Combustion chambers in CI and SI enginesDocument10 pagesCombustion chambers in CI and SI enginesAshutosh KumarNo ratings yet

- Turbo ChargerDocument13 pagesTurbo ChargerSwaraj TodankarNo ratings yet

- GDI Stratified Charge Engine 1Document9 pagesGDI Stratified Charge Engine 1Jasdeep SandhuNo ratings yet

- DEFSModule 1 Preview PagesDocument9 pagesDEFSModule 1 Preview PageshumbuNo ratings yet

- Unit II - Turbo Super ChargerDocument14 pagesUnit II - Turbo Super ChargerdrkbalaNo ratings yet

- Combustion in Compression-Ignition Engines: R. Adhitya Gugan (08M130) Rohan Bayan (08M133)Document16 pagesCombustion in Compression-Ignition Engines: R. Adhitya Gugan (08M130) Rohan Bayan (08M133)Adhitya Gugan RaviNo ratings yet

- Himanshu Singh Turbocharger-SeminarDocument20 pagesHimanshu Singh Turbocharger-SeminarHimanshu SinghNo ratings yet

- Turbo Charger AND Performance of I.C. EnginesDocument22 pagesTurbo Charger AND Performance of I.C. EnginesTejas UpadhyeNo ratings yet

- Me 56Document9 pagesMe 56RhizhailNo ratings yet

- Study On Thermal Storage From Exhaust of A Diesel EngineDocument38 pagesStudy On Thermal Storage From Exhaust of A Diesel EngineHimanshu SharmaNo ratings yet

- Reciprocating Engines Section BDocument45 pagesReciprocating Engines Section BJuly TadeNo ratings yet

- EngineDocument35 pagesEnginesarah rashaNo ratings yet

- Spark PlugsDocument6 pagesSpark PlugsJC PinoNo ratings yet

- Combustion in Ci EngineDocument38 pagesCombustion in Ci EngineAnamul HaqueNo ratings yet

- Stratified Charge Engine Tech An Cal PaperDocument18 pagesStratified Charge Engine Tech An Cal PaperVikas Kr Gupta100% (1)

- Gas Turbines: Working of An Open Cycle Single Stage Gas TurbineDocument5 pagesGas Turbines: Working of An Open Cycle Single Stage Gas TurbineGerald ValenzuelaNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Teknik Permesinan Kapal Ii: Jurusan Teknik Sistem Perkapalan ITS SurabayaDocument20 pagesTeknik Permesinan Kapal Ii: Jurusan Teknik Sistem Perkapalan ITS Surabayahemsladyvsky9164No ratings yet

- 2017OfficialBasketballRules Final (YellowBlueversion)Document90 pages2017OfficialBasketballRules Final (YellowBlueversion)JayNo ratings yet

- 6.3 RedoxDocument11 pages6.3 RedoxJosceline YeohNo ratings yet

- Physics I ProblemsDocument1 pagePhysics I ProblemsbosschellenNo ratings yet

- How Microprocessors Are Manufactured PDFDocument2 pagesHow Microprocessors Are Manufactured PDFdanielconstantin4No ratings yet

- Cold Formed Steel Design.Document8 pagesCold Formed Steel Design.Shivaji SarvadeNo ratings yet

- Spray Nozzles Total STDDocument3 pagesSpray Nozzles Total STDDylan RamasamyNo ratings yet

- Antioxidant Enzyme EvaluationDocument14 pagesAntioxidant Enzyme EvaluationArpit JainNo ratings yet

- Development of A Projectile Penetration Theory. Report 1Document101 pagesDevelopment of A Projectile Penetration Theory. Report 1yararaNo ratings yet

- Anderson Greenwood Series 60 andDocument48 pagesAnderson Greenwood Series 60 andjairo moralesNo ratings yet

- QSonic Brochure 209Document12 pagesQSonic Brochure 209Anish DonaldNo ratings yet

- MSDS Lasco Underbody CoatDocument5 pagesMSDS Lasco Underbody CoatMarshall TerreceNo ratings yet

- 1 02 Coco PDFDocument13 pages1 02 Coco PDFsandeep lalNo ratings yet

- FIITJEE ALL INDIA TEST SERIES FULL TEST – XI PHYSICS ANSWERS AND SOLUTIONSDocument19 pagesFIITJEE ALL INDIA TEST SERIES FULL TEST – XI PHYSICS ANSWERS AND SOLUTIONSVoxNo ratings yet

- Reforming 2Document15 pagesReforming 2HAFIZ IMRAN AKHTERNo ratings yet

- The Effect of Open Area On Sieve Tray Performance: T. YanagiDocument24 pagesThe Effect of Open Area On Sieve Tray Performance: T. Yanagifumanchu@fastmail.fmNo ratings yet

- ISC Class 12 Chemistry Practical SyllabusDocument3 pagesISC Class 12 Chemistry Practical SyllabusmaniksinghmehraNo ratings yet

- A-3 LM Sol (Pulley)Document28 pagesA-3 LM Sol (Pulley)rockingjoeNo ratings yet

- MSDS - Robond L-330 - ISS130910Document7 pagesMSDS - Robond L-330 - ISS130910Anonymous pXU4tefJNo ratings yet

- Hardsurfacing HandbookDocument24 pagesHardsurfacing HandbookscribdphinNo ratings yet

- Especificacion Tecnica Tanques FRP CANATUREDocument3 pagesEspecificacion Tecnica Tanques FRP CANATURETomasae1980No ratings yet

- Interactive Textbook 5 PDF Elelments 3 1Document5 pagesInteractive Textbook 5 PDF Elelments 3 1api-240094705No ratings yet

- Device Fabrication Technology: Modern Semiconductor Devices For Integrated Circuits (C. Hu) Slide 3-1Document40 pagesDevice Fabrication Technology: Modern Semiconductor Devices For Integrated Circuits (C. Hu) Slide 3-1EASACOLLEGENo ratings yet

- Solomons Frsolomons-Fryhlesyhles Organic Chemistry For Iit JeeDocument2 pagesSolomons Frsolomons-Fryhlesyhles Organic Chemistry For Iit JeeFazle Rahman Ejazi50% (4)

- Phase Inversion of W/O Emulsions by Adding Hydrophilic Surfactant - A Technique For Making Cosmetics ProductsDocument8 pagesPhase Inversion of W/O Emulsions by Adding Hydrophilic Surfactant - A Technique For Making Cosmetics ProductsAsshole FuckerNo ratings yet

- An114 Hand Soldering Tutorial For The Fine Pitch QFP DevicesDocument22 pagesAn114 Hand Soldering Tutorial For The Fine Pitch QFP DevicesPat Jojo SadavongvivadNo ratings yet