Professional Documents

Culture Documents

DAT 18B BMS4 Pnuematic Level Transmitter

Uploaded by

Žarko Močnik0 ratings0% found this document useful (0 votes)

14 views2 pagesDAT 18B BMS4 Pnuematic Level Transmitter

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDAT 18B BMS4 Pnuematic Level Transmitter

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views2 pagesDAT 18B BMS4 Pnuematic Level Transmitter

Uploaded by

Žarko MočnikDAT 18B BMS4 Pnuematic Level Transmitter

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

T: +44 (0)1444 410040 E: sales@psmmarine.

com

www.psmmarine.com

BMS4 Pnematic Level Measurement

System

Key features

• A complete system engineered and

configured for each application

• Adaptive pulse operation reduces air

consumption

• Built-in periodic zero self calibration

of pressure sensors, with automatic

monitoring for leaks

• Self purging of air tubes for

protection from contamination and

freezing

• Back-up pressure sensor for

continuous operation if the main

sensor fails

• Modbus output for direct interface to

PSM TankView or VPM 4300 HMI

systems

• Functionality of HMI system provides

level display, alarm handling and

interface to other shipboard systems

Part of the product group

PSM Instrumentation Ltd, Unit 3 Burrell Road, Haywards Heath, West Sussex, RH16 1TW. UK

DAT 18B 08/04/2016 PSM is a Scanjet Group Company

T: +44 (0)1444 410040 E: sales@psmmarine.com

www.psmmarine.com

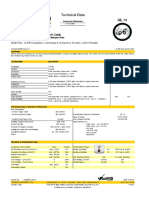

BMS4 Pneumatic (bubbler) Level Specifications

Measurement System

Air handling unit According to

application

PSM’s pneumatic level measurement modules

provide 12 independent measurement Number of Up to 12 per

channels to give a robust and reliable solution measurement channels transmitter module

for level gauging on multi-tank marine

Measurement range - 0 - 1.8 bar

installations with open or vented tanks.

pressure

The level measurement principle of BMS4 is Measurement range - 0 - 18 m (water

based on periodic purging (pulses) of level density)

compressed air from the system to the tank

Measurement accuracy 0.25%

bottom through an air tube, with associated

measurement of the steady state air back Measurement update Adjustable between

pressure in the tube. The back pressure is rate 5 - 30 seconds

directly related to the head pressure of the

HMI display Panel or wall mount

liquid in the tank, and consequently with a

known density of liquid, the level can be Screen size and res- Depending on

calculated. olution TankView or

VPM 4300 option

A complete system comprises:

Functionality Local display and

alarm for tank levels

Air handling unit - a cabinet containing the

filter and regulator components required to

Optional outputs for

condition the incoming compressed air supply

remote alarm control

and transmission to

Multi-point pneumatic transmitter module -

ships control system

an integrated unit for air pulsing into the tubes,

providing back pressure measurement and

calculation of level, with pressure sensors for Part of the product group

up to 12 measurement channels (tanks) per

module. A complete range of transmitters and switches

with HMI display and control modules.

HMI display - Receives the Modbus

measurement output from the transmitter unit Together these comprise simple-to-install but

and provides a visual display of tank levels scalable solutions for marine level

with associated functionality for alarms outputs measurement systems for ballast, cargo,

and measurement retransmission. service and bunker fuel oil tanks, as well as

vessel draught and trim & heel measurement.

With no active electronics needed to be in-

stalled in the hazardous area the system is

suitable for measurement of flammable liquids

and is certified for marine duty by many

approval organisations.

© PSM INSTRUMENTATION LTD

Data Sheet Ref: DAT 18B 08/04/2016

PSM Instrumentation Ltd, Unit 3 Burrell Road, Haywards Heath, West Sussex, RH16 1TW. UK Subject to change without notice

You might also like

- Bushing Monitor FlyerDocument4 pagesBushing Monitor FlyerCarlos JaraNo ratings yet

- RE2446 1e Draft3Document2 pagesRE2446 1e Draft3sadsasdasdaNo ratings yet

- Control Systems: Chem Energy Pharm Food WaterDocument12 pagesControl Systems: Chem Energy Pharm Food WaterAlejandro GonzalezNo ratings yet

- Turbomachinery Automation Anti Surge Control For All Axial and Centrifugal Compressors EngDocument6 pagesTurbomachinery Automation Anti Surge Control For All Axial and Centrifugal Compressors EngVahid MostajerNo ratings yet

- Cont Ent S Mai N Menu Sear CH Hel PDocument8 pagesCont Ent S Mai N Menu Sear CH Hel PAli AliNo ratings yet

- Vyntus-CPX BR EN PDFDocument8 pagesVyntus-CPX BR EN PDFLajoskaNo ratings yet

- Meter Clamping Device ManualDocument2 pagesMeter Clamping Device ManualNenad VlašičekNo ratings yet

- Vyntus CPX Sports - BR - EN PDFDocument16 pagesVyntus CPX Sports - BR - EN PDFLajoskaNo ratings yet

- MALCON4/4E Electronic Control System: and Documentation UnitDocument2 pagesMALCON4/4E Electronic Control System: and Documentation UnityasirNo ratings yet

- Aerzen Control System AertronicDocument4 pagesAerzen Control System AertronicBlas LuevanoNo ratings yet

- Flow Monitoring System Sure-Aire - GreenheckDocument4 pagesFlow Monitoring System Sure-Aire - GreenheckAliNo ratings yet

- Top FlowDocument2 pagesTop FlowmontanovillarroelfabiolalourdeNo ratings yet

- Signal Conditioner: Clip. Measure. ControlDocument12 pagesSignal Conditioner: Clip. Measure. ControlMichael GuckesNo ratings yet

- 03 Measurement TechnologyDocument5 pages03 Measurement TechnologyVitor FreitasNo ratings yet

- Tubing Wallmaster Umac.002.0003.eDocument8 pagesTubing Wallmaster Umac.002.0003.eAbhijith S AnchanNo ratings yet

- A6V10304838_enDocument4 pagesA6V10304838_enESNo ratings yet

- Atmos Tightness Monitor: Statistical Tightness Monitoring System For Airport Hydrant SystemsDocument2 pagesAtmos Tightness Monitor: Statistical Tightness Monitoring System For Airport Hydrant SystemsBen Hamed KhaterNo ratings yet

- L1-5 - Process Instumentation 5 Lectures New 2021Document87 pagesL1-5 - Process Instumentation 5 Lectures New 2021Anubhav ShrivastavaNo ratings yet

- Auto Zero Calibration Technique Pressure Sensors Technical Note 008326 1 enDocument10 pagesAuto Zero Calibration Technique Pressure Sensors Technical Note 008326 1 enmohammedNo ratings yet

- Manara: Production and Reservoir Management SystemDocument2 pagesManara: Production and Reservoir Management SystemabdouNo ratings yet

- Oil-Less Scroll Air Compressor System With Desiccant Air TreatmentDocument2 pagesOil-Less Scroll Air Compressor System With Desiccant Air TreatmentroyvindasNo ratings yet

- PF - SCD - Scroll With Dessicant DryerDocument2 pagesPF - SCD - Scroll With Dessicant DryerEmanuel Naskosi Santiz AguilarNo ratings yet

- en PDFDocument2 pagesen PDFMed Rachid ZianiNo ratings yet

- FenAMI - Codes-II HC - LowDocument2 pagesFenAMI - Codes-II HC - Lowanh NGUYENNo ratings yet

- HASSAN instrumentationDocument12 pagesHASSAN instrumentationGodlisten NyariNo ratings yet

- A2000 PDFDocument2 pagesA2000 PDFMohammedFikry50% (2)

- 00 Industrial Automation - OverviewDocument38 pages00 Industrial Automation - OverviewRAJESH PANIGRAHINo ratings yet

- Technical Information Liquisys M COM223/253: Dissolved Oxygen MeasurementDocument24 pagesTechnical Information Liquisys M COM223/253: Dissolved Oxygen MeasurementHectorNo ratings yet

- Proline Promass 80/83 E: Coriolis Mass Flow Measuring SystemDocument32 pagesProline Promass 80/83 E: Coriolis Mass Flow Measuring SystemwilfredoNo ratings yet

- Leybold VakumDocument2 pagesLeybold VakumUtku InanNo ratings yet

- W2 W3-309E MEERgauges EinzelnDocument6 pagesW2 W3-309E MEERgauges Einzelnbbcsteeltech LtdNo ratings yet

- Liquisys M CLM223/253: Technical InformationDocument20 pagesLiquisys M CLM223/253: Technical InformationKwameOpareNo ratings yet

- 1671 Test Unit For Rapid Crack Propagation RCP S4 E.inddDocument3 pages1671 Test Unit For Rapid Crack Propagation RCP S4 E.inddSunil Devdutt ThakoreNo ratings yet

- New Condition Monitoring Techniques for Flexible Plant OperationDocument15 pagesNew Condition Monitoring Techniques for Flexible Plant OperationOmar KhaledNo ratings yet

- ProductOverview 2023 EN-11Document1 pageProductOverview 2023 EN-11Ismail AliNo ratings yet

- Af 2400 985b1 English CatalogDocument2 pagesAf 2400 985b1 English CatalogThanh Hai StarkNo ratings yet

- MP85A FASTpress Industrial Amplifier - 447Document12 pagesMP85A FASTpress Industrial Amplifier - 447Alta MirNo ratings yet

- Viscosity Process Analyzer VISC-4Document4 pagesViscosity Process Analyzer VISC-4Nicolae VisanNo ratings yet

- 5.0 IBMS SlideDocument40 pages5.0 IBMS Slidedhevashini narayananNo ratings yet

- Censeo UKDocument2 pagesCenseo UKAulia RahmanNo ratings yet

- INTECONT® PLUS For Measuring Systems: % Compact Weighing Electronics ForDocument8 pagesINTECONT® PLUS For Measuring Systems: % Compact Weighing Electronics ForNaseer HydenNo ratings yet

- RevampingDocument2 pagesRevampingKhalid Latif NiemaNo ratings yet

- Automatic Mains Failure Controller for Single GenSet ApplicationsDocument2 pagesAutomatic Mains Failure Controller for Single GenSet ApplicationsRodrigo GoeringNo ratings yet

- Pim MasterDocument8 pagesPim Masterhd centratama2No ratings yet

- Siemens Bushing Monitoring System: Answers For EnergyDocument4 pagesSiemens Bushing Monitoring System: Answers For EnergyBia AlvesNo ratings yet

- Profibus PA Pressure and Temperature: InnovationsDocument6 pagesProfibus PA Pressure and Temperature: InnovationssandeshshivaNo ratings yet

- Pamas S40 Avtur: Portable Particle Counting System For Aviation Turbine FuelDocument2 pagesPamas S40 Avtur: Portable Particle Counting System For Aviation Turbine FuelRickie EdwardoNo ratings yet

- Datasheet 9000Document2 pagesDatasheet 9000LucasNo ratings yet

- Mercury Analyzer For Continuous Monitoring in Flue GasDocument8 pagesMercury Analyzer For Continuous Monitoring in Flue Gasnobby52No ratings yet

- Tia11 VPPM enDocument2 pagesTia11 VPPM enelimecboyNo ratings yet

- SF6 Partial Discharge MonitorDocument6 pagesSF6 Partial Discharge Monitoraviral mishraNo ratings yet

- Condumax II Transportable 97149 RESPURDocument4 pagesCondumax II Transportable 97149 RESPURMostafa NabilNo ratings yet

- Additive Controller b044 Bro GB Rev0Document2 pagesAdditive Controller b044 Bro GB Rev0Damjan BabicNo ratings yet

- b13 InspectionDocument3 pagesb13 InspectionharmlesdragonNo ratings yet

- DB Calibrator Microtrak OmnitrakDocument4 pagesDB Calibrator Microtrak OmnitrakKikie KieeNo ratings yet

- Pulsimsuite2 LeafletDocument2 pagesPulsimsuite2 LeafletahmadmortazaviNo ratings yet

- Pulsation and Vibration Control Software: Pulsimsuite2: The Next GenerationDocument2 pagesPulsation and Vibration Control Software: Pulsimsuite2: The Next GenerationEnamulKhanNo ratings yet

- 3000EM Common Rail Test StandDocument1 page3000EM Common Rail Test StandkampeeNo ratings yet

- Optimum Reliability: Synchrotact 6Document1 pageOptimum Reliability: Synchrotact 6Žarko MočnikNo ratings yet

- SY Part 15Document1 pageSY Part 15Žarko MočnikNo ratings yet

- Synchronizing Devices and Systems Data SheetDocument1 pageSynchronizing Devices and Systems Data SheetŽarko MočnikNo ratings yet

- Device Types: Synchrotact 6Document1 pageDevice Types: Synchrotact 6Žarko MočnikNo ratings yet

- Synchronizing devices and systems data sheetDocument1 pageSynchronizing devices and systems data sheetŽarko Močnik100% (1)

- Optimum Reliability: Synchrotact 6Document1 pageOptimum Reliability: Synchrotact 6Žarko MočnikNo ratings yet

- Option Details: Synchrotact 6Document1 pageOption Details: Synchrotact 6Žarko MočnikNo ratings yet

- Technical Bulletin: 1X Series General Purpose Supervision RelaysDocument8 pagesTechnical Bulletin: 1X Series General Purpose Supervision RelaysŽarko MočnikNo ratings yet

- Price List November 2017Document48 pagesPrice List November 2017Žarko Močnik100% (1)

- Dry-Type Transformers: Installation and Instruction ManualDocument24 pagesDry-Type Transformers: Installation and Instruction Manualosvald97No ratings yet

- 20-in-1 synchronizing deviceDocument1 page20-in-1 synchronizing deviceŽarko MočnikNo ratings yet

- 01 - Presentation Code - AsterDocument37 pages01 - Presentation Code - AsterStefano MilaniNo ratings yet

- ABB Guidelines To MV LV Transformer SubstationsDocument25 pagesABB Guidelines To MV LV Transformer SubstationsHaytham BafoNo ratings yet

- Gas-Insulated Medium Voltage Switchgear: Technic Al C Atalogue TK 503/14 enDocument78 pagesGas-Insulated Medium Voltage Switchgear: Technic Al C Atalogue TK 503/14 enŽarko MočnikNo ratings yet

- 01$GC Cable-Install Manual PowerControl Cables-7 14Document102 pages01$GC Cable-Install Manual PowerControl Cables-7 14galdreyNo ratings yet

- Tesla SCE Powerpack Case Study 2017Document1 pageTesla SCE Powerpack Case Study 2017Žarko MočnikNo ratings yet

- 01 Relays PDFDocument110 pages01 Relays PDFŽarko MočnikNo ratings yet

- Price List SLO 20200604Document1 pagePrice List SLO 20200604Žarko MočnikNo ratings yet

- Sentei Syosai e PDFDocument7 pagesSentei Syosai e PDFŽarko MočnikNo ratings yet

- DatasheetDocument5 pagesDatasheetŽarko MočnikNo ratings yet

- YyyDocument2 pagesYyyŽarko MočnikNo ratings yet

- Revit Phasing CADMWDocument28 pagesRevit Phasing CADMWSIRLINONo ratings yet

- Switch Disconnectors OT OTM PDFDocument116 pagesSwitch Disconnectors OT OTM PDFŽarko MočnikNo ratings yet

- 7 Coatings PDFDocument3 pages7 Coatings PDFŽarko MočnikNo ratings yet

- Tesla SCE Powerpack Case Study 2017Document1 pageTesla SCE Powerpack Case Study 2017Žarko MočnikNo ratings yet

- BussmanDocument124 pagesBussmanŽarko MočnikNo ratings yet

- High Speed Fuse Application GuideDocument40 pagesHigh Speed Fuse Application Guideangel1885No ratings yet

- Self-Intersection Detection and Elimination in Freeform Curves and SurfacesDocument10 pagesSelf-Intersection Detection and Elimination in Freeform Curves and SurfacesŽarko MočnikNo ratings yet

- UltraQuick ApplicationGuideDocument31 pagesUltraQuick ApplicationGuideWashington MirandaNo ratings yet

- A Study of K-Factor Power TransformerDocument7 pagesA Study of K-Factor Power TransformerŽarko MočnikNo ratings yet

- 3WL11-13 Air Circuit Breakers: Reliable, Versatile and Perfectly IntegratedDocument2 pages3WL11-13 Air Circuit Breakers: Reliable, Versatile and Perfectly IntegratedDinuro DiNo ratings yet

- Lab Report On Standard DiodeDocument13 pagesLab Report On Standard DiodeDANSTAN KULENo ratings yet

- Operating Instructions: Coring Stripping ToolDocument2 pagesOperating Instructions: Coring Stripping ToolCarlos CastilloNo ratings yet

- PTC Thermistor & Single Phasing Preventer Series PD 225Document3 pagesPTC Thermistor & Single Phasing Preventer Series PD 225PrasadPurohitNo ratings yet

- Photoelectric Effect and EinsteinDocument6 pagesPhotoelectric Effect and EinsteinmylinhxoNo ratings yet

- AX-R551XBK Service ManualDocument66 pagesAX-R551XBK Service ManualHeraclio Camacho UlloaNo ratings yet

- How to repair a 150W power amplifierDocument1 pageHow to repair a 150W power amplifiermiguel perez100% (7)

- TC906A, TC907A, TC908A: Eclipse™ Series: Intelligent Low-Profile Plug-In DetectorsDocument2 pagesTC906A, TC907A, TC908A: Eclipse™ Series: Intelligent Low-Profile Plug-In DetectorssureshNo ratings yet

- Generating Set Diesel GE.L3W.15.BF DocumentationDocument9 pagesGenerating Set Diesel GE.L3W.15.BF DocumentationCallany AnycallNo ratings yet

- Zoneline 3100 SeriesDocument16 pagesZoneline 3100 SeriespotoculNo ratings yet

- Amplifier Transistors: NPN SiliconDocument6 pagesAmplifier Transistors: NPN SilicondiegooliveiraEENo ratings yet

- Lab 4 - Properties of The Op-Amp 1 (Buffer Non Inverting Op-Amp)Document9 pagesLab 4 - Properties of The Op-Amp 1 (Buffer Non Inverting Op-Amp)Alia Atikah100% (1)

- AKNM - 3049 - AKNMGptcDocument53 pagesAKNM - 3049 - AKNMGptchod eceNo ratings yet

- Manitou Electric Aerial Work Platforms (EN)Document36 pagesManitou Electric Aerial Work Platforms (EN)Manitou100% (2)

- Drude ModelDocument12 pagesDrude Modelright12351No ratings yet

- Epson L1800 PDFDocument149 pagesEpson L1800 PDFIon Ionut50% (2)

- Deka Unigy I 12v 75 100ahDocument2 pagesDeka Unigy I 12v 75 100ahRonald Victor Galarza HermitañoNo ratings yet

- Find and store device codes and program channel controlsDocument2 pagesFind and store device codes and program channel controlsMallorie Roxanne NunierNo ratings yet

- TM 11-6625-213-34P - Test - Set - TS-538 - 1978 PDFDocument55 pagesTM 11-6625-213-34P - Test - Set - TS-538 - 1978 PDFWurzel1946No ratings yet

- Info Iec60529 (Ed2.2) BDocument39 pagesInfo Iec60529 (Ed2.2) BKennedy Alves VieiraNo ratings yet

- IOTDocument29 pagesIOTdvdreadsNo ratings yet

- Bharti Cellular IN equipment inventoryDocument36 pagesBharti Cellular IN equipment inventoryPowerstormNo ratings yet

- Week 04, Memory ManagementDocument31 pagesWeek 04, Memory Managementnino sulitNo ratings yet

- UL13 Instrumentation Cable Technical DataDocument1 pageUL13 Instrumentation Cable Technical DataMario MejiaNo ratings yet

- Practical 5 Aim: Low Pass Average Filter and High Pass Filter Used On An Image With Gaussian NoiseDocument1 pagePractical 5 Aim: Low Pass Average Filter and High Pass Filter Used On An Image With Gaussian Noisevaibhavmakkar54No ratings yet

- Last Saved:: Date Description Last Modif Name Index-LabDocument3 pagesLast Saved:: Date Description Last Modif Name Index-Labluiz carlos de souzaNo ratings yet

- JVC KD-LX100J Manual de Servicio PDFDocument38 pagesJVC KD-LX100J Manual de Servicio PDFMIGUELNo ratings yet

- Operating Principles of Electronic Engine Management SystemsDocument6 pagesOperating Principles of Electronic Engine Management SystemsVaishali Wagh100% (2)

- The Main Circuit Board of A MicrocomputerDocument16 pagesThe Main Circuit Board of A Microcomputeramandeep123No ratings yet

- Calculate Bus Bar Size For Panel (1.1.17)Document7 pagesCalculate Bus Bar Size For Panel (1.1.17)Vishal SharmaNo ratings yet