Professional Documents

Culture Documents

Formulation and in Vitro Evaluation of Oro Dispersible Tablets of Lorazepam

Uploaded by

iajpsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Formulation and in Vitro Evaluation of Oro Dispersible Tablets of Lorazepam

Uploaded by

iajpsCopyright:

Available Formats

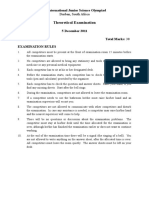

IAJPS 2018, 05 (05), 3945-3953 Bommana Anusha et al ISSN 2349-7750

CODEN [USA]: IAJPBB ISSN: 2349-7750

INDO AMERICAN JOURNAL OF

PHARMACEUTICAL SCIENCES

http://doi.org/10.5281/zenodo.1249808

Available online at: http://www.iajps.com Research Article

FORMULATION AND IN VITRO EVALUATION OF ORO

DISPERSIBLE TABLETS OF LORAZEPAM

Bommana Anusha1*, Girija Karike2, Koppula Maheshwari3, Ramya Sri Sura4

1

Department of Pharmaceutics, Bhaskar Pharmacy College, Bhaskar Nagar, Yenkapally (V),

Moinabad (M), RR Dist. Hyderabad. 500075

2,3

Department of Pharmaceutics, Joginpally B.R Pharmacy College, Bhaskar Nagar, Yenkapally

(V), Moinabad (M), RR Dist. Hyderabad. 500075

4

Department of Pharmaceutics, University of Technology, Osmania University, Hyderabad,

Telangana.

Abstract:

The present investigation was done on lorazepam orodispersible tablets using super disintegrants. The prepared

powder blend for all formulations was found to be within limits. Tablets were compressed using rotary tablet

compression machine. Post compression studies like weight variation, hardness, thickness, friability, drug content,

in vitro disintegration time were carried out which were found to be within limits. In vitro drug release studies

revealed that Among all formulations F4 formulation were shown maximum drug release(99.99%) at 45 min.

Among these three formulations F4 was considered as optimised formulation due to 2 mg of croscarmellose sodium.

Key words: Lorazepam, Super disintegrants, Orodispersble tablets.

Corresponding author:

Bommana Anusha, QR code

Department of Pharmaceutics,

Bhaskar Pharmacy College,

Bhaskar Nagar, Yenkapally (V),

Moinabad (M), RR Dist.

Hyderabad. 500075

Please cite this article in press Bommana Anusha et al., Formulation And In Vitro Evaluation of Oro Dispersible

Tablets of Lorazepam, Indo Am. J. P. Sci, 2018; 05(05).

www.iajps.com Page 3945

IAJPS 2018, 05 (05), 3945-3953 Bommana Anusha et al ISSN 2349-7750

INTRODUCTION: replace the original regulatory definition

FDT mentioned. In other words, disintegration within

The oral route of administration is considered as the a matter of seconds remains the target for an

most widely accepted route because of its ODT.

convenience of self-administration, compactness and

easy manufacturing.[1-2] But the most evident MATERIALS AND METHODS:

drawback of the commonly used oral dosage forms Materials Used:

like tablets and capsules is difficulty in swallowing, Lorazepam was a gift sample Provided by Sura Labs,

leading to patients incompliance particularly in case Dilsukhnagar. Crospovidone, Croscarmellosesodium,

of paediatric and geriatric patients1, but it also sodium starch glycolate, Sucralose, Talc, Magnesium

applies to people who are ill in bed and to those Stearate, MCC were obtained from Sd fine

active working patients who are busy or travelling, Chem.Ltd. Mumbai, India.

especially those who have no access to water.[2] METHODOLOGY

For these reasons, tablets that can rapidly dissolve or Analytical method development for Lorazepam:

disintegrate in the oral cavity have attracted a great a)Determination of absorption maxima

deal of attention. Oral dispersible tablets are not only A spectrum of the working standards was obtained by

indicated for people who have swallowing scanning from 200-400 nm against the reagent blank

difficulties, but also are ideal for active people.[3] to fix absorption maxima. The λmax was found to be

Oral dispersible tablets (ODT)is a solid dosage form 240 nm. Hence all further investigations were carried

that contains medicinal substances and disintegrates out at the same wavelength.

rapidly (within seconds) without water when placed b) Construction of standard graph

on the tongue. The drug is released, dissolved, or 100 mg of Lorazepam was dissolved in 100 mL of

dispersed in the saliva, and then swallowed and pH 6.8 phosphate buffer to give a concentration in

absorbed across the GIT.[4] US FDA defined ODT 1mg/mL (1000µg/mL) 1 ml was taken and diluted to

tablets as “A solid dosage form containing medicinal 100 ml with pH 6.8 phosphate buffer to give a

substances which disintegrates rapidly usually within concentration of 0.01 mg/ml (10µg/ml). From this

a matter of seconds, when placed upon the tongue”. stock solution aliquots of 0.2 ml, 0.4 ml, 0.6 ml, 0.8

Recently European Pharmacopoeia used the term ml, 1 ml, were pipette out in 10 ml volumetric flask

‘Fast dissolving tablet’ as a tablet that is to be placed and volume was made up to the mark with pH 6.8

in the Mouth. Where it disperses rapidly before phosphate buffer to produce concentration of 2,4,6,8

swallowing. and 10µg/ml respectively. The absorbance of each

concentration was measured at respective (λmax) i.e.,

Oral dispersible tablets are also called as Fast - 240 nm.

dissolving tablets, fast disintegrating tablets, fast Formulation development:

dissolving tablets, Fast dissolving tablets, rapimelts, Drug and different concentrations of super

porous tablets, quick dissolving tablet[5]. disintegrants (Sodium starch glycolate, Cross

caramellose Sodium, Cross povidone) and

The US Food and Drug Administration responded to required ingredients were accurately weighed

this challenge with the 2008 publication of Guidance and passed through a 40-mesh screen to get

for Industry: Oral dispersible Tablets[6].Three main uniform size particles and mixed in a glass motor

points stand out in the final guidance: for 15 min.

Oral dispersible Tablets should have an in vitro The obtained blend was lubricated with

disintegration time of approximately 30sec or magnesium stearate and glidant (Aerosil) was

less. added and mixing was continued for further 5

Generally, the ODT tablet weight should not min.

exceed 500 mg, although the combined influence The resultant mixture was directly compressed

of tablet weight, size, and component solubility into tablets by using punch of rotary tablet

all factor into the acceptability of an ODT for compression machine. Compression force was

both patients and regulators. kept constant for all formulations.

The guidance serves to define the upper limits of

the ODT category, but it does not supersede or

www.iajps.com Page 3946

IAJPS 2018, 05 (05), 3945-3953 Bommana Anusha et al ISSN 2349-7750

Table 1: Formulation table showing various compositions

Ingrediants F1 F2 F3 F4 F5 F6 F7 F8 F9

Lorazepam 1 1 1 1 1 1 1 1 1

Crospovidone 2 4 6 - - - - - -

Croscarmellosesodium - - - 2 4 6 - - -

sodium starch glycolate - - - - - - 2 4 6

Sucralose 3 3 3 3 3 3 3 3 3

Talc 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5

Magnesium Stearate 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5

MCC 36 34 32 36 34 32 36 34 32

Total weight 50 50 50 50 50 50 50 50 50

The tablets were prepared by using tablet is noted . The bulk density is calculated in g/cm3 by

compression machine. The hardness of the tablet was the formula.

maintained as (2.2-3.0) kg/cm2

Evaluation of tablets: Bulk density = M/V0 …………………. (2)

Pre compression parameters: V0 = apparent unstirred volume

Measurement of Micromeritic properties of powders M= Powder mass

1.Angle of repose 3. Tapped density

The angle of repose of API powder is determined by The powder sample under test is screened through

the funnel method . The accurately weighed powder sieve No. 18 and the weight of the sample equivalent

blend is taken in the funnel. The height of the funnel to 25 gm filled in 100ml graduated cylinder . The

is adjusted in a way that the tip of the funnel just mechanical tapping of cylinder is carried out using

touched the apex of the powder blend. The powder tapped density tester at a nominal rate for 500 times

blend is allowed to flow through the funnel freely on initially and the tapped volume V0 is noted .

o the surface . The diameter of the powder cone is Tappings are proceeded further for an additional

measured and angle of repose is calculated using the tapping 750 times and tapped volume , Vb is noted.

following equation. The difference between two tapping volume is < 2%,

tan Ɵ= h/r ………………(1) Vb is considered as a tapped volume Vf . The

Where , h and r are the height and radius of the tapped density is calculated in g/cm3 by the formula.

powder cone. Tapped density = M/Vf ………………… (3)

M = weight of sample powder taken

Table 2: Flow Properties and Corresponding Vf = Tapped volume

Angle of Repose 4. Compressibility index

Flow Property Angle of Repose (0) The compressibility index of the powder blend is

Excellent 25-30 determined by Carr’s index to know the flow

Good 31-35 character of a powder . This formula for Carr’s index

Fair- aid not needed 36-40 is as below :

Passable-may hang up 41-45 Carr’s Index (%) = [ (TD-BD)/TD] x100

Poor-must agitate, …………… (4)

46-55 5. Hausner’s ratio

Vibrate

Very Poor 56-65 The Hausner’s ratio is a number that is correlated to

Very, very Poor >66 the flowability of a powder or granular material. The

ratio of tapped density to bulk density of the powders

2.Bulk density is called the Hausner’s ratio. It is calculated by the

The powder sample under test is screened through following equation.

sieve No.18 and the sample equivalent to 25 gm is H = Ρt / ρB …………………….(5)

weighed and filled in 100 ml graduated cylinder and Where ρT= tapped density, ρB = bulk density

the powder is leveled and the un setled volume , V0

www.iajps.com Page 3947

IAJPS 2018, 05 (05), 3945-3953 Bommana Anusha et al ISSN 2349-7750

Table 3: Scale of Flowability

Compressibility index (%) Flow character Hausner Ratio

≤ 10 Excellent 1.00-1.11

11-15 Good 1.12-1.18

16-20 Fair 1.19-1.25

21-25 Passable 1.26-1.34

26-31 Poor 1.35-1.45

32-37 Very Poor 1.46-1.59

> 38 Very, very Poor > 1.60

Post compression parameters : e) Disintegration test

a) Thickness Six tablets were taken randomly from each batch

The thickness of the tablets was determined by and placed in USP disintegration apparatus baskets .

using Digital micrometer. 10 individual tablets Apparatus was run for 10 min. and the basket was

from each batch were used and the results lift from the fluid, observe whether all of the tablets

averaged. have disintegrated.

b) Weight variation f) Dissolution test of Lorazepam

Twenty tablets were randomly selected from Drug release from Lorazepam tablets was determined

each batch and individually weighed . The by using dissolution test USP 24 type ΙΙ (paddle) .

average weight and standard deviation 3 batches The parameters used for performing the dissolution

were calculated. It passes the test for weight were pH 6.8 medium as the dissolution medium of

variation test if not more than 2 of the individual quantity 900 ml . The whole study is being carried

tablet weights deviate from the average weight out at room temperature of 37˚ C and at a speed of 75

by more than the allowed percentage deviation RPM.

and none deviate by more than twice the % 5 ml aliquots of dissolution media were withdrawn

shown. It was calculated on an electronic each time intervals (5, 10,15 , 20 , 25, 30, 35, 40,45

weighing balance. min) and appropriate dilution by UV

c) Friability spectrophotometer . The concentration was calculated

The friability values of the tablets were using standard calibration curve.

determined using a Roche-friabilator . Drug-Excipients compatibility studies:

Accurately weighed six tablets were placed in Drug excipients compatibility studies were carried

The Roche friabilator and rotated at 25 RPM for out by mixing the drug with various excipiennts in

4 min. Percentage friability was calculated using different proportions ( in 1;1 ratio were to have

the following equation. maximum likelihood interaction between them) was

Friability = ( [ w0-w]/w0) x 100 placed in a vial, and closed with rubber stopper and

Where w0 = weight of tablet at time zero before sealed properly. Fourier Transform Infrared

revolution. Spectroscopy (FTIR) studies were performed on

w = weight of the tablet after 100 revolutions drug, optimized formulation using Bruker FTIR. The

d) Drug content samples were analyzed between wave numbers 4000

The content of drug carried out by 5 randomly cm-1 and 550 cm-1.

selected tablets of each formulation. The 5

tablets were grinded to get powder, this powder RESULTS AND DISCUSSION:

was dissolved in pH 6.8 phosphate buffer by Preparation of calibration curve of Lorazepam

sonication for 30 min and filtered through filter The regression coefficient was found to be 0.999

paper. The drug content was analysed which indicates a linearity with an equation of y =

spectrophotometrically at 240 nm using UV 0.092x - 0.009. Hence Beer-Lmbert’s law was

spectrophotometer. Each measurement was obeyed.

carried out in triplicate and the average drug

content was calculated.

www.iajps.com Page 3948

IAJPS 2018, 05 (05), 3945-3953 Bommana Anusha et al ISSN 2349-7750

Table 4: Calibration curve data of Lorazepam in pH 6.8 phosphate buffer

Concentration Absorbance

0 0

2 0.167

4 0.352

6 0.539

8 0.742

10 0.909

EVALUATION OF PRE-COMPRESION PARAMETERS OF POWDER BLEND

Table 5: Evaluation of pre-compression parameters of powder blend

Formulation code Angle of repose Bulk Tapped density Carr’s index(%) Hausner’s ratio

density(gm/mL) (gm/mL)

F1 32.67 0.435 0.522 16.66 1.2

F2 29.08 0.429 0.518 17.18 1.2

F3 31.78 0.43 0.524 17.93 1.21

F4 30.64 0.432 0.528 18.18 1.22

F5 30.36 0.428 0.518 17.37 1.21

F6 31.05 0.42 0.51 17.64 1.21

F7 32.54 0.416 0.509 18.27 1.22

F8 29.67 0.417 0.515 19.02 1.23

F9 31.85 0.425 0.515 17.47 1.21

For each formulation blend of drug and excipients were prepared and evaluated for various pre compression

parameters described earlier in methodology chapter.

The bulk density of all formulations was found in the range of 0.416 -0.435 and tapped density was in the

range of 0.509-0.528

The Carr’s index and Hausner’s ratio was calculated from tapped density and bulk density.

EVALUATIONS OF POST COMPRESSION PARAMETERS OF LORAZEPAM ODTs

Table 6: Evaluation of post compression parameters of LORAZEPAM Fast dissolving tablets

In vitro

Formulation Average Hardness Friability Thickness Drug content

disintegration

codes weight(mg) (kg/cm2 (%loss) (mm) (%)

Time(min)

F1 49.1 5.10±0.4 0.225 3.77±0.007 97.93±0.04 29±4.5

F2 48.4 4.00±0.2 0.341 3.80±0.059 98.31±0.03 26±3.2

F3 49.3 6.24±0.4 0.314 3.78±0.006 96.94±0.02 30±3.2

F4 47.8 5.12±0.2 0.272 3.80±0.011 97.49±0.04 25±0.41

F5 48.2 6.24±0.5 0.331 3.79±0.010 99.25±0.02 31±4.12

F6 49.1 4.13±0.3 0.534 3.78±0.008 98.52±0.04 29±0.9

F7 48.6 5.34±0.2 0.249 3.80±0.007 97.80±0.03 30±0.12

F8 49.5 6.25±0.1 0.375 3.79±0.009 98.33±0.04 29±4.12

F9 49.8 4.21±0.3 0.295 3.78±0.009 99.75±0.03 28±0.12

www.iajps.com Page 3949

IAJPS 2018, 05 (05), 3945-3953 Bommana Anusha et al ISSN 2349-7750

Weight variation and Thickness: All the friability for all the formulations was between 0.225-

formulations were evaluated for uniformity of weight 0.375 which was found to be within the limit.

using electronic weighing balance and the results are Drug content : All formulations were evaluated for

shown above. The average tablet weights of all the drug content according to the procedure described in

formulations were noted down. methodology section and the results were shown

Hardness and friability: All the ODT formulations above . The assay values for all formulations were

were evaluated for their hardness using Monsanto found to be in the range of (96.94±0.02 -

hardness tester and the results are shown above. The 99.75±0.03.). According to IP standards the tablets

average hardness for all formulations was found to be must contain not less than 95% and not more than

between (4.00±0.2-6.24±0.5) kg/cm2 which was 105% of the stated amount of the drug. Thus, all the

found to be acceptable. Friability was determined to ODT formulation comply with the standards given in

evaluate the ability of the tablets to with stand the IP.

abrasion during packing, handling and transpoting. In vitro disintegration time : In vitro disintegration

All the ODT formulations were evaluated for their studies showed from 15-35 minutes. The F4

percentage friability using Roche friabilator and the formulation showed very less in vitro disintegration

results are shown above. The average percentage time i.e. 30 minutes.

IN VITRO DRUG RELEASE SYUDIES OF LORAZEPAM

Table 7: Dissolution data of LORAZEPAM

Ti

F1 F2 F3 F4 F5 F6 F7 F8 F9

me

0 0 0 0 0 0 0 0 0 0

5 25.35 19.35 22.46 26.31 24.35 18.43 15.33 13.38 11.33

10 38.33 29.36 32.28 35.33 31.57 28.43 25.36 21.19 19.36

15 57.46 41.31 45.35 47.33 41.36 39.36 37.46 34.43 29.45

20 64.46 58.35 64.31 71.48 54.41 48.38 44.43 41.46 38.43

25 71.38 71.48 78.46 82.38 62.55 57.38 53.28 49.46 42.48

30 83.35 81.45 84.53 89.69 69.48 71.46 65.41 56.58 52.46

35 92.45 94.31 95.31 96.89 75.45 79.31 72.28 69.42 58.58

40 96.89 97.57 96.76 97.95 82.57 85.48 82.28 76.48 65.43

45 97.78 98.85 97.96 99.99 92.53 95.36 91.46 89.43 78.47

Fig.1: Dissolution profile of formulations F1,F2,F3

www.iajps.com Page 3950

IAJPS 2018, 05 (05), 3945-3953 Bommana Anusha et al ISSN 2349-7750

Fig.2: Dissolution profile of formulations F4,F5,F6

Fig.3: Dissolution profile of formulations F7,F8,F9

Fig. 4: Dissolution profile of all formulations F1-F9

www.iajps.com Page 3951

IAJPS 2018, 05 (05), 3945-3953 Bommana Anusha et al ISSN 2349-7750

FTIR RESULTS :

Fig.5 : FTIR of Lorazepam Pure Drug

Fig. 6: FTIR of Lorazepam optimized formulation

Lorazepam was mixed with proportions of excipients showed no colour change providing no drug-excipient

interactions

CONCLUSION: ACKNOWLWDGEMENT:

In the present study it can be concluded from the The authors are thankful to Sura Labs,

characterization of orally disintegrating tablets of Dilshukhnagar, Hyderabad, T.S., India for

Lorazepam that formulation containing providing the necessary facilities for the research

Croscarmellose sodium is most acceptable. It was work.

observed that to further increases the drug release

from orally disintegrating tablets . The pre REFERENCES:

compression and post compression parameters have 1. Sastry SV, Nyshdham JR, Fix JA. Recent

got in IP limits. The formulation F4 has got good technological advances in oral drug delivery: A

results and it consider as optimized 98.89%. review. Pharmaceutical Science and Technology

Today. 2000; 3:138-45.

www.iajps.com Page 3952

IAJPS 2018, 05 (05), 3945-3953 Bommana Anusha et al ISSN 2349-7750

2. Seager H. Drug-delivery products and the Zydis controller of publications, New Delhi, 1996, pp.

fast-dissolving dosage form. Journal of A-54.

Pharmacy and Pharmacology. 1998; 50(4):375- 7. Schiermeier S, Schmidt PC. Fast dispersible

82. ibuprofen tablets. Eur J Pharm Sci, 2002; 15:

3. Debjit, B., Chiranjib, B., Krishnakanth., Pankaj., 295‐305

Margret, R., Fast Dissolving Tablets: An 8. Simone SS, Peter CS, Fast dispersible ibuprofen

Overiew. Journal. Chem. Pharm. Research., tablets, European Journal of Pharmaceutical

1(1), 163 – 177 (2009). Sciences, 2002;15: 295–305.

4. Jaysukh J Hirani1*, Dhaval A Rathod1 , Kantilal 9. In vitro dissolution. The United States

R Vadalia2, Orally Disintegrating Tablets: A pharmacopoeia, United States pharmacy

Review , Tropical Journal of Pharmaceutical convention, inc., Asian edition, 2000; 1941-

Research, April 2009; 8 (2): 161-172 . 1943.

5. Suresh, B., Rajender, M., Ramesh, G., 10. Mishra D.N., Rapidly disintegrating oral tablets

Madhusudan Rao, Y., Orodispersible tablets: An of meloxicam by direct compression method,

overview. Asian J Pharm., 2(1), 2-11 (2008). Indian Drugs, 2006, 43, 117-121.

6. Indian Pharmacopoeia. 4th Ed, Ministry of

Health and Family Welfare, Govt. of India. The

11.

www.iajps.com Page 3953

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 196 Iajps196092020 PDFDocument4 pages196 Iajps196092020 PDFiajpsNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- 44 Iajps44102020Document4 pages44 Iajps44102020iajpsNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Pharmaceutical Sciences: Pregnancy Outcomes of Covid-19 Positive Patients A Systematic Review of LiteratureDocument6 pagesPharmaceutical Sciences: Pregnancy Outcomes of Covid-19 Positive Patients A Systematic Review of LiteratureiajpsNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 193 Iajps193092020-1 PDFDocument8 pages193 Iajps193092020-1 PDFiajpsNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Pharmaceutical Sciences: Urinary Sodium and Potassium Discharge and Danger of Hypertension in Pakistani PopulationDocument4 pagesPharmaceutical Sciences: Urinary Sodium and Potassium Discharge and Danger of Hypertension in Pakistani PopulationiajpsNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 50 Iajps50102020Document13 pages50 Iajps50102020iajpsNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 197 Iajps197092020 PDFDocument5 pages197 Iajps197092020 PDFiajpsNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- 195 Iajps195092020 PDFDocument5 pages195 Iajps195092020 PDFiajpsNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 193 Iajps193092020-1 PDFDocument8 pages193 Iajps193092020-1 PDFiajpsNo ratings yet

- Pharmaceutical Sciences: Flipping Impacts of Middle School Laboratory in Health School EducationDocument4 pagesPharmaceutical Sciences: Flipping Impacts of Middle School Laboratory in Health School EducationiajpsNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 192 Iajps192092020 PDFDocument5 pages192 Iajps192092020 PDFiajpsNo ratings yet

- Pharmaceutical Sciences: Management of Proximal Ureteric Stone (10 - 15 MM Size) Via Urs & EswlDocument6 pagesPharmaceutical Sciences: Management of Proximal Ureteric Stone (10 - 15 MM Size) Via Urs & EswliajpsNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 194 Iajps194092020 PDFDocument7 pages194 Iajps194092020 PDFiajpsNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- 191 Iajps191092020Document8 pages191 Iajps191092020iajpsNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Pharmaceutical Sciences: Observation of Metabolism According To The Growth Hormone Control in Mayo Hospital LahoreDocument6 pagesPharmaceutical Sciences: Observation of Metabolism According To The Growth Hormone Control in Mayo Hospital LahoreiajpsNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Pharmaceutical Sciences: The Impact of Ox Like Lactoferrin (BLF) On Prevention of The Diarrhoea in YoungstersDocument7 pagesPharmaceutical Sciences: The Impact of Ox Like Lactoferrin (BLF) On Prevention of The Diarrhoea in YoungstersiajpsNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- 40 Iajps40102020Document4 pages40 Iajps40102020iajpsNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- 46 Iajps46102020Document7 pages46 Iajps46102020iajpsNo ratings yet

- 35 Iajps35102020Document4 pages35 Iajps35102020iajpsNo ratings yet

- Pharmaceutical Sciences: Psychophysiological Features of Students Aerobic Abilities and Maintaining A Healthy LifestyleDocument6 pagesPharmaceutical Sciences: Psychophysiological Features of Students Aerobic Abilities and Maintaining A Healthy LifestyleiajpsNo ratings yet

- Pharmaceutical Sciences: Study To Determine The Pattern of Primary Glomerulonephritis in PakistanDocument5 pagesPharmaceutical Sciences: Study To Determine The Pattern of Primary Glomerulonephritis in PakistaniajpsNo ratings yet

- 42 Iajps42102020Document8 pages42 Iajps42102020iajpsNo ratings yet

- Pharmaceutical Sciences: A Young Male With Splenic Vein and SMV Thrombosis and Jak 22 MutationDocument12 pagesPharmaceutical Sciences: A Young Male With Splenic Vein and SMV Thrombosis and Jak 22 MutationiajpsNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pharmaceutical SciencesDocument5 pagesPharmaceutical SciencesiajpsNo ratings yet

- 34 Iajps34102020Document7 pages34 Iajps34102020iajpsNo ratings yet

- 37 Iajps37102020Document9 pages37 Iajps37102020iajpsNo ratings yet

- 33 Iajps33102020Document6 pages33 Iajps33102020iajpsNo ratings yet

- Pharmaceutical Sciences: Teneligliptin Induced Persistent DiarrheaDocument3 pagesPharmaceutical Sciences: Teneligliptin Induced Persistent DiarrheaiajpsNo ratings yet

- Pharmaceutical Sciences: Cognitive Schemes For Clinical Diagnostic Reasoning by Medical StudentsDocument8 pagesPharmaceutical Sciences: Cognitive Schemes For Clinical Diagnostic Reasoning by Medical StudentsiajpsNo ratings yet

- Pharmaceutical Sciences: Massive Inguinal Hernia-A Rare Presentation of Common DiseaseDocument4 pagesPharmaceutical Sciences: Massive Inguinal Hernia-A Rare Presentation of Common DiseaseiajpsNo ratings yet

- Advance Engine Timing with STCDocument28 pagesAdvance Engine Timing with STCLuisPupiales100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Thermodynamics Chapter OverviewDocument40 pagesThermodynamics Chapter OverviewdeusleanNo ratings yet

- CAB Cable Rings and SaddlesDocument5 pagesCAB Cable Rings and SaddlesgoyalmanojNo ratings yet

- Plant tissue culture techniques for plant transformationDocument19 pagesPlant tissue culture techniques for plant transformationPayal Chauhan57% (7)

- TDS - Mastertop 1330Document2 pagesTDS - Mastertop 1330Venkata RaoNo ratings yet

- MCQ IjsoDocument20 pagesMCQ IjsommhabgNo ratings yet

- Chapter 4 and 5Document51 pagesChapter 4 and 5Kyla Gabrielle TutoNo ratings yet

- Selective MediaDocument10 pagesSelective Mediaprincess_likemist4No ratings yet

- Merck Price List 2018 To 2019 Vijay ChemicalsDocument404 pagesMerck Price List 2018 To 2019 Vijay Chemicalsnikhilesh2011No ratings yet

- Wolter Jetfan Broschuere English 2017 PDFDocument15 pagesWolter Jetfan Broschuere English 2017 PDFViệt Đặng XuânNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Astm A181-2001 PDFDocument3 pagesAstm A181-2001 PDFMohammed TariqNo ratings yet

- New Australian Curriculum Senior Secondary ChemistryDocument44 pagesNew Australian Curriculum Senior Secondary Chemistryapi-252350138No ratings yet

- S1XBIG58 M500 4 Tech InfoDocument15 pagesS1XBIG58 M500 4 Tech InfoFredy DanielNo ratings yet

- MScSYChem18 19Document40 pagesMScSYChem18 19kumarNo ratings yet

- Makrolon® ET3137: Grades / ExtrusionDocument4 pagesMakrolon® ET3137: Grades / ExtrusionDiegoTierradentroNo ratings yet

- Sspc-Ab 1Document5 pagesSspc-Ab 1Anton Thomas Punzalan100% (3)

- Flax 7Document7 pagesFlax 7Rajyalakshmi MNo ratings yet

- ASPHALT METHOD STATEMENTDocument7 pagesASPHALT METHOD STATEMENTBasem Donia100% (1)

- Binary and TernaryDocument13 pagesBinary and TernaryRosemarie Degala LateNo ratings yet

- Chem 2 Course OutlineDocument15 pagesChem 2 Course Outlineapi-607966786No ratings yet

- Catalysis Norskov 05 15 02Document36 pagesCatalysis Norskov 05 15 02Rafael Ricardo Celin ManceraNo ratings yet

- U15 S1-2 HW KeysDocument6 pagesU15 S1-2 HW KeysRohith GudatiNo ratings yet

- C.02 - Gas-Freeing and Cleaning of TanksDocument7 pagesC.02 - Gas-Freeing and Cleaning of TanksmkkamarajNo ratings yet

- Solutions of ElectrolytesDocument55 pagesSolutions of Electrolytesneha_dand1591100% (1)

- ANSWER A. Diesel Cycle Has Lower Efficiency Than Otto CycleDocument12 pagesANSWER A. Diesel Cycle Has Lower Efficiency Than Otto CycleParmeshwarPaulNo ratings yet

- Magnaglo 14a Dry PowderDocument2 pagesMagnaglo 14a Dry Powdermlowe680No ratings yet

- Concrete Strength by Brick ChipsDocument10 pagesConcrete Strength by Brick ChipsHamayet RaselNo ratings yet

- Insect PestsDocument164 pagesInsect PestsKenneth100% (11)

- P-X-Y Diagram For Benzene (1) /ethylbenzene (2) at 363.15KDocument2 pagesP-X-Y Diagram For Benzene (1) /ethylbenzene (2) at 363.15Ksiti azilaNo ratings yet

- Bio HGHDocument19 pagesBio HGHapi-240332064No ratings yet