Professional Documents

Culture Documents

Yawmc 0425 Us

Uploaded by

achmadh_2010Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Yawmc 0425 Us

Uploaded by

achmadh_2010Copyright:

Available Formats

Yarway 9200 Series ARC® Valve

For Centrifugal Pump Protection

Self-contained valve functions as integral check valve,

flow sensing element and bypass control valve.

Features

• Eliminates high cost of installation and

maintenance of complex conventional

flow control loops.

• Eliminates multiple vendors of

components.

• Eliminates cavitation in the valving

and piping.

• Only three pipe connections.

• Eliminates any power source or

instrument signal.

• One piece body design. Bonnetless,

packless design eliminates a potential

leak path to atmosphere. Valve is

intrinsically safe for a broad range

of pumping applications in the

hydrocarbon industry.

• Totally mechanical activation of the

bypass with no levers, linkage, control

signals or pilot valves to fail. Greatly

reduced maintenance, improved

reliability and confidence that the

valve will operate when needed.

• Integral vortex inducing flow

conditioner; controls the damaging

effects of any cavitation resulting

from the fluid pressure reduction by

directing cavitation away from the

pipeline walls.

• Balanced stem designed with

characterized orifices provides a

one-stage pressure reduction.

Extends trim life and eliminates the

creation of potentially destructive Sizes and Connections Options

cavitation while insuring a more stable • 2", 3", 4", 6", 8", 10", 12" and 14" • NACE Valve conforming to MR0175

operation. External Back Pressure Regulator

• 2" to 14" Class 150 - 300 ANSI

(if required)

• Flow loop testing and performance RF flanged

curve evaluation certify each 9200 • DIN, BS, JIS, and RTJ flanges

ARC® Valve order. Assures reliable Ratings optional

performance from every valve. • ANSI Class: 150 - 300

• 6 Mo SS construction for sea

• Temperature Range: -150°F to 550°F water applications

• Super Duplex SS construction

www.pentair.com/valves Copyright © 2013 Pentair. All rights reserved. YAWMC-0425-US-0909

Yarway 9200 Series ARC® Valve

For Centrifugal Pump Protection

Series 9200 ARC® Valve

Stable by Design – Large

disc, spring and snubber

design combined to achieve

Integral Check Valve –

optimum operating stability

Spring-leaded against seat, the

at various process flow

flow sensing disc acts as a main

conditions.

flow check valve.

Superior Recirculation

Flow Control – Characterized

orifices in the bypass element

provide accurate, modulated

recirculation flow.

Staged Pressure Letdown –

Bypass trim design provides

multistage pressure reduction.

Copyright © 2013 Pentair. All rights reserved. YAWMC-0425

2

Yarway 9200 Series ARC® Valve

For Centrifugal Pump Protection

The New Series 9200 ARC® Valve

The Series 9200 ARC® represents the Control Loop System

latest concepts in valve design. It is Storage

truly a valve designed for today’s market vessel

needs. Like its predecessors, it uses Gate valve

(optional)

proven technology in providing economical, Multiple pressure-

as well as effective, protection for reducing orifice

Four-way air

centrifugal pumps against damage solenoid valve

resulting from low flow instability or

Recirculation

overheating. By providing recirculation

control valve

flow to the suction source of the pump,

the 9200 ARC® assures a minimum flow FIC

for stable pump operation. To process Gate valve

(optional)

Flow meter

Among the many improvements are a

balanced bypass trim design offering

improved efficiency in pressure letdown,

improved flow capacity, and improved

stability and performance at all service Gate or Check

control valve valve

conditions. Externally a more compact

and lighter weight one-piece design Pump Sensing orifice

is used to ease valve installation,

handling, maintenance and pipe

support requirements and considerations.

A new range of sizes through 14" is also

offered. Internally, a flow conditioner is

used to further improve pressure letdown Yarway System

Remote back pressure

in the bypass and reduce noise. For regulator (optional)

those special requirements,the 9200 Storage

ARC® offers a configurable trim design. vessel

In all cases the 9200 ARC® is flow tested

prior to shipment to assure your Check

valve

performance requirements are met. To process

The modulating 9200 Series ARC®

provides operating economies in several

ways. The ARC® recirculates only the Bypass

element

flow required to assure minimum flow

through the pump at all times. Under full

process flow, recirculation flow is not

required. But as process flow demand Gate or

decreases, recirculation flow becomes control valve Automatic

necessary. Unlike continuous recirculation

valve Pump

recirculation, the ARC® responds

directly to this need. This avoids the

need to oversize the pump and prime

mover which can add substantially to

the capital, energy and operating costs

of the system. pressure letdown device. Moreover, it of recirculation control valves

The ARC® also provides cost savings requires no instrument signal or power manufactured by Yarway over the

over an instrumented flow control loop. source, and requires none of the past 30 years.

Instead of a multiple component system, maintenance associated with

ARC® valves have been installed in

the ARC® is a self-contained system; a these systems.

power plants, refineries and process

flow sensing orifice; a check valve; Manufactured and tested in the USA, plants worldwide, providing consistent

a recirculation control valve and a the 9200 ARC® is one of an entire family and reliable service.

Copyright © 2013 Pentair. All rights reserved. YAWMC-0425

3

Yarway 9200 Series ARC® Valve

For Centrifugal Pump Protection

How it Works: ARC® Operation and Pump/System Curve

The heart of the recirculation valve is As the disc lifts (Figure 2) in response to characterized orifices inside the disc

a main flow sensing check valve disc, an increase in flow to the process, the stem. Flow continues through an

which is flow sensitive, not pressure bypass element, which is integral to the annulus in the bypass bushing and

sensitive. The disc modulates to the disc, closes the bypass flow orifices is directed to the outlet of the valve.

demand for process flow at the same reducing recirculation flow. Recirculation

The valve provides for single phase flow

time assuring a minimum flow through flow is controlled with disc position. This

in the bypass eliminating the possibility

the pump. This modulating characteristic modulation feature assures that the total

of flashing or cavitation. This is

results in a consistent, stable, and of process flow and recirculation flow

accomplished by the valve trim and

repeatable performance over full exceed the minimum flow through the

flow conditioner design, and if

pressure range. pump as specified by the pump

necessary, an integral second stage

manufacturer.

The disc is shown in the closed position pressure letdown device or external

in Figure 1. In this position there is no When the disc is set at full lift position, back pressure regulator.

process flow and the bypass is fully as in Figure 3, the bypass is closed.

open. This protects the pump against As process flow decreases, the reverse

planned or accidental “dead heading” action occurs and the recirculation flow

which can result from a closed down again increases. Flow enters the bypass

stream pump isolation valve or process element at the bottom of the disc

control valve. assembly and is controlled by

Figure 1 Figure 2 Figure 3

No Process Flow Changing Process Flow Increased Process Flow

Full Recirculation Controlled Recirculation No Recirculation

Copyright © 2013 Pentair. All rights reserved. YAWMC-0425

4

Yarway 9200 Series ARC® Valve

For Centrifugal Pump Protection

The cost of the electricity consumed in Continuously pumping 400 gpm against

continuous recirculation cooling is a 500-foot head requires 65 horsepower.

significantly higher than usually realized. In a 5¢/kwh power cost area, total annual

For example, the manufacturer of a 1200 cost savings using an ARC® valve would

gpm pump with a discharge head of 500 be approximately $24,000 (Figure 5).

feet, may require 400 gpm recirculated

flow to keep it cool (Figure 4).

1600

200 400 600 800 600

400,000

1500

1400

1300 14¢

500

wh

pm

¢/k

,g

1200

12

me

te

lu

Ra

Vo

1100

ic

on

Pump Operating Cost (8760 h/yr.) $/yr.

ctr

Discharge Head (ft. of water)

400

lati

1000

Ele

cu

cir

Re

900

Discharge Head (psi)

800

300 10¢

700

600 160,000

200

500

120,000

400

300 80,000

100

200 48,000

40,000

Assume SP GR = 0.90

100

0

0 65 100 200 300 400 0 65 100 200 300 400

Requirements for Pump Circulation (hp) Power Required for Recirculation (hp)

Figure 4 Figure 5

Copyright © 2013 Pentair. All rights reserved. YAWMC-0425

5

Yarway 9200 Series ARC® Valve

For Centrifugal Pump Protection

How it Works

Valve Installation Receiver vessel Piping Installation Receiver vessel

(common line to receiver) (separate line to receiver)

Recommended location

of back pressure device

when specified

Check

valve

To process To process

Check

valve

3R Elbow radius 3R Elbow radius

Flow from Flow from equal to 3 times

equal to 3 times

feed pump feed pump normal pipe size

normal pipe size

Valve Installation The 9200 ARC® can be installed in a applications. Pressure reduction even

Two common installation approaches vertical flow up or horizontal position. by multiple stage cascading can

are pictured above. In the first, a Other piping practices regarding minimize the requirement, however

common recirculation line is used velocity, geometry and location of no valve design will redefine a fluid’s

to return bypass flow to the receiver valve and pipe members should be physical properties.

consistent with good industry practices

vessel where multiple pumps are This becomes especially important in

and standards.

used to produce process flow. In modulating systems. A fixed orifice will

these installations, each pump must Back Pressure Regulator not provide the proper back pressure

be protected with a dedicated pump In high pressure pumping applications at all flow levels. As the flow in the

protection valve. The second diagram the system often does not provide bypass line is reduced, the orifice

shows the more common one pump, adequate pressure in the bypass line becomes less effective. Proper system

one bypass system approach. to prevent cavitation or flashing. Either design should be used to optimize

In each of these cases, treatment of of these conditions is undesirable valve pressure reduction and consider

the bypass line is very similar once flow in that it can cause damage to both all fluid dynamic effects downstream

requirements have been determined. valves and the pipe system or cause or any pressure reducing device.

A backpressure device with fixed or a reduction in flow below the minimum A responsible ARC® valve manufacturer

variable orifice is commonly mounted desired, jeopardizing the pump will determine the need and supply

close to the receiver vessel where protection system. All PRVs will a back pressure regulator when it

flashing liquid is safely discharged. experience a velocity induced recovery is required.

Check valves are installed in the effect which will limit the amount of

bypass line to prevent bypass back pressure drop a valve can take and

flow and block valves are installed cause a reduction in flow capacity.

with a lock open option to allow The requirement of back pressure

closure by authorized personnel only. is generic to all pressure reducing

Copyright © 2013 Pentair. All rights reserved. YAWMC-0425

6

Yarway 9200 Series ARC® Valve

For Centrifugal Pump Protection

9200 Series – Sizes 2", 3" and 4"

3

3 88

2

2

10

14

14

7

11

11

44

44 5

12

12 13

13

C

C

6 B

B

11

Parts and Materials

Item Part Material Item Part Material

ASTM A-216 Grade WCB with ASTM A747 7 Spring AISI 316 Stainless Steel

1 Body Grade CB7Cu-1 (17-4 PH Cast) Condition 8 Gasket Sigraflex BP (Graphite)

H900 (J92180) Seat Ring

9 Snubber Seal Variseal – Carbon filled TFE

2 Upper Stop ASTM A216 WCB

10 Screw AISI 316 Stainless Steel

3 Orifice 18-8

11 Snubber Ring ASTM A276-S21800A (Nitronic 60 Bar)

4 Disc Assembly ASTM A351 Type CF8M

12 Spiral Ring PH15-7MO

5 Flow Conditioner ASTM A351 Type CF8M

13 Snubber Washer AISI 316 Stainless Steel

ASTM A747 Grade CB7Cu-1 (17-4 PH Cast)

6 Bypass Bushing 14 Nameplate AISI 300 Series Stainless Steel

Condition H900 (J92180)

Dimensions and Weights

Valve Size Class Dimensions, in. [mm] Bypass Flange Size Weight

in. [DN] ANSI A B C in. [DN] lb. (kg)

150 42 (19.0)

2 [50] 300 41/4 [108.4] 4 3/4 [120.7] 11 [279.4] 11/2 [40] 46 (20.9)

150 73 (33.1)

3 [80] 4 3/4 [120.7] 5 3/4 [146.1] 13 3/4 [349.3] 2 [50]

300 81 (36.7)

150 126 (57.2)

4 [100] 51/2 [139.7] 7 3/4 [196.9] 17 3/4 [450.9] 3 [80]

300 147 (66.7)

Copyright © 2013 Pentair. All rights reserved. YAWMC-0425

7

Yarway 9200 Series ARC® Valve

For Centrifugal Pump Protection

9200 Series – Sizes 6" and 8"

88 2

2

10

10

7

7

14

11

11

9

9

44

3

3

12

12

33 13

13 4

4

55

C

C

66

11

A

Parts and Materials

Item Part Material Item Part Material

ASTM A-216 Grade WCB with ASTM A747 7 Spring AISI 316 Stainless Steel

1 Body Grade CB7Cu-1 (17-4 PH Cast) Condition 8 Gasket Sigraflex BP (Graphite)

H900 (J92180) Seat Ring

9 Snubber Seal Variseal – Carbon filled TFE

2 Upper Stop ASTM A216 WCB

10 Screw AISI 316 Stainless Steel

3 Orifice 18-8

11 Snubber Ring ASTM A276-S21800A (Nitronic 60 Bar)

4 Disc Assembly ASTM A351 Type CF8M

12 Spiral Ring PH15-7MO

5 Flow Conditioner ASTM A351 Type CF8M

13 Snubber Washer AISI 316 Stainless Steel

ASTM A747 Grade CB7Cu-1 (17-4 PH Cast)

6 Bypass Bushing 14 Nameplate AISI 300 Series Stainless Steel

Condition H900 (J92180)

Dimensions and Weights

Valve Size Class Dimensions, in. [mm] Bypass Flange Size Weight

in. [DN] ANSI A B C D in. [DN] lb. (kg)

150 296 (135)

6 [150] 300 71/2 [190] 81/2 [216] 211/2 [546] N/A 4 [100] 344 (156)

150 559 (254)

8 [20] 10 [254] 11 [279.5] 28 [711] 8 3/4 [222] 6 [150]

300 613 (278)

Copyright © 2013 Pentair. All rights reserved. YAWMC-0425

8

Yarway 9200 Series ARC® Valve

For Centrifugal Pump Protection

9200 Series – Sizes 10", 12" and 14"

3

3 2

2

19

19

12

12 24

24

23

23

17

17

11

11 7

4

4

15

15

10

21

21

99 18

18

20

20

16

16

8

8 55 C

C

14

14

B

B

13

13

66

1

1

D

D A

Parts and Materials

Item Part Material Item Part Material

1 Body ASTM A-216 Grade WCB 12 Backup Ring Carbon/Graphite Reinforced PTFE (Turcite 51)

2 Upper Stop ASTM A-216 Grade WCB 13 O-ring EPDM

3 Orifice Stainless Steel 18-8 14 Backup Carbon/Graphite Reinforced PTFE (Turcite 51)

ASTM A351 Type CF8M 15 O-ring EPDM

4 Disc Assembly

Disc with ASTM A479 Type A21800A Stem 16 Backup Ring Carbon/Graphite Reinforced PTFE (Turcite 51)

5 Flow Conditioner ASTM A351 Type CF8M 17 Snubber Seal Variseal Turcon 10

ASTM A747 Grade CB7Cu-1 (17-4 PH Cast) 18 O-ring EPDM

6 Bypass Bushing

Condition H900 (J92180) 19 Screw Stainless Steel 316

7 Spring 17-7 PH Condition CH-900 20 Spiral Ring ASTM A564 Type 631 (17-7 PH)

8 Bushing Retainer ASTM A479 Type 410 21 Snubber Ring ASTM A479 Type S21800A (Nitronic 60 Bar)

9 Spiral Ring ASTM A564 Type 631 (17-7 PH) 20 Spiral Ring ASTM A564 Type 631 (17-7 PH)

10 Set Screw ASTM A286 UNS S66286 23 Spiral Ring ASTM A564 Type 631 (17-7 PH)

11 O-ring EPDM 24 Nameplate 300 Series Stainless Steel

Dimensions and Weights

Valve Size Class Dimensions, in. [mm] Bypass Flange Size Weight

in. [DN] ANSI A B C D in. [DN] lb. (kg)

150

10 [250] 300 13 [330] 16 [406] 411/2 [1054] 11 [279.4] 8 [200] 1600 (726)

150

12 [305] 15 [381] 19 [483] 50 [1270] 13 [330.2] 10 [250] 2650 (1200)

300

150

14 [355] 161/2 [419] 21 [533] 57 1/2 [1461] 15 [381] 10 [250] 3350 (1520)

300

Copyright © 2013 Pentair. All rights reserved. YAWMC-0425

9

Yarway 9200 Series ARC® Valve

For Centrifugal Pump Protection

Hydraulic Performance Test Lab

Performance – Profiled in Yarway’s Hydraulic Performance Test Lab

In our hydraulic performance test laboratory, state-of-the-art data acquisition and

computer graphics techniques are called upon for evaluation of the significant performance

characteristics of Yarway recirculation control valves. The lab’s equipment makes it

possible to test a valve over its complete flow range for factors including:

• Total flow through the pump

• Disc position

• Pressure drop across the main check

• Bypass Cv

• Bypass DP

• Valve response to sudden changes in flow

• Bypass piston pressure

These detailed analyses are the user’s complete assurance that the valve meets

performance requirements in all respects and can be supplied with the valve.

A certified test curve is shipped with each valve (see page 11 for example).

Insist on it, as you would for your pump!

Copyright © 2013 Pentair. All rights reserved. YAWMC-0425

10

Yarway 9200 Series ARC® Valve

For Centrifugal Pump Protection

Certified Test Curve

Main (GPM)

0 200 400 600 800 1000 1200 1400 1600

25.0

20.0

Main DP (PSID)

15.0

10.0

5.0

0.0

2.50

2.00

1.50

Disc Lift (IN)

1.00

0.50

0.00

0 200 400 600 800 1000 1200 1400 1600

30.0

25.0

20.0

Bypass Cv

15.0

10.0

5.0

0.0

0 200 400 600 800 1000 1200 1400 1600

Main (GPM)

1600.0

1400.0

1200.0

1000.0

Total Flow (GPM)

800.0

600.0

400.0

200.0

0.0

0 200 400 600 800 1000 1200 1400 1600

Main Flow (GPM)

Maximum Main Flow (gpm [m3/hr] @ Specific Gravity = 1)

Inch: 2 3 4 6 8 10 12 14

[DN]: [50] [80] [100] [150] [200] [250] [305] [355]

190 430 765 1600 2800 4500 6500 8500

[43] [98] [174] [364] [636] [1023] [1477] [1932]

Copyright © 2013 Pentair. All rights reserved. YAWMC-0425

11

Yarway 9200 Series ARC® Valve

For Centrifugal Pump Protection

How to Order

Our sales representatives will help you select the correct valve for your application.

Please complete this form before contacting the sales office to help ensure all necessary information is provided.

Automatic Recirculating Control (ARC®) Valve Data Sheet

Customer:

Company:

Project:

Location:

Phone: E-Mail:

Qty Required: Delivery Required: Additional Info:

Tag(s) ID:

Pump Flow Please Complete Flow Requirements

Normal -Process- flow: GPM M3/H BPD

Maximum -Process- flow:

Minimum -Process- flow (optional): (if Minimum Flow is to be considered in sizing)

Minimum pump protection flow: (Minimum required “Recirculation Flow”)

Pump Discharge Pressure Please Complete Pressure Requirements

Pump pressure at Shut-off (zero flow): psi bar KgF/cm2 Kpa

Pump pressure at Normal -Process- flow:

Pump pressure at Minimum -Process- flow (optional): (if Minimum Flow is to be considered in sizing)

Pump pressure at Minimum pump protection flow: (at Minimum required “Recirculation Flow”)

ARC Valve Bypass line pressure: (Line pressure at ARC Valve bypass port)

Temperature Please Enter Both Temperatures

Normal temperature at ARC Valve: °F °C

Maximum temperature at ARC Valve:

Fluid

Liquid: Boiler Feed Water (In this case disregard S.G. and V.P.)

Other (Please specify) _________________

Specific Gravity:

Orientation of ARC Valve: Vertical Horizontal

Vapor Pressure:

Desired End Connections: Raised Face Flange

Viscosity: Ring Type Joint (RTJ)

Flat Face Flange

Butt Weld Ends

Other - Specify in “Comments”

Desired Pressure Class: 150 300 600 900 1500 2500

Desired Body Material: A216 Gr. WCB

A351 Gr. CF8M

A351 Gr. CK3MCuN (6Mo)

A995 Gr. CD3MWCuN (Super Duplex)

Desired Seal Material (except 2" to 8" 9200 and 9300): Ethylene Propylene (EPR or EPDM)

TFE Propylene (Aflas or Fluoraz)

Fluorocarbon Rubber (Viton®)

Other - Specify in “Comments”

Pump Drive Type: Constant Speed - Motor Driven

Variable Speed (VFD) - Motor Driven

Variable Speed - Turbine Driven

Other - Specify in “Comments”

Comments:

NACE Materials Required? Certificate of Compliance for Hydro Test Required?

Flow Test with Performance Certificate Required? Magnetic Particle Test Required?

Customer Inspection Required Prior to Shipment? Radiograph Inspection Required (specify scope)?

Certified Material Test Report (Pressure Containing Components only)?

Flow tests are generally conducted on all model 5300 and 7100 ARC® valves and one model 9100 or 9200 ARC® valve per sales order line item at no additional cost.

Model 9300 ARC® valves and other flow test requirements are upon request and at additional cost. If flange drilling is other than ANSI, please specify in “Comments.”

Please include Pump Curve if available.

Copyright © 2013 Pentair. All rights reserved. YAWMC-0425

12

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- TIASA - Thermal Insulation HandbookDocument58 pagesTIASA - Thermal Insulation HandbookSirGawain99No ratings yet

- Jresv2n3p561 A2b PDFDocument100 pagesJresv2n3p561 A2b PDFachmadh_2010No ratings yet

- Recommended velocities and pressure drops for common process pipelinesDocument5 pagesRecommended velocities and pressure drops for common process pipelinesger80100% (1)

- NSFMW 1992 Technical PapersDocument379 pagesNSFMW 1992 Technical Papersachmadh_2010No ratings yet

- CV and K FactorDocument3 pagesCV and K Factorsjk_akolNo ratings yet

- W15958Leahey2001 Flare PaperDocument7 pagesW15958Leahey2001 Flare Paperachmadh_2010No ratings yet

- Flow MeasurementDocument113 pagesFlow Measurementprasathesr100% (1)

- Natural Circulation in BoilerDocument9 pagesNatural Circulation in BoilerSajjad AhmedNo ratings yet

- Wire Mesh Mist Elim.Document6 pagesWire Mesh Mist Elim.perrychemNo ratings yet

- CHE204-HD18 - Minimum Fluidization Velocity PDFDocument3 pagesCHE204-HD18 - Minimum Fluidization Velocity PDFachmadh_2010No ratings yet

- Pressure Drop Calculation - XpsDocument21 pagesPressure Drop Calculation - Xpsachmadh_2010No ratings yet

- Valve Size ManualDocument43 pagesValve Size Manualarthur_toafkNo ratings yet

- Experimental Investigation (STHE)Document13 pagesExperimental Investigation (STHE)achmadh_2010No ratings yet

- Heat Transfer Ch14Document9 pagesHeat Transfer Ch14Yehuda SimanjuntakNo ratings yet

- Preparing Process Unit for Initial StartupDocument7 pagesPreparing Process Unit for Initial StartupTan JieShengNo ratings yet

- Sizing Shell and Tube Heat ExchangerDocument17 pagesSizing Shell and Tube Heat ExchangerCallum Biggs100% (3)

- Air Drier TypeDocument6 pagesAir Drier Typeachmadh_2010No ratings yet

- Shell& Tube Heat ExchangerDocument57 pagesShell& Tube Heat ExchangermirzafarhathNo ratings yet

- The Application of Control Valves To Compressor Anti-Surge SystemsDocument27 pagesThe Application of Control Valves To Compressor Anti-Surge Systemsamms9988No ratings yet

- Gas SweeteningDocument66 pagesGas Sweeteningachmadh_2010No ratings yet

- Norsok ST 2001Document131 pagesNorsok ST 2001mamounsdNo ratings yet

- Lower (LEL) & Upper (UEL) Explosive Limits PDFDocument1 pageLower (LEL) & Upper (UEL) Explosive Limits PDFSale RadosavljevicNo ratings yet

- STHE 0026 190711 ColinDeddis BP TubeRupture-EIMeetingJuly2011Document33 pagesSTHE 0026 190711 ColinDeddis BP TubeRupture-EIMeetingJuly2011achmadh_2010No ratings yet

- 2014eikrem (Slug)Document39 pages2014eikrem (Slug)achmadh_2010No ratings yet

- Pressure Relief Safety ValvesDocument52 pagesPressure Relief Safety Valveswah_ma100% (3)

- Ion Exchange ResinDocument7 pagesIon Exchange ResinAnup Bajracharya75% (4)

- Wa - 03 - 02 - e Capacity Control (Reciprocating Compressor Capacity Control)Document15 pagesWa - 03 - 02 - e Capacity Control (Reciprocating Compressor Capacity Control)achmadh_2010100% (1)

- Darcy - Weisbach - EquationDocument6 pagesDarcy - Weisbach - Equationachmadh_2010No ratings yet

- Secondary Drinking Water Regulations - EPADocument3 pagesSecondary Drinking Water Regulations - EPAcarlcrowNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Canusa GTS - 3LPEDocument2 pagesCanusa GTS - 3LPEarifin rizalNo ratings yet

- Reliance Jio Industry AnalysisDocument45 pagesReliance Jio Industry AnalysisBhavya BhartiNo ratings yet

- Vienna ModernDocument85 pagesVienna ModernZain ZulfiqarNo ratings yet

- Petri Net Modeling and ApplicationsDocument13 pagesPetri Net Modeling and ApplicationsRishiraj SenguptaNo ratings yet

- Physical and Rheological Properties of Modified Sulfur Asphalt BinderDocument8 pagesPhysical and Rheological Properties of Modified Sulfur Asphalt Binderramesh naikNo ratings yet

- Acee 2018 039Document13 pagesAcee 2018 039threedlabsNo ratings yet

- TF Section - MICET 2016Document21 pagesTF Section - MICET 2016Eddie D SouzaNo ratings yet

- 2010 Xstrata VOD Implementation - BartschDocument35 pages2010 Xstrata VOD Implementation - BartschFlávia GomesNo ratings yet

- Ee09 704 - Electrical Machine Design Model QPDocument2 pagesEe09 704 - Electrical Machine Design Model QPGīřïşh McNo ratings yet

- DESIGN II - ChemTran General Reference GuideDocument332 pagesDESIGN II - ChemTran General Reference GuideDebabrata MitraNo ratings yet

- Elevator Installation Contract - 2022 - CNMDocument5 pagesElevator Installation Contract - 2022 - CNMsolid groupNo ratings yet

- Saes N 004Document5 pagesSaes N 004Mo'tasem SerdanehNo ratings yet

- FTS ScaleoEUserManualEN 10 1082177Document2,044 pagesFTS ScaleoEUserManualEN 10 1082177JNo ratings yet

- Wind Load CompututationsDocument31 pagesWind Load Compututationskim suarezNo ratings yet

- SQL Server 2008 R2 Express Installation GuideDocument53 pagesSQL Server 2008 R2 Express Installation GuideGersonGamas100% (2)

- Nurul Ain - nurulain@gmail.comDocument32 pagesNurul Ain - nurulain@gmail.comMuhamad FarhanNo ratings yet

- T REC K.Sup16 201905 I!!PDF E PDFDocument24 pagesT REC K.Sup16 201905 I!!PDF E PDFMark LionNo ratings yet

- Technical Report PDFDocument184 pagesTechnical Report PDFSrinivasan RajenderanNo ratings yet

- Cat 120H, 12H, 140H, 143H, 160H, 163H TransmisiónDocument8 pagesCat 120H, 12H, 140H, 143H, 160H, 163H TransmisiónJefferson Maldonado.No ratings yet

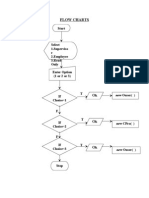

- Flow Charts Option: StartDocument13 pagesFlow Charts Option: StartbalabooksNo ratings yet

- A Practical Introductory Guide On Using Satellite Technology For CommunicationsDocument15 pagesA Practical Introductory Guide On Using Satellite Technology For CommunicationsJohan PrinslooNo ratings yet

- Comb Manual IM 106 6888QSDocument36 pagesComb Manual IM 106 6888QSsathish2829No ratings yet

- CS As Corporate Saviour - Oil and Gas Industry PDFDocument48 pagesCS As Corporate Saviour - Oil and Gas Industry PDFBalraj JNo ratings yet

- High Build Epoxy Coating for Hulls and Ballast TanksDocument3 pagesHigh Build Epoxy Coating for Hulls and Ballast Tankskasosei0% (1)

- Sop Hydraulic Punch and ShearDocument1 pageSop Hydraulic Punch and ShearBorislav VulićNo ratings yet

- AIR Modeller 75 2017-12-20 - 01Document68 pagesAIR Modeller 75 2017-12-20 - 01JoãoGilbertoAraújoPontes100% (4)

- Textbook of Applied ElectronicsDocument8 pagesTextbook of Applied Electronicsshehnasheh99No ratings yet

- M-III (II ECE-B, 1st SEM)Document63 pagesM-III (II ECE-B, 1st SEM)venkatesh sripadNo ratings yet

- As 2560.2.1-2003 Sports Lighting Specific Applications - Lighting For Outdoor TennisDocument7 pagesAs 2560.2.1-2003 Sports Lighting Specific Applications - Lighting For Outdoor TennisSAI Global - APAC0% (1)

- Mechanical Testing of MaterialsDocument38 pagesMechanical Testing of MaterialsAanand Rishabh DagaNo ratings yet