Professional Documents

Culture Documents

Agrietamiento - Tablero

Uploaded by

vladimirjimboOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Agrietamiento - Tablero

Uploaded by

vladimirjimboCopyright:

Available Formats

5-46 AASHTO LRFD BRIDGE DESIGN SPECIFICATIONS, SEVENTH EDITION, 2014

Snc = section modulus for the extreme fiber of the Based on this observation, a reduced (yO factor of 1.2 is

monolithic or noncomposite section where justified.

tensile stress is caused by externally applied

loads (in.3)

Appropriate valúes for Mdnc and SK shall be used for

any intermedíate composite sections. Where the beams

are designed for the monolithic or noncomposite section

to resist all loads, S^ shall be substituted for Sc in the

above equation for the calculation of Mcr.

The following factors shall be used to account for

variability in the flexural cracking strength of concrete,

variability of prestress, and the ratio of nominal yield

stress of reinforcement to ultímate:

Yi = flexural cracking variability factor

= 1.2 forprecast segmenta! structures

= 1.6 for all other concrete structures

j2 = prestress variability factor

= 1.1 for bonded tendons

= 1.0 for unbonded tendons

y3 = ratio of specified mínimum yield strength

to ultímate tensile strength of the

reinforcement

= 0.67 for A615, Grade 60 reinforcement

= 0.75 for A706, Grade 60 reinforcement

= 1.00 for prestressed concrete structures

The provisions of Article 5.10.8 shall apply.

5,73.4—Control of Cracking by Distribution of C5.7.3.4

Reinforcement

The provisions specified herein shall apply to the All reinforced concrete members are subject to

reinforcement of all concrete components, except that of cracking under any load condition, including thermal

deck slabs designed in accordance with Article 9.7.2, in effects and restraint of deformations, which produces

which tensión in the cross-section exceeds 80 percent of tensión in the gross section in excess of the cracking

the modulus of rupture, specified in Article 5.4.2.6, at strength of the concrete. Locations particularly

applicable service limit state load combination specified vulnerable to cracking include those where mere is an

inTable3.4.1-l. abrupt change in section and intermedíate post-

tensioning anchorage zones.

Provisions specified, herein, are used for the

distribution of tensión reinforcement to control flexural

cracking.

Crack width is inherently subject to wide scatter.

even in careful laboratory work, and is influenced by

shrinkage and other time-dependent effects. Steps

should be taken in detailing of the reinforcement to

control cracking. From the standpoint of appearance,

many fine cracks are preferable to a few wide cracks.

Improved crack control is obtained when the steel

reinforcement is well distributed over the zone of

máximum concrete tensión. Severa! bars at modérate

spacing are more effective in controlling cracking than

one or tvvo larger bars of equivalent área.

© 2014 by the American Association of State Highway and Transportation Officials.

All rights reserved. Duplícatíon ís a violation of applicable law.

SECTION 5: CONCRETE STRUCTURES 5-47

The spacing s of mild steel reinforcement in the Extensivo laboratory work involving deformed

layer closest to the tensión face shall satisfy the reinforcíng bars has confirmed that the crack width at

following: the service limit state is proportional to steel stress.

However, the significant variables reflecting steel

detailing were found to be the thickness of concrete

- 2d (5.7.3.4-1) cover and spacing of the reinforcement.

Eq. 5.7.3.4-1 is expected to provide a distribution of

reinforcement that will control flexural cracking. The

in which: equation is based on a physical crack model (Frosch,

2001) rather tiían the statistically-based model used in

previous editions of the specifications. It is written in a

P, = 1-

form emphasizing reinforcement details, i.e., limiting bar

spacing, rather than crack width. Furthermore, the physical

where: crack model has been shown to provide a more realistic

estimate of crack widths for larger concrete covers

exposure factor compared to the previous equation (Destefano, 2003).

1.00 for Class 1 exposure condition Eq. 5.7.3.4-1 with Class 1 exposure condition is

0.75 for Class 2 exposure condition based on an assumed crack width of 0.017 in. Previous

de 5 thickness of concrete cover measured from research indicates that there appears to be littíe or no

extreme tensión fiber to canter of the flexural correlation between crack width and corrosión, however,

reinforcement located closest thereto (in.) the different classes of exposure conditions have been so

calculated tensile stress in mild steel defined in order to provide fiexibility in the application of

fss ~

reinforcement at the service limit state not to these provisions to meet the needs of the Authority having

exceed 0.60 ./¿(ksi) jurisdiction. Class 1 exposure condition could be thought

h = overall thickness or depth of the component of as an upper bound in regards to crack width for

(in.) appearance and corrosión. Áreas that the Authority

having jurisdiction may consider for Class 2 exposure

condition would include decks and substructures exposed

to water. The crack width is directly proportional to the je

exposure factor, therefore, if the individual Authority with

jurisdiction desires an altérnate crack width, the je

factor can be adjusted directly. For example a je factor

of 0.5 will result in an approximate crack width of

0.0085 in.

Class 1 exposure condition applies when cracks can Where members are exposed to aggressive exposure

be tolerated due to reduced concerns of appearance or corrosive environments, additional protection beyond

and/or corrosión. Class 2 exposure condition applies to that provided by satisfying Eq. 5.7.3.4-1 may be

transverso design of segmental concrete box girders for provided by decreasing the permeability of the concrete

any loads applied prior to attaining full nominal concrete and/or waterproofmg the exposed surface.

strength and when there is increased concern of Cracks in segmental concrete box girders may result

appearance and/or corrosión. from stresses due to handling and storing segments for

In the computation of dc, the actual concrete cover precast construction and to stripping forms and supports

thickness is to be used. from cast4n-place construction before attainment of the

When computing the actual stress in the steel nominal f'c.

reinforcement, axial tensión effects shall be considered, The ps factor, which is a geometric relationship

while axial compression effects may be considered. between the crack width at the tensión face versus the

The mínimum and máximum spacing of crack width at the reinforcement level, has been

reinforcement shall also comply with the provisions of incorporated into the basic crack control equation in

Arricies 5.10.3.1 and 5.10.3.2, respectively. order to provide uniformity of application for flexural

The effects of bonded prestressing steel may be member depths ranging from thin slabs in box culverts

considered, in which case the valué of f , used in to deep pier caps and thick footings. The theoretical

Eq. 5.7.3.4-1, for the bonded prestressing steel, shall be definition of PJ may be used in lieu of the approximate

the stress that develops beyond the decompression state expression provided.

calculated on the basis of a cracked section or strain Research by Shahrooz et al. (2011) indicated that

compatibility analysis. Eq. 5.7.3.4-1 can be applied to reinforcement with

Where flanges of reinforced concrete T-girders and specified mínimum yield strengths up to 100 ksi but the

box girders are in tensión at the service limit state, the tensile stress in the steel reinforcement at the service

flexural tensión reinforcement shall be distributed over limit state, fss, cannot exceed 60.0 ksi with fy 100 ksi. A

the lesser of: limit offss< 0.60_/J,was adopted.

© 2014 by the American Association of State Highway and Transportation Officials.

All rights reserved. Duplication is a violation of applicable law.

PROYECTO: PUENTE SOBRE EL RIO QUEVEDO

Cálculo: Caminosca.- Ing. Juan M. Vinueza Moreno

Hoja:

SUPERESTRUCTURA: TRAMO L = 85,00 m

EVALUACIÓN DEL DISEÑO PARA EL ESTADO LIMITE DE SERVICIO AASHTO LRFD 2014 Art. 5,7.3.4

Para no tener problemas de agrietamiento, el espaciamiento del acero de refuerzo en la cara en tracción deberá satisfacer:

700 ye

s < 2dc Ec: 5.7.3.4-1 Espaciamiento máximo

PS fes

de

Bs = 1 + -

0,7(h - de)

fs = Esfuerzo de tracción en el acero de refuerzo en el Estado Límite de Servicio.

h.- Altura total del elemento

YC = 0,75 Condición de exposición.

n = 10,00 Relación de módulos de elasticidad

b = 100,00 cm Ancho de faja de diseño

nAs (de-y) = by(y/2)

nAs de - nAs y

As de (b^y2 + nAs y - nAsde = O

nAs ! -nAs + \J(nAs)2 + 2bnAsde~

b

Itranf = nAs (de - y)2 +

fs = M c x n

I

c = de - y Distancia desde eje neutro a cg del acero

CONTROL AGRIETAMIENTO: ZONA MOMENTO NEGATIVO.- APOYO INTERIOR

dc(-) = 3,0 cm

h 20,0 cm Alltura del tablero

(3s 1,3

M 4,034 tm Servicio I

As = 16,08 cm2

de 17,00 cm2

y 5,96 cm2 Ubicación eje neutro

Itranf = 26.655,5 cm" Inercia de la sección transformada

fe 1.670,89 kg/cm2 Calculado

Stnáx = 38,62 cm Separación máxima

Svar = 12,5 cm Separación entre varillas

CONTROL AGRIETAMIENTO: ZONA MOMENTO NEGATIVO.- VOLADIZO

dc(-) = 3,0 cm

h 20,0 cm Alltura del tablero

ps 1,3

M 4,389 tm Servicio I

As 16,08 cm2

de 17,00 cm2

y 5,96 cm2 Ubicación eje neutro

Itranf = 26.655,5 cm"

fe 1.818,07 kg/cm2 Esfuerzo en el acero

Smáx = 35,01 cm Separación máxima

Svar = 12,5 cm Separación entre varillas

CONTROL AGRIETAMIENTO: ZONA MOMENTO POSITIVO.- TRAMO

dc(+) = 3,0 cm

h 20,0 cm Alltura del tablero

ps • = 1,3

M 4,034 tm Servicio I

As 16,08 cm2

de 17,00 cm2

y 5,96 cm2 Ubicación eje neutro

Itranf = 26.655,5 cm"

fe 1 .670,89 kg/cm2 Esfuerzo en el acero

smáx = 38,62 cm Separación máxima

Svar = 12,5 cm Separación entre varillas

PROYECTO: PUENTE SOBRE EL RIO QUEVEDO

Cálculo: Caminosca.- !ng. Juan M. Vinueza Moreno

Hoja:

SUPERESTRUCTURA: TRAMO L =85,00 m

EVALUACIÓN DEL DISEÑO PARA EL ESTADO LIMITE DE SERVICIO AASHTO LRFD 2014 Art. 5,7.3,4

Para no tener problemas de agrietamiento, el espaciamiento del acero de refuerzo en la cara en tracción deberá satisfacer:

700 ye

-2dc Ec: 5.7,3.4-1 Espaciamiento máximo

de

0,7(h - de)

fs = Esfuerzo de tracción en el acero de refuerzo en el Estado Límite de Servicio.

h.- Altura total del elemento

yc = 0,50 Condición de exposición.

n = 10,00 Relación de módulos de elasticidad

b = 100,00 cm Ancho de faja de diseño

nAs ( de - y) = by(y/2)

nAs de - nAs y =

As de (b/2)y* + nAs y - nAsde = O_

nAs i -nAs + \2 + 2b nAsüeT

y = _L

Itranf = nAs (de - y)2 + b y3/3

fs M c x n

I

c = de - y Distancia desde eje neutro a cg deí acero

CONTROL AGRIETAMIENTO: ZONA MOMENTO NEGATIVO.-APOYO INTERIOR

dc(-) = 4,0 cm

h 20,0 cm Alltura del tablero

ps 1,4

M 4,034 tm Servicio I

As 16,08 cm2

de 16,00 cm2

U — 5,74 cm2 Ubicación eje neutro

Itranf = 23.231,0 cm" Inercia de la sección transformada

fs = 1.780,99 kg/cm2 Calculado

Smáx = 17,75 cm Separación máxima

Svar = 12,5 cm Separación entre varillas

CONTROL AGRIETAMIENTO: ZONA MOMENTO NEGATIVO.- VOLADIZO

dc(-) = 4,0 cm

h = 20,0 cm Alltura del tablero

ps 1,4

M 4,389 tm Servicio I

As = 16,08 cm2

de 16,00 cm2

y 5,74 cm2 Ubicación eje neutro

Itranf = 23.231 ,0 cm"

fs 1.937,87 kg/cm2 Esfuerzo en el acero

smáx = 15,66 cm Separación máxima

Svar = 12,5 cm Separación entre varillas

CONTROL AGRIETAMIENTO: ZONA MOMENTO POSITIVO.- TRAMO

dc(+) = 4,0 cm

h 20,0 cm Alltura del tablero

PS . = 1,4

M 4,034 tm Servicio I

As 16,08 cm2

de 16,00 cm2

y 5,74 cm2 Ubicación eje neutro

Itranf = 23.231,0 cm"

fs 1.780,99 kg/cm2 Esfuerzo en el acero

Smáx = 17,75 cm Separación máxima

Svar = 12,5 cm Separación entre varillas

You might also like

- Agrietamiento - TableroDocument4 pagesAgrietamiento - TablerovladimirjimboNo ratings yet

- Solucionario de Resistencia de MaterialesDocument38 pagesSolucionario de Resistencia de Materialesguillermo socualaya100% (2)

- Muro de Contencià N - Ing. Roberto Morales Morales UNI - PERUDocument31 pagesMuro de Contencià N - Ing. Roberto Morales Morales UNI - PERUleandromituniNo ratings yet

- Diseño de muro de contención en voladizoDocument9 pagesDiseño de muro de contención en voladizovladimirjimboNo ratings yet

- Elementos de Diseño para Acueductos y Alcantarillado - Ricardo Lopez Cualla PDFDocument278 pagesElementos de Diseño para Acueductos y Alcantarillado - Ricardo Lopez Cualla PDFwil100% (3)

- Guía para el diseño de desarenadores y sedimentadoresDocument34 pagesGuía para el diseño de desarenadores y sedimentadoresjhonromerNo ratings yet

- AnaDocument356 pagesAnaPercy ChavezNo ratings yet

- Manual Acero Refuerzo ArmadurasDocument285 pagesManual Acero Refuerzo ArmadurasCris Anwandter100% (1)

- 37 Sistemas Fijos Proteccion Rociadores 1a Edicion Julio2011Document44 pages37 Sistemas Fijos Proteccion Rociadores 1a Edicion Julio2011Boris GorgonaNo ratings yet

- Plantas de Filtracion Rapida - Manual I TeoriaDocument597 pagesPlantas de Filtracion Rapida - Manual I TeoriaIp Jorge100% (1)

- Libro de Texto Primer Ano de BachilleratoDocument228 pagesLibro de Texto Primer Ano de BachilleratoCecy Guerra80% (5)

- Carton Paja!Document2 pagesCarton Paja!Vanegrii Rodriiguez50% (2)

- Los 10 Pilares de La Gestión para Un Plan de Lubricación ExitosoDocument16 pagesLos 10 Pilares de La Gestión para Un Plan de Lubricación Exitosoallmcbeall100% (1)

- Importancia Y Operaciones de NúmerosDocument4 pagesImportancia Y Operaciones de NúmeroselcoqueticoclasicoNo ratings yet

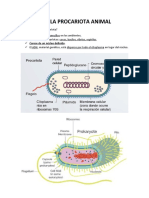

- CÉLULA PROCARIOTA y Eucariota ANIMALDocument4 pagesCÉLULA PROCARIOTA y Eucariota ANIMALMelisa Mtz. Quijano.No ratings yet

- Ejercicio Urbanismo Que No Me GustaDocument18 pagesEjercicio Urbanismo Que No Me GustaJonathan HernándezNo ratings yet

- Ejercicios 094819Document6 pagesEjercicios 094819Fausto JoaquinNo ratings yet

- Presupuesto Etapa 2 Encinas QuilinDocument410 pagesPresupuesto Etapa 2 Encinas QuilinCristian LarrainNo ratings yet

- JUSTIFICACION Area InformaticaDocument3 pagesJUSTIFICACION Area InformaticaYohanna Heidy100% (3)

- Rodea Garcia Rafael CuadroSinopticoDocument3 pagesRodea Garcia Rafael CuadroSinopticoRafael Rodea GarcìaNo ratings yet

- Acta 20230120213540Document2 pagesActa 20230120213540MARYORIE BELEN ALCA MONTESINOSNo ratings yet

- Personalidad, Salud y EnfermedadDocument31 pagesPersonalidad, Salud y EnfermedadLuz Valderrama DurandNo ratings yet

- Diseño de Casa Habitacion Del Siglo XXDocument21 pagesDiseño de Casa Habitacion Del Siglo XXAdrian TamayoNo ratings yet

- Tesis para Ver AutomatizaciónDocument94 pagesTesis para Ver AutomatizaciónAlexandra ZúñigaNo ratings yet

- Jonathan Gonzalez Introduccion A La Programacion Semana 7Document10 pagesJonathan Gonzalez Introduccion A La Programacion Semana 7cristian chacon muñozNo ratings yet

- Razonamiento Matemático - 2°Document136 pagesRazonamiento Matemático - 2°laplace200078% (9)

- Foreach inDocument3 pagesForeach inKevinqNo ratings yet

- Libro Blanco GRP-SAP 31102018 LightDocument76 pagesLibro Blanco GRP-SAP 31102018 LightyovocNo ratings yet

- Factores de Riesgo de IncendioDocument19 pagesFactores de Riesgo de IncendioJosé Manuel Chávez SagardíaNo ratings yet

- Actividad Evaluativa Eje 1Document4 pagesActividad Evaluativa Eje 1Esteban Alexander C.No ratings yet

- BowTieXP Visión General de PropiedadesDocument9 pagesBowTieXP Visión General de PropiedadesCesar CordovaNo ratings yet

- GUIA DE APRENDIZAJE SOBRE EL PROCESO DE CARTERA EN ENTIDADES DE SALUDDocument2 pagesGUIA DE APRENDIZAJE SOBRE EL PROCESO DE CARTERA EN ENTIDADES DE SALUDMaria Elisa Molina ComasNo ratings yet

- Fisicoquimica Informe Peso MolecularDocument17 pagesFisicoquimica Informe Peso MolecularedithNo ratings yet

- ActiveMQ SDDocument10 pagesActiveMQ SDDiegoNo ratings yet

- Evaluar El Potencial Turistico de Un TerritorioDocument5 pagesEvaluar El Potencial Turistico de Un TerritorioLucy Dominguez100% (1)

- Función exponencialDocument5 pagesFunción exponencialPACONo ratings yet

- Tedesco y su visión de la educación como motor de justicia socialDocument5 pagesTedesco y su visión de la educación como motor de justicia socialPamela Mishell Morales FernandezNo ratings yet

- Guia Practica Hospitalseguro PDFDocument24 pagesGuia Practica Hospitalseguro PDFRuben MartinezNo ratings yet

- Ejercicios 1 2 y 3 Letra BDocument3 pagesEjercicios 1 2 y 3 Letra Bchristian muñozNo ratings yet