Professional Documents

Culture Documents

Jeffus Chapters

Uploaded by

Anonymous dh6DITCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jeffus Chapters

Uploaded by

Anonymous dh6DITCopyright:

Available Formats

Chapter 1 Introduction to Welding

Introduction ................................................... 4

Welding Defined ........................................... 5

Uses of Welding ............................................ 6

Welding and Cutting Processes .................... 8

Oxyacetylene Welding, Brazing, and Cutting 10

Thermal Cutting Processes ......................... 11

Occupational Opportunities in Welding ..... 13

Training for Welding Occupations ............. 14

Experiments and Practices .......................... 15

Welding Video Series ................................. 17

Metric Units ................................................ 17

Summary ..................................................... 19

Chapter 2 Safety in Welding

Introduction ................................................. 24

Burn Classification...................................... 24

Face, Eye, and Ear Protection ..................... 26

Respiratory Protection ................................ 28

Ventilation................................................... 31

Material Safety Data Sheets (MSDSs) ........ 32

General Work Clothing ............................... 32

Special Protective Clothing......................... 33

Handling and Storing Cylinders.................. 34

Fire Protection ............................................. 35

Equipment Maintenance ............................. 37

Work Area ................................................... 38

Hand Tools .................................................. 38

Electrical Safety .......................................... 40

Electrical Safety Systems ............................ 40

Voltage Warnings ....................................... 42

Extension Cords .......................................... 42

Safety Rules for Portable Electric Tools ..... 43

Metal Cutting Machines .............................. 45

Material Handling ....................................... 46

Ladder Safety .............................................. 47

Summary ..................................................... 48

Chapter 3 Shielded Metal Arc Equipment, Setup, and Operation

Introduction ................................................. 55

Welding Current.......................................... 55

Electrical Measurement .............................. 56

SMA Welding Arc Temperature and Heat . 56

Types of Welding Power ............................ 57

Open Circuit Voltage .................................. 58

Operating Voltage ....................................... 59

Arc Blow ..................................................... 59

Types of Power Sources.............................. 60

Generator- and Alternator-Type Welders ... 63

Converting AC to DC ................................. 65

Duty Cycle .................................................. 65

Welder Accessories ..................................... 66

Equipment Setup ......................................... 68

Summary ..................................................... 69

Chapter 4 Shielded Metal Arc Welding of Plate

Introduction ................................................. 73

Effect of Too High or Too Low Current Settings 75

Electrode Size and Heat .............................. 76

Arc Length .................................................. 77

Electrode Angle .......................................... 78

Electrode Manipulation ............................... 80

Positioning of the Welder and the Plate ...... 82

Practice Welds ............................................ 82

Stringer Beads ............................................. 83

Square Butt Joint ......................................... 86

Edge Weld ................................................... 89

Outside Corner Joint ................................... 93

Lap Joint ..................................................... 96

Tee Joint ..................................................... 99

Summary................................................... 102

Chapter 5 Shielded Metal Arc Welding of Pipe

Introduction .............................................. 106

Pipe and Tubing ........................................ 107

Preparation and Fit-Up ............................. 111

Practice Welds .......................................... 112

1G Horizontal Rolled Position ................. 116

2G Vertical Fixed Position ....................... 120

5G Horizontal Fixed Position ................... 122

6G 45° Inclined Position .......................... 123

Summary................................................... 125

Chapter 6 Advanced Shielded Metal Arc Welding

Introduction .............................................. 129

Root Pass .................................................. 129

Hot Pass .................................................... 134

Filler Pass ................................................. 136

Cover Pass ................................................ 138

Plate Preparation ....................................... 139

Preparing Specimens for Testing .............. 141

Restarting a Weld Bead ............................ 142

Preheating and Postheating ....................... 144

Poor Fit-Up ............................................... 152

Summary................................................... 154

Chapter 7 Flame Cutting

Introduction .............................................. 161

Metals Cut by the Oxyfuel Process .......... 161

Eye Protection for Flame Cutting ............. 162

Cutting Torches ........................................ 162

Cutting Tips .............................................. 163

Oxyfuel Cutting, Setup, and Operation .... 169

Hand Cutting............................................. 171

Layout ....................................................... 174

Selecting the Correct Tip and Setting the Pressure 175

The Chemistry of a Cut ............................. 176

The Physics of a Cut ................................. 177

Plate Cutting.............................................. 179

Cutting Table ............................................ 180

Torch Guides ............................................. 180

Distortion .................................................. 182

Cutting Applications ................................. 183

Pipe Cutting .............................................. 184

Summary ................................................... 187

Chapter 8 Plasma Arc Cutting

Introduction ............................................... 190

Plasma ....................................................... 192

Plasma Torch ............................................ 192

Power and Gas Cables .............................. 194

Power Requirements ................................. 196

Compressed Air ........................................ 196

Heat Input.................................................. 197

Distortion .................................................. 197

Applications .............................................. 198

Machine Cutting........................................ 203

Manual Cutting ......................................... 205

Safety ........................................................ 205

Straight Cuts.............................................. 206

Plasma Arc Gouging ................................. 209

Cutting Round Stock ................................. 210

Summary ................................................... 210

Chapter 9 Related Cutting Processes

Introduction ............................................... 214

Laser Beam Cutting (LBC) and Laser Beam Drilling (LBD) 215

Lasers ........................................................ 215

Applications .............................................. 217

Air Carbon Arc Cutting ............................ 219

Manual Torch Design ............................... 220

Application ................................................ 221

Safety ........................................................ 222

U-Grooves ................................................. 223

Oxygen Lance Cutting .............................. 226

Applications .............................................. 227

Safety ........................................................ 227

Water Jet Cutting ...................................... 227

Applications .............................................. 227

Arc Cutting Electrodes .............................. 227

Applications .............................................. 229

Summary ................................................... 229

Chapter 10 Gas Metal Arc Welding Equipment, Setup, and Operation

Introduction ............................................... 234

Weld Metal Transfer Methods .................. 236

Short-Circuiting Transfer GMAW-S ........ 236

Globular Transfer ...................................... 238

Axial Spray Metal Transfer ...................... 238

Pulsed-Arc Metal Transfer ........................ 239

Pulsed-Arc Metal Transfer Current Cycle 240

Shielding Gases for Spray or Pulsed-Spray Transfer 243

Buried-Arc Transfer .................................. 243

GMAW Filler Metal Specifications .......... 244

Wire Melting and Deposition Rates .......... 244

Welding Power Supplies ........................... 244

Speed of the Wire Electrode ..................... 245

Power Supplies for Short-Circuiting Transfer 246

Molten Weld Pool Control ........................ 247

Power Settings .......................................... 249

Weave Pattern ........................................... 249

Travel Speed ............................................. 249

Electrode Extension .................................. 249

Gun Angle ................................................. 250

Equipment ................................................. 252

Power Source ............................................ 253

Electrode (Wire) Feed Unit ....................... 253

GMA Spot Welding .................................. 257

Summary ................................................... 259

Chapter 11 Gas Metal Arc Welding

Introduction ............................................... 262

Setup ......................................................... 263

Gas Density and Flow Rates ..................... 268

Wire-Feed Speed ....................................... 268

Arc-Voltage and Amperage Characteristics 270

Electrode Extension .................................. 271

Welding Gun Angle .................................. 273

Effect of Shielding Gas on Welding ......... 274

Practices .................................................... 276

Metal Preparation ...................................... 277

Flat Position, 1G and 1F Positions............ 277

Vertical Up 3G and 3F Positions .............. 281

Vertical Down 3G and 3F Positions ......... 283

Horizontal 2G and 2F Positions ................ 284

Overhead 4G and 4F Positions ................. 286

Globular Metal Transfer, 1G Position ...... 288

Axial Spray ............................................... 291

Summary ................................................... 292

Chapter 12 Flux Cored Arc Welding Equipment, Setup, and Operation

Introduction ............................................... 296

Principles of Operation ............................. 297

Equipment ................................................. 299

Advantages ................................................ 300

Limitations ................................................ 301

FCAW Electrodes ..................................... 301

FCA Welding Electrode Flux ................... 304

Shielding Gas ............................................ 308

Welding Techniques ................................. 308

Troubleshooting FCA Welding................. 314

Summary ................................................... 315

Chapter 13 Flux Cored Arc Welding

Introduction ............................................... 318

Practices .................................................... 319

Flat-Position Welds................................... 322

Square-Groove Welds ............................... 322

V-Groove and Bevel-Groove Welds ......... 326

Fillet Welds ............................................... 331

Vertical Welds .......................................... 336

Horizontal Welds ...................................... 341

Overhead-Position Welds ......................... 347

Thin-Gauge Welding ................................ 350

Plug Welds ................................................ 356

Summary ................................................... 358

Chapter 14 Other Constant-Potential Welding Processes

Introduction ............................................... 361

Submerged Arc Welding (SAW) .............. 362

Weld Travel .............................................. 362

Electrode Feed .......................................... 362

Contact Tip................................................ 362

Electrode ................................................... 363

Flux ........................................................... 364

Advantages of SAW ................................. 364

Disadvantages of SAW ............................. 365

Arc Starting ............................................... 365

Weld Backing............................................ 365

Handheld SAW ......................................... 366

Experiments .............................................. 366

Electroslag Welding (ESW) ...................... 367

Electrogas Welding (EGW) ...................... 369

Summary ................................................... 370

Chapter 15 Gas Tungsten Arc Welding Equipment, Setup, Operation, and Filler Metals

Introduction ............................................... 374

Tungsten .................................................... 374

Types of Tungsten Electrodes ................... 376

Shaping the Tungsten ................................ 377

GTA Welding Equipment ......................... 380

Types of Welding Current ........................ 384

Shielding Gases ......................................... 386

Preflow and Postflow ................................ 388

Shielding Gas Flow Rate .......................... 388

Remote Controls ....................................... 389

Summary ................................................... 393

Chapter 16 Gas Tungsten Arc Welding of Plate

Introduction ............................................... 398

Torch Angle .............................................. 399

Filler Rod Manipulation ............................ 399

Tungsten Contamination ........................... 401

Current Setting .......................................... 401

Experiments .............................................. 402

Gas Flow ................................................... 403

Practice Welds .......................................... 404

Summary ................................................... 425

Chapter 17 Gas Tungsten Arc Welding of Pipe

Introduction ............................................... 429

Practices .................................................... 430

Joint Preparation ....................................... 430

Root ........................................................... 431

Backing Gas .............................................. 433

Filler Metal................................................ 434

Cup Walking ............................................. 436

Practice Welds .......................................... 438

Hot Pass .................................................... 440

Filler Pass .................................................. 444

Cover Pass................................................. 445

Summary ................................................... 450

Chapter 18 Shop Math and Weld Cost

Introduction ............................................... 456

Shop Math ................................................. 457

Types of Numbers ..................................... 457

General Math Rules .................................. 457

Equations and Formulas ............................ 458

Mixed Units .............................................. 460

Adding and Subtracting Mixed Units ....... 460

Fractions .................................................... 462

Finding the Fraction’s Common Denominator 462

Reducing Fractions ................................... 463

Multiplying and Dividing Fractions.......... 463

Converting Numbers ................................. 463

Converting Fractions to Decimals ............ 463

Converting Decimals to Fractions ............ 464

Conversion Charts ..................................... 465

Measuring ................................................. 465

Welding Costs ........................................... 465

Cost Estimation ......................................... 466

Joint Design .............................................. 466

Weld Metal Cost ....................................... 469

Cost of Electrodes, Wires, Gases, and Flux 469

Deposition Efficiency ............................... 470

Deposition Rate ......................................... 471

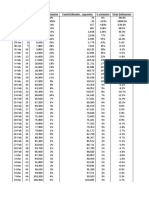

Deposition Data Tables ............................. 471

Operating Factor ....................................... 474

Other Useful Formulas .............................. 476

Summary ................................................... 477

Chapter 19 Reading Technical Drawings

Introduction ............................................... 481

Mechanical Drawings ............................... 482

Lines .......................................................... 482

Types of Drawings .................................... 485

Special Views............................................ 485

Dimensioning ............................................ 487

Drawing Scale ........................................... 488

Reading Mechanical Drawings ................. 489

Sketching................................................... 490

Erasers and Erasing ................................... 493

Graph Paper .............................................. 494

Computers and Drawings .......................... 496

Summary ................................................... 499

Chapter 20 Welding Joint Design and Welding Symbols

Introduction ............................................... 502

Weld Joint Design ..................................... 503

Welding Process........................................ 505

Edge Preparation ....................................... 505

Joint Dimensions....................................... 505

Metal Thickness ........................................ 505

Metal Type ................................................ 507

Welding Position....................................... 507

Code or Standards Requirements .............. 508

Welder Skill .............................................. 509

Acceptable Cost ........................................ 509

Welding Symbols ...................................... 509

Indicating Types of Welds ........................ 510

Weld Location ........................................... 510

Location Significance of Arrow................ 512

Fillet Welds ............................................... 512

Plug Welds ................................................ 513

Spot Welds ................................................ 513

Seam Welds .............................................. 514

Groove Welds ........................................... 514

Backing ..................................................... 515

Flanged Welds .......................................... 516

Nondestructive Testing Symbols .............. 516

Summary ................................................... 519

Chapter 21 Fabricating Techniques

and Practices

Introduction ............................................... 522

Fabrication ................................................ 523

Safety ........................................................ 523

Parts and Pieces......................................... 524

Layout ....................................................... 525

Nesting ...................................................... 530

Kerf Space ................................................. 531

Material Shapes ......................................... 535

Bill of Materials Form .............................. 535

Overall Tolerance...................................... 535

Assembly................................................... 537

Assembly Tools ........................................ 539

Fitting ........................................................ 541

Tack Welds ............................................... 543

Welding ..................................................... 544

Finishing ................................................... 545

Summary ................................................... 546

Chapter 22 Welding Codes and Standards

Introduction ............................................... 550

Codes, Standards, Procedures, and Specifications 551

Welding Procedure Qualification ............. 552

Welding Procedure Specification (WPS).. 552

Qualifying the Welding Procedure Specification 552

Qualifying and Certifying ......................... 552

General Information .................................. 555

Summary ................................................... 564

Chapter 23 Testing and Inspection of Welds

Introduction ............................................... 567

Quality Control (QC) ................................ 568

Discontinuities and Defects ...................... 568

Porosity ..................................................... 568

Inclusions .................................................. 570

Inadequate Joint Penetration ..................... 570

Incomplete Fusion ..................................... 571

Arc Strikes ................................................ 572

Overlap ...................................................... 572

Undercut .................................................... 573

Crater Cracks ............................................ 573

Underfill .................................................... 573

Plate-Generated Problems ......................... 573

Lamination ................................................ 574

Delamination ............................................. 574

Lamellar Tears .......................................... 574

Destructive Testing (DT) .......................... 575

Tensile Testing .......................................... 575

Fatigue Testing.......................................... 576

Shearing Strength of Welds ...................... 577

Welded Butt Joints .................................... 577

Fillet Weld Break Test .............................. 581

Testing by Etching .................................... 582

Impact Testing .......................................... 582

Nondestructive Testing (NDT) ................. 583

Visual Inspection (VT) ............................. 583

Penetrant Inspection (PT) ......................... 583

Magnetic Particle Inspection (MT) ........... 584

Radiographic Inspection (RT)................... 585

Ultrasonic Inspection (UT) ....................... 590

Leak Checking .......................................... 591

Eddy Current Inspection (ET) ................... 591

Hardness Testing ....................................... 591

Summary ................................................... 592

Chapter 24 Welder Certification

Introduction ............................................... 596

Qualified and Certified Welders ............... 597

Welder Performance Qualification ........... 597

Welder Certification.................................. 597

AWS Entry-Level Welder Qualification and Welder Certification 597

Practical Knowledge ................................. 597

Welder Qualification and Certification Test Instructions for Practices 598

Preparing Specimens for Testing .............. 599

Restarting a Weld Bead ............................ 600

Summary ................................................... 635

Chapter 25 Welding Metallurgy

Introduction ............................................... 641

Heat, Temperature, and Energy ................ 641

Heat ........................................................... 641

Temperature .............................................. 642

Mechanical Properties of Metal ................ 643

Hardness .................................................... 643

Brittleness ................................................. 643

Ductility .................................................... 643

Toughness ................................................. 643

Strength ..................................................... 644

Other Mechanical Concepts ...................... 644

Structure of Matter .................................... 645

Crystalline Structures of Metal ................. 645

Phase Diagrams ......................................... 646

Lead-Tin Phase Diagram .......................... 646

Iron-Carbon Phase Diagram ..................... 647

Strengthening Mechanisms ....................... 650

Solid-Solution Hardening ......................... 651

Precipitation Hardening ............................ 651

Mechanical Mixtures of Phases ................ 652

Quench, Temper, and Anneal ................... 652

Martensitic Reactions................................ 654

Cold Work................................................. 656

Grain Size Control .................................... 656

Heat Treatments Associated with Welding 656

Preheat....................................................... 656

Stress Relief, Process Annealing .............. 657

Annealing .................................................. 658

Normalizing .............................................. 658

Thermal Effects Caused by Arc Welding . 658

Gases in Welding ...................................... 660

Hydrogen................................................... 661

Nitrogen .................................................... 661

Oxygen ...................................................... 661

Carbon Dioxide ......................................... 661

Metallurgical Defects ................................ 662

Cold Cracking ........................................... 662

Hot Cracking ............................................. 662

Carbide Precipitation ................................ 663

Summary ................................................... 664

Chapter 26 Weldability of Metals

Introduction ............................................... 668

Steel Classification and Identification ...... 671

SAE and AISI Classification Systems ...... 671

Unified Numbering System (UNS) ........... 671

Carbon and Alloy Steels ........................... 671

Low Carbon Also Called Mild Steel ......... 671

Medium Carbon Steel ............................... 673

High Carbon Steel ..................................... 673

Tool Steel .................................................. 674

High Manganese Steel .............................. 674

Low Alloy, High Tensile Strength Steels . 674

Stainless Steels .......................................... 674

Chromium-Molybdenum Steel ................. 676

Cast Iron .................................................... 676

Practice Welding Cast Iron ....................... 677

Nonferrous Metals .................................... 681

Copper and Copper Alloys........................ 681

Aluminum Weldability ............................. 681

Titanium .................................................... 682

Magnesium ................................................ 682

Repair Welding ......................................... 682

Summary ................................................... 685

Chapter 27 Filler Metal Selection

Introduction ............................................... 689

Manufacturers’ Electrode Information ..... 690

Understanding the Electrode Data ............ 690

Data Resulting from Mechanical Tests ..... 690

Data Resulting from Chemical Analysis... 691

Carbon Equivalent (CE) ............................ 691

SMAW Operating Information ................. 691

Core Wire .................................................. 692

Functions of the Flux Covering ................ 692

Filler Metal Selection ................................ 693

Shielded Metal Arc Welding Electrode Selection 693

AWS Filler Metal Classifications ............. 696

Carbon Steel .............................................. 696

Carbon and Low Alloy Steel–Covered

Electrodes .............................................. 696

Wire-Type Steel Filler Metals .................. 699

Solid Wire ................................................. 699

Tubular Wire ............................................. 700

Stainless Steel Electrodes ......................... 701

Nonferrous Electrodes .............................. 704

Aluminum and Aluminum Alloys ............ 704

Aluminum-Covered Arc Welding Electrodes 704

Aluminum Bare Welding Rods and Electrodes 704

Special-purpose Filler Metals ................... 704

Surface and Buildup Electrode Classification 705

Magnesium Alloys .................................... 706

Hydrogen Embrittlement .......................... 706

Summary ................................................... 707

Chapter 28 Welding Automation

and Robotics

Introduction ............................................... 710

Manual Joining Process ............................ 711

Semiautomatic Joining Processes ............. 712

Machine Joining Processes ....................... 713

Automatic Joining Processes .................... 713

Automated Joining .................................... 713

Industrial Robots ....................................... 714

Robot Programming .................................. 715

System Planning........................................ 717

Future Automation .................................... 723

Summary ................................................... 723

Chapter 29 Other Welding Processes

Introduction ............................................... 727

Resistance Welding (RW)......................... 728

Resistance Spot Welding (RSW) .............. 728

Seam Welding (RSEW) ............................ 730

High-Frequency Resistance Seam Welding (RSEW-HF) 731

Resistance Projection Welding (RPW) ..... 731

Flash Welding (FW) ................................. 732

Upset Welding (UW) ................................ 732

Percussion Welding (PEW) ...................... 733

Electron Beam Welding (EBW) ............... 733

Electron Beam Welding Gun .................... 733

Electron Beam Seam Tracking ................. 734

Ultrasonic Welding (USW)....................... 734

Ultrasonic Welding Applications .............. 735

Inertia Welding Process ............................ 735

Inertia Weld Bond Characteristics ............ 737

Advantages of the Process ........................ 738

Laser Beam Welding (LBW) .................... 738

Laser Welding Advantages and Disadvantages 739

Laser Beam ............................................... 739

Plasma Arc Welding (PAW) Process ....... 739

Stud Welding (SW) ................................... 740

Thermal Spraying (THSP) ........................ 740

Thermal Spraying Equipment ................... 740

Thermospray (Powder) Process ................ 741

Plasma Spraying Process .......................... 742

Cold Welding (CW) .................................. 743

Thermite Welding (TW) ........................... 743

Hardfacing................................................. 745

Selection of Hardfacing Metals ................ 745

Hardfacing Welding Processes ................. 746

Quality of Surfacing Deposit .................... 747

Hardfacing Electrodes ............................... 747

Shielded Metal Arc Method ...................... 748

Hardfacing with Gas Shielded Arc ........... 748

Carbon Arc Method .................................. 748

Summary ................................................... 749

Chapter 30 Oxyfuel Welding and Cutting Equipment, Setup, and Operation

Introduction ............................................... 756

Pressure Regulators ................................... 757

Regulator Operation .................................. 757

Regulator Gauges ...................................... 758

Regulator Safety Pressure Release Device 759

Cylinder and Regulator Fittings ................ 760

Regulator Safety Precautions .................... 761

Regulator Care and Use ............................ 762

Welding and Cutting Torches: Design and Service 763

Mixing the Gases ...................................... 763

Torch Care and Use .................................. 764

Welding and Heating Torch Tips .............. 765

Torch Tip Care and Use ............................ 766

Backfires ................................................... 766

Flashbacks ................................................. 766

Reverse Flow and Flashback Valves ........ 767

Care of the Reverse Flow Valve and Flashback Arrestor 768

Hoses and Fittings ..................................... 768

Hose Care and Use .................................... 768

Types of Flames ........................................ 769

Leak Detection .......................................... 770

Manifold Systems ..................................... 775

Manifold Operation ................................... 776

Summary ................................................... 777

Chapter 31 Oxyfuel Gases and Filler Metals

Introduction .............................................. 782

Oxyfuel Flame .......................................... 783

Characteristics of the Fuel-Gas Flame ..... 783

Fuel Gases ................................................ 783

Flame Rate of Burning ............................. 785

Acetylene (C2H2) ...................................... 786

Liquefied Fuel Gases ................................ 788

Methylacetylene-Propadiene (MPS) ........ 788

MAPP ....................................................... 790

Propane and Natural Gas .......................... 791

Hydrogen .................................................. 792

Filler Metals ............................................. 794

Ferrous Metals .......................................... 795

Mild Steel ................................................. 795

Cast Iron ................................................... 795

Summary .................................................. 796

Chapter 32 Oxyacetylene Welding

Introduction .............................................. 798

Mild Steel Welds ...................................... 799

Factors Affecting the Weld ...................... 799

Characteristics of the Weld ...................... 800

Flat Position Welding ............................... 807

Outside Corner Joint ................................. 807

Butt Joint .................................................. 808

Lap Joint ................................................... 810

Tee Joint ................................................... 812

Out-of-Position Welding .......................... 813

Vertical Welds .......................................... 813

Butt Joint .................................................. 815

Lap Joint ................................................... 817

Tee Joint ................................................... 817

Horizontal Welds ...................................... 818

Horizontal Stringer Bead .......................... 818

Butt Joint .................................................. 819

Lap Joint ................................................... 819

Tee Joint ................................................... 819

Overhead Welds ....................................... 819

Stringer Bead ............................................ 819

Mild Steel Pipe and Tubing ...................... 820

Horizontal Rolled Position 1G ................. 820

Horizontal Fixed Position 5G ................... 823

Vertical Fixed Position 2G ....................... 824

45° Fixed Position 6G .............................. 825

Thin-Wall Tubing ..................................... 826

Summary .................................................. 827

Chapter 33 Soldering, Brazing, and Braze Welding

Introduction .............................................. 830

Advantages of Soldering and Brazing ...... 831

Physical Properties of the Joint...………….. 832

Shear Strength .......................................... 832

Ductility .................................................... 832

Fatigue Resistance .................................... 832

Corrosion Resistance ................................ 833

Fluxes ....................................................... 834

Flux ........................................................... 834

Fluxing Action .......................................... 835

Soldering and Brazing Methods ............... 835

Method Grouping ..................................... 835

Torch Soldering and Brazing ................... 835

Furnace Soldering and Brazing ................ 837

Induction Soldering and Brazing .............. 837

Dip Soldering and Brazing ....................... 838

Resistance Soldering and Brazing ............ 838

Special Methods ....................................... 839

Filler Metals ............................................. 839

Types of Filler Metals .............................. 839

Soldering Alloys ....................................... 840

Brazing Alloys .......................................... 841

Joint Design ....................................................................... 843

Joint Spacing ............................................ 843

Brazing Practices ...................................... 845

Surface Buildup and Hole Fill Practices .. 851

Silver Brazing Practices ........................... 853

Soldering Practices ................................... 856

Summary .................................................. 859

You might also like

- Bedienungs-Und Wartungsanleitung: (Robin)Document28 pagesBedienungs-Und Wartungsanleitung: (Robin)Krunoslav100% (1)

- Texecom Premier Alarm ManualDocument132 pagesTexecom Premier Alarm ManualChiew Soo HaNo ratings yet

- 1250 DG - IndexDocument139 pages1250 DG - IndexAstrid Navarro Jarquín100% (1)

- Operating Instructions For Actuators Type AB: OM-ENGLISH-AB-V2.05-2017.06.28Document21 pagesOperating Instructions For Actuators Type AB: OM-ENGLISH-AB-V2.05-2017.06.28Nikhil AggarwalNo ratings yet

- Service Manual FSH PDFDocument82 pagesService Manual FSH PDFRamiz3zNo ratings yet

- Application Manual Integrated Dispensing Function Package (IDFP) 3HDAK00000A0252-001Document700 pagesApplication Manual Integrated Dispensing Function Package (IDFP) 3HDAK00000A0252-001JAIR RODRIGUEZ100% (1)

- 02-773 Iss2Document48 pages02-773 Iss2Shane BowenNo ratings yet

- Manual D403-N3046 PDFDocument103 pagesManual D403-N3046 PDFBob Wiggins0% (1)

- IRC5-MultiMove Application Manual 3HAC021272-001 - RevBDocument116 pagesIRC5-MultiMove Application Manual 3HAC021272-001 - RevBmartinimartiiniNo ratings yet

- Racks Ventilados Tecniplast BlueLineDocument81 pagesRacks Ventilados Tecniplast BlueLinepablo elviraNo ratings yet

- Dse3210 ManualDocument32 pagesDse3210 Manualabuzer1981No ratings yet

- VIVA Software For Flying Probe Systems MA-VI-VIVASWEN-02Document198 pagesVIVA Software For Flying Probe Systems MA-VI-VIVASWEN-02Army AnguianoNo ratings yet

- Manual Ascon - 2Document62 pagesManual Ascon - 2Sadikul FuadNo ratings yet

- Omega V Op Ins 1384.8v3-10Document88 pagesOmega V Op Ins 1384.8v3-10laythmasNo ratings yet

- LXM32M 0198441113767.11Document651 pagesLXM32M 0198441113767.11Marcos CastañoNo ratings yet

- KSR-4480 Sealing Head ManualDocument58 pagesKSR-4480 Sealing Head ManualMarco VargasNo ratings yet

- Display Kuhn 5901034-C-En-1214Document106 pagesDisplay Kuhn 5901034-C-En-1214Piri ViruzabNo ratings yet

- VT Hacd 1Document262 pagesVT Hacd 1MateusMendonca100% (1)

- Manuale Operativo Open Sun 1050Document92 pagesManuale Operativo Open Sun 1050Paulmanke50% (2)

- Kaukan Oil Cooler Instruction HandbookDocument14 pagesKaukan Oil Cooler Instruction HandbooksunhuynhNo ratings yet

- FCZ740 Operation ManualDocument68 pagesFCZ740 Operation ManualroqueNo ratings yet

- Cha5 Hazard ClassificationDocument5 pagesCha5 Hazard ClassificationYoesof HilabyNo ratings yet

- Bsxy 15193 001 02Document66 pagesBsxy 15193 001 02CarlNo ratings yet

- LMI-IOM-3390089000-02.10 - SG-User-Manual PETARYDocument56 pagesLMI-IOM-3390089000-02.10 - SG-User-Manual PETARYWilliam Melo100% (1)

- Parts Manual 300: International - 335 SUNDANCERDocument96 pagesParts Manual 300: International - 335 SUNDANCERthesaneroneNo ratings yet

- b70 3570en PDFDocument84 pagesb70 3570en PDFAshish TripathiNo ratings yet

- Zeus Catalog 11Document76 pagesZeus Catalog 11a100acomNo ratings yet

- 31-WF7005/7010/7015 Dynatriax: Manuale Di Istruzioni Instruction ManualDocument152 pages31-WF7005/7010/7015 Dynatriax: Manuale Di Istruzioni Instruction ManualJessica MendezNo ratings yet

- Twinning-Induced Plasticity (TWIP) SteelsDocument80 pagesTwinning-Induced Plasticity (TWIP) SteelsFernandoNo ratings yet

- Operation Manual: Asian Plastic Machinery Co., Ltd. Chen Hsong Machinery Taiwan Co., LTDDocument253 pagesOperation Manual: Asian Plastic Machinery Co., Ltd. Chen Hsong Machinery Taiwan Co., LTDFedericoNo ratings yet

- US Steel General - ProvisionsDocument67 pagesUS Steel General - ProvisionsAnonymous w0egAgMouGNo ratings yet

- Sebu7877-08 M PDFDocument60 pagesSebu7877-08 M PDFGerardo Esteban Lagos Rojas100% (2)

- OperationManualCPM ACT2500 MBT2500 MEK3000 MEK2500 OM2003 11 English 20200327Document84 pagesOperationManualCPM ACT2500 MBT2500 MEK3000 MEK2500 OM2003 11 English 20200327ads100% (1)

- G330 IntelysisDocument330 pagesG330 IntelysisLIBERTADNo ratings yet

- Trico CatalogoDocument120 pagesTrico CatalogoAndreina FajardoNo ratings yet

- BEK3 Ingles PDFDocument36 pagesBEK3 Ingles PDFGonzalo DoniniNo ratings yet

- MIE12175-STS - FAMILY - APPLICATION - GUIDE Manual Completo AGOSTO 2014Document305 pagesMIE12175-STS - FAMILY - APPLICATION - GUIDE Manual Completo AGOSTO 2014cachilet100% (1)

- Instructions For Use: RaxofixDocument22 pagesInstructions For Use: Raxofixtiago calderNo ratings yet

- Martin Gear ManualDocument62 pagesMartin Gear ManualChristian QuinteroNo ratings yet

- Kioti DK4510, DK5010, DK5510 Tractor Operator's ManualDocument15 pagesKioti DK4510, DK5010, DK5510 Tractor Operator's ManualLisakolyNo ratings yet

- HMS827 Manual 17-1298Document56 pagesHMS827 Manual 17-1298Kevin RoseNo ratings yet

- Installation Manual: Veritas R8 Plus/Veritas ExcelDocument40 pagesInstallation Manual: Veritas R8 Plus/Veritas ExcelUserNo ratings yet

- DGIIDocument58 pagesDGIIAriel Oscar HuertaNo ratings yet

- Uss Summary 2012Document16 pagesUss Summary 2012meverman7035No ratings yet

- Kioti EX50-SA, EX55-SA, EX5310-AU, EX5810-AU Tractor Operator's ManualDocument15 pagesKioti EX50-SA, EX55-SA, EX5310-AU, EX5810-AU Tractor Operator's ManualLisakolyNo ratings yet

- Hydraulic gear pumps and motors performance guideDocument88 pagesHydraulic gear pumps and motors performance guideSasko DimitrovNo ratings yet

- RW CuttingDocument140 pagesRW CuttingpitNo ratings yet

- EDAVN121718A (1) - Catalog Kỹ ThuậtDocument996 pagesEDAVN121718A (1) - Catalog Kỹ ThuậtThanh LãNo ratings yet

- UserManual TCR-25XX TCT-25X1 RET-25X2 M2072 9 English 20180509Document64 pagesUserManual TCR-25XX TCT-25X1 RET-25X2 M2072 9 English 20180509Daniel CardonaNo ratings yet

- F45 Elmodrive ManualDocument265 pagesF45 Elmodrive ManualErasmo Franco SNo ratings yet

- Im50 Service ManualDocument59 pagesIm50 Service ManualJAVIER100% (1)

- BCS100 Height Controller User Manual V3.15Document46 pagesBCS100 Height Controller User Manual V3.15sebastian carreñoNo ratings yet

- Tube-Mac Metric CatalogeDocument279 pagesTube-Mac Metric CatalogeTheAnonymousLugia100% (2)

- Installation and Operating Instruction: Remote Control Station WCM-FS 2.0 and Solar Controller WCM-SOL 1.0 HomeDocument80 pagesInstallation and Operating Instruction: Remote Control Station WCM-FS 2.0 and Solar Controller WCM-SOL 1.0 HomeAnd B100% (2)

- Esab Vision 500 ManualDocument327 pagesEsab Vision 500 ManualHELIO SANTOS JUNIOR100% (1)

- Arc Welding Folder WEBDocument4 pagesArc Welding Folder WEBlemchast9No ratings yet

- 710-04840-00M EMX3 User Manual EN - Web PDFDocument96 pages710-04840-00M EMX3 User Manual EN - Web PDFJokerNekromorphicNo ratings yet

- Welding Handbook - Welding Processes-Arc and Gas Welding and Cutting, Brazing, and SolderingDocument600 pagesWelding Handbook - Welding Processes-Arc and Gas Welding and Cutting, Brazing, and SolderingAnonymous QHMuqEMBmNo ratings yet

- Brazing DescriptionDocument80 pagesBrazing Descriptiondanish0% (1)

- Dupont Nemours General Plastic DesignDocument136 pagesDupont Nemours General Plastic DesignlittlexavNo ratings yet

- Bureau of Labor Statistics Data 2016 - 2019 (State and Regional)Document4 pagesBureau of Labor Statistics Data 2016 - 2019 (State and Regional)Anonymous dh6DITNo ratings yet

- Approximate Guide To Temper ColorsDocument1 pageApproximate Guide To Temper ColorsAnonymous dh6DITNo ratings yet

- Fixed Jaw Tube: Notes: Use Seamless Tubing or Remove The Weld SeamDocument10 pagesFixed Jaw Tube: Notes: Use Seamless Tubing or Remove The Weld SeamAnonymous dh6DITNo ratings yet

- Approximate Guide To Temper ColorsDocument1 pageApproximate Guide To Temper ColorsAnonymous dh6DITNo ratings yet

- Post Summer Welding AssignmentsDocument2 pagesPost Summer Welding AssignmentsAnonymous dh6DITNo ratings yet

- Fireball Tool: Adjustable Fixture TableDocument7 pagesFireball Tool: Adjustable Fixture TableAnonymous dh6DIT100% (3)

- Martensitic StructureDocument1 pageMartensitic StructureAnonymous dh6DITNo ratings yet

- The Structure of The AtomDocument28 pagesThe Structure of The AtomAnonymous dh6DITNo ratings yet

- Iron Carbon Phase Diagram TEDDocument6 pagesIron Carbon Phase Diagram TEDAnonymous dh6DITNo ratings yet

- Screw Assembly for Fireball Style ViseDocument15 pagesScrew Assembly for Fireball Style ViseAnonymous dh6DITNo ratings yet

- Main AssemblyDocument1 pageMain AssemblyAnonymous dh6DITNo ratings yet

- Fixed Jaw Side SupportDocument2 pagesFixed Jaw Side SupportAnonymous dh6DITNo ratings yet

- SWPS ListDocument6 pagesSWPS ListAnonymous dh6DIT100% (1)

- Approximate Guide To Temper ColorsDocument1 pageApproximate Guide To Temper ColorsAnonymous dh6DITNo ratings yet

- 2nd Year Drawing RubricDocument1 page2nd Year Drawing RubricAnonymous dh6DITNo ratings yet

- 4140 Heat TreatDocument1 page4140 Heat TreatAnonymous dh6DITNo ratings yet

- NestingDocument5 pagesNestingAnonymous dh6DITNo ratings yet

- Fireball Vise Cost SheetDocument4 pagesFireball Vise Cost SheetAnonymous dh6DITNo ratings yet

- Basic Engine Lathe QuestionsDocument4 pagesBasic Engine Lathe QuestionsAnonymous dh6DITNo ratings yet

- Breakdown of Modules and Key IndicatorsDocument4 pagesBreakdown of Modules and Key IndicatorsAnonymous dh6DITNo ratings yet

- Usability Designators FCAWDocument5 pagesUsability Designators FCAWAnonymous dh6DITNo ratings yet

- Training Organization Benefits: It Just Makes SENSE!Document1 pageTraining Organization Benefits: It Just Makes SENSE!Anonymous dh6DITNo ratings yet

- Quality Assurance ManualDocument9 pagesQuality Assurance ManualAnonymous dh6DITNo ratings yet

- EIM BenefitsDocument1 pageEIM BenefitsAnonymous dh6DITNo ratings yet

- Autocad Tip - Line, Spline or Polyline? Creating Linework: SurveyDocument3 pagesAutocad Tip - Line, Spline or Polyline? Creating Linework: SurveyAnonymous dh6DITNo ratings yet

- Steel Grade NumberingDocument2 pagesSteel Grade NumberingVijay GuravNo ratings yet

- Basic Properties That Cutting Must Possess AreDocument5 pagesBasic Properties That Cutting Must Possess AreAnonymous dh6DITNo ratings yet

- In Their FootstepsDocument27 pagesIn Their FootstepsAnonymous dh6DITNo ratings yet

- Metallurgy Test AnswersDocument2 pagesMetallurgy Test AnswersAnonymous dh6DITNo ratings yet

- Design of A Low Power 10T SRAM Cell: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologyDocument3 pagesDesign of A Low Power 10T SRAM Cell: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologySuyash KumarNo ratings yet

- Hilti Anchor Specification GuidelineDocument3 pagesHilti Anchor Specification GuidelineenggmohanNo ratings yet

- NE03 002revfDocument3 pagesNE03 002revfMarlene Yuriserll Ruiz MuñozNo ratings yet

- 4418 DatasheetDocument5 pages4418 DatasheetwholenumberNo ratings yet

- Aluminum in AircraftDocument117 pagesAluminum in AircraftMark Evan Salutin91% (11)

- Assab Royalloy: Prehardened Free Machining Stainless Holder SteelDocument7 pagesAssab Royalloy: Prehardened Free Machining Stainless Holder SteelNugroho Faris SudrajatNo ratings yet

- Blown FilmDocument4 pagesBlown FilmAdinda LNo ratings yet

- Partsbook Pegasus MX3200 SERIESDocument16 pagesPartsbook Pegasus MX3200 SERIESMaskusyani50% (2)

- Millenium Bypass: Layout Por Bruno C. Bicalho (Visioncb)Document1 pageMillenium Bypass: Layout Por Bruno C. Bicalho (Visioncb)Eduardo BarbosaNo ratings yet

- Procedure For WQTDocument13 pagesProcedure For WQTwalitedisonNo ratings yet

- Parts ListDocument18 pagesParts ListRobin Dario Noriega CastañoNo ratings yet

- VRM OKoookuuiiiiljjjjyggyyDocument8 pagesVRM OKoookuuiiiiljjjjyggyyRakaNo ratings yet

- SPARE PARTS PRICE LIST VALID FROM 15/08/2017Document107 pagesSPARE PARTS PRICE LIST VALID FROM 15/08/2017satriayfNo ratings yet

- 2017 Racing General Catalog PDFDocument20 pages2017 Racing General Catalog PDFsheandtooryNo ratings yet

- CD4007Document2 pagesCD4007Juan CuervoNo ratings yet

- Astm 182Document15 pagesAstm 182DieguitoOmarMoralesNo ratings yet

- 9A03708 Modern Manufacturing MethodsDocument4 pages9A03708 Modern Manufacturing MethodssivabharathamurthyNo ratings yet

- Popular Inventions - Quiz Questions & Answers: Author: Administrator Saved FromDocument2 pagesPopular Inventions - Quiz Questions & Answers: Author: Administrator Saved FromPradnya JoshiNo ratings yet

- I Need A Dollar: Aloe BlackDocument2 pagesI Need A Dollar: Aloe BlackJoakim FontaineNo ratings yet

- Homemade FETDocument18 pagesHomemade FETAli IjazNo ratings yet

- Avaliação Inglês Oitavo AnoDocument2 pagesAvaliação Inglês Oitavo AnoEdivania Pereira SouzaNo ratings yet

- Properties of Ss410Document5 pagesProperties of Ss410gregkilatonNo ratings yet

- Essential Coffee GearDocument31 pagesEssential Coffee GearMaru PabloNo ratings yet

- We Will Fall TogetherDocument55 pagesWe Will Fall TogetherReese MorinNo ratings yet

- Weld carbon steel plate with OK FLUX 231 fluxDocument2 pagesWeld carbon steel plate with OK FLUX 231 fluxborovniskiNo ratings yet

- Surface Treatment For Erosion Resistance: 28 July 2015Document59 pagesSurface Treatment For Erosion Resistance: 28 July 2015juneeNo ratings yet

- Nuevo Hoja de Cálculo de Microsoft ExcelDocument14 pagesNuevo Hoja de Cálculo de Microsoft ExcelMarcelo SalasNo ratings yet

- Tabla Qw-252.1 - Asme IxDocument1 pageTabla Qw-252.1 - Asme IxAngelTinocoNo ratings yet

- VOLITION SPAS - Catalog PremiumDocument8 pagesVOLITION SPAS - Catalog Premiumanouk_betonNo ratings yet

- (Hospital) Accepting Specialist Nationwide Dec. 2022Document629 pages(Hospital) Accepting Specialist Nationwide Dec. 2022Jayr SedecalpNo ratings yet