Professional Documents

Culture Documents

2700 en PDF

Uploaded by

Niten GuptaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2700 en PDF

Uploaded by

Niten GuptaCopyright:

Available Formats

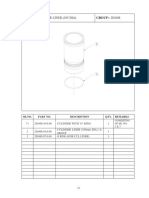

Technical Data Sheet

LOCTITE® 2700™

May-2009

PRODUCT DESCRIPTION 175

% of Full Strength on Steel

LOCTITE® 2700™ provides the following product

150 Zinc dichromate

characteristics:

Technology Acrylic 125

Steel

Chemical Type Dimethacrylate ester 100

Appearance (uncured) Green liquidLMS Nickel Plated

Fluorescence Positive under UV lightLMS 75

Stainless steel

Components One component - 50

requires no mixing Brass

Viscosity Low 25

Cure Anaerobic 0

Secondary Cure Activator 1min 5min 10min 30min 1h 3h 6h 24h 72h

Application Threadlocking Cure Time

Strength High

Cure Speed vs. Bond Gap

® The rate of cure will depend on the bondline gap. Gaps in

LOCTITE 2700™ is designed for the permanent locking and

threaded fasteners depends on thread type, quality and size.

sealing of threaded fasteners. The product cures when The following graph shows shear strength developed with time

confined in the absence of air between close fitting metal on steel pins and collars at different controlled gaps and tested

surfaces and prevents loosening and leakage from shock and according to ISO 10123.

vibration. LOCTITE® 2700™ is developed for applications

where disassembly is not required. 100

% of Full Strength on Steel

m

5m

0.0

TYPICAL PROPERTIES OF UNCURED MATERIAL

75

Specific Gravity @ 25 °C 1.1

Flash Point - See SDS

Viscosity, Cone & Plate, 25 °C, mPa·s (cP): 50 m

Shear rate 129 s-1 350 to 550LMS 5m

0.1

m

TYPICAL CURING PERFORMANCE 25

5m

0.2

Cure Speed vs. Substrate 0

The rate of cure will depend on the substrate used. The graph 1min 5min 10min 30min 1h 3h 6h 24h 72h

below shows the breakaway strength developed with time on Cure Time

M10 steel nuts and bolts compared to different materials and

tested according to ISO 10964. Cure Speed vs. Temperature

The rate of cure will depend on the temperature. The graph

below shows the breakaway strength developed with time at

different temperatures on M10 steel nuts and bolts and tested

according to ISO 10964.

TDS LOCTITE® 2700™, May-2009

% of Full Strength on Steel 100 Cured for 24 hours @ 22 °C

Breakaway Torque, ISO 10964:

M10 steel nuts and Black oxide steel N·m 20

°C

75 bolts (unseated) (lb.in.) (180)

22

°C

5

Prevail Torque, ISO 10964:

M10 steel nuts and Black oxide steel N·m 19

°C

50

bolts (unseated) (lb.in.) (168)

40 Breakloose Torque, ISO 10964, Pre-torqued to 5 N·m:

25 M10 steel nuts and Black oxide steel N·m 34

bolts (lb.in.) (300)

0 Prevail Torque, ISO 10964, Pre-torqued to 5 N·m:

1min 5min 10min 30min 1h 3h 6h 24h 72h M10 steel nuts and Black oxide steel N·m 30

Cure Time bolts (seated) (lb.in.) (265)

Compressive Shear Strength, ISO 10123:

Steel pins and collars (degreased) N/mm² ≥8LMS

(psi) (≥1,160)

TYPICAL ENVIRONMENTAL RESISTANCE

Cured for 1 week @ 22 °C

Breakloose Torque, ISO 10964, Pre-torqued to 5 N·m:

M10 zinc phosphate steel nuts and bolts

Hot Strength

Cure Speed vs. Activator Tested at temperature

Where cure speed is unacceptably long, or large gaps are 100

present, applying activator to the surface will improve cure

speed. The graph below shows the breakaway strength

% Strength @ 22 °C

developed with time on M10 zinc dichromate steel nuts and 75

bolts using Activator 7471™ and 7649™ and tested according

to ISO 10964.

50

175

% of Full Strength on Steel

150 25

™

49

125 76

ator

100 tiv 0

Ac 0 50 100 150

r

Temperature, °C

ato

75

1™

tiv

ac

47

50

r7

No

Heat Aging

to

25

a

Aged at temperature indicated and tested @ 22 °C

tiv

Ac

0 150

% Initial Strength @ 22 °C

1min 5min 10min 30min 1h 3h 6h 24h 72h

Cure Time 125

100 °C

TYPICAL PROPERTIES OF CURED MATERIAL 100

Physical Properties: 120 °C

75

Coefficient of Thermal Expansion, ISO 11359-2, K-1:

150 °C

Below Tg 75×10-6 50

Above Tg 166×10-6

Coefficient of Thermal Conductivity, ISO 8302, 0.4 25

W/(m·K)

Glass Transition Temperature (Tg) by TMA 80 0

, ISO 11359-2, °C 0 100 250 500 1000

Exposure Time, hours

TYPICAL PERFORMANCE OF CURED MATERIAL

Adhesive Properties

Henkel Americas Henkel Europe Henkel Asia Pacific

+860.571.5100 +49.89.320800.1800 +86.21.2891.8859

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

TDS LOCTITE® 2700™, May-2009

Chemical/Solvent Resistance Storage

Aged under conditions indicated and tested @ 22 °C. Store product in the unopened container in a dry location. Storage

information may be indicated on the product container labeling.

% of initial strength

Optimal Storage: 8 °C to 21 °C. Storage below 8 °C or greater

Environment °C 100 h 500 h 1000 h than 28 °C can adversely affect product propertiesMaterial

Acetone 22 100 105 100 removed from containers may be contaminated during use. Do not

return product to the original container. Henkel Corporation cannot

Brake fluid 22 105 100 95 assume responsibility for product which has been contaminated or

Ethanol 22 105 100 95 stored under conditions other than those previously indicated. If

Motor oil 125 85 80 85 additional information is required, please contact your local Technical

Service Center or Customer Service Representative.

Gasoline 22 110 100 105

Water/glycol 50/50 87 90 95 90 Conversions

(°C x 1.8) + 32 = °F

kV/mm x 25.4 = V/mil

mm / 25.4 = inches

GENERAL INFORMATION µm / 25.4 = mil

This product is not recommended for use in pure oxygen and/or N x 0.225 = lb

oxygen rich systems and should not be selected as a sealant for N/mm x 5.71 = lb/in

chlorine or other strong oxidizing materials. N/mm² x 145 = psi

MPa x 145 = psi

For safe handling information on this product, consult the Safety

N·m x 8.851 = lb·in

Data Sheet (SDS).

N·m x 0.738 = lb·ft

Where aqueous washing systems are used to clean the surfaces N·mm x 0.142 = oz·in

before bonding, it is important to check for compatibility of the washing mPa·s = cP

solution with the adhesive. In some cases these aqueous washes can Note:

affect the cure and performance of the adhesive. The information provided in this Technical Data Sheet (TDS) including the

recommendations for use and application of the product are based on our

This product is not normally recommended for use on plastics knowledge and experience of the product as at the date of this TDS. The product

(particularly thermoplastic materials where stress cracking of the can have a variety of different applications as well as differing application and

plastic could result). Users are recommended to confirm compatibility working conditions in your environment that are beyond our control. Henkel is,

of the product with such substrates. therefore, not liable for the suitability of our product for the production processes

and conditions in respect of which you use them, as well as the intended

applications and results. We strongly recommend that you carry out your own

Directions for use: prior trials to confirm such suitability of our product.

For Assembly Any liability in respect of the information in the Technical Data Sheet or any other

written or oral recommendation(s) regarding the concerned product is excluded,

1. For best results, clean all surfaces (external and internal) with a except if otherwise explicitly agreed and except in relation to death or personal

LOCTITE® cleaning solvent and allow to dry. injury caused by our negligence and any liability under any applicable mandatory

product liability law.

2. If the material is an inactive metal or the cure speed is too slow,

spray all threads with Activator 7471™ or 7649™ and allow to In case products are delivered by Henkel Belgium NV, Henkel Electronic

dry. Materials NV, Henkel Nederland BV, Henkel Technologies France SAS and

3. Shake the product thoroughly before use. Henkel France SA please additionally note the following:

In case Henkel would be nevertheless held liable, on whatever legal ground,

4. To prevent the product from clogging in the nozzle, do not allow

Henkel’s liability will in no event exceed the amount of the concerned delivery.

the tip to touch metal surfaces during application.

5. For Thru Holes, apply several drops of the product onto the bolt In case products are delivered by Henkel Colombiana, S.A.S. the following

at the nut engagement area. disclaimer is applicable:

The information provided in this Technical Data Sheet (TDS) including the

6. For Blind Holes, apply several drops of the product down the

recommendations for use and application of the product are based on our

internal threads to the bottom of the hole. knowledge and experience of the product as at the date of this TDS. Henkel is,

7. For Sealing Applications, apply a 360° bead of product to the therefore, not liable for the suitability of our product for the production processes

leading threads of the male fitting, leaving the first thread and conditions in respect of which you use them, as well as the intended

free. For bigger threads and voids, adjust product amount applications and results. We strongly recommend that you carry out your own

accordingly . prior trials to confirm such suitability of our product.

Any liability in respect of the information in the Technical Data Sheet or any other

8. Assemble and tighten as required. written or oral recommendation(s) regarding the concerned product is excluded,

except if otherwise explicitly agreed and except in relation to death or personal

For Disassembly injury caused by our negligence and any liability under any applicable mandatory

1. Apply localized heat to nut or bolt to approximately 250 °C. product liability law.

Disassemble while hot.

For Cleanup

1. Cured product can be removed with a combination of soaking in

a Loctite solvent and mechanical abrasion such as a wire brush.

Loctite Material SpecificationLMS

LMS dated March-18, 2009. Test reports for each batch are available

for the indicated properties. LMS test reports include selected QC test

parameters considered appropriate to specifications for customer use.

Additionally, comprehensive controls are in place to assure product

quality and consistency. Special customer specification requirements

may be coordinated through Henkel Quality.

Henkel Americas Henkel Europe Henkel Asia Pacific

+860.571.5100 +49.89.320800.1800 +86.21.2891.8859

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

TDS LOCTITE® 2700™, May-2009

In case products are delivered by Henkel Corporation, Resin Technology

Group, Inc., or Henkel Canada Corporation, the following disclaimer is

applicable:

The data contained herein are furnished for information only and are believed to

be reliable. We cannot assume responsibility for the results obtained by others

over whose methods we have no control. It is the user's responsibility to

determine suitability for the user's purpose of any production methods mentioned

herein and to adopt such precautions as may be advisable for the protection of

property and of persons against any hazards that may be involved in the handling

and use thereof. In light of the foregoing, Henkel Corporation specifically

disclaims all warranties expressed or implied, including warranties of

merchantability or fitness for a particular purpose, arising from sale or use

of Henkel Corporation’s products. Henkel Corporation specifically

disclaims any liability for consequential or incidental damages of any kind,

including lost profits. The discussion herein of various processes or

compositions is not to be interpreted as representation that they are free from

domination of patents owned by others or as a license under any Henkel

Corporation patents that may cover such processes or compositions. We

recommend that each prospective user test his proposed application before

repetitive use, using this data as a guide. This product may be covered by one or

more United States or foreign patents or patent applications.

Trademark usage

Except as otherwise noted, all trademarks in this document are trademarks of

Henkel Corporation in the U.S. and elsewhere. ® denotes a trademark

registered in the U.S. Patent and Trademark Office.

Reference 0.1

Henkel Americas Henkel Europe Henkel Asia Pacific

+860.571.5100 +49.89.320800.1800 +86.21.2891.8859

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

You might also like

- SensorDocument1 pageSensorNiten GuptaNo ratings yet

- Combination SwitchDocument1 pageCombination SwitchNiten GuptaNo ratings yet

- Harness KG 934 4r1040tDocument1 pageHarness KG 934 4r1040tNiten GuptaNo ratings yet

- Lic'S Bima Account - I (Plan No. 805) (UIN: 512N263V01)Document8 pagesLic'S Bima Account - I (Plan No. 805) (UIN: 512N263V01)Niten GuptaNo ratings yet

- SEBP487Document1 pageSEBP487Niten GuptaNo ratings yet

- Captain Door Lock and GlassDocument2 pagesCaptain Door Lock and GlassNiten GuptaNo ratings yet

- KG934V1 User Manual: Typical Contactor ControlDocument1 pageKG934V1 User Manual: Typical Contactor ControlNiten GuptaNo ratings yet

- KG934V129 30Document2 pagesKG934V129 30Niten GuptaNo ratings yet

- SL. NO. Ill. NO. NO. Description Remarks LH Door Trims - Alcab189Document1 pageSL. NO. Ill. NO. NO. Description Remarks LH Door Trims - Alcab189Niten GuptaNo ratings yet

- KG934V1 13-18Document6 pagesKG934V1 13-18Niten GuptaNo ratings yet

- KG934V1 7-14Document8 pagesKG934V1 7-14Niten GuptaNo ratings yet

- Kirloskar 6R1080TA 41-50Document10 pagesKirloskar 6R1080TA 41-50Niten GuptaNo ratings yet

- KG934V1 1-6 KirloskarDocument6 pagesKG934V1 1-6 KirloskarNiten Gupta100% (2)

- KG934V1 Page 25-30Document6 pagesKG934V1 Page 25-30Niten GuptaNo ratings yet

- KG934V1 Page 11-15Document5 pagesKG934V1 Page 11-15Niten GuptaNo ratings yet

- KG934V1 19-26Document8 pagesKG934V1 19-26Niten GuptaNo ratings yet

- KG934V1 21-25Document5 pagesKG934V1 21-25Niten GuptaNo ratings yet

- Kirloskar 6R1080TA 21-40Document20 pagesKirloskar 6R1080TA 21-40Niten GuptaNo ratings yet

- Kirloskar 6R1080TA Page 51-60Document10 pagesKirloskar 6R1080TA Page 51-60Niten GuptaNo ratings yet

- VCR 2420.pdf1Document4 pagesVCR 2420.pdf1Niten GuptaNo ratings yet

- Excavator 320 DDocument1 pageExcavator 320 DNiten GuptaNo ratings yet

- Kirloskar 6R1080TA PAGE 1-10Document10 pagesKirloskar 6R1080TA PAGE 1-10Niten Gupta0% (1)

- A M Jmba BM Tvs-Girling Bx. A% Bx. 4 Wmvi' Ba.' KZVCM VBB &/A.&W 9/A BDocument1 pageA M Jmba BM Tvs-Girling Bx. A% Bx. 4 Wmvi' Ba.' KZVCM VBB &/A.&W 9/A BNiten GuptaNo ratings yet

- Abbreviations: ABS AL Al RF PTC SPLDocument1 pageAbbreviations: ABS AL Al RF PTC SPLNiten GuptaNo ratings yet

- Price List 2Document1 pagePrice List 2Niten GuptaNo ratings yet

- Wabco Gen Catalogue 2014 LRDocument53 pagesWabco Gen Catalogue 2014 LRmhmd_saad100% (4)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Lanxess Resin ApplicationDocument2 pagesLanxess Resin ApplicationiamNo ratings yet

- Experimental Study of Natural Rubber Shock Attenuation DevicesDocument10 pagesExperimental Study of Natural Rubber Shock Attenuation DevicesMeyNo ratings yet

- The Oolitization Rate Determination of Bentonite Moulding MixturesDocument4 pagesThe Oolitization Rate Determination of Bentonite Moulding Mixturesvivek1312No ratings yet

- SKD61-Forged Hot Work Tool SteelDocument1 pageSKD61-Forged Hot Work Tool SteelAgustine SetiawanNo ratings yet

- Stewmac: Two-Tone Fender Sunburst in The Pre-1956 StyleDocument4 pagesStewmac: Two-Tone Fender Sunburst in The Pre-1956 StyleAlexandre KlüppelNo ratings yet

- AMCP 706-177 Properties of ExplosivesDocument408 pagesAMCP 706-177 Properties of ExplosivesSam LarterNo ratings yet

- Gouging Processes: Arc-Air Gouging Plasma GougingDocument4 pagesGouging Processes: Arc-Air Gouging Plasma GougingMika VelinovNo ratings yet

- Concrete Drain Tile: Standard Specification ForDocument6 pagesConcrete Drain Tile: Standard Specification ForEligio Antonio CerdaNo ratings yet

- Industrial Anodizing Co Inc A967Document9 pagesIndustrial Anodizing Co Inc A967Daryna KupriianovaNo ratings yet

- C 1Document4 pagesC 1alphamale3No ratings yet

- Experiment-2 ChemistryDocument2 pagesExperiment-2 Chemistryanshsoni1101No ratings yet

- Bumper Systems - An IntroductionDocument25 pagesBumper Systems - An IntroductionMichaelNo ratings yet

- Ak 088 Worn Effects PDFDocument1 pageAk 088 Worn Effects PDFLea LeaNo ratings yet

- Allowable Stress & Factor of SafetyDocument2 pagesAllowable Stress & Factor of SafetySusan Mcknight100% (1)

- Vortex DMT Extraction Tek BKLTDocument6 pagesVortex DMT Extraction Tek BKLTDora L. Gutierrez100% (1)

- Exercise 1 (Isolation of Caffeine)Document2 pagesExercise 1 (Isolation of Caffeine)Albert CorderoNo ratings yet

- Atmospheric CorrosionDocument14 pagesAtmospheric Corrosioncaytuero100% (1)

- Indu Incompleted PDFDocument15 pagesIndu Incompleted PDFUday BagadeNo ratings yet

- Astm D4060 10 PDFDocument5 pagesAstm D4060 10 PDFHsiao Yoyo0% (1)

- Numerical Analysis of Carbon Fibre Reinforced Aircraft WinDocument4 pagesNumerical Analysis of Carbon Fibre Reinforced Aircraft WinSiva BhaskarNo ratings yet

- Chemistry of PetroleumDocument23 pagesChemistry of PetroleumShehzad khanNo ratings yet

- Easi Joist Technical Manual PDFDocument36 pagesEasi Joist Technical Manual PDFAndyNo ratings yet

- SUewBSEA CORROSION11Document4 pagesSUewBSEA CORROSION11mayheartNo ratings yet

- WOW Notes! DLP Chemistry, Carbon CompoundDocument32 pagesWOW Notes! DLP Chemistry, Carbon Compoundnur asyiqinNo ratings yet

- Mcgraw-Hill Series in Chemical Engineering: The Chemical Process IndustriesDocument67 pagesMcgraw-Hill Series in Chemical Engineering: The Chemical Process IndustriesSHASHWA USOPNo ratings yet

- Solubility Equilibrium HomeworkDocument2 pagesSolubility Equilibrium HomeworkEyayu ZewduNo ratings yet

- LPG Storage and Piping SystemsDocument6 pagesLPG Storage and Piping SystemsAhmed Mohamed FarahatNo ratings yet

- Tivar 88-2: Drop-In Liners Solve Flow ProblemsDocument1 pageTivar 88-2: Drop-In Liners Solve Flow Problemsacas35100% (1)

- Catalyst and CatalysisDocument11 pagesCatalyst and CatalysisRehinaNo ratings yet

- The Density of Liquids and An Introduction To Graphing PDFDocument5 pagesThe Density of Liquids and An Introduction To Graphing PDFEric BirdNo ratings yet