Professional Documents

Culture Documents

Fag Powerpull Spider Trisection Plate WL 80-344 Ea

Uploaded by

Mariano Javier Mendonça0 ratings0% found this document useful (0 votes)

172 views6 pagesFAG PowerPull SPIDER hydraulic extraction pullers and puller plates for rolling bearings and other machine elements. Long stroke length - more efficient extraction work the extension fitted to the piston rod increases the stroke length of the integral hydraulic cylinder to 250 mm. 120 kN SPIDER 40 152 mm 150 mm SPIDER 60 SPIDER 80 200 mm Quick, easy dismantling integral hydraulic cylinder with hand pump Filled with high viscosity hydraulic oil R 68

Original Description:

Original Title

Fag Powerpull Spider Trisection Plate Wl 80-344 Ea

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFAG PowerPull SPIDER hydraulic extraction pullers and puller plates for rolling bearings and other machine elements. Long stroke length - more efficient extraction work the extension fitted to the piston rod increases the stroke length of the integral hydraulic cylinder to 250 mm. 120 kN SPIDER 40 152 mm 150 mm SPIDER 60 SPIDER 80 200 mm Quick, easy dismantling integral hydraulic cylinder with hand pump Filled with high viscosity hydraulic oil R 68

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

172 views6 pagesFag Powerpull Spider Trisection Plate WL 80-344 Ea

Uploaded by

Mariano Javier MendonçaFAG PowerPull SPIDER hydraulic extraction pullers and puller plates for rolling bearings and other machine elements. Long stroke length - more efficient extraction work the extension fitted to the piston rod increases the stroke length of the integral hydraulic cylinder to 250 mm. 120 kN SPIDER 40 152 mm 150 mm SPIDER 60 SPIDER 80 200 mm Quick, easy dismantling integral hydraulic cylinder with hand pump Filled with high viscosity hydraulic oil R 68

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

FAG PowerPull SPIDER FAG PowerPull

Don’t settle 1 TRISECTION PLATE

for anything less! 2

Bearings and machine parts

stay in one piece!

•1 Safety grip allows easier pumping For hydraulic and mechanical pullers:

using industrial gloves the FAG PowerPull TRISECTION

•2 Optimum operating position due PLATE.

to 360° rotary coupling for pump 3 This allows the extraction of com-

hand lever

plete bearings, inner rings with a

(SPIDER 175+400 with separate

pump) 4 firm seating or other workpieces.

The load capacity and extraction force

•3 Application or reduction in

are precisely matched to each other and the

pressure by rotation of hand 5

lever on cut-off valve unique design is patented.

The SPIDER puller hooks grip directly under the

•4 Pressure control valve gives

screw studs of the TRISECTION PLATE and give

protection against overload

uniform force distribution. Even where parts are

•

5 Parts under mechanical 6 firmly seated, there is no tilting or bending.

load are made from

high quality chromium/ The high extraction forces are concentrated,

molybdenum steel for example in a bearing, on the inner ring;

in general, the bearing and shaft remain intact

•6 Maximum possible

and can be used again. The optimised application

reduction in torsional 7

and frictional forces by of forces also reduces the work required for extraction.

chromium plated piston made from

The TRISECTION PLATE can be fitted under the bearing

quenched and tempered steel 8

with only a small number of manual operations and is

7 Stroke travel can be changed by proven in practical use. FAG Kugelfischer AG

means of standard adapter

Georg-Schäfer-Straße 30 FAG PowerPull

8 Single piece puller arm and grip

hook for high load capacity

c 97421 Schweinfurt

Germany

SPIDER

TRISECTION PLATE

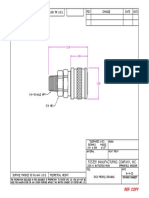

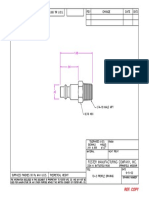

•9 Simple centring by spring-loaded b (Ø max.)

Tel: +49-(0) 2407 - 91 49 99

steel cone 11 Fax: +49-(0) 2407 - 91 49 59

•10 “Quick” screw thread for

7 a (Ø min.) E-Mail: support@fis-services.de Hydraulic extraction pullers and puller plates

setting of optimum grip www.fis-services.de

depth 9 for rolling bearings and other machine elements

•11 Not enough space for three puller

arms? Simply change to two

FAG PowerPull TRISECTION PLATE

opposing arms!

Puller plate Dimensions Mass Recommended for

[mm] [kg] hydr. puller SPIDER mech. puller

a b c

83/03/04 Printed in Germany

Every care has been taken to ensure the

TRISECTION PLATE 50 12 50 113 0,5 – 53.130 correctness of the information contained in

TRISECTION PLATE 100 26 100 218 2,6 40/60/80/100 53.230 this publication but no liability can be

10 TRISECTION PLATE 160 50 160 322 5,8 80/100/20/175/200 53.295 accepted for any errors or omissions.

We reserve the right to make changes in the

TRISECTION PLATE 260 90 260 480 18,4 175/200/250/300 53.390

interest of technical progress.

TRISECTION PLATE 380 140 380 656 50,3 250/300/400 53.640 © by FAG 2004

This publication or parts thereof may not be

A Member of the

reproduced without our permission.

Schaeffler Group

WL 80 344 EA

Force

FAG PowerPull SPIDER Selecting the right puller SP IDER 40... 80

Strong, easy, Grip width ➔ Grip depth ➔ Force Standard version

quick Grip The allocation of hydraulic forces is based

Compact, user-friendly FAG pullers with SPIDER 175 + 400

depth integral hand pump for extraction forces Extra strong with separate pump

on many years of experience.

Grip up to 80 kN.

width The designs and forces are calculated Restricted spaces and poorly accessible

SPIDER 40 can be used up to a grip depth

so that they cover almost locations can impede or prevent rapid,

40

kN

of 152 mm. SPIDER 60 and 80 are alter-

any application. SPIDER secure dismantling.

40 natively available with longer arms (for

Longer stroke length – more grip depths of 190 and 229 mm). The

SPIDER 175 and 400 are designed

for this type of work. The pump,

efficient extraction work 152 mm

longer arms are available as accessories

60

which is connected to the puller

The extension fitted to the piston rod (from

kN

SPIDER

150 mm

or replacement parts.

60 by a 1,5 m long hydraulic hose,

SPIDER 250 upwards) or the adapter (SPIDER Case is operated using a hand lever.

152/190*

Easy transport – the compact SPIDER Both pullers are available with

40/60/80/100/120/200) increases the stroke 80 mm

kN

SPIDER 200 mm standard pullers are held, together with appropriate arm lengths and grip

length of the integral hydraulic cylinder to 80 depths.

the safety grid, in a sturdy plastic case.

250 mm. The shortened stroke travel speeds 100

The top model of the FAG PowerPull

190/229* kN

mm SPIDER

up the extraction process; it is not necessary range, the SPIDER 400, is the ideal solution

10 0

250 mm FAG PowerPull SPIDER 40...80 when high forces up to 400 kN are required

to change to shorter puller arms.

User-friendly 182/220* Standard version for extraction of very large bearings

• Quick, easy dismantling 120

kN

mm

Puller Extraction force Grip width Grip depth Stroke Mass and components.

• Integral hydraulic cylinder with hand pump SPIDER

12 0

280 mm

[kN] [t] [mm] [mm] [mm] [kg]

• Filled with high viscosity hydraulic oil R 68 175

SPIDER 40 40 4 150 152 55 4,5

• 2 and 3 arm pullers in a single device 220/259* kN

SPIDER

SPIDER 60 60 6 200 152 (190*) 82 4,9

• Low mass 305 mm

mm

17 5 SPIDER 80 80 8

* With longer puller arms as an option

250 190 (229*) 82 6,6

• Pump handle can be turned through 360°

• Automatic centring on shaft by spring- 229/300*

mm

SPIDER 100 ...300

200

loaded centring cone Extra strong with integral pump

kN 356 mm

• Can be used in any position SPIDER

200 With an extraction force up to 300 kN and

Operator protection a grip depth up to 405 mm, these pullers

Versatile are a valuable aid in difficult dismantling

The safety cover 259/300*

• For extraction of rolling bearings, gears, mm work.

sleeves, washers and many other shrink • captures any parts that fly off under

356 mm

250 Thanks to the optimised design of the

extreme load, kN puller arms, they are clearly superior to

fitted parts SPIDER

• Large grip width due to optimised • is made from extremely tough plastic and 25 0 conventional tools due to their higher

extraction force and improved safety.

arrangement of puller arms is transparent – you can see what is

Longer puller arms are available for all

going on,

• Very large grip depth with extra long 300/375*

mm

sizes in the SPIDER 100...300 range.

puller arms (accessories) • can be easily fitted around any tool or

Transport and storage

workpiece, 406 mm

• Grip depth can be optimised by means 300 Neat and tidy, ready to hand – SPIDER

of screw thread and piston rod extension • is easily fixed in place using velcro strips. kN 100...300 pullers are supplied, together

or separate adapter

SPIDER

In the compact pullers SPIDER 40,60 and 80, 30 0 with the safety cover and accessories, in

a sturdy metal chest.

a safety grid serves the same purpose.

Safe

• Safety grid (SPIDER 40...80) or transpa- 375/405*

mm

FAG PowerPull SPIDER 100...300

rent safety cover included in delivery Extra strong

540/800*

• Protection against overload by integral mm 400 Puller Extraction force Grip width

[kN] [t] [mm]

Grip depth

[mm]

Stroke

[mm]

Mass

[kg]

safety pressure control valve kN FAG PowerPull SPIDER 175 + 400

SPIDER SPIDER 100 100 10 280 182 (220*) 82 5,6 Extra strong

40 0 SPIDER 120 120 12 305 220 (259*) 82 7,6 Puller Extraction force Grip width Grip depth Stroke Mass

SPIDER 200 200 20 356 259 (300*) 82 10,0 [kN] [t] [mm] [mm] [mm] [kg]

* optional SPIDER 250 250 25 406 300 (375*) 110 20,0 SPIDER 175 175 17,5 356 229 (300*) 82 15,6

405/635*

mm SPIDER 300 300 30 540 (800*) 375 (405*) 110 25,0 SPIDER 400 400 40 800 (1200*) 405 (635*) 250 49,0

* With longer puller arms as an option * With longer puller arms as an option

800/1200*

mm

Force

FAG PowerPull SPIDER Selecting the right puller SP IDER 40... 80

Strong, easy, Grip width ➔ Grip depth ➔ Force Standard version

quick Grip The allocation of hydraulic forces is based

Compact, user-friendly FAG pullers with SPIDER 175 + 400

depth integral hand pump for extraction forces Extra strong with separate pump

on many years of experience.

Grip up to 80 kN.

width The designs and forces are calculated Restricted spaces and poorly accessible

SPIDER 40 can be used up to a grip depth

so that they cover almost locations can impede or prevent rapid,

40

kN

of 152 mm. SPIDER 60 and 80 are alter-

any application. SPIDER secure dismantling.

40 natively available with longer arms (for

Longer stroke length – more grip depths of 190 and 229 mm). The

SPIDER 175 and 400 are designed

for this type of work. The pump,

efficient extraction work 152 mm

longer arms are available as accessories

60

which is connected to the puller

The extension fitted to the piston rod (from

kN

SPIDER

150 mm

or replacement parts.

60 by a 1,5 m long hydraulic hose,

SPIDER 250 upwards) or the adapter (SPIDER Case is operated using a hand lever.

152/190*

Easy transport – the compact SPIDER Both pullers are available with

40/60/80/100/120/200) increases the stroke 80 mm

kN

SPIDER 200 mm standard pullers are held, together with appropriate arm lengths and grip

length of the integral hydraulic cylinder to 80 depths.

the safety grid, in a sturdy plastic case.

250 mm. The shortened stroke travel speeds 100

The top model of the FAG PowerPull

190/229* kN

mm SPIDER

up the extraction process; it is not necessary range, the SPIDER 400, is the ideal solution

10 0

250 mm FAG PowerPull SPIDER 40...80 when high forces up to 400 kN are required

to change to shorter puller arms.

User-friendly 182/220* Standard version for extraction of very large bearings

• Quick, easy dismantling 120

kN

mm

Puller Extraction force Grip width Grip depth Stroke Mass and components.

• Integral hydraulic cylinder with hand pump SPIDER

12 0

280 mm

[kN] [t] [mm] [mm] [mm] [kg]

• Filled with high viscosity hydraulic oil R 68 175

SPIDER 40 40 4 150 152 55 4,5

• 2 and 3 arm pullers in a single device 220/259* kN

SPIDER

SPIDER 60 60 6 200 152 (190*) 82 4,9

• Low mass 305 mm

mm

17 5 SPIDER 80 80 8

* With longer puller arms as an option

250 190 (229*) 82 6,6

• Pump handle can be turned through 360°

• Automatic centring on shaft by spring- 229/300*

mm

SPIDER 100 ...300

200

loaded centring cone Extra strong with integral pump

kN 356 mm

• Can be used in any position SPIDER

200 With an extraction force up to 300 kN and

Operator protection a grip depth up to 405 mm, these pullers

Versatile are a valuable aid in difficult dismantling

The safety cover 259/300*

• For extraction of rolling bearings, gears, mm work.

sleeves, washers and many other shrink • captures any parts that fly off under

356 mm

250 Thanks to the optimised design of the

extreme load, kN puller arms, they are clearly superior to

fitted parts SPIDER

• Large grip width due to optimised • is made from extremely tough plastic and 25 0 conventional tools due to their higher

extraction force and improved safety.

arrangement of puller arms is transparent – you can see what is

Longer puller arms are available for all

going on,

• Very large grip depth with extra long 300/375*

mm

sizes in the SPIDER 100...300 range.

puller arms (accessories) • can be easily fitted around any tool or

Transport and storage

workpiece, 406 mm

• Grip depth can be optimised by means 300 Neat and tidy, ready to hand – SPIDER

of screw thread and piston rod extension • is easily fixed in place using velcro strips. kN 100...300 pullers are supplied, together

or separate adapter

SPIDER

In the compact pullers SPIDER 40,60 and 80, 30 0 with the safety cover and accessories, in

a sturdy metal chest.

a safety grid serves the same purpose.

Safe

• Safety grid (SPIDER 40...80) or transpa- 375/405*

mm

FAG PowerPull SPIDER 100...300

rent safety cover included in delivery Extra strong

540/800*

• Protection against overload by integral mm 400 Puller Extraction force Grip width

[kN] [t] [mm]

Grip depth

[mm]

Stroke

[mm]

Mass

[kg]

safety pressure control valve kN FAG PowerPull SPIDER 175 + 400

SPIDER SPIDER 100 100 10 280 182 (220*) 82 5,6 Extra strong

40 0 SPIDER 120 120 12 305 220 (259*) 82 7,6 Puller Extraction force Grip width Grip depth Stroke Mass

SPIDER 200 200 20 356 259 (300*) 82 10,0 [kN] [t] [mm] [mm] [mm] [kg]

* optional SPIDER 250 250 25 406 300 (375*) 110 20,0 SPIDER 175 175 17,5 356 229 (300*) 82 15,6

405/635*

mm SPIDER 300 300 30 540 (800*) 375 (405*) 110 25,0 SPIDER 400 400 40 800 (1200*) 405 (635*) 250 49,0

* With longer puller arms as an option * With longer puller arms as an option

800/1200*

mm

Force

FAG PowerPull SPIDER Selecting the right puller SP IDER 40... 80

Strong, easy, Grip width ➔ Grip depth ➔ Force Standard version

quick Grip The allocation of hydraulic forces is based

Compact, user-friendly FAG pullers with SPIDER 175 + 400

depth integral hand pump for extraction forces Extra strong with separate pump

on many years of experience.

Grip up to 80 kN.

width The designs and forces are calculated Restricted spaces and poorly accessible

SPIDER 40 can be used up to a grip depth

so that they cover almost locations can impede or prevent rapid,

40

kN

of 152 mm. SPIDER 60 and 80 are alter-

any application. SPIDER secure dismantling.

40 natively available with longer arms (for

Longer stroke length – more grip depths of 190 and 229 mm). The

SPIDER 175 and 400 are designed

for this type of work. The pump,

efficient extraction work 152 mm

longer arms are available as accessories

60

which is connected to the puller

The extension fitted to the piston rod (from

kN

SPIDER

150 mm

or replacement parts.

60 by a 1,5 m long hydraulic hose,

SPIDER 250 upwards) or the adapter (SPIDER Case is operated using a hand lever.

152/190*

Easy transport – the compact SPIDER Both pullers are available with

40/60/80/100/120/200) increases the stroke 80 mm

kN

SPIDER 200 mm standard pullers are held, together with appropriate arm lengths and grip

length of the integral hydraulic cylinder to 80 depths.

the safety grid, in a sturdy plastic case.

250 mm. The shortened stroke travel speeds 100

The top model of the FAG PowerPull

190/229* kN

mm SPIDER

up the extraction process; it is not necessary range, the SPIDER 400, is the ideal solution

10 0

250 mm FAG PowerPull SPIDER 40...80 when high forces up to 400 kN are required

to change to shorter puller arms.

User-friendly 182/220* Standard version for extraction of very large bearings

• Quick, easy dismantling 120

kN

mm

Puller Extraction force Grip width Grip depth Stroke Mass and components.

• Integral hydraulic cylinder with hand pump SPIDER

12 0

280 mm

[kN] [t] [mm] [mm] [mm] [kg]

• Filled with high viscosity hydraulic oil R 68 175

SPIDER 40 40 4 150 152 55 4,5

• 2 and 3 arm pullers in a single device 220/259* kN

SPIDER

SPIDER 60 60 6 200 152 (190*) 82 4,9

• Low mass 305 mm

mm

17 5 SPIDER 80 80 8

* With longer puller arms as an option

250 190 (229*) 82 6,6

• Pump handle can be turned through 360°

• Automatic centring on shaft by spring- 229/300*

mm

SPIDER 100 ...300

200

loaded centring cone Extra strong with integral pump

kN 356 mm

• Can be used in any position SPIDER

200 With an extraction force up to 300 kN and

Operator protection a grip depth up to 405 mm, these pullers

Versatile are a valuable aid in difficult dismantling

The safety cover 259/300*

• For extraction of rolling bearings, gears, mm work.

sleeves, washers and many other shrink • captures any parts that fly off under

356 mm

250 Thanks to the optimised design of the

extreme load, kN puller arms, they are clearly superior to

fitted parts SPIDER

• Large grip width due to optimised • is made from extremely tough plastic and 25 0 conventional tools due to their higher

extraction force and improved safety.

arrangement of puller arms is transparent – you can see what is

Longer puller arms are available for all

going on,

• Very large grip depth with extra long 300/375*

mm

sizes in the SPIDER 100...300 range.

puller arms (accessories) • can be easily fitted around any tool or

Transport and storage

workpiece, 406 mm

• Grip depth can be optimised by means 300 Neat and tidy, ready to hand – SPIDER

of screw thread and piston rod extension • is easily fixed in place using velcro strips. kN 100...300 pullers are supplied, together

or separate adapter

SPIDER

In the compact pullers SPIDER 40,60 and 80, 30 0 with the safety cover and accessories, in

a sturdy metal chest.

a safety grid serves the same purpose.

Safe

• Safety grid (SPIDER 40...80) or transpa- 375/405*

mm

FAG PowerPull SPIDER 100...300

rent safety cover included in delivery Extra strong

540/800*

• Protection against overload by integral mm 400 Puller Extraction force Grip width

[kN] [t] [mm]

Grip depth

[mm]

Stroke

[mm]

Mass

[kg]

safety pressure control valve kN FAG PowerPull SPIDER 175 + 400

SPIDER SPIDER 100 100 10 280 182 (220*) 82 5,6 Extra strong

40 0 SPIDER 120 120 12 305 220 (259*) 82 7,6 Puller Extraction force Grip width Grip depth Stroke Mass

SPIDER 200 200 20 356 259 (300*) 82 10,0 [kN] [t] [mm] [mm] [mm] [kg]

* optional SPIDER 250 250 25 406 300 (375*) 110 20,0 SPIDER 175 175 17,5 356 229 (300*) 82 15,6

405/635*

mm SPIDER 300 300 30 540 (800*) 375 (405*) 110 25,0 SPIDER 400 400 40 800 (1200*) 405 (635*) 250 49,0

* With longer puller arms as an option * With longer puller arms as an option

800/1200*

mm

FAG PowerPull SPIDER FAG PowerPull

Don’t settle 1 TRISECTION PLATE

for anything less! 2

Bearings and machine parts

stay in one piece!

•1 Safety grip allows easier pumping For hydraulic and mechanical pullers:

using industrial gloves the FAG PowerPull TRISECTION

•2 Optimum operating position due PLATE.

to 360° rotary coupling for pump 3 This allows the extraction of com-

hand lever

plete bearings, inner rings with a

(SPIDER 175+400 with separate

pump) 4 firm seating or other workpieces.

The load capacity and extraction force

•3 Application or reduction in

are precisely matched to each other and the

pressure by rotation of hand 5

lever on cut-off valve unique design is patented.

The SPIDER puller hooks grip directly under the

•4 Pressure control valve gives

screw studs of the TRISECTION PLATE and give

protection against overload

uniform force distribution. Even where parts are

•

5 Parts under mechanical 6 firmly seated, there is no tilting or bending.

load are made from

high quality chromium/ The high extraction forces are concentrated,

molybdenum steel for example in a bearing, on the inner ring;

in general, the bearing and shaft remain intact

•6 Maximum possible

and can be used again. The optimised application

reduction in torsional 7

and frictional forces by of forces also reduces the work required for extraction.

chromium plated piston made from

The TRISECTION PLATE can be fitted under the bearing

quenched and tempered steel 8

with only a small number of manual operations and is

7 Stroke travel can be changed by proven in practical use. FAG Kugelfischer AG

means of standard adapter

Georg-Schäfer-Straße 30 FAG PowerPull

8 Single piece puller arm and grip

hook for high load capacity

c 97421 Schweinfurt

Germany

SPIDER

TRISECTION PLATE

•9 Simple centring by spring-loaded b (Ø max.)

Tel: +49-(0) 2407 - 91 49 99

steel cone 11 Fax: +49-(0) 2407 - 91 49 59

•10 “Quick” screw thread for

7 a (Ø min.) E-Mail: support@fis-services.de Hydraulic extraction pullers and puller plates

setting of optimum grip www.fis-services.de

depth 9 for rolling bearings and other machine elements

•11 Not enough space for three puller

arms? Simply change to two

FAG PowerPull TRISECTION PLATE

opposing arms!

Puller plate Dimensions Mass Recommended for

[mm] [kg] hydr. puller SPIDER mech. puller

a b c

83/03/04 Printed in Germany

Every care has been taken to ensure the

TRISECTION PLATE 50 12 50 113 0,5 – 53.130 correctness of the information contained in

TRISECTION PLATE 100 26 100 218 2,6 40/60/80/100 53.230 this publication but no liability can be

10 TRISECTION PLATE 160 50 160 322 5,8 80/100/20/175/200 53.295 accepted for any errors or omissions.

We reserve the right to make changes in the

TRISECTION PLATE 260 90 260 480 18,4 175/200/250/300 53.390

interest of technical progress.

TRISECTION PLATE 380 140 380 656 50,3 250/300/400 53.640 © by FAG 2004

This publication or parts thereof may not be

A Member of the

reproduced without our permission.

Schaeffler Group

WL 80 344 EA

FAG PowerPull SPIDER FAG PowerPull

Don’t settle 1 TRISECTION PLATE

for anything less! 2

Bearings and machine parts

stay in one piece!

•1 Safety grip allows easier pumping For hydraulic and mechanical pullers:

using industrial gloves the FAG PowerPull TRISECTION

•2 Optimum operating position due PLATE.

to 360° rotary coupling for pump 3 This allows the extraction of com-

hand lever

plete bearings, inner rings with a

(SPIDER 175+400 with separate

pump) 4 firm seating or other workpieces.

The load capacity and extraction force

•3 Application or reduction in

are precisely matched to each other and the

pressure by rotation of hand 5

lever on cut-off valve unique design is patented.

The SPIDER puller hooks grip directly under the

•4 Pressure control valve gives

screw studs of the TRISECTION PLATE and give

protection against overload

uniform force distribution. Even where parts are

•

5 Parts under mechanical 6 firmly seated, there is no tilting or bending.

load are made from

high quality chromium/ The high extraction forces are concentrated,

molybdenum steel for example in a bearing, on the inner ring;

in general, the bearing and shaft remain intact

•6 Maximum possible

and can be used again. The optimised application

reduction in torsional 7

and frictional forces by of forces also reduces the work required for extraction.

chromium plated piston made from

The TRISECTION PLATE can be fitted under the bearing

quenched and tempered steel 8

with only a small number of manual operations and is

7 Stroke travel can be changed by proven in practical use. FAG Kugelfischer AG

means of standard adapter

Georg-Schäfer-Straße 30 FAG PowerPull

8 Single piece puller arm and grip

hook for high load capacity

c 97421 Schweinfurt

Germany

SPIDER

TRISECTION PLATE

•9 Simple centring by spring-loaded b (Ø max.)

Tel: +49-(0) 2407 - 91 49 99

steel cone 11 Fax: +49-(0) 2407 - 91 49 59

•10 “Quick” screw thread for

7 a (Ø min.) E-Mail: support@fis-services.de Hydraulic extraction pullers and puller plates

setting of optimum grip www.fis-services.de

depth 9 for rolling bearings and other machine elements

•11 Not enough space for three puller

arms? Simply change to two

FAG PowerPull TRISECTION PLATE

opposing arms!

Puller plate Dimensions Mass Recommended for

[mm] [kg] hydr. puller SPIDER mech. puller

a b c

83/03/04 Printed in Germany

Every care has been taken to ensure the

TRISECTION PLATE 50 12 50 113 0,5 – 53.130 correctness of the information contained in

TRISECTION PLATE 100 26 100 218 2,6 40/60/80/100 53.230 this publication but no liability can be

10 TRISECTION PLATE 160 50 160 322 5,8 80/100/20/175/200 53.295 accepted for any errors or omissions.

We reserve the right to make changes in the

TRISECTION PLATE 260 90 260 480 18,4 175/200/250/300 53.390

interest of technical progress.

TRISECTION PLATE 380 140 380 656 50,3 250/300/400 53.640 © by FAG 2004

This publication or parts thereof may not be

A Member of the

reproduced without our permission.

Schaeffler Group

WL 80 344 EA

You might also like

- All-in-one firewood processorDocument14 pagesAll-in-one firewood processorspeeder86meNo ratings yet

- Ci NLDocument12 pagesCi NLanuraeNo ratings yet

- Catalogo Giunti Samiflex - GB PDFDocument8 pagesCatalogo Giunti Samiflex - GB PDFDANE80No ratings yet

- IR LM100A Crawlair Drill PDFDocument8 pagesIR LM100A Crawlair Drill PDFAnonymous 8yIptglHhNo ratings yet

- Max Air PDFDocument8 pagesMax Air PDFKNIGHTHAGENNo ratings yet

- Scule HidrauliceDocument34 pagesScule HidraulicelucianbordeutNo ratings yet

- KTR 2015 Attachment Catalogue - LowDocument16 pagesKTR 2015 Attachment Catalogue - LowAlexander RuizNo ratings yet

- Leader PPV Positive Pressure Ventilation FanDocument6 pagesLeader PPV Positive Pressure Ventilation Fandonald_wilson4741No ratings yet

- Hydraulic & Mechanical PullersDocument9 pagesHydraulic & Mechanical PullersMeilvy Rahmadani PaneNo ratings yet

- Comal Italia: Beta 4Document11 pagesComal Italia: Beta 4ac1robertoNo ratings yet

- Mustang 4-F4 6991 1324 01Document4 pagesMustang 4-F4 6991 1324 01Girish Kasturi0% (1)

- Saws and PrunersDocument4 pagesSaws and PrunersOctavio SantarossaNo ratings yet

- Heman AttachmentsDocument25 pagesHeman AttachmentsLalit KumarNo ratings yet

- Profile FOR Automobile Lifters: First Time in PakistanDocument11 pagesProfile FOR Automobile Lifters: First Time in PakistanShoaib Rais SiddiquiNo ratings yet

- Doosan Puma 2600yDocument24 pagesDoosan Puma 2600ybaumgconradoNo ratings yet

- Drilling and Foundation Equipment CatalogueDocument28 pagesDrilling and Foundation Equipment CatalogueMelahat AkyolNo ratings yet

- Thomson Super Metric Ball Bushing Bearings SpecsheetDocument11 pagesThomson Super Metric Ball Bushing Bearings SpecsheetElectromateNo ratings yet

- PB Acc en WW - LDocument120 pagesPB Acc en WW - LmarcotecsupNo ratings yet

- Vio38U: Call For Yanmar SolutionsDocument8 pagesVio38U: Call For Yanmar SolutionsTomy Abad AbadNo ratings yet

- Hand ToolsDocument273 pagesHand ToolsTone Ratanalert100% (1)

- Hydra Jaw 0211 H 3244 LRDocument4 pagesHydra Jaw 0211 H 3244 LRLuis Miguel Añasco CorimayhuaNo ratings yet

- ProfilDocument18 pagesProfilAnonymous 6EW2MsFbkNo ratings yet

- SRW - DRW and 800Document12 pagesSRW - DRW and 800razen_inNo ratings yet

- CI Close-Coupled End Suction Pumps: Water Circulation Pumps & CirculatorsDocument12 pagesCI Close-Coupled End Suction Pumps: Water Circulation Pumps & CirculatorsAndre Gazali MalikNo ratings yet

- b3311 722-2Document7 pagesb3311 722-2Arnaldo BenitezNo ratings yet

- Yale Lift EquipmentDocument11 pagesYale Lift EquipmentJetame PoonanNo ratings yet

- XH100 Diesel Drive Auto Prime PumpDocument2 pagesXH100 Diesel Drive Auto Prime PumpBenCrowleyNo ratings yet

- Pump Sales WebDocument7 pagesPump Sales WebGermán Soledad MolinaNo ratings yet

- Super 800Document2 pagesSuper 800api-36492444No ratings yet

- Goulds 3186: High-temperature/Pressure Paper Stock/ Process PumpsDocument8 pagesGoulds 3186: High-temperature/Pressure Paper Stock/ Process PumpsGorea AndreiNo ratings yet

- HRP Motor Sports Products and Services CatalogDocument16 pagesHRP Motor Sports Products and Services CatalogGus McGrathNo ratings yet

- Well HandyDocument6 pagesWell HandymtonellyNo ratings yet

- LUKAS Double-Acting Telescopic CylindersDocument5 pagesLUKAS Double-Acting Telescopic CylindersEduardo Andres Contreras LetelierNo ratings yet

- Goulds AF: Axial Flow PumpsDocument11 pagesGoulds AF: Axial Flow PumpsKarthick VenkateshNo ratings yet

- Axminster 02 - Industrial Machines - p85-p108Document24 pagesAxminster 02 - Industrial Machines - p85-p108Pierre799esNo ratings yet

- Ik12max3 Pga Eng WebDocument4 pagesIk12max3 Pga Eng Websjalife1No ratings yet

- 20140324090225532ff4a1c4f18Document7 pages20140324090225532ff4a1c4f18MansarNo ratings yet

- Portable welding and gas/plasma cutting machineDocument4 pagesPortable welding and gas/plasma cutting machineCarlos PadillaNo ratings yet

- Vilter CatalogDocument28 pagesVilter CatalogDang Anh Tuan0% (1)

- Mud Pumps 1Document2 pagesMud Pumps 1John RongNo ratings yet

- Agri ManualDocument34 pagesAgri ManualLu1sFeRNo ratings yet

- Kunal PPT Jumbo DrillDocument37 pagesKunal PPT Jumbo DrillKunal Singh67% (3)

- D-25 Drill Rig SpecificationsDocument5 pagesD-25 Drill Rig SpecificationsHou RasmeyNo ratings yet

- PX Pumps FolletoDocument4 pagesPX Pumps FolletoBenicio Joaquín Ferrero BrebesNo ratings yet

- Drill Floor Equipment 1Document10 pagesDrill Floor Equipment 1John RongNo ratings yet

- Groundworks BrochureDocument19 pagesGroundworks BrochureMagdy BakryNo ratings yet

- Monarch TT 30Document4 pagesMonarch TT 30Migue ToasaNo ratings yet

- Modelo Pequeño2Document32 pagesModelo Pequeño2Robert Orosco B.No ratings yet

- Presentation ON Student Industrial Work Experience Scheme (Siwes) Training ProgrammeDocument42 pagesPresentation ON Student Industrial Work Experience Scheme (Siwes) Training ProgrammethoundeNo ratings yet

- Elliot TurbineDocument2 pagesElliot TurbinefjafarvandNo ratings yet

- XL1100 Brochure PDFDocument8 pagesXL1100 Brochure PDFDanny Joel Espinoza CastañedaNo ratings yet

- Screw Pump Brochure USA LowResDocument12 pagesScrew Pump Brochure USA LowResSandeep LeeNo ratings yet

- WallDocument0 pagesWallgks6043No ratings yet

- YCM GT SeriesDocument30 pagesYCM GT SeriesCNC SYSTEMSNo ratings yet

- Bombas Gorman RuppDocument12 pagesBombas Gorman RuppRafael Hernández RcrewNo ratings yet

- Modelling a Focke-Wulf Fw 190A-8/R8: In 1/32 scaleFrom EverandModelling a Focke-Wulf Fw 190A-8/R8: In 1/32 scaleRating: 5 out of 5 stars5/5 (1)

- Cce LB Historic 580 Specs 06-26-2009Document4 pagesCce LB Historic 580 Specs 06-26-2009CTN2010100% (1)

- Cce - LB - B Series - 580B - Specs - 06-26-2009Document6 pagesCce - LB - B Series - 580B - Specs - 06-26-2009CTN2010No ratings yet

- Build Your Own Magneto TimerDocument1 pageBuild Your Own Magneto TimerCTN2010No ratings yet

- Is 21 010B e PDFDocument12 pagesIs 21 010B e PDFCTN2010No ratings yet

- Aerospace Fasteners and Supplier GuideDocument2 pagesAerospace Fasteners and Supplier GuideCTN2010No ratings yet

- Build Your Owner LeakDocument2 pagesBuild Your Owner LeakCTN2010No ratings yet

- Stahovaky 2Document27 pagesStahovaky 2CTN2010No ratings yet

- EATON Togle Switches Vol11 - Tab04Document35 pagesEATON Togle Switches Vol11 - Tab04CTN2010No ratings yet

- Easa Sib 2008-54 1Document2 pagesEasa Sib 2008-54 1CTN2010No ratings yet

- CMI Current Publication Listing - Jan-2017Document8 pagesCMI Current Publication Listing - Jan-2017CTN2010No ratings yet

- Wheel Parts Cross ReferenceDocument2 pagesWheel Parts Cross ReferenceCTN2010No ratings yet

- BendixMagnetoFilterInstall PDFDocument1 pageBendixMagnetoFilterInstall PDFCTN2010No ratings yet

- Portfolio LAGUNADocument6 pagesPortfolio LAGUNACTN2010No ratings yet

- 3103 Profile DrawingDocument1 page3103 Profile DrawingCTN2010No ratings yet

- Bendix Magneto Filter InstallDocument1 pageBendix Magneto Filter InstallCTN2010No ratings yet

- DTP Amg 2015Document108 pagesDTP Amg 2015CTN2010No ratings yet

- AN6204Document4 pagesAN6204CTN2010No ratings yet

- 3003 Profile DrawingDocument1 page3003 Profile DrawingCTN2010No ratings yet

- CT Pag Oil Reference Chart 05Document2 pagesCT Pag Oil Reference Chart 05jldamascenoNo ratings yet

- Is 21 010B e PDFDocument12 pagesIs 21 010B e PDFCTN2010No ratings yet

- EATON Catalog IntroductionDocument2 pagesEATON Catalog IntroductionCTN2010No ratings yet

- 10-3 Profile DrawingDocument1 page10-3 Profile DrawingCTN2010No ratings yet

- Visteon AutomotiveDocument4 pagesVisteon AutomotiveCTN2010No ratings yet

- 5305 Service Manual Model 44 Front Hub LokDocument6 pages5305 Service Manual Model 44 Front Hub LokCTN2010No ratings yet

- Air Conditioning Compressor/Clutch Service ManualDocument2 pagesAir Conditioning Compressor/Clutch Service ManualromulofcarreraNo ratings yet

- 5310 2Document11 pages5310 2CTN2010No ratings yet

- Air Conditioning Compressor/Clutch Service ManualDocument2 pagesAir Conditioning Compressor/Clutch Service ManualromulofcarreraNo ratings yet

- Periodic Table of ElementsDocument1 pagePeriodic Table of ElementsMonte Carlo PaladoNo ratings yet

- Is 21 010B eDocument12 pagesIs 21 010B eCTN2010No ratings yet

- OrbitalsDocument1 pageOrbitalshttp://spmchem.blogspot.com/No ratings yet