Professional Documents

Culture Documents

16021647

Uploaded by

Dmitriy SemakovCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

16021647

Uploaded by

Dmitriy SemakovCopyright:

Available Formats

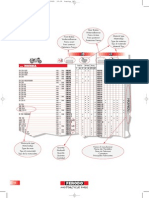

Amana Domestic Washer¾Technical Information

120 V, 60 Hz Models

ALW895SAC PALW895SAC ALW895SAW PALW895SAW

· Due to possibility of personal injury or property damage, always contact an authorized technician for servicing or

repair of this unit.

· Refer to Service Manual RS3100007 for detailed installation, operating, testing, troubleshooting, and disassembly

instructions.

· Refer to Parts Manual RP3100023 for part number information.

! CAUTION

All safety information must be followed as provided in this Technical Sheet and in Service Manual RS3100007.

! WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to unit and discharge capacitor

before servicing, unless testing requires it.

Models ALW895SA* Models ALW895SA*

Power Source Wash cycles 13

Voltage AC 120 VAC Water temperatures 6

Amperage (Single Unit) 10 A Water level Variable

Frequency 60 Hz Features

Motor horsepower ½ Steady Spinä Balance System X

Receptacle 6-20R Self-cleaning lint filter X

Plug 6-20P Self-adjusting rear leveling legs X

Dimensions 210° Agitation stroke X

Cabinet Tri-Actionä wash system X

1

Height-overall 43- /4" Fabric softener dispenser X

Height of cabinet 36" Extra rinse X

7

Width 26- /8" SofSoundä Quiet Pack II X

Depth 28" Motor speed 3 speed

1

Clearance-washer lid 23- /2" Spin speed (revolutions per minute) 1725 / 1140 /

850 rpm

Weight Agitation speed (strokes per minute)

Crated 193 lbs. High 69 spm

Medium 46 spm

Low 35 spm

May 2002 1 16021647 Rev. 0

Component Testing Information

! WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing, unless

testing requires it.

Illustration Component Test Procedure Results

40131101 Temperature Disconnect wires from component to properly measure the

switch resistance of the component.

Place switch in the following positions and measure across

the terminals below:

TEMPERATURE MODE

POS ANGLE SHAFT CONNECTION

WASH RINSE WASH RINSE

1 0° HOT COLD A-1 UNREG. UNREG. >1 W

2 45° HOT COLD A-2,B-3 REG. UNREG. >1 W

3 90° WARM WARM A-2,B-1,C-1 REG. REG. >1 W

4 135° WARM COLD A-2,B-3,C-1 REG. UNREG. >1 W

5 180° COLD COLD A-2,B-3,C-1,D-1 REG. UNREG. >1 W

6 225° COLD COLD B-3 UNREG. UNREG. >1 W

40039501 Speed switch Disconnect wires from component to properly measure the

resistance of the component.

Place switch in the following positions and measure across

the terminals shown below:

ANGLE SHAFT CONNECTION

0° L1-C L2-C

>1 W

60° L1-C L2-2 >1 W

120° L1-2 L2-C >1 W

180° L1-2 L2-2 >1 W

40107001 Mixing valve Measure resistance of terminals on each valve.

Resistance across each valve.

Approximately 1000 W ±

10%

40131201 Timer Verify input and output voltage is present. See timing sequence chart

0 2 4 6 8 10 12 14 for functional description of

T

C

Verify wiring is correctly connected to the timer. the component.

B

40055101 Pressure Do not disconnect the pressure hose from pressure switch Refer to wiring

switch to perform measurements. diagram/schematic for

Measure resistance across the following terminals on the correct contacts.

pressure switch:

2 Terminal 1 to 2 Air pressure that

1 Terminal 1 to 3 actuates switch is

3

determined by the water

level of the tub.

Continuity (no pressure)

Continuity (pressure)

40035001 Lid Disconnect wire terminals from switch.

switch-SPST Test terminals with switch closed. Continuity >1 W

Test terminals with switch open. Infinite 1 MW

16021647 Rev. 0 2 May 2002

Component Testing Information

! WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing, unless

testing requires it.

Illustration Component Test Procedure Results

R0000014 Brake pad kit If washtub does not stop spinning

within seven seconds after opening

loading door. Replace all three brake pads.

If brake pads make noise. Apply a thin layer of silicone (26594P) on

pads, see Service Bulletin

“ASQ-213-B”

40131001 Control board Rotate temperature switch to

2 3

60-74-86

40131001

00N20000002

4

2 3 4

8 7 6 5

Warm/Cold Regulated Cycle

60C20000301 TLA

1 8 9

MADE IN MEXICO

D3

R25

R26

D1

R21

R19

R22

R2

C3

R3

R4

R11

D4

R8

R7

R5

Both valves activate for 55 seconds

R1

R20

Q2

R9

± 15 seconds. ................................

Q3

C4

R24

Control board is working

PATENT PENDING

C2

R16

Q1

Only HOT valve is activated..........

R6

R27

Control board has failed, replace control

R17

R18

R13

U1

C

board.

40096303 Motor Type of motor: See following section “Internal Motor

Three speed Diagram and Schematic” for correct wiring

contacts.

40040301 Drain pump Verify drain pump is not clogged or Remove clog and verify proper operation.

damaged.

Replace drain pump if damaged.

40032701 Transmission Type of transmission: Externally identical, must be identified by

assembly 710 rpm part number.

If transmission locks-up, replace.

27001006 Drive belt Type of drive belt: Refer to “Parts Manual”, to verify which

710 rpm drive belt and pulley size is required.

Refer to “Parts Manual” for proper

pulley size.

May 2002 3 16021647 Rev. 0

Internal Motor Diagram and Schematic

! WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing, unless

testing requires it.

Three Speed Motors

Continuity exists between switch

NO

terminal R and Black wire.

Start YES

Terminals

Manually depress actuator. Inoperative start switch.

Continuity broken between NO Replace switch.

switch terminal R and Black wire.

YES

Continuity exists between switch

NO

terminal P and Blue wire.

High Speed YES

Terminals

Manually depress actuator. Inoperative high speed

Continuity broken between NO switch. Replace switch.

switch terminal P and Blue wire.

YES

Continuity broken between

NO

switch terminal P and switch

Medium/Low terminal V.

Speed Terminals YES

Manually depress actuator. Inoperative medium/low

Continuity exists between switch NO speed switch. Replace

terminal P and switch terminal V. switch.

YES

Motor switch checks OK.

Start 4-5 ohms between Brown wire Inoperative start winding.

NO

Winding and Red wire. Replace motor.

YES

High Speed 1-2 ohms between Blue wire and Inoperative high speed winding.

NO

Winding White/Black wire. Replace motor.

YES

Medium Speed 2-3 ohms between White/Violet Inoperative medium speed winding.

NO

Winding wire and White/Black wire. Replace motor.

YES

Low Speed 2.5 ohms between White/Black

NO Inoperative low speed winding.

Winding wire and 3.5 ohms between Replace motor.

White/Orange wire.

YES

Continuity exists between NO Inoperative common lead.

Protector

White/Black wire and White wire. Replace motor.

YES

All motor windings check OK.

16021647 Rev. 0 4 May 2002

Internal Motor Diagram and Schematic

! WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing, unless

testing requires it.

Wire harness BR

connection W

block BU

White

Yellow

Black

Blue

White/Black

AUX

YEL.

WHITE

6P MAIN

8P MAIN

PROT

4P MAIN

WHT -BLK

W/OR

K.

W/V

BL

BLU

PLUG

Y

BU

OR

BK

R

W-BK

V

G

START

RUN

Motor Assembly

(three speed motor)

May 2002 5 16021647 Rev. 0

Wiring Diagram and Schematic

! WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing, unless

testing requires it.

SCHEMATIC

L1 120VAC 60 HZ N

6 POSITION WATER

TEMP. SWITCH PRESSURE SWITCH A ATC BOARD

2 9 1 3 4 8

HOT BP BYPASS PS R

A-1 A

COLD

* HOT A-2,B-3

COLD EX

PRESSURE SWITCH

* WARM A-2,B-1,C-1

* WARM 3

1 1 2 3

*WARM A-2,B-3,C-1 WATER

COLD

2 TEMP.

* COLD A-2,B-3,C-1,D-1 EXTRA RINSE SWITCH

COLD SELECT SWITCH LID SWITCH

COLD W

B-3 NO V A B C D

COLD

R

* REGLATED TEMPERATURE

SPRAY RINSE = COLD ME

CS

MOTOR

4 POSITION SP L2 SPEED

ACTION SWITCH SELECT MIXING C

2 H O

SWITCH VALVE

CS L0 O

REGULAR

L1-L2-C L1 L

FAST C

T D

REGULAR

AG

L1-C

SLOW L2-2

(2) 8P-LOW

GENTLE

L1-2

FAST L2-C W-OR

HI 6P-MED

GENTLE TM W-V

L1-L2-2 (1)

SLOW

K 9 V LINE

MM 4P-HIGH NEUT.

3 OR

TIMER G 7 BU TP W 4

AUX

MOTOR L

START/

DIRECTION 1 R

K 6 Y SPIN AGIT

F

MACH8 W-BK

NEUT.

3 SPEED MOTOR

L

INDICATES INTERNAL

TIMER BUSS

16021647 Rev. 0 6 May 2002

Wiring Diagram and Schematic

! WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing, unless

testing requires it.

CONNECTION DIAGRAM

May 2002 7 16021647 Rev. 0

Timer Cycle Chart

! WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing, unless

testing requires it.

TIMER CHART

Failure to install, maintain, and/or

operate this machine according to

manufacturer's instructions may

result in conditions which can

produce bodily injury and/or

property damage.

THIS MACHINE MANUFACTURED

UNDER ONE OR MORE OF THE

FOLLOWING PATENTS:

UNITED STATES NO: 3,253,874;

3,838,755; 3,845,642

CANADIAN NO: 1,008,265;

994,685

OTHER PATENTS PENDING

PART NO. 40131401

MM

AG

SP

EX

PS

R

L

L

CS

CS

TM

A

ME

LO

BP

PS

W

HI

24 PIN HOUSING

WHT/

WIRE POSITION

WHT/

RED

BLU/

PNK

BLK/

YLW

WHT

BLU

PNK/

GRY/

BLK

BLU

&

18

15

12

24

21

6

WHK/

PNK/

BLK

RED/

BLK

BLK

BRN

BLK

VLT

17

14

23

20

11

5

& PNK

ORG/

RED/

PNK/

YLW

RED

BLK

PNK

BLU

X2

19

16

13

10

22

16021647 Rev. 0 8 May 2002

You might also like

- Modulating & On/Off Globe Valve Actuators: Description MVLDocument5 pagesModulating & On/Off Globe Valve Actuators: Description MVLxozepkNo ratings yet

- 4 - Hci434fDocument8 pages4 - Hci434fmnezamiNo ratings yet

- Square D Vacuum Switches (9016-GVG-1)Document2 pagesSquare D Vacuum Switches (9016-GVG-1)John KingNo ratings yet

- Ak225 Fdi1gDocument7 pagesAk225 Fdi1gChristian Rivera FloverNo ratings yet

- Werna: WR274C - Technical Data SheetDocument8 pagesWerna: WR274C - Technical Data SheetAbeiroNo ratings yet

- 30 kVA - PI144GDocument8 pages30 kVA - PI144GMaxlabNo ratings yet

- PI736F - Technical Data SheetDocument8 pagesPI736F - Technical Data SheetalstomNo ratings yet

- Ak111 (Three Phases, 50&60hz)Document8 pagesAk111 (Three Phases, 50&60hz)Christian Rivera FloverNo ratings yet

- HCKI 534D/544D - Technical Data SheetDocument8 pagesHCKI 534D/544D - Technical Data SheetMajo MolinaNo ratings yet

- 30CPQ080/30CPQ100: Vishay High Power ProductsDocument6 pages30CPQ080/30CPQ100: Vishay High Power Productsdavid johnNo ratings yet

- DG224E - Technical Data SheetDocument8 pagesDG224E - Technical Data Sheet刘金星No ratings yet

- 72CPQ030 Dual Diode Rectif PDFDocument6 pages72CPQ030 Dual Diode Rectif PDFagus2kNo ratings yet

- AK351 - Technical Data SheetDocument8 pagesAK351 - Technical Data SheetCris_eu09No ratings yet

- GeneradorDocument8 pagesGeneradorNANDORG27No ratings yet

- UCM274E Tech Data SheetDocument8 pagesUCM274E Tech Data Sheetengmohsen.ramadanhotmail.comNo ratings yet

- Hoja Tecnica Control de NivelDocument3 pagesHoja Tecnica Control de NivelpawerxlNo ratings yet

- Generatordatenblatt STAMFORD PI144DDocument9 pagesGeneratordatenblatt STAMFORD PI144DudindNo ratings yet

- Aksa Alternator - AK7600Document8 pagesAksa Alternator - AK7600Cris_eu09No ratings yet

- TS 400 SpecDocument2 pagesTS 400 SpecMohamed shebat elhamdNo ratings yet

- A.R.K274H Data SheetDocument8 pagesA.R.K274H Data SheetdmytroNo ratings yet

- Alternator Aksa AK4200Document8 pagesAlternator Aksa AK4200Cris_eu09No ratings yet

- HCM 434 CDocument8 pagesHCM 434 CCRIS SEDANTONo ratings yet

- Page 1271Document1 pagePage 1271EmilyTheDwarfNo ratings yet

- Ultrafast Soft Recovery Rectifier Diode: Dual Die Isotop PackageDocument4 pagesUltrafast Soft Recovery Rectifier Diode: Dual Die Isotop PackageMahtab HassanzadehNo ratings yet

- Linz GeneratorDocument7 pagesLinz GeneratorMohammad HazbehzadNo ratings yet

- Diode MSR1560GDocument7 pagesDiode MSR1560G유진No ratings yet

- HCI434FS/444FS - Technical Data SheetDocument8 pagesHCI434FS/444FS - Technical Data SheetHERS14No ratings yet

- Electro-Prop ValveDocument2 pagesElectro-Prop Valvemaikel.mNo ratings yet

- 3000W True Sine Wave DC-AC Inverter: SeriesDocument2 pages3000W True Sine Wave DC-AC Inverter: Serieshassoun01No ratings yet

- Low Voltage Alternators - 4 Pole LSA 42.3: 25 To 60 kVA - 50 HZ / 31.5 To 75 kVA - 60 HZDocument12 pagesLow Voltage Alternators - 4 Pole LSA 42.3: 25 To 60 kVA - 50 HZ / 31.5 To 75 kVA - 60 HZhafid CJSPNo ratings yet

- Union TransformerDocument8 pagesUnion TransformerReynanNo ratings yet

- UCDI274K - Technical Data SheetDocument8 pagesUCDI274K - Technical Data SheetLeopoldo Godinez HernandezNo ratings yet

- BL2 & BL4 DriverDocument68 pagesBL2 & BL4 DriverVasuPatelNo ratings yet

- 04-20kva Alternator Data Sheet Es10456927-N20g4-D-W212-20Document4 pages04-20kva Alternator Data Sheet Es10456927-N20g4-D-W212-20Muse AFNo ratings yet

- 2N6400 Series Silicon Controlled Rectifiers: Reverse Blocking ThyristorsDocument7 pages2N6400 Series Silicon Controlled Rectifiers: Reverse Blocking ThyristorsPedro lealNo ratings yet

- Brochure VARIPURE 20160519 EN PDFDocument8 pagesBrochure VARIPURE 20160519 EN PDFMhs EngineerNo ratings yet

- UCM274H Tech Data SheetDocument8 pagesUCM274H Tech Data Sheetengmohsen.ramadanhotmail.comNo ratings yet

- 500kVA K600C Rigsafe Diesel Generator Flyer PDFDocument2 pages500kVA K600C Rigsafe Diesel Generator Flyer PDFMd MkNo ratings yet

- MG HC6HDocument7 pagesMG HC6HCristian VegaNo ratings yet

- Inhouse LecDocument54 pagesInhouse LecAS BrarNo ratings yet

- Generatordatenblatt STAMFORD HCI5FDocument8 pagesGeneratordatenblatt STAMFORD HCI5FAminMannaniNo ratings yet

- Ficha Tecnica Generador Tensite Ts4000iyDocument2 pagesFicha Tecnica Generador Tensite Ts4000iyRaúl Cañete AmorósNo ratings yet

- Schott KyDocument7 pagesSchott KysateeshNo ratings yet

- Datasheet Leroy Somer Alternator Lsa40m5 3 Phase PDFDocument12 pagesDatasheet Leroy Somer Alternator Lsa40m5 3 Phase PDFGustavo de la CruzNo ratings yet

- Alternator Datasheet HCI634GDocument8 pagesAlternator Datasheet HCI634Gmohamed aymanNo ratings yet

- Reverse Power Relay TestDocument8 pagesReverse Power Relay TestAndy ShrmaNo ratings yet

- DG184ESDocument7 pagesDG184ES刘金星No ratings yet

- HCI534C Alternator Datasheet, HC5CDocument8 pagesHCI534C Alternator Datasheet, HC5CmnezamiNo ratings yet

- P1500 Open (N)Document3 pagesP1500 Open (N)Nyoman SuryasaNo ratings yet

- (Vis) 63cpq100pbfDocument7 pages(Vis) 63cpq100pbfDávid KisNo ratings yet

- Ultrafast Soft Recovery Rectifier Diode: 600V 2x30a APT30DQ60BCT APT30DQ60BCTGDocument4 pagesUltrafast Soft Recovery Rectifier Diode: 600V 2x30a APT30DQ60BCT APT30DQ60BCTGAmir QayyumNo ratings yet

- HCI634H (Alternator - HCI634H)Document8 pagesHCI634H (Alternator - HCI634H)Angga D SantosoNo ratings yet

- HCI634G1 Installation+Service+Maintenance ManualDocument8 pagesHCI634G1 Installation+Service+Maintenance ManualdanyNo ratings yet

- KSW-230 (Water Flow Switch)Document2 pagesKSW-230 (Water Flow Switch)Anonymous XYAPaxjbYNo ratings yet

- Automatic Voltage Regulating Relay (Avr-03) : FeaturesDocument1 pageAutomatic Voltage Regulating Relay (Avr-03) : Featuresss subramanyamNo ratings yet

- Data Sheet Prolec - 1500 Kva - 22860V - 480-240VDocument2 pagesData Sheet Prolec - 1500 Kva - 22860V - 480-240VAlfrhNo ratings yet

- CapacitorDocument2 pagesCapacitorDULCE KATAURANo ratings yet

- Hci634h For 800 KvaDocument8 pagesHci634h For 800 KvaAhmed KotbNo ratings yet

- Bosch Dryer - WTV76100US Testing ProceduresDocument2 pagesBosch Dryer - WTV76100US Testing ProceduresDmitriy SemakovNo ratings yet

- Bosc248 PDFDocument82 pagesBosc248 PDFspeedbitNo ratings yet

- Dishwasher Installation Instructions: Import Ant!Document14 pagesDishwasher Installation Instructions: Import Ant!Dmitriy SemakovNo ratings yet

- UMG80BS-41 SPMDocument111 pagesUMG80BS-41 SPMDmitriy SemakovNo ratings yet

- Bosch Ascenta Dishwasher E25 E24 Error Code Service Bulletin 1.0.0 PUB 58300000150815 PDFDocument1 pageBosch Ascenta Dishwasher E25 E24 Error Code Service Bulletin 1.0.0 PUB 58300000150815 PDFDmitriy SemakovNo ratings yet

- Model 125bo LP and 125bo NG - Outdoor Model: For Exterior Use OnlyDocument24 pagesModel 125bo LP and 125bo NG - Outdoor Model: For Exterior Use OnlyDmitriy SemakovNo ratings yet

- Basics of Gas Appliances - 4314010Document37 pagesBasics of Gas Appliances - 4314010Dmitriy SemakovNo ratings yet

- Tech Sheet PDFDocument11 pagesTech Sheet PDFDmitriy SemakovNo ratings yet

- Wcr682ss-2 Explosion View and Parts ListDocument2 pagesWcr682ss-2 Explosion View and Parts ListDmitriy SemakovNo ratings yet

- Apollo Direct Vent Residential Gas Water HeaterDocument44 pagesApollo Direct Vent Residential Gas Water HeaterDmitriy Semakov100% (1)

- Maytag Amana Top Load Washer Service ManualDocument107 pagesMaytag Amana Top Load Washer Service ManualBob CollNo ratings yet

- A.O. Smith Water Heater VentingDocument2 pagesA.O. Smith Water Heater VentingDmitriy SemakovNo ratings yet

- 16021647Document8 pages16021647Dmitriy SemakovNo ratings yet

- Technical Bulletin: Technical Diagnosis and SolutionsDocument2 pagesTechnical Bulletin: Technical Diagnosis and SolutionsDmitriy SemakovNo ratings yet

- American Residential Gas Water Heater Power Vent With FVIRDocument25 pagesAmerican Residential Gas Water Heater Power Vent With FVIRDmitriy SemakovNo ratings yet

- Service: Home Laundry DryersDocument65 pagesService: Home Laundry DryersjitmarineNo ratings yet

- A.O.smith Intellli Vent Control Information When Used On Gas Residential, Power Vented Water HDocument27 pagesA.O.smith Intellli Vent Control Information When Used On Gas Residential, Power Vented Water HDmitriy SemakovNo ratings yet

- TC 048 R 6Document60 pagesTC 048 R 6IgsmorphFNo ratings yet

- A.O. Smith PWR Vent 185363-001Document32 pagesA.O. Smith PWR Vent 185363-001Dmitriy SemakovNo ratings yet

- A.O.smith Intelli-Vent FVIR Troubleshooting ChartDocument6 pagesA.O.smith Intelli-Vent FVIR Troubleshooting ChartDmitriy SemakovNo ratings yet

- A.O. Smith - Pilot Outage - HighAmbientDocument4 pagesA.O. Smith - Pilot Outage - HighAmbientDmitriy SemakovNo ratings yet

- 03 Modern Photoelectric Effect LabDocument3 pages03 Modern Photoelectric Effect LabJuan David ParraNo ratings yet

- Dynamic (Vibration) Testing: Design-Certification of Aerospace SystemDocument16 pagesDynamic (Vibration) Testing: Design-Certification of Aerospace SystemCamelia MunteanuNo ratings yet

- Bottom Failure - Annex K - en 14015 - Rev 3Document3 pagesBottom Failure - Annex K - en 14015 - Rev 3KP SahuNo ratings yet

- Non Traditional MachiningDocument17 pagesNon Traditional MachiningLeo Dev WinsNo ratings yet

- E-RAB Abnormal Release Causes: Huawei Technologies Co., LTDDocument14 pagesE-RAB Abnormal Release Causes: Huawei Technologies Co., LTDMShabbar Syed0% (1)

- Wtm-058 Ut Procedure Aws d1.5 (2010)Document9 pagesWtm-058 Ut Procedure Aws d1.5 (2010)Wisüttisäk Peäröön0% (1)

- BrochureDocument4 pagesBrochureChristina MaierNo ratings yet

- Launchpad S and Mini Advanced Features GuideDocument6 pagesLaunchpad S and Mini Advanced Features GuidealessoniaNo ratings yet

- Bill of Materials Computation SheetDocument45 pagesBill of Materials Computation SheetNicole RodilNo ratings yet

- Extended Cell ConfigurationDocument31 pagesExtended Cell Configurationrfabre76No ratings yet

- Open Channel FlowDocument14 pagesOpen Channel FlowHijab Renjana100% (1)

- Design of Seismic Force On BuildingDocument12 pagesDesign of Seismic Force On BuildingAjay DalviNo ratings yet

- Fieldbus FoundationDocument38 pagesFieldbus FoundationFelipe Andrés Espinoza RivasNo ratings yet

- Cross Platform Migration Using Transportable Tablespace 12c With Zero Downtime DBACLASS PDFDocument22 pagesCross Platform Migration Using Transportable Tablespace 12c With Zero Downtime DBACLASS PDFSiva KumarNo ratings yet

- SH5002-7J S EnuDocument304 pagesSH5002-7J S Enu19848096No ratings yet

- Venkataraman RDocument2 pagesVenkataraman RVenkat RamanNo ratings yet

- Francis and Kaplan Reaction TurbinesDocument5 pagesFrancis and Kaplan Reaction TurbinesfahadNo ratings yet

- Nte 123 ADocument4 pagesNte 123 AAndres Mauricio Quiceno BetancourtNo ratings yet

- Com Profinet-Io 7UM62 UsDocument36 pagesCom Profinet-Io 7UM62 Usmirage1977No ratings yet

- EN VEGASWING 63 Two WireDocument48 pagesEN VEGASWING 63 Two WireLucas FiordelisiNo ratings yet

- 03-Application List Moto, ATVDocument97 pages03-Application List Moto, ATVΗλίας ΓεωργιάδηςNo ratings yet

- N-1-1 Contingency Analysis Using Powerworld SimulatorDocument15 pagesN-1-1 Contingency Analysis Using Powerworld Simulatorchandana901No ratings yet

- Flocon MC11: Membrane Cleaner For Organics and ParticulatesDocument2 pagesFlocon MC11: Membrane Cleaner For Organics and ParticulatesCyrilDepalomaNo ratings yet

- RBC NiceDocument56 pagesRBC NiceTIOCA01No ratings yet

- MEISER Grating PDFDocument136 pagesMEISER Grating PDFEngr Qaisar NazeerNo ratings yet

- Project EngineerDocument3 pagesProject EngineerMuhammad NadeemNo ratings yet

- Chery A1 PartesDocument54 pagesChery A1 PartesAlexferminNo ratings yet

- N Queen ProblemDocument2 pagesN Queen ProblemManikandanNo ratings yet

- 343 - 135 - 278 - 80 7 Stud Vulkollan Drive Wheel - Wet GripDocument1 page343 - 135 - 278 - 80 7 Stud Vulkollan Drive Wheel - Wet GripASIFNo ratings yet

- HW5Document7 pagesHW5Rahul Patil100% (1)