Professional Documents

Culture Documents

Estogrout MP 50

Uploaded by

Rio CahyantoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Estogrout MP 50

Uploaded by

Rio CahyantoCopyright:

Available Formats

Estogrout MP 50

Multi purpose Shrinkage Compensated Grout

Description Application Instructions

Estogrout MP 50 multi purpose cementitious non-shrink cement

grout is formulated to provide good flexural and compressive Preparation

strength performance. It is a ready to use product in powder form

and requires addition of water to produce as non-shrink grout Foundation Surface

performance. The surface of the substrate must be sound and free from oil,

grease or any loosely adherent material. Bolt holes and fixing

Estogrout MP 50 is a blend of Portland cement, graded fillers and pockets must be blown clean of any dirt or debris. To assist in

chemical additives that create controlled expansion in the plastic the formation of bond between substrate and grout, pre

state. soaking of the substrate surface with water is advisable.

Uses Base Plate

Estogrout MP 50 is suitable for a wide variety of precision

It is essential that this is clean and free from oil, grease or scale.

applications at any consistency from flow able to damp-pack. It is

Air pressure relief holes should be provided to allow venting of

recommended for:-

any isolated high spots.

• General Repair

• Formwork & base plate grouting

Formwork

• Gap filling for non-shrinkage joints

• Precast elements / Anchor bolts All formwork used for grouting should be leak proof. This can

• Structural repair below 40 N/mm2 be achieved by sealing the joints/gap between formworks with

a foam rubber strip or sealant.

Advantages

Mixing Water

• Non Shrink (Shrinkage Compensated)

• Chloride free & Adjustable consistency The quantity of clean water required to be added to a 25kg bag

• No metallic iron content to cause staining of Estogrout MP 50 to achieve the desired flowable consistency

• Excellent workability retention even at high ambient is 3.8 – 3.9 litres

temperature

• Pre-packaged grout overcomes potential on-site

Application

proportioning variations

• High bond strength to steel and concrete Estogrout MP 50 may be placed in thickness up to 50mm at

• Good fatigue and impact resistance one pour. For thicker sections above 100mm it is advisable to

add in well-graded aggregates, size range between 3mm to

15mm. Quantities of aggregate added to the Estogrout MP 50

Standards Compliance

should not exceeded ratio of 1:1 by weight.

• ASTM C940

• BS 6319

Curing

On completion of the grouting operation all exposed areas,

Physical Properties which are not to be cut back, should be thoroughly cured. This

should be done after the initial hardening of the grout by

Water Powder Ratio At 0.155 1 day 7 days 28 days continuous application of water or by application of suitable

(N/mm2) (N/mm2) (N/mm2) curing compound such as Estocure Product Range.

Compressive Strength, > 18 > 35 > 50

BS 6319

Time For Expansion 15 mins to 2 hours

Fresh Weight Density 2131 kg/m3

Expansion Characteristics, 0.5 -2.0%

ASTM C940

A Mem ber of Gr ou p www.estop-group.com

05-07-02

Estogrout MP 50

Multi purpose Shrinkage Compensated Grout

Packing & Size

Estogrout MP 50 25 kg bag

Yield

Estogrout MP 50 13.00 litres per 25 kg bag

Coverage

Estogrout MP 50 10 mm × 1.30 m2 per 25 kg bag

Technical Support

Estop offers a comprehensive range of high performance, high

quality of product for both new and existing concrete surfaces. In

addition, the company offers a technical support package to

specifies, end-users and contractors, as well as on-site technical

assistance.

Storage

Estogrout MP 50 should be stored on pallets in dry conditions.

Under these conditions the product will have a shelf life of 12

months.

Precaution

Estogrout MP 50 is alkaline and should not in contact with skin and

eyes. Avoid inhalation of dust during mixing. Glovers, goggles and

dust mask should be worn.

Additional Information

Estop manufactures and offers a wide range of complementary

products which includes waterstops, waterproofing products,

grouts, anchors, specialized flooring products. In addition, a wide

range of products formulated for repair and refurbishment of

spalled concrete are available.

Important Note

Estop products are guaranteed against defective materials and manufacture and are sold subject to its standard Terms and Conditions of Sale, copies of which may

be obtained on request. Whilst Estop endeavors to ensure that any advice, recommendation, specification or information in may give is accurate and correct, it shall

not, because it has no direct or continuous control over where or how its products are applied, accept any liability either directly or indirectly arising from the use of

its products, whether or not in accordance with any advice, specification, recommendation or information given by it.

You might also like

- Grout - Estogrout MP60 - Data Sheet - 08-07-04Document2 pagesGrout - Estogrout MP60 - Data Sheet - 08-07-04burhanuddin syedNo ratings yet

- 0422-06-29-34 Datasheet File Estogrout MP 70 08-07-04Document2 pages0422-06-29-34 Datasheet File Estogrout MP 70 08-07-04rezza182No ratings yet

- Concrete Repair - Estopatch MP - Data Sheet - 160704Document2 pagesConcrete Repair - Estopatch MP - Data Sheet - 160704Edy SumaryantoNo ratings yet

- Estogrout MP70 PremixDocument2 pagesEstogrout MP70 PremixElias Jaya PerkasaNo ratings yet

- Estogrout MP70Document2 pagesEstogrout MP70Lei100% (1)

- Trial PDF Estogrout Admix Yang Sudah Di MargeDocument14 pagesTrial PDF Estogrout Admix Yang Sudah Di Margeadhy paulusNo ratings yet

- Flo-Grout PC100 - TDSDocument2 pagesFlo-Grout PC100 - TDSAhmed AbuoelnagaNo ratings yet

- Estocure P Concrete Curing CompoundDocument2 pagesEstocure P Concrete Curing CompoundFaiz RahmatNo ratings yet

- Estofill PDFDocument2 pagesEstofill PDFKaren MiradNo ratings yet

- Waterproofing - Estokote Grey - Data Sheet - 100106Document2 pagesWaterproofing - Estokote Grey - Data Sheet - 100106Azizy YusofNo ratings yet

- Egrout S50Document2 pagesEgrout S50m.elsanee.cubicNo ratings yet

- CONBEXTRA GP - JordanDocument4 pagesCONBEXTRA GP - JordanShabbir HussainNo ratings yet

- Estocrete FR - Data SheetDocument2 pagesEstocrete FR - Data SheetrifkirahmadianNo ratings yet

- Technical Datasheets Masteremaco P 158Document2 pagesTechnical Datasheets Masteremaco P 158sumitha_kumarageNo ratings yet

- High Strength Solvent Free Epoxy Resin Patching MortarDocument2 pagesHigh Strength Solvent Free Epoxy Resin Patching Mortaralan2191No ratings yet

- Fosroc Conbextra EP10: Constructive SolutionsDocument2 pagesFosroc Conbextra EP10: Constructive SolutionsVincent JavateNo ratings yet

- ESTOP TDS - Estoflex PU 980 (AR) R1Document3 pagesESTOP TDS - Estoflex PU 980 (AR) R1PT Gigantara Sukses Mandiri RaharjaNo ratings yet

- Cementitious Plaster Application InstructionsDocument2 pagesCementitious Plaster Application InstructionsMike MikejNo ratings yet

- E33 Epoxy Grout Technical Data SheetDocument2 pagesE33 Epoxy Grout Technical Data SheetUa AnyanhunNo ratings yet

- 25 KG Gyproc Elite 100 One Coat Gypsum PlasterDocument3 pages25 KG Gyproc Elite 100 One Coat Gypsum Plastersyedaliabl2023No ratings yet

- Dura Grout: A.B.E. Construction ChemicalsDocument3 pagesDura Grout: A.B.E. Construction ChemicalsVirah Sammy ChandraNo ratings yet

- 404 Dr. Fixit Fevimate TG Tile GroutingDocument3 pages404 Dr. Fixit Fevimate TG Tile GroutingJoseph EzekielNo ratings yet

- Conbextra STDDocument2 pagesConbextra STDPritha DasNo ratings yet

- Sikagrout 215 M: Non-Shrink Cementitious Grout For Marine Structure and Concrete RepairDocument2 pagesSikagrout 215 M: Non-Shrink Cementitious Grout For Marine Structure and Concrete RepairDani LerviNo ratings yet

- 02 Bim Per 2 2011Document3 pages02 Bim Per 2 2011Agus Be PeNo ratings yet

- Emaco s188 AseanDocument2 pagesEmaco s188 AseanDoby YuniardiNo ratings yet

- Conbextra GP PDFDocument4 pagesConbextra GP PDFPrabowo SandiNo ratings yet

- 4006 Ultratopliving GB PDFDocument4 pages4006 Ultratopliving GB PDFSzaboNo ratings yet

- Fosroc Conbextra EP40: Free Flowing, Epoxy Resin GroutDocument2 pagesFosroc Conbextra EP40: Free Flowing, Epoxy Resin GroutVincent JavateNo ratings yet

- Sikagrout 215: General Purpose Non-Shrink Cementitious GroutDocument3 pagesSikagrout 215: General Purpose Non-Shrink Cementitious GroutDani LerviNo ratings yet

- Estokote GreyDocument2 pagesEstokote GreyNano Koes ArdhiyantoNo ratings yet

- Monneli Elastoseal Ps Doc Technical Map en 1119Document3 pagesMonneli Elastoseal Ps Doc Technical Map en 1119mikeNo ratings yet

- TDS Estorex EP10Document2 pagesTDS Estorex EP10Elias Jaya PerkasaNo ratings yet

- Estorex EP10 Rev 01techIV20Document2 pagesEstorex EP10 Rev 01techIV20Fawwaz IlmiNo ratings yet

- DBASF Mastertile30Document3 pagesDBASF Mastertile30bassem muhannaNo ratings yet

- High strength epoxy grout for heavy duty applicationsDocument2 pagesHigh strength epoxy grout for heavy duty applicationszulfikarNo ratings yet

- Conbextra GPIDocument4 pagesConbextra GPIVenkata Raju KalidindiNo ratings yet

- Waterstop - Estojoint - Data Sheet - 040603Document2 pagesWaterstop - Estojoint - Data Sheet - 040603thohiruddin.engineerNo ratings yet

- High Strength Epoxy Grout for Heavy LoadsDocument2 pagesHigh Strength Epoxy Grout for Heavy LoadsAcho SupraholicNo ratings yet

- Masterflow 150 v3Document2 pagesMasterflow 150 v3Souronil MondalNo ratings yet

- Sika - Sikagrout 215Document9 pagesSika - Sikagrout 215afnan hamimiNo ratings yet

- Grout - Estogrout UW - Data Sheet - 120404Document2 pagesGrout - Estogrout UW - Data Sheet - 120404Dana IrmawanNo ratings yet

- Masteremaco S 5410 Ci Tds PDFDocument3 pagesMasteremaco S 5410 Ci Tds PDFSolomon AhimbisibweNo ratings yet

- Sikagrout - 215: Pumpable Shrinkage Compensated Cementitious GroutDocument2 pagesSikagrout - 215: Pumpable Shrinkage Compensated Cementitious GroutKent BasigaNo ratings yet

- PDS Sikacrete 113 PPDocument4 pagesPDS Sikacrete 113 PPKoh HanNo ratings yet

- Fosroc Nitocote EP405 TDSDocument3 pagesFosroc Nitocote EP405 TDSEmilAbdoNo ratings yet

- Standard Grout PDFDocument3 pagesStandard Grout PDFFrancois-No ratings yet

- Sika PDS - E - SikaGrout - 214-11Document3 pagesSika PDS - E - SikaGrout - 214-11Dipak BorsaikiaNo ratings yet

- Basf Mastertop 430 TdsDocument3 pagesBasf Mastertop 430 TdsPanruti S SathiyavendhanNo ratings yet

- MasterEmaco - S 348 v2Document2 pagesMasterEmaco - S 348 v2Umeshchandra PatilNo ratings yet

- Nitoflor Hardtop PDFDocument4 pagesNitoflor Hardtop PDFVincent JavateNo ratings yet

- Foslok Data SheetDocument4 pagesFoslok Data Sheetemma boatNo ratings yet

- UltraTech Master BrochureDocument17 pagesUltraTech Master BrochureHimanshu Kumar100% (1)

- Conbextra EP40 UAEDocument2 pagesConbextra EP40 UAEjasonNo ratings yet

- T 570 RubbersealDocument5 pagesT 570 RubbersealVinitJory100% (1)

- High Efficient Mould Releasing Agent Estoform OBDocument1 pageHigh Efficient Mould Releasing Agent Estoform OByoga pratamaNo ratings yet

- 0325-11-55-28 Datasheet File Sikagrout 214-11 PDFDocument2 pages0325-11-55-28 Datasheet File Sikagrout 214-11 PDFFajar SodiqNo ratings yet

- (PDS) Conbextra STDDocument3 pages(PDS) Conbextra STDPritha DasNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- TABLE 2 Grading Requirements For Coarse AggregatesDocument1 pageTABLE 2 Grading Requirements For Coarse AggregatesRio CahyantoNo ratings yet

- TABLE 2 Grading Requirements For Coarse AggregatesDocument1 pageTABLE 2 Grading Requirements For Coarse AggregatesRio CahyantoNo ratings yet

- Separated Batching Plant 1Document1 pageSeparated Batching Plant 1Rio CahyantoNo ratings yet

- SikaTop Armatec 110 EpoCemDocument3 pagesSikaTop Armatec 110 EpoCemseagull70No ratings yet

- Brosur Rucika Update November 2015 PDFDocument8 pagesBrosur Rucika Update November 2015 PDFRio CahyantoNo ratings yet

- Separated PMIDocument1 pageSeparated PMIRio CahyantoNo ratings yet

- Orientation Angle ElbowDocument1 pageOrientation Angle ElbowRio CahyantoNo ratings yet

- Sikagard 720 Epocem HC Pds enDocument4 pagesSikagard 720 Epocem HC Pds enRio CahyantoNo ratings yet

- Piping AbbreviationDocument14 pagesPiping AbbreviationRio Cahyanto100% (1)

- Sikatoparmatec110epocem Pds PDFDocument2 pagesSikatoparmatec110epocem Pds PDFRio CahyantoNo ratings yet

- Final ESCO NB PDFDocument1 pageFinal ESCO NB PDFRio CahyantoNo ratings yet

- Sikagard 63n Pds enDocument3 pagesSikagard 63n Pds enRio CahyantoNo ratings yet

- 50 Grad CCEC Degrees Catalog 2010-11Document14 pages50 Grad CCEC Degrees Catalog 2010-11Rio CahyantoNo ratings yet

- June 2017 Calendar PrintableDocument1 pageJune 2017 Calendar PrintableRio CahyantoNo ratings yet

- Obo VacanciesDocument2 pagesObo VacanciesRio CahyantoNo ratings yet

- Bailey Lightweight Steel Framing Details Brick ConnectorsDocument2 pagesBailey Lightweight Steel Framing Details Brick ConnectorsRio CahyantoNo ratings yet

- Astm C-42 Core TestDocument5 pagesAstm C-42 Core TestPapaDaplisNo ratings yet

- Glossary of Architectural TermsDocument13 pagesGlossary of Architectural TermsJulieta Baillo de HortaNo ratings yet

- Ladiana ModelDocument1 pageLadiana ModelRio CahyantoNo ratings yet

- R.gas Tampak DepanDocument1 pageR.gas Tampak DepanRio CahyantoNo ratings yet

- Full Page PhotoDocument1 pageFull Page PhotoRio CahyantoNo ratings yet

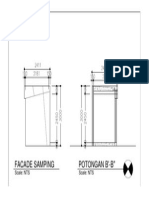

- Facade Sampling Section B'-BDocument1 pageFacade Sampling Section B'-BRio CahyantoNo ratings yet

- Ladiana ModelDocument1 pageLadiana ModelRio CahyantoNo ratings yet

- Ladiana ModelDocument1 pageLadiana ModelRio CahyantoNo ratings yet

- Ladiana ModelDocument1 pageLadiana ModelRio CahyantoNo ratings yet

- PMBOK Process Diagram 5th EditionDocument1 pagePMBOK Process Diagram 5th Editionjonathan0820No ratings yet

- Ladiana ModelDocument1 pageLadiana ModelRio CahyantoNo ratings yet

- Smartplant Materials: A-Z Training - Bidder QuotationDocument8 pagesSmartplant Materials: A-Z Training - Bidder QuotationRio CahyantoNo ratings yet

- User Guide IMS (Vendor)Document5 pagesUser Guide IMS (Vendor)Rio CahyantoNo ratings yet

- Specification Section S30: Concrete 1.0 GeneralDocument54 pagesSpecification Section S30: Concrete 1.0 Generalkiet eel100% (1)

- BOQ Canteen BlockDocument80 pagesBOQ Canteen BlockyogeshNo ratings yet

- Addis Ababa Science&Technology University College of Civil&Architectural Engineering Department of Civil EngineringDocument63 pagesAddis Ababa Science&Technology University College of Civil&Architectural Engineering Department of Civil Engineringalem bayableNo ratings yet

- Anchor Bolt MSDocument7 pagesAnchor Bolt MSGaneshNo ratings yet

- MECANOFLEX English-Product-General-catalogDocument206 pagesMECANOFLEX English-Product-General-catalogaction columnsNo ratings yet

- Soqr Civil - SC - Ho Panipat 71134Document18 pagesSoqr Civil - SC - Ho Panipat 71134rverma2528No ratings yet

- ReportDocument6 pagesReportramiahyuriNo ratings yet

- MFG Fiberglass Column Forms Product SheetDocument3 pagesMFG Fiberglass Column Forms Product SheetAboalmaail AlaminNo ratings yet

- Shell StructuresDocument23 pagesShell StructuresAnjalySinhaNo ratings yet

- Presentation (U Boot) Sai ManojDocument15 pagesPresentation (U Boot) Sai Manojabcd100% (1)

- ABT 5 Floor Slab System, Wall Panel System PDFDocument23 pagesABT 5 Floor Slab System, Wall Panel System PDFRuel Malabanan Alvarez Barinque60% (5)

- Cubipod® Manual 2016: September 2016Document160 pagesCubipod® Manual 2016: September 2016Danilo VallenasNo ratings yet

- Scope of Work DuplexDocument7 pagesScope of Work Duplexjet toledo100% (1)

- SD - Folded Plate Structures - V1Document46 pagesSD - Folded Plate Structures - V1Vedasri Racha100% (1)

- Cost Comparison On Industrialized Building System (IBS) and Conventional Method For School Construction ProjectDocument7 pagesCost Comparison On Industrialized Building System (IBS) and Conventional Method For School Construction ProjectJudy TanNo ratings yet

- CH3 SlabDocument31 pagesCH3 SlabChanel Cute100% (1)

- JPT Review Center Building Technology and Materials Multiple Choice ExamDocument6 pagesJPT Review Center Building Technology and Materials Multiple Choice ExamdaydarasenganNo ratings yet

- Building With Rammed EarthDocument29 pagesBuilding With Rammed EarthMaria RennóNo ratings yet

- A 43 D 31 1283235580113 Peri Cofraj Flexibil Gridflex EngDocument20 pagesA 43 D 31 1283235580113 Peri Cofraj Flexibil Gridflex EngSamuraiStefNo ratings yet

- Tower Foundation BOM For SST 30m 4L 290kph - HDocument20 pagesTower Foundation BOM For SST 30m 4L 290kph - Hhenjie mirasolNo ratings yet

- Taking Off & EstimationDocument22 pagesTaking Off & EstimationOlawale OnikeNo ratings yet

- Multi-layer construction method saves timeDocument5 pagesMulti-layer construction method saves timeUkhti EvHaNo ratings yet

- Flat Slab (Efficient Construction)Document4 pagesFlat Slab (Efficient Construction)tanhh5678No ratings yet

- Ulo PDFDocument39 pagesUlo PDFAkhmad MuflihNo ratings yet

- Standard Construction Productivity Norms-ManpowerDocument1 pageStandard Construction Productivity Norms-ManpowerGold Agharese90% (84)

- Summary Bill of Quantities: Project Identifying InformationDocument15 pagesSummary Bill of Quantities: Project Identifying InformationRussel Renz de MesaNo ratings yet

- Knowledge EngineerDocument48 pagesKnowledge EngineerPheakdeyNo ratings yet

- Project FinalDocument30 pagesProject FinalApdy- HakimNo ratings yet

- 2 - Concrete Formwrk OverviewDocument39 pages2 - Concrete Formwrk Overviewbehnam shirkhanghahNo ratings yet