Professional Documents

Culture Documents

Ra For Fire Protection Piping Installation Works

Uploaded by

prince0 ratings0% found this document useful (0 votes)

129 views7 pagesra for fire protection piping installation works

Original Title

Ra for Fire Protection Piping Installation Works

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentra for fire protection piping installation works

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

129 views7 pagesRa For Fire Protection Piping Installation Works

Uploaded by

princera for fire protection piping installation works

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

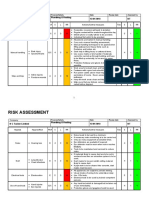

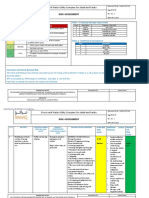

RISK ASSESMENT

PROJECT REF NO

CLIENT LOCATIO

MAIN CONTRACTOR DATE

SUB CONTRACTOR ORIGINA

TITLE FIRE PROTECTION PIPING INSTALLATION WORKS CHECKED

Identified at Risk Initial Risk

o. Hazard Description Control Measures

(People / Property e t c) L S R

.Ensure that toolbox talks an

is given

Authorised person should be

1 Material Stacking People /Property 2 2 4 job.

All operatives must wear pr

time during work.

Ensure first aid facility is avai

Tool box Talks.

Tools and tackles inspection.

Competent and qualified rigg

Lifting plan for heavy loads.

2 Loading and Unloading People/property 2 3 6

Proper pipe stacking.

Barricade the area.

Use of proper signage.

Proper supervision.

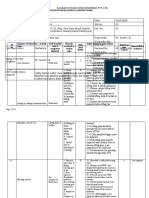

Ensure toolbox talks are h

highlighted.

Using a mechanical handl

work shall be located as clos

possible.

When erecting pipe work m

shall be avoided (wherev

mechanical handling device s

All combustible materials s

from worksite prior to comm

Be aware of other personne

Fabrication of Supports and

3 People /Property 2 2 4 the vicinity (conflicting activi

pipes

Scaffold platforms shall be

installation (wherever possib

Barricade the area beneat

commencing.

Inform other personnel in ar

Colour coding and all test

equipment shall be checked

are in date.

Visually inspect all equipmen

ensure it is free from any def

All damaged/defective equ

marked with “DO NOT

returned to the stores. (

immediately)

All equipment shall be of ad

perform operations.

Only trained & Exp. Pers

allowed for welding

Work should be done after

permit

Area should be barricaded be

work

Before starting the activit

should be properly inspect

Flammable materials

Welding holder should be he

Welding M/c should be

separate earthling

4 Welding works People & property 2 3 6

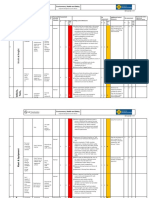

Use of good quality leath

(Dry Condition)

Looking at welders ARC sh

while working with in the vic

Use welding screen of correc

The atmosphere inside the

removes & replenish by fresh

Provide ventilation

Use of full body safety harn

lanyard and the anchoring

hooks must be ensured.

All applicable work permit,

statement must be available

work.

Follow heat stress prevention

by TRG

Scaffolding not adaptable to

require the use of safety harn

lanyard attached to a secure

object.

Scaffold supervisor to ensure

5 Scaffolding People /Property 2 3 6 inspected and tagged safe fo

use thereof and weekly there

competent scaffold inspector

A proper scaffold inspection

system, which is consistent w

universally recognized indust

shall be utilized and maintain

Unsafe scaffolds will be tagge

rectified immediately.

A safe means of entry and ex

provided and used whenever

work area is .6 meters above

working surface.

Means of exit shall be provid

100 ft. or 30 meters.

Toe board shall be installed a

working platform to prevent

Erection and installation of pipes materials from falling.

6 People property 2 3 6

and supports Barricade the area below into

can fall and not permitting w

the hazard area.

Use of 3M respiratory mask.

MSDS to be made available

Solvent and paint shall n

surfaces that have attained

which is greater than the s

temperature.

Paint mixing area shall be

SMOKING AREA and sited a

flame and where machinery

7 Painting People 1 3 3 Solvents paint or coating m

sheltered from exposure

summer heat, and stored in

area.

Tool box talks to be carried o

equipment operation.

Daily inspections of operator

checklist).

Temporary welfare provision

transport / first aid /rest shel

toilets, etc.

Provide correct & quality too

selection and adequate num

for the job.

8 Lifting People /Property 2 3 6

Provide onsite training on ha

to all personnel

Personnel to conduct pre-sta

all tools.

Any tools found with defect s

to store and get replaced.

Fulltime competent supervisi

throughout the activity.

Deploy trained banks man to

moving equipment operators

Trained banks man properly

reflective vest and competen

with whistles and traffic flags

Taking rest/sleep/shade unde

equipment is strictly forbidde

Arrange cooler for water stor

the day and proper Instructio

for frequent drinking of wate

Wear lightweight, light-color

preferably with a loose weav

lets air get to your skin.

Proper awareness shall be m

staffs working at the site by t

etc.

Ensure all personnel are well

weather condition Acclimatiz

Ensure availability of fire exti

Always maintain good house

Protruding object should be

Do not use damage equipme

Use proper personnel protec

Ensure toolbox meeting and

is given to all.

Use of good quality masks 3M

Use of good quality hand glo

9 Drilling of wall People 1 3 3

Use of Drilling goggles

Deployment skill labour only

Only authorised persons a

working at height.

Work to be done after ta

permit

Use double rope full body

must be anchored above the

Use correct lifting techniqu

strain on the back; do not

doubt its weight or ad

equipment.

Ensure the load is resting on

before releasing the load

10 Manual handling People 2 3 6 equipment.

Ensure there are enough

before lifting the load.

Use the following techniq

manually

Check for any obstruction be

Check out the area where

placed before lifting the loa

Place feet – apart, leading le

Bend your legs and not you

load

Keep a firm grip and keep

the body

Don’t jerk or make an

movements

Keep the load down and

necessary.

If in need take more manpow

Proper communication sha

between crew members whi

employee is lifting same obje

Follow wok permit system.

Use of body harness while w

11 Work at Height People & Property 2 3 6

.Ensure first aid facility availa

Ensure tool box meeting give

Proper vehicle inspection.

provided.

Back up alarm for vehicl

lights.

Properly select rigging gea

rigging gears to be carried o

color coded.

A look out for vehicles. Neve

between two trucks whe

loaded. During reversing, a

will signal the driver All re

Protective Equipment (app

worn.

12 Equipment operation People /Property 2 3 6

Shock absorbed harness b

lanyards shall be worn. Us

protection system. Proper

Cover all the openings for

when at height 100% tie-off

implemented.

Proper tools and tackles s

carry out the job safely.

Ensure proper documentatio

Ensure coverage of insurance

Ensure periodic maintenance

Barricade the area.

Use of flag man .

Employees performing the a

be given detailed instructio

technical data and techniqu

pressure testing and

13 Pressure testing People /Property 2 3 6

equipment, tools of the tr

devices.

Any ancillary equipment not

be isolated by valves or bl

vented or disconnected.

Where isolation valves are

test pressures, they must

rating for the pressure to be

isolation valves are used in

provisions shall be made to

over-pressurizing can occu

that is not being tested, due

leak.

Only calibrated equipment

during pressure testing.

Ensure that respective pres

consistent with the test requ

Piping designed for vapor

provided with additional tem

if necessary to support the w

liquids.

Vents or other high point c

be opened to eliminate air fr

to receive a hydrostatic test.

Systems shall be purged

hydrostatic test pressure is a

The area where the pressure

performed shall be properly

sign posted as “Pressure Test

Nobody shall be allowed to

until the required pressure

maintained for 10 minutes.

Ensure that relief valve devic

than the test pressure plus

lesser of 50 PSI or 10% of the

The entire line should be wal

to determine whether ther

evidence of leakage prior to

soaping of joints.

Tool box meeting to all.

Proper housekeeping.

Walkways, Stairways footpat

used by pedestrians are kept

obstruction at all time.

Tie up loose cables on or adja

walkways.

14 House Keeping People & Property 2 2 4 Put barrier around or cover o

floor openings into which peo

Suitable and sufficient lightin

work areas and traffic routes

Adequate storage or store ar

items encroaching onto walk

Management of store areas.

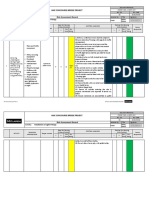

Risk Likelihood Risk Rating The above risk assessment has bee

Rating 3 2 1 Name

Severity 3 Name

Severity

3 9 6 3 3 Major Injury / Pollution / Damage Name

2 6 4 2 2 Minor / Pollution / Damage / Loss Name

1 3 2 1 1 Injury / Low Damage / Loss Name

Likelihood 1 Name

3 Likely Name

4 or more = unacceptable Risk

2 Possible Name

Risk Rating = S x L = R

RATING = 3 1 Never / Very Unlikely Name

Name of Person Given Risk Assessment Briefing

Name Date:

Signature Time:

You might also like

- JSA Format Erection of Column 903-C-02,03Document5 pagesJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- False CeilingDocument1 pageFalse CeilingGyanendra Narayan Nayak100% (1)

- RA For Plumbing and HeatingDocument8 pagesRA For Plumbing and HeatingAngela DaveyNo ratings yet

- JSA Formet New Blasting & PaintingDocument5 pagesJSA Formet New Blasting & Paintingsakthi venkatNo ratings yet

- Iaslc Ra 013 Working Under Direct Sun LightDocument4 pagesIaslc Ra 013 Working Under Direct Sun LightJoe PsNo ratings yet

- WPRA No. 2221-TK-61-273 - Scaffolding Erection and DismatlingDocument4 pagesWPRA No. 2221-TK-61-273 - Scaffolding Erection and DismatlingMohamed RizwanNo ratings yet

- JSA Fire Fighting WorkDocument8 pagesJSA Fire Fighting WorkMehul KolambkarNo ratings yet

- RCC at Height HiraDocument1 pageRCC at Height Hiraskfahimuddin100% (1)

- Method Statement For Interfacing With The Tarping & De-Tarping Station of 021-c13 Ver.00Document6 pagesMethod Statement For Interfacing With The Tarping & De-Tarping Station of 021-c13 Ver.00bryanNo ratings yet

- RA For Snake BiteDocument5 pagesRA For Snake Biteshamroz khan100% (1)

- JSA-Using A Type Ladder 2015Document1 pageJSA-Using A Type Ladder 2015nishanthNo ratings yet

- Nasda Wind Power Project: Sub-Station Excavation Job Safety Analysis WorksheetDocument2 pagesNasda Wind Power Project: Sub-Station Excavation Job Safety Analysis WorksheetRaza Muhammad SoomroNo ratings yet

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 pagesPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNo ratings yet

- JSA - Batching Plant OperationDocument3 pagesJSA - Batching Plant OperationNisith SahooNo ratings yet

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNo ratings yet

- 13-F06 EMERGENCY ALARM TESTING and INSPECTIONDocument1 page13-F06 EMERGENCY ALARM TESTING and INSPECTIONSn AhsanNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- 011 Duct Lifter SWMSDocument2 pages011 Duct Lifter SWMSJ JohnsonNo ratings yet

- Sharing of Industry Best Practice - Straits ConstructionDocument79 pagesSharing of Industry Best Practice - Straits Construction88sanNo ratings yet

- JHA 02 Lifting and SlingingDocument4 pagesJHA 02 Lifting and Slingingadil khanNo ratings yet

- Instructions For Using The Risk Assessment FormDocument9 pagesInstructions For Using The Risk Assessment FormMalik Khuram ShazadNo ratings yet

- Precast Erection JSWDocument6 pagesPrecast Erection JSWPrabhakaran GurunathanNo ratings yet

- Application To Perform Work - Grass CuttingDocument2 pagesApplication To Perform Work - Grass CuttingRauf HuseynovNo ratings yet

- Risk Assesment-Rebar Loading & UnloadingDocument1 pageRisk Assesment-Rebar Loading & Unloadingmainraj rajNo ratings yet

- Swms For Glass Partition FixingDocument6 pagesSwms For Glass Partition FixingSiddharth PNo ratings yet

- Asm Risk Assesment fv2 PDFDocument3 pagesAsm Risk Assesment fv2 PDFshijadNo ratings yet

- 06-F03 Ohs Introduction & Induction: Safety Induction Training Check-ListDocument2 pages06-F03 Ohs Introduction & Induction: Safety Induction Training Check-ListSn AhsanNo ratings yet

- DLF RCC HiraDocument8 pagesDLF RCC HiraskfahimuddinNo ratings yet

- JSA ScaffoldingDocument2 pagesJSA ScaffoldingHrishikesh UnnikrishnanNo ratings yet

- JSA For EXCAVATION AND BACKFILLING ARAMCO PROJECTDocument6 pagesJSA For EXCAVATION AND BACKFILLING ARAMCO PROJECTshaibaz chafekarNo ratings yet

- HIRA FOR Equipment Instalation.Document8 pagesHIRA FOR Equipment Instalation.Deepak G100% (1)

- SOP SOP0022 Concrete Core DrillDocument3 pagesSOP SOP0022 Concrete Core Drillkristian08No ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 6Document6 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 6Nitesh kumar yadavNo ratings yet

- Hot Work Activities (Cutting)Document9 pagesHot Work Activities (Cutting)Al Mughsar CompanyNo ratings yet

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDocument2 pagesProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohn100% (1)

- Jsa Ducting Rev 00Document1 pageJsa Ducting Rev 00SRR HSE Department, Sandvik Project,No ratings yet

- Construction Site Housekeeping ChecklistDocument3 pagesConstruction Site Housekeeping ChecklistMuhammad Zarul Aziri Bin MaamurNo ratings yet

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- Ra For Hot Work (Welding & Cutting Works)Document3 pagesRa For Hot Work (Welding & Cutting Works)Abrar AhmedNo ratings yet

- Safe Working Procedure ExcavationsDocument4 pagesSafe Working Procedure ExcavationsMunaku TafadzwaNo ratings yet

- Rec. PPEsDocument2 pagesRec. PPEsManoj Kumar100% (1)

- Demolition JhaDocument2 pagesDemolition JhaElvyn Fabellore HerreraNo ratings yet

- Risk Assesmennt For OutfallDocument9 pagesRisk Assesmennt For Outfallchinmay jagdeepNo ratings yet

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- 19.17 (SWMS) All Work HvacDocument17 pages19.17 (SWMS) All Work Hvacsyed khaja misbhuddinNo ratings yet

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelNo ratings yet

- Jsa Loading and Unloading of Pile PipesDocument4 pagesJsa Loading and Unloading of Pile PipesOsiobe Ewomazino100% (1)

- Electrical Work Checklist: Saline Water Desalination Plant On The West CoastDocument1 pageElectrical Work Checklist: Saline Water Desalination Plant On The West CoastBRC HSE Dept.No ratings yet

- De-Shuttering PermitDocument1 pageDe-Shuttering PermitHariharan Muthukrishanan100% (1)

- Weekly HSE Inspection Closeout Report - 01Document2 pagesWeekly HSE Inspection Closeout Report - 01niyas100% (1)

- Job Safety Analysis (JSA) - Carpentry Works DateDocument1 pageJob Safety Analysis (JSA) - Carpentry Works DatenabeelNo ratings yet

- Fire Fighting Equipments Checklist: No. Items Inspected Status (Yes or No) Fire PumpDocument4 pagesFire Fighting Equipments Checklist: No. Items Inspected Status (Yes or No) Fire PumpAbeSanNo ratings yet

- JSA E&I 4.earthing Bonding InstallationDocument3 pagesJSA E&I 4.earthing Bonding InstallationAmyNo ratings yet

- RSP Safety & InspectionDocument39 pagesRSP Safety & InspectionSunil Panicker100% (1)

- Cuplocks Scaffolding JSA UtilityDocument4 pagesCuplocks Scaffolding JSA UtilitysoubhagyaNo ratings yet

- Job Safety Analysis (Jsa) : Fabrication Works, Welding Works Using Power Tools, Hand Tools, Welding Machine WapstechDocument3 pagesJob Safety Analysis (Jsa) : Fabrication Works, Welding Works Using Power Tools, Hand Tools, Welding Machine WapstechMohamedSaidNo ratings yet

- Risk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)Document3 pagesRisk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)AmeerHamzaWarraichNo ratings yet

- Qusahwira Field Development Phase Ii Project Project No. 14395 Forklift ChecklistDocument1 pageQusahwira Field Development Phase Ii Project Project No. 14395 Forklift ChecklistJayaprakasan Koyadan KorothNo ratings yet

- Risk Assessment Concrete Cutting - 01Document5 pagesRisk Assessment Concrete Cutting - 01kapsarcNo ratings yet

- Underground Above Ground Drainage Works and Plumbing Works Risk AssessmentDocument4 pagesUnderground Above Ground Drainage Works and Plumbing Works Risk Assessmentmohsin.meizaNo ratings yet

- Ra For EarthingDocument5 pagesRa For EarthingprinceNo ratings yet

- Proposed Tia 1325 Nfpa 5000 CH 21Document3 pagesProposed Tia 1325 Nfpa 5000 CH 21princeNo ratings yet

- CFPA E Guideline No 26 2010 FDocument30 pagesCFPA E Guideline No 26 2010 Fdvs99No ratings yet

- Ra For EarthingDocument5 pagesRa For EarthingprinceNo ratings yet

- Gas Monitoring Checklist: Integrated Management System (ISO 9001:2015, ISO 14001:2015 & OHSAS 18001:2007)Document1 pageGas Monitoring Checklist: Integrated Management System (ISO 9001:2015, ISO 14001:2015 & OHSAS 18001:2007)princeNo ratings yet

- Inspection Checklist Chain BlockDocument2 pagesInspection Checklist Chain Blockprince100% (3)

- Gas Monitoring Checklist: Integrated Management System (ISO 9001:2015, ISO 14001:2015 & OHSAS 18001:2007)Document1 pageGas Monitoring Checklist: Integrated Management System (ISO 9001:2015, ISO 14001:2015 & OHSAS 18001:2007)princeNo ratings yet

- Daeling With Hazards and RisksDocument121 pagesDaeling With Hazards and RisksprinceNo ratings yet

- Constr. Safety JeopardyDocument25 pagesConstr. Safety JeopardyprinceNo ratings yet

- List of Mandatory Documents - IMSDocument1 pageList of Mandatory Documents - IMSprince100% (1)

- RA For Equipment InstallationDocument2 pagesRA For Equipment InstallationprinceNo ratings yet

- RA For Fire Detection SystemDocument4 pagesRA For Fire Detection SystemprinceNo ratings yet

- RA For Equipment InstallationDocument2 pagesRA For Equipment InstallationprinceNo ratings yet

- MAB-Emergency Evacuation Plan Rev OA (Repaired)Document20 pagesMAB-Emergency Evacuation Plan Rev OA (Repaired)princeNo ratings yet

- Fire Protection Plan - 1Document11 pagesFire Protection Plan - 1princeNo ratings yet

- Saudi Hse LAWS and Its ChecklistDocument19 pagesSaudi Hse LAWS and Its ChecklistprinceNo ratings yet

- Hazard Identification Plan (Schedule XX Jobs) Test - NewDocument20 pagesHazard Identification Plan (Schedule XX Jobs) Test - Newprince100% (1)

- Excavation Checklist Pocket CardDocument2 pagesExcavation Checklist Pocket CardprinceNo ratings yet

- Excavation Checklist Pocket CardDocument2 pagesExcavation Checklist Pocket CardprinceNo ratings yet

- Hip Oil WellsDocument30 pagesHip Oil WellsprinceNo ratings yet

- Excavation CollapseDocument3 pagesExcavation CollapseprinceNo ratings yet

- SWP CHECKLISTS - Works at HeightsDocument2 pagesSWP CHECKLISTS - Works at HeightsSrinivas Dumpala HSENo ratings yet

- PERIDocument9 pagesPERIkrmcharigdc100% (1)

- KHK HandbookDocument37 pagesKHK HandbookA JoshiNo ratings yet

- Dos &Don'Ts in Concrete WorksDocument29 pagesDos &Don'Ts in Concrete WorksSaravanan B Saravanan BNo ratings yet

- Roof Repair Work: What You Need To Know As A Busy BuilderDocument2 pagesRoof Repair Work: What You Need To Know As A Busy BuildervictorNo ratings yet

- Metro Hse Plan 01Document49 pagesMetro Hse Plan 01Wasique Nesar100% (1)

- SOP-61 Working at HeightDocument1 pageSOP-61 Working at HeightFareed KhanNo ratings yet

- 18.ladders & ScaffoldsDocument17 pages18.ladders & ScaffoldsbabadapbadapNo ratings yet

- HSE Plan-TDDocument52 pagesHSE Plan-TDPeshteenNo ratings yet

- SCAFFOLDING SUPERVISOR UpdateDocument3 pagesSCAFFOLDING SUPERVISOR UpdateAzad pravesh khanNo ratings yet

- Form Work GuideDocument37 pagesForm Work Guideozziem100% (1)

- Weekly Safety Patrol ChecklistDocument1 pageWeekly Safety Patrol ChecklistAlif ShahrilNo ratings yet

- Shoring Failure 384 794Document2 pagesShoring Failure 384 794Ahmed Y. AlsahharNo ratings yet

- Staircase Tower CuplockDocument1 pageStaircase Tower CuplockManu MohanNo ratings yet

- Method Statement For Tank ErectionDocument8 pagesMethod Statement For Tank Erectionmanish pathrabeNo ratings yet

- Shoring RMD Kwikform UAE 9929 LowDocument8 pagesShoring RMD Kwikform UAE 9929 LowShima ZamzamiNo ratings yet

- Floor Props Eurex EcoDocument16 pagesFloor Props Eurex Ecoali kartalNo ratings yet

- JSA For Scaffolding Erection Dismantling and Modification WorkDocument20 pagesJSA For Scaffolding Erection Dismantling and Modification Workbagas prakoso100% (1)

- MS For Installation of Light FittingsDocument11 pagesMS For Installation of Light FittingsAnandu Ashokan100% (2)

- Scaffolding Inside The Pre-Heater &: Cyclones CalcinerDocument23 pagesScaffolding Inside The Pre-Heater &: Cyclones CalcinerSuad BushiNo ratings yet

- R.C.C Project Upto Plinth Level: Abstract SheetDocument10 pagesR.C.C Project Upto Plinth Level: Abstract SheetVivÊk Síngh PâlNo ratings yet

- Scaffold Basic PartsDocument57 pagesScaffold Basic PartsSn Carbonel100% (1)

- Building ConstructionDocument37 pagesBuilding Constructiontilak mehraNo ratings yet

- Tadepally GudamDocument469 pagesTadepally Gudamkiran raghukiranNo ratings yet

- Meisei Scaffolding Materials ForecastDocument4 pagesMeisei Scaffolding Materials ForecastDelta akathehuskyNo ratings yet

- WAH 01 Working at Height Slide Presentation SSP.Document87 pagesWAH 01 Working at Height Slide Presentation SSP.Liya Staari100% (3)

- JSA For Scaffolding.Document16 pagesJSA For Scaffolding.jeswinimanualNo ratings yet

- 17.10 Pericad & ElposDocument16 pages17.10 Pericad & ElposDarren ThoonNo ratings yet

- Risk Assessment For .Testing and Commissioning of Fire Rated Bus DuctDocument13 pagesRisk Assessment For .Testing and Commissioning of Fire Rated Bus Ductarun kurlanNo ratings yet

- Scaffold Basic Design ExampleDocument15 pagesScaffold Basic Design Exampleahmadhatake88% (34)