Professional Documents

Culture Documents

Design Flex Duct

Uploaded by

VietHienCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Flex Duct

Uploaded by

VietHienCopyright:

Available Formats

Design of Flexible-duct

Junction Boxes

Robert Beach, IBACOS

Duncan Prahl, IBACOS

Presentation Outline

• Current Standards and Practice

• Analysis Methods

• Recommendations

Design of Flexible-duct Junction Boxes

• Detailed report is in peer review anticipated to be

published T3 this year.

– http://www1.eere.energy.gov/library/default.aspx?page=2&spi

d=2.

• Measure guide to be part of Building America Solutions

Center

– http://basc.pnnl.gov/

Design of Flexible-duct Junction Boxes

Typical Installations

As Plenum As Monster

Design of Flexible-duct Junction Boxes

Current Standards

• ASHRAE 2012 HVAC Systems and Equipment, Box

Plenum Systems Using Flexible Duct

– Constrains Box Width to 2-3x Entrance Width

– Constrains Box Length to 2 x Box Width

– Flat Pressure Loss = 0.05 in. of water (50 ft of EL)

– Mentions Entrance Fitting

• ACCA Manual D, Residential Duct Systems (2009)

– Residential Industry Standard for Sizing Ducts (if done at all)

– Group 11, Flex-duct Junction Boxes and Radius Bends

• Gilman reference – 1951 etc. U of I bulletin

(https://www.ideals.illinois.edu/handle/2142/4424)

Design of Flexible-duct Junction Boxes

ACCA Manual D, Group 11 Fittings

• Recommendations:

• Entrance has a diffuse fitting

that recovers velocity

pressures and prevents swirl

(optional)

• Straight approach and straight

exit

• Exit opening on side (no top or

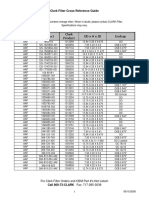

Velocity In Flex Duct Equivalent Length (ft)

bottom exits) (fpm)

• Exit opening at least two 400 20

diameters from entrance (L)

500 30

• Make box as small as

600 40

possible, but comply with

700 60

• L=2xD

800 75

900 95

Design of Flexible-duct Junction Boxes

University of Illinois: Gilman Study

Flow Instability Entrance Diffuser

Design of Flexible-duct Junction Boxes

What did we look at?

• Three configurations to limit variation

• 2, 3 or 4 outlets

• Outlets with 10, 150 or 250 cfm

• Ducts Sized to 0.08 IWC / 100 ft design friction rate

Design of Flexible-duct Junction Boxes

Small fan coil applications

Design of Flexible-duct Junction Boxes

What did we look at?

• We simulated Set Name

using CFD over 1 Four Outlets with an Entrance Diffuser

50 configurations 2 Four Outlets, Equal Flows

in 7 different sets. 3 Four Outlets, Unequal Flows

4 Four Outlets, Equal Flows, High

Velocities

5 Three Outlets, Unequal Flows,

Equilateral Triangle Box

6 Three Outlets, Unequal Flows,

Isosceles Triangle Box

7 Two Outlets, Unequal Flows,

Equilateral Triangle Box

Design of Flexible-duct Junction Boxes

Analysis Method

• Computational Fluid

Dynamics (CFD)

Potential alternative to

physical testing

Used to determine

pressure loss of

box configurations

Calculates pressures

within system

consisting of Inlet

Duct, Junction Box

and Outlet Ducts

Designs were

reconfigured and

measured to

determine

variations in

pressure due to

changes in

configuration.

Design of Flexible-duct Junction Boxes

Typical Simulation Configuration

• For each individual

configuration

• Induced flow into

inlet

• Noted unbalanced

flows out of each

outlet

• Balancing

resistance was

added to match

intended flows.

Design of Flexible-duct Junction Boxes

Conclusions

• Designers must recognize that junction boxes are cost

effective but add more pressure to systems compared

to trunk and branch designs.

• Pressures varied significantly with size of box, relative

positions of outlets, air velocity and volumetric flow

rate, friction rate of ducts, the number of outlets.

Design of Flexible-duct Junction Boxes

Recommendations

Design of Flexible-duct Junction Boxes

Recommendations

Design of Flexible-duct Junction Boxes

Recommendations

Design of Flexible-duct Junction Boxes

Recommendations

Design of Flexible-duct Junction Boxes

Recommendations

Design of Flexible-duct Junction Boxes

Recommendations

Design of Flexible-duct Junction Boxes

Recommendations

Design of Flexible-duct Junction Boxes

Recommendations

Design of Flexible-duct Junction Boxes

Recommendations

Design of Flexible-duct Junction Boxes

Balancing Losses

• ACCA indicates a flat 0.03 IWC for each damper

• Balancing dampers are necessary due to uncontrolled

factors at installation.

• Our maximum calculated balanced condition received

only 0.016 IWC, most did not require balancing.

• In symmetrical cases 0.03 is highly conservative

Design of Flexible-duct Junction Boxes

Low Flow Cases

• Balancing losses generally increased with flow rate

• In low flow configurations (10 cfm outlet flows)

balancing was greatly reduced. (most unbalanced

flows were within 10% of targets)

Design of Flexible-duct Junction Boxes

Questions?

• rbeach@ibacos.com

• dprahl@ibacos.com

Design of Flexible-duct Junction Boxes

You might also like

- 296 Balt Evaporative CondensersDocument20 pages296 Balt Evaporative CondensersJohnnybacsiNo ratings yet

- Workover Tubing DesignDocument120 pagesWorkover Tubing DesignMohammed IbrahimNo ratings yet

- Eaton Fabricated Strainer Model 90 Technical Information USDocument2 pagesEaton Fabricated Strainer Model 90 Technical Information USlucasNo ratings yet

- Canal Outlets PDFDocument32 pagesCanal Outlets PDFHitesh ParmarNo ratings yet

- EAT356 Lecture 2 WASTEWATER COLLECTION SYSTEMSDocument44 pagesEAT356 Lecture 2 WASTEWATER COLLECTION SYSTEMSAin Zulkefli100% (1)

- 2013.04.05 - HVAC Design 101 (WB)Document37 pages2013.04.05 - HVAC Design 101 (WB)clintNo ratings yet

- Piping Quiz & Ans (Fluor Daniel) PDFDocument13 pagesPiping Quiz & Ans (Fluor Daniel) PDFaslam.ambNo ratings yet

- Pigging OperationsDocument157 pagesPigging OperationsRizwan FaridNo ratings yet

- Canal OutletsDocument32 pagesCanal OutletsAhmed Hassan83% (6)

- Distribution Ppt-2020-Lecture NotesDocument117 pagesDistribution Ppt-2020-Lecture NotesLeonardo ValentineNo ratings yet

- Ideas To Achieve Optimal Combination of Axial & Cross FlowDocument28 pagesIdeas To Achieve Optimal Combination of Axial & Cross FlowAmirah SufianNo ratings yet

- Duct DesignDocument67 pagesDuct DesignShahrukh Ansari100% (1)

- Well Completion PETRONASDocument56 pagesWell Completion PETRONASAbdul Azis Zaenal Mustopa100% (4)

- IDE Lec9 Canal Outlets&CDWDocument79 pagesIDE Lec9 Canal Outlets&CDWFortiter FysproNo ratings yet

- Hydraulics Training Lesson 10Document22 pagesHydraulics Training Lesson 10sponky05100% (1)

- Pipe Rack / Ways & Rack Piping: Akshaya SharmaDocument23 pagesPipe Rack / Ways & Rack Piping: Akshaya SharmaWahyu IrwansyahNo ratings yet

- 4 - Slab Form DesignDocument31 pages4 - Slab Form DesignosmanhmdyNo ratings yet

- FC15 Flow Visualisation DatasheetDocument2 pagesFC15 Flow Visualisation DatasheetMiguel SilvaNo ratings yet

- Vanguard Electric 2022Document24 pagesVanguard Electric 2022Frederick GuerreroNo ratings yet

- Hydraulic Engineering Design Workshop: Live Streamed ViaDocument1 pageHydraulic Engineering Design Workshop: Live Streamed ViaThaiNguyenNo ratings yet

- Casing DesignDocument65 pagesCasing DesignRizwan FaridNo ratings yet

- PDS FlowMaster LTR EN LRDocument2 pagesPDS FlowMaster LTR EN LRahmed ktebahNo ratings yet

- Pipe Rack & Rack PipingDocument23 pagesPipe Rack & Rack Pipingtrung652092100% (2)

- Pipeline Integrity and Difficult To Pig PipelinesDocument158 pagesPipeline Integrity and Difficult To Pig Pipelinesfrank71FERRERNo ratings yet

- HYDRAULIC Brochure 2023 ZOOMDocument1 pageHYDRAULIC Brochure 2023 ZOOMMandeep JaimanNo ratings yet

- CAE 464 517 Sp21 Lecture15 Air Distribution Systems Duct Design MethodsDocument57 pagesCAE 464 517 Sp21 Lecture15 Air Distribution Systems Duct Design MethodsXiangyang ChenNo ratings yet

- Busbar PDFDocument46 pagesBusbar PDFJishnu M PillaiNo ratings yet

- 1A Plastixs Custom Manifold Assemblies BrochureDocument6 pages1A Plastixs Custom Manifold Assemblies BrochureMNNo ratings yet

- Manholes PresentationDocument143 pagesManholes PresentationMar MaslanNo ratings yet

- Spiral Tube Heat ExchangerDocument2 pagesSpiral Tube Heat ExchangerM AhmadNo ratings yet

- Evaporative CondensersDocument20 pagesEvaporative CondensersAl Musabbir LeeonNo ratings yet

- Needle ValvesDocument8 pagesNeedle Valvessrave_k07No ratings yet

- Casing Design FundamentalsDocument70 pagesCasing Design FundamentalsBibarys04No ratings yet

- 7.canal OutletsDocument27 pages7.canal OutletsWajahat Hussain BangashNo ratings yet

- Piping QA Quiz Answers for Fluor Daniel ProjectsDocument13 pagesPiping QA Quiz Answers for Fluor Daniel Projectssairam2234100% (1)

- Pig PipelinesDocument158 pagesPig PipelinesnerdsarmyNo ratings yet

- Shell and TubeDocument55 pagesShell and Tubesatish lukkaNo ratings yet

- AlOtaibi, 2016Document8 pagesAlOtaibi, 201620-013 Mordekhai Yosep S.No ratings yet

- Drainage Systems Design GuideDocument64 pagesDrainage Systems Design GuideRichardLaraMedinaNo ratings yet

- Heat Operation ExchangersDocument67 pagesHeat Operation ExchangersAkankshya MishraNo ratings yet

- Concise Beam Precast Beam Design SoftwareDocument33 pagesConcise Beam Precast Beam Design Softwarezaeem_sidd5291100% (1)

- Design of Vertical KO Pot-V2Document45 pagesDesign of Vertical KO Pot-V2myself_riteshNo ratings yet

- AISC Design Guides: A Resource For Practicing EngineersDocument40 pagesAISC Design Guides: A Resource For Practicing EngineersSergio Manuel Céh ChaleNo ratings yet

- Trench Coil ProductsDocument10 pagesTrench Coil ProductsAgus ptdNo ratings yet

- INTALOX High Performance DistributorsDocument4 pagesINTALOX High Performance Distributorsyakesh19No ratings yet

- Basf Masterflow 816 TdsDocument4 pagesBasf Masterflow 816 TdsSanja RadovicNo ratings yet

- Computational Rheology for Pipeline and Annular Flow: Non-Newtonian Flow Modeling for Drilling and Production, and Flow Assurance Methods in Subsea Pipeline DesignFrom EverandComputational Rheology for Pipeline and Annular Flow: Non-Newtonian Flow Modeling for Drilling and Production, and Flow Assurance Methods in Subsea Pipeline DesignRating: 3.5 out of 5 stars3.5/5 (2)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Screwcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsFrom EverandScrewcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Pipeline Design for Water EngineersFrom EverandPipeline Design for Water EngineersRating: 5 out of 5 stars5/5 (1)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Designing, Building, and Testing Your Own Speaker System with ProjectsFrom EverandDesigning, Building, and Testing Your Own Speaker System with ProjectsRating: 3 out of 5 stars3/5 (2)

- Catalog VRV IV - 2016Document62 pagesCatalog VRV IV - 2016VietHienNo ratings yet

- DAIKIN SKYAIR AIR CONDITIONING SYSTEMDocument24 pagesDAIKIN SKYAIR AIR CONDITIONING SYSTEMVietHienNo ratings yet

- Installation Manual FXMQDocument13 pagesInstallation Manual FXMQVietHienNo ratings yet

- IB-189 TES Myths ASHRAE Journal PDFDocument6 pagesIB-189 TES Myths ASHRAE Journal PDFVietHienNo ratings yet

- Ky Thuat Lanh Co So PDFDocument382 pagesKy Thuat Lanh Co So PDFVietHienNo ratings yet

- Ampatzi - The Potential For Solar Thermal Technologies v.2Document263 pagesAmpatzi - The Potential For Solar Thermal Technologies v.2VietHienNo ratings yet

- Ky Thuat Lanh Co So PDFDocument382 pagesKy Thuat Lanh Co So PDFVietHienNo ratings yet

- Ky Thuat Lanh Dieu Hoa Khong Khi PDFDocument382 pagesKy Thuat Lanh Dieu Hoa Khong Khi PDFVietHienNo ratings yet

- GettingstartedDocument88 pagesGettingstartedPhanhai Kaka100% (1)

- IB-187 Fundamentals of Ice Storage ASHRAE Journal PDFDocument7 pagesIB-187 Fundamentals of Ice Storage ASHRAE Journal PDFVietHienNo ratings yet

- CLCH-PRC026A-En - 072015 - Performance UCCA Outdoor CatalogDocument88 pagesCLCH-PRC026A-En - 072015 - Performance UCCA Outdoor CatalogVietHienNo ratings yet

- TRACE 700 - Users ManualDocument468 pagesTRACE 700 - Users Manualantmang100% (3)

- Technical Mmanual CristopiaDocument58 pagesTechnical Mmanual CristopiaVietHienNo ratings yet

- Thermaline ST ManualDocument2 pagesThermaline ST ManualVietHienNo ratings yet

- NA14631A - CristopiaDocument3 pagesNA14631A - CristopiaVietHienNo ratings yet

- IceStorage ControlDocument19 pagesIceStorage ControlVietHienNo ratings yet

- Thermal Ice Storage - SmallDocument64 pagesThermal Ice Storage - Smallsiva_nagesh_2100% (1)

- Trane Quantum Air Handler Installation GuideDocument72 pagesTrane Quantum Air Handler Installation GuideYutt WattNo ratings yet

- Design Ice Thermal Energy StorageDocument55 pagesDesign Ice Thermal Energy StorageVietHienNo ratings yet

- Catalogue Khớp Nối Mềm Rắc CoDocument2 pagesCatalogue Khớp Nối Mềm Rắc CoVietHienNo ratings yet

- 2 - Thermal Energy Storage Systems PDFDocument21 pages2 - Thermal Energy Storage Systems PDFVitalremainsNo ratings yet

- Rocket Propulsion Nozzle Divergence LossDocument24 pagesRocket Propulsion Nozzle Divergence LossMohd TauqeerNo ratings yet

- Sizing Charts For Pipe Fittings Flanges and AccessoriesDocument61 pagesSizing Charts For Pipe Fittings Flanges and AccessoriesahmedNo ratings yet

- 1 Gasturbine PDFDocument74 pages1 Gasturbine PDFshaonaaNo ratings yet

- Progressing Cavity Pump ApplicationsDocument63 pagesProgressing Cavity Pump Applicationsadtijanic-1100% (1)

- 793F, 793F, WTR, Oem PDFDocument18 pages793F, 793F, WTR, Oem PDFDennis OlayaNo ratings yet

- V-Cone Ficha TécnicaDocument2 pagesV-Cone Ficha TécnicaIrving Uc Fernandez100% (1)

- 6 Centrifugal Pump Performance SixDocument20 pages6 Centrifugal Pump Performance SixAbdallah MansourNo ratings yet

- Experiment 5 Pressure Distribution On Circular Cylinder and AirfoilDocument8 pagesExperiment 5 Pressure Distribution On Circular Cylinder and AirfoilMarilynYunLing50% (2)

- 4 Eng 4 Components PDFDocument14 pages4 Eng 4 Components PDFAGNIDEEP BAIDYANo ratings yet

- IversehwDocument81 pagesIversehwKhairy ElsayedNo ratings yet

- Egger Iris LeafletDocument2 pagesEgger Iris LeafletEdg MerlínNo ratings yet

- Oblique Shock WavesDocument25 pagesOblique Shock WavesDhinasuga DhinakaranNo ratings yet

- Hydraulic & Electric Circuit Guide for ECD45 Crawler DrillDocument14 pagesHydraulic & Electric Circuit Guide for ECD45 Crawler DrillrolandNo ratings yet

- Catalogo Filtro CLARKDocument21 pagesCatalogo Filtro CLARKjulioebc2014No ratings yet

- W07. Open Centre Control ValvesDocument3 pagesW07. Open Centre Control ValvesMohamed BakheetNo ratings yet

- Katalog MKS Mei 2010Document22 pagesKatalog MKS Mei 2010Maulia SabrinaNo ratings yet

- 10.1007@s42405 018 0134 ZDocument8 pages10.1007@s42405 018 0134 ZsergukesikNo ratings yet

- Pump Head Calculation Sheet: S U P P L Y P U M PDocument6 pagesPump Head Calculation Sheet: S U P P L Y P U M PGokul GopalakrishnanNo ratings yet

- Rr210201 Hydraulics and Hydraulic MachineryDocument8 pagesRr210201 Hydraulics and Hydraulic MachinerySRINIVASA RAO GANTANo ratings yet

- AirCom Quick LineDocument19 pagesAirCom Quick Linea ferreira e oliveiraNo ratings yet

- Manual of Hyd Control UnitDocument13 pagesManual of Hyd Control UnitGamal El Deen KamalNo ratings yet

- Piping Design, Layout and Stress Analysis: Foreword 1 Scope 2 Normative References 3 Definitions and AbbreviationsDocument15 pagesPiping Design, Layout and Stress Analysis: Foreword 1 Scope 2 Normative References 3 Definitions and AbbreviationsWalid LabidiNo ratings yet

- RT 06 Centrif Comp PDFDocument22 pagesRT 06 Centrif Comp PDFAdrian García MoyanoNo ratings yet

- S6D95L-1L Engine Parts Catalog for Serial Numbers 22170-UPDocument105 pagesS6D95L-1L Engine Parts Catalog for Serial Numbers 22170-UPCarlos Alberto BaptistaNo ratings yet

- r07220302 Mechanics of FluidsDocument8 pagesr07220302 Mechanics of FluidsandhracollegesNo ratings yet

- Ku-Twk-41-Ic-Lst-0200 A Instrument Index Io List-Peshkbir PDFDocument28 pagesKu-Twk-41-Ic-Lst-0200 A Instrument Index Io List-Peshkbir PDFLienu PrinceNo ratings yet

- EC250D BRIC - Hyd - eng-GB20025770B - HDocument30 pagesEC250D BRIC - Hyd - eng-GB20025770B - Hفتحي الجمل فتحي الجملNo ratings yet

- BSPP & BSPT Thread Identification TableDocument5 pagesBSPP & BSPT Thread Identification TableguslohNo ratings yet

- IIT Bombay Chemical Engineering Mini Project Analysis of Piping Network and Natural Gas ReformerDocument3 pagesIIT Bombay Chemical Engineering Mini Project Analysis of Piping Network and Natural Gas ReformerFake Account 1No ratings yet

- Unprice Quotation - Forged Steel ValveDocument3 pagesUnprice Quotation - Forged Steel ValveTommy ArjanggiNo ratings yet