Professional Documents

Culture Documents

WPC STP 3 PDF

Uploaded by

Israel Muhi0 ratings0% found this document useful (0 votes)

4 views4 pagesOriginal Title

wpc_stp_3.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views4 pagesWPC STP 3 PDF

Uploaded by

Israel MuhiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

3.2

3.3

34

DESIGN PARAMETERS

The designer should give a reasonable estimate of population and a

detailed breakdown of the total flow rate in the calculation.

The basic design parameters for residential populations shall be taken as

follows:

+ 0.30 to 0.46m*/h/d (cu.m. per head per day) depending on types of

development

+ 55g BOD/h/d

+ 55g SS/h/d

For other types of population, reference should be made to Civil

Engineering Manual Vol. 6 and Water Supplies Department Provisional

Standing Order 1309, relevant data of which has been attached as

Appendix 2. If service trades (shops, restaurants etc.) occur in the

development, the flows and loads of the trades shall also be included as per

Appendix 2.

The design peak flow arriving at the STP as a proportion of dry weather

flow (DWF) shall be taken as:

+ 6 DWF for population equal to or under 1 000,

+ 4 DWF for population over 1 000 but not less than that based on 1000

population.

Either the STP can be designed for the above peak flow rate or it can be

designed to cater for a peak flow of 3 DWF, excess flow over 3 DWF

being equalized in an equalization tank. In the latter case the feed pumps

must be sized accurately to avoid excessive peak flow rate production.

Equalization tanks should be designed to hold the excess flow for a period

of two hours. Only the tank volume above the duty pump cut- in level

should be considered as effective equalization volume. Air ejectors should

be provided to prevent septicity of sewage.

Primary sedimentation tanks shall be designed for:

+ maximum surface loading of 40 m*/m?/d at peak flow,

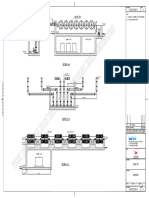

1 DISTANCE ‘a’ TO SATISFY THE

REQUIREMENT THAT PUMP STARTS

NOT TO EXCEED 10 TIMES PER HOUR

HIGH LeveL

ALARM

POSSIBLE

FIG.2 EFFECTIVE EQUALIZATION VOLUME IN AN

EQUALIZATION TANK

3.5

3.6

3.7

3.8

3.9

+ minimum retention time of 2 hours at peak flow,

+ maximum weir loading of 250 m}/m/d at peak flow.

Final sedimentation tanks shall be designed for:

+ maximum surface loading of 35 m/m?/d at peak’ flow if they are

preceded by Rotating Biological Contactor (RBC) or biological filters,

+ maximum surface loading of 22 m*/m?/d at peak flow if they are

preceded by the extended aeration process,

+ minimum retention time of 2 hours at peak flow.

The reduction of total BOD by different stages of the primary treatment

processes should be taken as follow:

+ equalization tank — ail

* coarse screen — oil

+ fine screen (max. opening 2 mm) — 75%

+ primary sedimentation — 30%

+ fine screen and primary sedimentation — 30%

‘The net BOD load going into the subsequent biological processes should be

computed accordingly.

Biological processes should be designed to the following organic loading:

RBC : 10 g total BOD/m?/d (i.e. per sq.m. of RBC

surface) entering into the RBC or as

recommended by manufacturer, whichever is

smaller,

+ Extended aeration : 0.07 kg total BOD/kg MLSS/d and MLSS in the

range between 2 000 and 3 500 mg/L,

+ Plastic biological : 0.5 kg total BOD/m*/d (i.e. per cu.m. of media

filter (Biofilter) volume) or as recommended by manufacturer,

whichever is smaller.

+ For other biological treatment methods, such as sequential batch reactor,

contact stabilization and other patented processes etc., organic

loadings proposed in the design should be justified by supporting

documents such as relevant literature, local monitoring results and

catalogues.

Chlorination tanks should be designed for minimum 30 minutes contact

time at peak flow.

Sludge quantities generated from the processes should include:

+ solids removed from primary sedimentation, which should be taken as

70% of the influent SS.

+ sludge yield from biological processes, which should be taken as

0.5 kg solids/kg BOD removed when preceded by primary

sedimentation, or 1 kg solids/kg BOD removed when not preceded by

primary sedimentation. In the latter case no inclusion of primary sludge

is necessary.

aaerenae

3.10 Solid concentration of sedimentation tank sludge shall be taken as:

+ 1% for extended aeration sludge,

+ 2% for RBC, biological filter and primary sludge.

You might also like

- SBR 1Document20 pagesSBR 1pragatheeskNo ratings yet

- SBR StudyDocument4 pagesSBR StudypragatheeskNo ratings yet

- List of Preferred BrandDocument8 pagesList of Preferred BrandpragatheeskNo ratings yet

- QuestionnaireDocument2 pagesQuestionnairepragatheeskNo ratings yet

- ComparisonDocument10 pagesComparisonpragatheeskNo ratings yet

- LabDocument12 pagesLabpragatheeskNo ratings yet

- Work Activity List For Lockdown Scenario - 2nd MonthDocument1 pageWork Activity List For Lockdown Scenario - 2nd MonthpragatheeskNo ratings yet

- MBR FibracastDocument83 pagesMBR FibracastCu AgNo ratings yet

- RFQ For Pumps-UpdatedDocument3 pagesRFQ For Pumps-UpdatedpragatheeskNo ratings yet

- AreaDocument6 pagesAreapragatheeskNo ratings yet

- List of Preferred BrandDocument8 pagesList of Preferred BrandpragatheeskNo ratings yet

- Tax Clearance Calculator Check ScenariosDocument1 pageTax Clearance Calculator Check ScenariospragatheeskNo ratings yet

- Chapter 2Document42 pagesChapter 2Manoj SinghNo ratings yet

- MSIG Jilid V 01 Title Page & ForewordDocument4 pagesMSIG Jilid V 01 Title Page & Forewordnaqie100% (1)

- Product Leaflet Seawater Electrochlorination PDFDocument4 pagesProduct Leaflet Seawater Electrochlorination PDFgkdora574No ratings yet

- Power PointDocument29 pagesPower PointswordprakashNo ratings yet

- Equipment: Respond To This Bidding DocumentDocument1 pageEquipment: Respond To This Bidding DocumentpragatheeskNo ratings yet

- MSIG Jilid V 02 Table of ContentDocument4 pagesMSIG Jilid V 02 Table of ContentnaqieNo ratings yet

- A-035-C-0005 - A Layout1Document1 pageA-035-C-0005 - A Layout1pragatheeskNo ratings yet

- Appendix A7 2Document2 pagesAppendix A7 2pragatheeskNo ratings yet

- Appendices O&MDocument115 pagesAppendices O&MpragatheeskNo ratings yet

- Table of Chapters and AbbreviationsDocument84 pagesTable of Chapters and AbbreviationspragatheeskNo ratings yet

- Coverpage and MessagesDocument14 pagesCoverpage and MessagespragatheeskNo ratings yet

- Centrifuge Appendix 2CDocument6 pagesCentrifuge Appendix 2Csachinsuvarna1987No ratings yet

- A-035-M-0010 - A Layout1Document1 pageA-035-M-0010 - A Layout1pragatheeskNo ratings yet

- Kubota-Mbr Technical PDFDocument13 pagesKubota-Mbr Technical PDFpragatheeskNo ratings yet

- A-035-C-0006 - A Layout1Document1 pageA-035-C-0006 - A Layout1pragatheeskNo ratings yet

- SeparatorDocument1 pageSeparatorpragatheeskNo ratings yet

- Transmittal TPCL 09004Document1 pageTransmittal TPCL 09004pragatheeskNo ratings yet

- 4Document1 page4pragatheeskNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)