Professional Documents

Culture Documents

The Measurement and Theory of Tire Friction On Contaminated Surfaces

Uploaded by

kannanmech87Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Measurement and Theory of Tire Friction On Contaminated Surfaces

Uploaded by

kannanmech87Copyright:

Available Formats

94 1998 TRANSPORTATION CONFERENCE PROCEEDINGS

The Measurement and Theory of Tire

Friction on Contaminated Surfaces

JAMES C. WAMBOLD AND ARILD ANDRESEN

In the past five years there has been an International Experiment to est encompasses all surface types and conditions, which are con-

Harmonize Friction Measurement by the World Road Association sidered operational for aircraft ground movements. The models

(PIARC) and within the past three years there have been at least four are developed in a context of defined surface classifications. Just

separate studies on winter friction, a five year joint winter runway pro-

gram between NASA, FAA, Transport Canada (TC), the Canadian as pavement friction models reflect the application to pavement as

National Research Council (NRC), the Norwegian Civil Aviation a base surface, we will look at friction models for ice based and

(NCAA) and the French Civil Aviation Administration; a study by the snow based surfaces.

Norwegian Road Administration with Norsemeter; a study by Minne-

sota DOT and the Concept Highway Maintenance Vehicle Study by the

Iowa Center for Transportation. In addition to these studies there are

standards under development: an International Friction Index (for wet Models Modification Requirements

pavements) and an International Runway Friction Index (for winter

operation). This paper summarizes the results of these various studies. One possible use of the model modifiers is to adjust an actual mea-

In the case of wet pavements we now know that the tire first determines surement to a standard condition with any modifier developed. For

the friction slip characteristics until the peak is reached and then be- example, if a reference is standardized to represent values of fric-

yond the peak the pavement’s ability to drain the water determines the tion at -10 degrees Celsius, the actual measurement can be adjusted

speed gradient. When the tire makes contact with the pavement the tire

is the sacrificed part of the friction pair; however, on ice and snow the

from the actual temperature during a measurement to the reference

opposite is true and the ice or snow is the sacrificed part of the friction temperature using a temperature modifier.

pair. Thus the peak friction that is developed depends on the shear A tire configuration term is used to group the signatures in fami-

strength of the sacrificed part. With these studies completed, the high- lies per tire configuration. A tire configuration comprises make

way and aviation communities will be better able to measure friction and type of tire (footprint, rubber compound, longitudinal stiffness),

on contaminated pavements. the inflation pressure used and the normal load used during brak-

ing operations. The brake actuator control technique is also con-

sidered part of the tire-configuration.

Modifications of the pavement friction models are studied as

INTRODUCTION the new parameters and variables are introduced to cater to the sac-

rificial surface mechanism (hardness/ultimate shear strength), sur-

In search for a better understanding of braking friction processes, face temperature, friction enhancing abrasives (sand, grit) and

mathematical and graphical models that can describe and visualise mechanisms such as rolling resistance, fluid planing and fluid drag.

the processes are useful. Engineered models are usually limited Contaminant compression is imbedded in the shear strength term

and often inadequate in their capabilities to capture the true, real and is considered for inclusion in a rolling resistance term, pending

world processes. We never accept the lesser models that simplify further investigation. These empirical modifications are good start-

the real world, when they yield plausible results in the area of focus ing points for experimental analysis.

or application.

This paper looks at some existing models for longitudinal fric-

tion in the tire-pavement interaction and tries to incorporate pa- GENERAL TIRE-SURFACE FRICTION MODELS FOR

rameters of influence found on winter surfaces. The area of inter- PAVEMENT

The following is a brief review of some available tire-surface fric-

tion models using ground speed and slip speed as the independent

variable. When the models are applied on experimental data, espe-

cially those obtained under the Joint Winter Runway Friction Mea-

surement Program, actual tire configurations will be reflected in

reference curves for the calibration and harmonisation of friction

J. C. Wambold, CDRM, Inc., 1911 East College Avenue, P.O. Box 1277, measurement devices. A single device or combination of several

State College, Pennsylvania, 16804. A. Andresen, Mobility Friction Tech- devices (called a virtual device) may be chosen as a Master Device

nology, Obersl Rodes vei 89b, 1165 Oslo, Norway. or Prime Calibration Reference Device.

95

Wambold and Andresen

FIGURE 3 A cross section of a winter surface. The pavement

can be found with any one or several of the indicated layers. All

possibilities of the surface classification are not shown, for

instance, wetness.

FIGURE 1 Effect of high and low speed constants Sp1=55,

Sp2=100, Sp3=340. Lower curve is Sp=55.

The Logarithmic Pavement Friction Model

The Logarithmic Pavement Friction Model (also called the Rado

Model) is currently used with variable slip friction devices to re-

port three friction variables. The model introduces a logarithmic

ratio of slip speed vs. critical slip speed and a shape factor, C (origi-

nally designated Ĉ ). The critical slip speed (abscissa value), Sc,

and peak friction value (ordinate value), P, fixes the location of the

maximum friction value on the Cartesian graph of friction vs. slip

speed and, therefore, governs the initial climb of the curve. We

note that P and Sc fix the position of the maximum friction point.

The set of parameters used in the Rado Model, Equation (2), is

s= 1 through 65 km/h, P= 0.5, Sc= 20 km/h, C= 1.4 and is shown in

Figure 2.

s

2

In

Sc

P • exp −

sfn(s) := C2

FIGURE 2 A sample friction curve generated with the Rado

Model.

Note that the actual resulting curve shape depends on both C

and Sc. It has been found that the three Rado Model parameters

generally vary with measuring speed. We shall propose speed func-

tion for these parameters for winter surfaces in later sections.

The Penn State Model

COMPOSITE WINTER SURFACES

The Penn State Model is an exponential function with slip speed as

independent variable. The model has been used for wet pavements We introduce the composite surface classification depicted in Fig-

to monitor macrotexture. The model is the basis for the PIARC ure 3.

Model used with the International Friction Index. The model is The braked wheel can displace all or a large part of a layer of

used here with a zero intercept constant, F0, and a constant slip slush, fresh snow or drifting snow that has a fluid powder charac-

speed constant, Sp. Equation (1) is given below and shown graphi- ter. This gives rise to contaminant displacement drag forces on the

cally in Figure 1 with the following set of parameters: wheel and varying levels of fluid lift and fluid lubrication as some

s = 1 through 65 km/h, F0 = 0.5, Sp = 55, 100, and 340 with of the fluid contaminant gets trapped under the tire. Compression

Equation (1). may occur with the trapped snow to build a thin layer of new snow

The speed constant governs the slope of the curve. A higher base in the track of the wheel. When there is sand applied to the

speed constant makes the curve more flat. The speed constant ex- surface (likely before the snow base in Figure 3), it will interact

presses the influence of macrotexture of the pavement. High with the tire and raise the friction force experienced. Even in cases

macrotexture corresponds with a high speed constant. For the In- without fresh snow/drifting snow, the snow base may be sufficiently

ternational Friction Index, it is derived from a texture measure- soft for the tire to shear off snow crystals during braked wheel roll-

ment and used with the friction value at the harmonization slip speed ing and create small amounts of powder to sustain a partial planing

of 60 km/h. condition.

96 1998 TRANSPORTATION CONFERENCE PROCEEDINGS

ments then show friction forces versus speed as a flat curve even

though there is no macrotexture. The interpretation of macrotexture

with the Penn State Model is not valid for the sacrificial base sur-

face like snow. The surface shear effect masks the macrotexture.

A parameter to reflect loss of coherence is therefore introduced.

In the following, pavement friction models are amended on an

empirical basis with a parameter for surface hardness, H. A rigid

surface base has a value of H = 1’ a soft surface base less than 1. C

of the Rado Model is associated with winter-contaminated surface

2

C

and is interpreted as

H . The parameters for Figure 4 are P =

0.5, Sc= 20 km/h, C = 2, H = 0.1 and H = 0.5.

Equation (3):

s s

2

In

Sc

FIGURE 4 A hardness parameter applied to the Rado Model. P • exp −

The upper curve is softest with H=0.1, middle curve is H=0.5 and 1

C • 2

sfh(s) := 2

lowest curve H=1 (hard surface).

H

Except for clean or damp pavement and clean ice there is al- Contaminant Displacement Drag

ways a presence of partial planing. For hydroplaning (liquid wa-

ter) the fluid dynamic lift part of planing does not contribute sig- The equation (Equation [4]) for contaminant displacement drag by

nificant frictional forces. Only the remaining tire surface contact the frontal area of the tire is generally:

area is yields braking friction.

For snow planing the shear forces of a laminar or turbulent flow FDRAG = 0.5 ⋅ CD ⋅ ρ ⋅ A ⋅ v 2

of snow powder at high speeds generates significant shear forces in Since we will be tabulating parameters per surface class and tire

the planing contact area. configuration, we can simplify the equation (Equation [5])to

FDRAG = k drag ⋅ v 2

THE MODIFIERS PROPOSED

Where kdrag = 0.5 ⋅ CD ⋅ ρ ⋅ A

The frontal area, A, on the tire is the product of the tire width

Surface Shear Strength and Compressive Strength of Snow and fluid contaminant layer thickness.

For a snow base we need a parameter to express the sacrifice of the

surface, as opposed to the pavement, where the sacrifice part of the Surface Temperature

friction pair is the tire. The onset of such a sacrifice, shearing off

or crunching the snow, occurs when the demand for shear force Surface temperature is observed to raise friction level on winter

exceeds the shear strength of the snow. The normal load may crunch contaminated surfaces as temperature falls. The mechanisms pro-

the snow at local stress concentration points. Automotive type tires ducing that effect are many. A major effect is believed to be a rise

and friction tester tires have stress concentrations along the in friction due to the increased shear strength and the absence of

sidewalls. The crushing occurs when the compressive strength of free water, which could act as a lubricant.

the contaminant material is exceeded. For convenience we choose the Kelvin temperature scale as ba-

In the Rado Model C is related to Sp when 1.7<C<6 for wet sis for temperature modelling. That way we do not have to work

pavements. In that range C expresses macrotexture influence for with a minus sign below freezing temperatures. The temperature

rigid surfaces. For winter contaminants the surface may behave as adjustments will be done with two linear equations. The number 1

a hard, non-sacrificial surface, or as a loose, sacrificial surface. adjustment will be valid from 268 to 273 Kelvin. Number 2 adjust-

The sacrificial surface should not be expected to show any strong ment will be valid below 268 Kelvin. These ranges will be ad-

relationship to macrotexture, when the ultimate shear strength has justed after investigating the available field-test database.

been exceeded and some material has been torn loose. Experi- The composite temperature function is shown in Figure 5.

97

Wambold and Andresen

TABLE 1 Winter Parameters for One Tire Configuration and One Surface Type and Condition

Winter Parameter per Desig- Unit Range Source

Tire Configuration nation

Shapefactor C Dimension less 1.4<C<11 Variable slip measurement

Shapefactor Speed Number cv km/h Variable slip measurement

Loss of Hardness Factor H Dimension less 0.05<H<1 Test program table per surface type and condition

Temperature Factor 1 ktemp1 Dimension less 0.001< ktemp1<0.1 Test program table per surface type and condition

Temperature Factor 2 ktemp2 Dimension less 0.0001< ktemp2<0.01 Test program table per surface type and condition

Planing Factor kp Dimension less 0<kp<1 Friction measurement or table from test program

Drag Factor kdrag sfn/km2/h2 1⋅10-5<kdrag <3⋅10-2 Friction measurement or table from test program

Rolling Resistance R Dimensionless 0.0001<R<0.3 Friction measurement or table from test program

Abrasive Application Aa Dimensionless 0.01<Aa<0.2 Friction measurement or table from test program

Peak Speed Factor kv km/h 100<kv<1000 Test program table per surface type and condition

Ultimate Friction Value P0 sfn 0<P0<1.2 Test program table of averages per surface type and condition

Ultimate Critical Slip Value S0 km/h 0<S0<30 Test program table of averages per surface type and condition

Critical Slip Ratio Factor kc km/h 100<kc<1000 Test program table per surface type and condition

Equation (7):

Fxc = k c • 1/ r. • w • d c • ρ • v

Where r is the tire radius, w is the tire width, dC is the depth of

snow layer compacted, ρ is the snow mass density, v is the tire

FIGURE 5 Temperature adjustment function consisting of two velocity and kC is a factor of compacting.

lines with an intercept at 267 Kelvin.

For a given tire configuration the r and w are fixed. These pa-

rameters can thus be combined into the kC factor.

Viscous and Dynamic Fluid Lift Planing

The presence of water or water in solutions of de-icer chemicals

A temperature dependency term, ktemp, is introduced as the gra-

introduces hydroplaning when the surface is hard and dense enough

dient of a linear equation, with T being a difference in temperature

to support it. Wet, hard ice is an obvious candidate for hydroplan-

from a reference.

ing.

Partial planing may be operational. It can be treated as loss of

contact area for solid interaction. As peak friction is very suscep-

Rolling Resistance tible to the net or real contact area, a planing fraction parameter,

kplaning, for the peak friction value is introduced. The general equa-

Rolling resistance has been shown to be a geometrical relationship tion (Equation [8]) for dynamic fluid lift (planing) is

involving the position, a, of the resultant normal force reaction from

ground and the deflected wheel radius, r. FL = 0.5 ⋅ CL ⋅ ρ ⋅ AL ⋅ v 2

Equation (6): Where CL is a lift coefficient, ρ is the density of the fluid and

FX ,R = ⋅ FWEIGHT

a

r

AL is the area of the tire being lifted.

For convenience we use the work by Horne of NASA.

Equation (9):

FL = kpl v / VC

Compaction Rolling Resistance Where kpl is a lift coefficient, VC is the critical planning speed

for the tire-surface and v is the speed this lift gives rise to a hori-

For loose snow the tire will compress the loose snow to a higher zontal slip friction on the remaining not detached tire-surface con-

density, when caught under vertical force, is treated as rolling re- tact area. Thus we have Equation (10):

sistance. The horizontal force is treated as a drag force, FXC. FXL = µslip Fweight (1 – v/VC )

98 1998 TRANSPORTATION CONFERENCE PROCEEDINGS

TABLE 2 Penn State Winter Parameters for One Tire Configuration and One Surface Type and Condition

Winter Parameter per Desig- Unit Range Source

Tire Configuration nation

Speed Constant Vp km/h 10<Vp <1000 Fixed slip measurement

Loss of Hardness Factor H Dimensionless 0.05<H<1 Test program table per surface type and condition

Temperature Factor 1 ktemp1 Dimensionless 0.001< ktemp1<0.1 Test program table per surface type and condition

Temperature Factor 2 ktemp2 Dimensionless 0.0001< ktemp2<0.01 Test program table per surface type and condition

Planing Factor kp Dimensionless 0<kp<1 Friction measurement or table from test program

Drag Factor kdrag sfn/km2/h2 1⋅10-5<kdrag <3⋅10-2 Friction measurement or table from test program

Rolling Resistance R Dimensionless 0.0001<R<0.3 Friction measurement or table from test program

Abrasive Application Aa Dimensionless 0.01<Aa<0.2 Friction measurement or table from test program

Ultimate Friction Value F0 sn 0<F0<1.2 Test program table of averages per surface type and condition

SUMMARY OF MODIFIERS • That contact pressure is a very strong influence, in fact in the

simple correlation there is a very strong influence of contact pres-

sure on the multiplier constant (correlation is R2=0.82).

The Logarithmic Model There is more work to do, however, preliminary results show

that the various modifiers are playing an important roll and help in

In summary, we have 13 parameters to determine, slip speed, s, developing the test plan.

travel speed, v, and temperature difference, T, are variables of the

process (Table 1).

PRELIMINARY RESULTS FOR MINNDOT AND

NORWAY TESTS

Penn State Model

This preliminary project was successful in establishing better Baye-

The modifiers are designated in the same manner as for the loga- sian values (filtered peak friction value) and showed that the Rado

rithmic friction model. Field-testing will show if they must be Model constants can be used to differentiate contaminates. The

treated as two different sets of modifiers or if we, in practice, may peak friction along with the slip speed at the peak separates the ice

use them with both models. The speed constant is unique for the and snow from dry or wet. The shape factor then separates loose

Penn State Model and is meaningless with the logarithmic model. snow and slush from packed snow and ice. The project showed

The modified Penn State Model comprises 9 modifiers (Table that friction levels can be monitored in real time and salting control

2). does appear to be feasible either with a go-no-go or perhaps with

varying levels of salting.

More sites where to be tested last season to finalize how the

PRELIMINARY RESULTS FOR NORTH BAY TESTS three Rado constants can be used to differentiate the contaminate;

however, there was not proper conditions and the tests are to be

From the North Bay tests it has been shown that there is no speed rescheduled for this coming year. It is planned to continue the study

effect. Since they are all run at low fixed slip ratios there is not a in the US with more experiments. MinnDOT, IowaDot and

very good speed range and thus not very good data to determine MichiganDOT mounted a unit on a salting truck and will evaluate

speed effect. Devices that had variable fixed slip ranges did show its use during the coming winter season.

speed effects, but not enough data was collected. This coming year

a better test plan to explore speed effect will need to be devised.

For some devices temperature effects were determined. It should ACKNOWLEDGMENTS

be noted that better temperature measurement will be needed and

all devices will need to be equipped with their own surface tem- This paper reflects the intellectual contributions of many people

perature measurement. Last, preliminary results show that for the The team of people working together in the Joint NASA/TC/FAA/

conditions of ice and packed snow that: /NRC Winter Runway Friction Measurement Program and the teams

• All devices participating, a simple correlation is possible if the working on highway friction measurement for winter maintenance

data is grouped so that only the same conditions, in the pared are sharing their ideas and research findings openly and frequently

groups are correlated. as the works progress.

You might also like

- Geometric Design of Linkages J Michael 27006480Document2 pagesGeometric Design of Linkages J Michael 27006480warekarNo ratings yet

- Minerals Engineering: Paul W. Cleary, Phil OwenDocument21 pagesMinerals Engineering: Paul W. Cleary, Phil OwenJuan Pablo Delgado PomachaguaNo ratings yet

- Similitude Requirements and Scaling Relationships Applied TestingDocument65 pagesSimilitude Requirements and Scaling Relationships Applied Testingmsmh.durrantNo ratings yet

- A New Look at The Analysis Coast-Down Test Results: PHD, and Department of Loughborough, LeicestershireDocument7 pagesA New Look at The Analysis Coast-Down Test Results: PHD, and Department of Loughborough, LeicestershireAndres ValenciaNo ratings yet

- Structural Number Prediction For Flexible Pavements Using The Long Term Pavement Performance DataDocument16 pagesStructural Number Prediction For Flexible Pavements Using The Long Term Pavement Performance DataVarun YadavNo ratings yet

- A Mathematical Model To Predict RailwayDocument12 pagesA Mathematical Model To Predict RailwaySergey KotovNo ratings yet

- Simulation of Gas-Solid Flow & Design Modifications of Cement Plant CyclonesDocument8 pagesSimulation of Gas-Solid Flow & Design Modifications of Cement Plant CyclonesNael100% (1)

- CFD Analysis of Propeller Performance in Oblique Flow: Giulio Dubbioso, Roberto Muscari, Andrea Di MascioDocument8 pagesCFD Analysis of Propeller Performance in Oblique Flow: Giulio Dubbioso, Roberto Muscari, Andrea Di MascioNoumanNo ratings yet

- Lu GRE Model Other Parameters 2Document6 pagesLu GRE Model Other Parameters 2Тимур РеджеповNo ratings yet

- 2008 JFE Dufour RC CentrifugeDocument11 pages2008 JFE Dufour RC CentrifugeBrahimABDNo ratings yet

- A Review - Base Drag Reduction Methods On Flying Vehicles and AutomobilesDocument11 pagesA Review - Base Drag Reduction Methods On Flying Vehicles and Automobilesshivaprasad047No ratings yet

- 1990 - CameronDocument8 pages1990 - CameronChiara GastaldiNo ratings yet

- Computational Model and Solver SetupDocument11 pagesComputational Model and Solver SetupaunbhuttaNo ratings yet

- LiteratureDocument7 pagesLiteratureRajesh KumarNo ratings yet

- Modeling and Simulation of The Bollard Pull Test For Vessels Using Computational Fluid DynamicsDocument6 pagesModeling and Simulation of The Bollard Pull Test For Vessels Using Computational Fluid DynamicsCarlos Ramón Plazaola LorioNo ratings yet

- Parte 3Document15 pagesParte 3João Victor Staub de MeloNo ratings yet

- Development of Correlation Equations BetDocument6 pagesDevelopment of Correlation Equations BetEngr.Hamid Ismail CheemaNo ratings yet

- Applied Sciences: Axial Turbine Cascade CorrelationDocument12 pagesApplied Sciences: Axial Turbine Cascade CorrelationPIYUSH PORWALNo ratings yet

- Kha Mari 2021Document19 pagesKha Mari 2021Jitesh DhimanNo ratings yet

- Simulation of The Aquaplane ProblemDocument10 pagesSimulation of The Aquaplane ProblemsiritapeNo ratings yet

- EpplerDocument5 pagesEpplersumon1314No ratings yet

- 2013, EngApplCompFluid, GalindoEtAl, Set-Up Analysis and Optimization of CFD Simulations For Radial TurbinesDocument20 pages2013, EngApplCompFluid, GalindoEtAl, Set-Up Analysis and Optimization of CFD Simulations For Radial TurbinesPaul LinberdNo ratings yet

- SW2022 KortschDocument11 pagesSW2022 KortschJuan BrugadaNo ratings yet

- CFD Assessment of Ropax Hull Resistance With Various Initial Drafts and Trim AnglesDocument8 pagesCFD Assessment of Ropax Hull Resistance With Various Initial Drafts and Trim AnglesRahul SunilNo ratings yet

- Sheltonetal Reno05Document13 pagesSheltonetal Reno05Karthik KNo ratings yet

- LooooDocument11 pagesLooooSudhanshu KansalNo ratings yet

- Effect of Interlayer Properties On AC Airfield Pavements Main ResponsesDocument15 pagesEffect of Interlayer Properties On AC Airfield Pavements Main ResponsesJohann CárdenasNo ratings yet

- LECTURA 2 Bortoleto2013Document8 pagesLECTURA 2 Bortoleto2013Victor Manuel CastañedaNo ratings yet

- Fatigue Life Calculation of Monopiles For Offshore Wind Turbines Using A Kinematic Hardening Soil ModelDocument6 pagesFatigue Life Calculation of Monopiles For Offshore Wind Turbines Using A Kinematic Hardening Soil ModelErnest Onoriode OshogbunuNo ratings yet

- 2020 M.F.Alwalan - Analytical Models of Impact Force-Time Response Generated From High StrainDocument14 pages2020 M.F.Alwalan - Analytical Models of Impact Force-Time Response Generated From High StrainlbiNo ratings yet

- Quadcopter Rotor Efficiency EstimationDocument19 pagesQuadcopter Rotor Efficiency EstimationJuan David Valderrama ArtunduagaNo ratings yet

- Pile-Soil Dynamic System With Variable DampingDocument8 pagesPile-Soil Dynamic System With Variable DampingmanachemiaaNo ratings yet

- Hard Coat Damping StudyDocument8 pagesHard Coat Damping StudydavimenaliNo ratings yet

- DEM Validation For A Scale Model SAG MillDocument8 pagesDEM Validation For A Scale Model SAG MillAdilene LaresNo ratings yet

- Resilient ModulusDocument254 pagesResilient ModulusbloomdidoNo ratings yet

- Virtual Maneuvering Test in CFD Media in Presence of Free SurfaceDocument19 pagesVirtual Maneuvering Test in CFD Media in Presence of Free SurfaceAhmad HajivandNo ratings yet

- KSCE Journal of Civil Engineering - Vol.20.Iss.1.A45Document11 pagesKSCE Journal of Civil Engineering - Vol.20.Iss.1.A45sonNo ratings yet

- Three-Dimensional CFD Rotordynamic Analysis of Gas Labyrinth SealsDocument7 pagesThree-Dimensional CFD Rotordynamic Analysis of Gas Labyrinth SealsTapanVaishnavNo ratings yet

- Numerical Investigation On The Effect of Trim On Ship Resistance by RANSE MethodDocument11 pagesNumerical Investigation On The Effect of Trim On Ship Resistance by RANSE Methodheinz billNo ratings yet

- Factors Affecting Dust Collector EfficiencyDocument6 pagesFactors Affecting Dust Collector EfficiencyVídeos Legendados BrasilNo ratings yet

- 0-Dynamic Modulus Master Curve Construction of Asphalt Mixtures Erroranalysis in Different Models and FieldDocument14 pages0-Dynamic Modulus Master Curve Construction of Asphalt Mixtures Erroranalysis in Different Models and Fieldzhizhang5591No ratings yet

- Numerical Simulations and Searching Methods of Thrust Oscillations For Solid Rocket BoostersDocument15 pagesNumerical Simulations and Searching Methods of Thrust Oscillations For Solid Rocket BoostersEdukondalu PentapatiNo ratings yet

- Numerical Simulation of The Flow Around The Ahmed Vehicle ModelDocument12 pagesNumerical Simulation of The Flow Around The Ahmed Vehicle ModelSamuel WooNo ratings yet

- Mechanical LossDocument16 pagesMechanical LosssiritapeNo ratings yet

- Literature (Desgin and Anaysis of Composite Tube)Document8 pagesLiterature (Desgin and Anaysis of Composite Tube)Bashar AlfadliNo ratings yet

- Triaxial Tests On SandDocument28 pagesTriaxial Tests On SandKrusovice15No ratings yet

- Procedure For Developing Dynamic Modulus Master Curves For Pavement Structural DesignDocument10 pagesProcedure For Developing Dynamic Modulus Master Curves For Pavement Structural Designzhizhang5591No ratings yet

- RANS and Panel Methods Comparison for Propeller AnalysisDocument13 pagesRANS and Panel Methods Comparison for Propeller AnalysiscupidkhhNo ratings yet

- Lu GRE Model Traction ControlDocument6 pagesLu GRE Model Traction ControlТимур РеджеповNo ratings yet

- m148 PDFDocument4 pagesm148 PDFvijihjiNo ratings yet

- 17-Bergsma FSI Paper RevisedDocument10 pages17-Bergsma FSI Paper RevisedSunil Kumar P GNo ratings yet

- Must ReadDocument8 pagesMust ReadaminardakaniNo ratings yet

- Turb Modeling Secondary Flow PredictionDocument9 pagesTurb Modeling Secondary Flow PredictionM usman qureshiNo ratings yet

- Aiaa Les Moin-SquarebackDocument9 pagesAiaa Les Moin-SquarebackPrateek JaiswalNo ratings yet

- Computational Analysis of Wind-Turbine Blade Rain ErosionDocument9 pagesComputational Analysis of Wind-Turbine Blade Rain ErosionJoanCastellóBelenguerNo ratings yet

- Experimental Research On The Similarity of Rime Icing On ADocument14 pagesExperimental Research On The Similarity of Rime Icing On Afaraz fotoohiNo ratings yet

- Estimating tire friction force using nonlinear observerDocument6 pagesEstimating tire friction force using nonlinear observerТимур РеджеповNo ratings yet

- Computational Analyses of Tail Fin Configurations For A Sounding RocketDocument14 pagesComputational Analyses of Tail Fin Configurations For A Sounding RocketMarcosNo ratings yet

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsFrom EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechNo ratings yet

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- Recruitment of Sales Executives TLs ASM Processing Staff BFSLDocument6 pagesRecruitment of Sales Executives TLs ASM Processing Staff BFSLTopRankersNo ratings yet

- Sel CV I Ae Agri 2k17 ListDocument2 pagesSel CV I Ae Agri 2k17 Listkannanmech87No ratings yet

- TNPSC GKDocument415 pagesTNPSC GKkannanmech87100% (2)

- Dept May2011gfDocument506 pagesDept May2011gfkannanmech87No ratings yet

- Nano TechnologyDocument10 pagesNano Technologykannanmech87100% (1)

- NEW507179சூலை 2012 மாத இதழ்Document26 pagesNEW507179சூலை 2012 மாத இதழ்David MayNo ratings yet

- Valla DuraiDocument2 pagesValla Duraikannanmech87No ratings yet

- AutoCAD 2013Document264 pagesAutoCAD 2013panosscribd100% (1)

- Alternative Fuels & Bio - FuelsDocument8 pagesAlternative Fuels & Bio - Fuelskannanmech87No ratings yet

- ME 3320 Kinematics Dynamics Machinery Course ObjectivesDocument1 pageME 3320 Kinematics Dynamics Machinery Course Objectiveskannanmech87No ratings yet

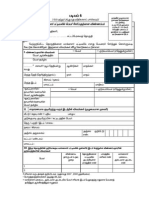

- பட்டா மாற்றத்திற்கான விண்ணப்படிவம்Document3 pagesபட்டா மாற்றத்திற்கான விண்ணப்படிவம்Bakrudeen Ali AhamedNo ratings yet

- KSR Institute For Engineering and Technology Department of Mechanical Engineering Mentoring Data SheetDocument2 pagesKSR Institute For Engineering and Technology Department of Mechanical Engineering Mentoring Data Sheetkannanmech87No ratings yet

- Form 8 AtamilDocument3 pagesForm 8 AtamilVijayabaskaran SundhareshwarNo ratings yet

- இருப்பிட சான்றிதழுக்கான விண்ணப்பபடிவம்Document1 pageஇருப்பிட சான்றிதழுக்கான விண்ணப்பபடிவம்Bakrudeen Ali Ahamed0% (1)

- Model TestDocument21 pagesModel Testanand_dec84No ratings yet

- TNPSC Model TamilDocument22 pagesTNPSC Model Tamilபிரகாஷ் பாரிNo ratings yet

- TNPSC Group 4 Model Question Paper 2Document20 pagesTNPSC Group 4 Model Question Paper 2training2jobs100% (1)

- குடும்ப அட்டை பெறுவதற்கான விண்ணப்ப படிவம்Document2 pagesகுடும்ப அட்டை பெறுவதற்கான விண்ணப்ப படிவம்Bakrudeen Ali AhamedNo ratings yet

- ST Forest Dwellers Act 2006 T 0Document3 pagesST Forest Dwellers Act 2006 T 0kannanmech87No ratings yet

- Form 6 TamilDocument7 pagesForm 6 Tamilapi-276452640No ratings yet

- Answer All The Questions (9X2 18 Marks) Answer All The Questions (9X2 18 Marks)Document1 pageAnswer All The Questions (9X2 18 Marks) Answer All The Questions (9X2 18 Marks)kannanmech87No ratings yet

- TN Fiscal Responsibility Act SummaryDocument9 pagesTN Fiscal Responsibility Act Summarykannanmech87No ratings yet

- PhysResInt 10 341016Document10 pagesPhysResInt 10 341016kannanmech87No ratings yet

- TNPSC Group 2 Model Question and AnswerDocument20 pagesTNPSC Group 2 Model Question and Answeruit@No ratings yet

- Dom QBDocument8 pagesDom QBkannanmech87No ratings yet

- Validation of A Vapour Compression Refrigeration System Design ModelDocument7 pagesValidation of A Vapour Compression Refrigeration System Design Modelkannanmech87No ratings yet

- Answer All The Questions (9X2 18 Marks) Answer All The Questions (9X2 18 Marks)Document1 pageAnswer All The Questions (9X2 18 Marks) Answer All The Questions (9X2 18 Marks)kannanmech87No ratings yet

- RBI & IMF CompensationDocument3 pagesRBI & IMF Compensationkannanmech87No ratings yet

- Jarme 3 1 2010Document8 pagesJarme 3 1 2010kannanmech87No ratings yet

- Validation of A Vapour Compression Refrigeration System Design ModelDocument7 pagesValidation of A Vapour Compression Refrigeration System Design Modelkannanmech87No ratings yet

- Integration TechniquesDocument45 pagesIntegration TechniquesMustafa SHAHZADNo ratings yet

- Two Samples (T-Test and Z-Test) - 2Document9 pagesTwo Samples (T-Test and Z-Test) - 2Letlie SemblanteNo ratings yet

- 01-Basics of AntennasDocument40 pages01-Basics of Antennaskomar33No ratings yet

- Uniform DistributionDocument10 pagesUniform DistributionvishwavichuNo ratings yet

- Research Chapter 3Document9 pagesResearch Chapter 3Ashly MacandiliNo ratings yet

- Determining Beta Factor For A 2N2222 TransistorDocument2 pagesDetermining Beta Factor For A 2N2222 TransistorJuan Carlos Morales ParraNo ratings yet

- Siop Lesson PlanDocument3 pagesSiop Lesson Planapi-371649683No ratings yet

- Detailed LP Dela Cruz FFFDocument8 pagesDetailed LP Dela Cruz FFFJaysan Dela CruzNo ratings yet

- ცდომილებათა თეორიის ელემენტები - 1, თსუ, 2003Document3 pagesცდომილებათა თეორიის ელემენტები - 1, თსუ, 2003Marina MenteshashviliNo ratings yet

- Gaining Confidence With GD T - Part 3Document20 pagesGaining Confidence With GD T - Part 3Abraham ThomasNo ratings yet

- Baseband Shaping for Data TransmissionDocument60 pagesBaseband Shaping for Data Transmissionrahul guptaNo ratings yet

- Technical Note 35Document13 pagesTechnical Note 35NatrajiNo ratings yet

- Acceleration and DecelerationDocument28 pagesAcceleration and DecelerationCt RahayuNo ratings yet

- Java Lab ManualDocument58 pagesJava Lab ManualViswaprem CANo ratings yet

- 2.8 Index of Refraction LabDocument4 pages2.8 Index of Refraction LabsashaNo ratings yet

- Jurnal Teknologi Dan Industri Pertanian Indonesia: KeywordsDocument12 pagesJurnal Teknologi Dan Industri Pertanian Indonesia: KeywordsWahyu AjiNo ratings yet

- DC Motor N GeneratorDocument23 pagesDC Motor N GeneratorGilbert SihombingNo ratings yet

- Shallow Foundation Notes 1Document49 pagesShallow Foundation Notes 1NziradzinengweNo ratings yet

- Recap of Physical and Chemical PropertiesDocument45 pagesRecap of Physical and Chemical PropertiesIsabelle HasheelaNo ratings yet

- View Answer: TH Withou L T: TDocument116 pagesView Answer: TH Withou L T: TshradhaNo ratings yet

- B.tech. Civil Engineering Full Syllabus IndiaDocument118 pagesB.tech. Civil Engineering Full Syllabus IndiaAnubhav GargNo ratings yet

- Answer of IKMC 2010Document1 pageAnswer of IKMC 2010Minh PhươngNo ratings yet

- Math Emetics ComputerDocument3 pagesMath Emetics ComputerAbhisek MohantaNo ratings yet

- Supplementary Note335Document21 pagesSupplementary Note335Syafiq ArtNo ratings yet

- Human Induced Vibrations On Footbridges: Application and Comparison of Pedestrian Load ModelsDocument140 pagesHuman Induced Vibrations On Footbridges: Application and Comparison of Pedestrian Load ModelsktricoteNo ratings yet

- Limit Load Analysis of Bolted Flange ConnectionsDocument11 pagesLimit Load Analysis of Bolted Flange ConnectionsMansonNo ratings yet

- Mathematics for Business Students Worksheet No. 7 SolutionDocument6 pagesMathematics for Business Students Worksheet No. 7 Solutionahmed wahshaNo ratings yet

- Good LabDocument23 pagesGood Labglories_No ratings yet

- Computer Applications (ICSE) Sample Paper 8Document4 pagesComputer Applications (ICSE) Sample Paper 8Guide For School77% (13)