Professional Documents

Culture Documents

Structural Steel Work Method Statement

Uploaded by

concretemadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Structural Steel Work Method Statement

Uploaded by

concretemadCopyright:

Available Formats

WORK METHOD STATEMENT STRUCTURAL STEEL

ORGANISATION DETAILS

Organisation Name: Gedoun Constructions Pty Ltd Contact Name: Joe Gedoun

ACN/ABN: 52 284 873 581 Contact Position: Director

Address: PO Box 1138, Townsville QLD 4810 Contact Phone Number: 0412 968 974

PROJECT DETAILS

Project: Gedoun Construction Sites Project Address: Gedoun Construction Sites

Project No: This WMS has been developed in consultation with: Joe Gedoun

Reviewed by: Stacy Jacobsen

Activity: Structural Steel Erection Position: Contract Administrator

Training/Instructions to be Site Induction Training Task Specific Training, Manual Handling Training

provided: OHS Induction Card Training Training Specified in any MSDS

Manual Handling Training Other (Specify): Workplace Specific Induction

Induction to this WMS

Resources/Trades Involved: Labourer and Tradesmen Engineering Hot work

Details/Certificates/EPA/QLD Work

Place Health & Safety Approvals:

Plant/Equipment Used: Boiler maker/Welder/Crane Operator/Dogman/Rigger Warning Signs and Controls As per Displayed Signage

Measures:

Details of Emergency Procedures: As per Site Safety Plan

Personal Protective High Visibility Clothing and Safety Footwear (Steel Safety Data Sheets Required: NIL

Equipment (PPE) to be used: Capped Boots) are to be worn by ALL worksites. Fire

retardant material long sleeve shirt, trousers, safety

helmet, safety glasses, rescue kit, low voltage insulating

gloves.

Task specific gloves, welding goggles.

WMS: STRUCTURAL STEEL Page 1 of 7

WORK METHOD STATEMENT STRUCTURAL STEEL

PROJECT DETAILS

Occupational Health Safety • Queensland Acts & Regulations Codes and/or Standards Applicable Building Code of Australia 2010

or Environmental Legislation: • Workplace Health & Safety Act 2011, Workplace to the Works: Queensland & National Codes of

Health & Safety Regulations 2011 Practice:

• Electrical Safety Act 2015, Electrical Safety • Building and Construction 2000

Regulations 2013 Updated 2011

• Building and Construction Industry Improvement • Noise 2004

Acts 2005 • Scaffold 2009

• Electrical 2013

• Manual Tasks 2010

• Plant 2013

• First Aid 2015

• Hazardous Substances 2011

• Prevention of Falls in Housing

Construction 2012

• Construction Work 2013

• Building Code of Australia 2015

• Hazardous Substance Code of

Practice 2003

National Standards:

• Risk Management AS/NZS150

31000:2009

• National Standard for

Construction Work NOSHC:1

016 (2005)

• National Standard for Manual

Tasks 2007

WMS: STRUCTURAL STEEL Page 2 of 7

WORK METHOD STATEMENT STRUCTURAL STEEL

HIGH RISK ACTIVITY: OPERATING A BOOM LIFT

JOB STEP POTENTIAL HAZARDS RISK SCORE CONTROLS RESIDUAL PERSON

(Before Control RISK RESPONSIBLE

Measures) (After Control

Measures)

L C R L C R

Staff Pre-Start Briefing - Unfamiliar with specific 4 3 12 - Contact site specific induction and daily pre-start 1 2 2 Project

site hazards meeting Manager/Site

- Unfamiliar with job - Brief employees on job requirements from scope of Supervisor

requirements works

- Changed plant conditions - General public interaction with project will require

- Aircraft hazards constant attention before any high risk activity is

undertaken

- Review work area to identify changed conditions.

- Ensure that airport control has been notified and all

conditions are met

Transport/Delivery’s - Unfamiliar with specific 4 3 12 - Brief the transport company on site requirements for 1 2 2 Project

site hazards delivery to site Manager/Site

- General public interaction - Have spotter in place when trucks arrive to minimise Supervisor

- Traffic movement risk of collision

- Set up barricading or spotter around the area to

unload trucks

Equipment Inspection - Plant/Equipment/Tools in 4 5 10 - Complete plant daily checks as required 2 1 2 Project

faulty condition - Inspect electrical tools to ensure they are in good Manager/Site

condition, no cuts in cables, electrical leads are Supervisor

tested, tagged and in date

- Inspect oxy/Act hoses, blow back arresters, gauges

and hand piece for defects

Site Delineation - Workers injury due to 4 5 20 - Exclusion zone nominated and controlled by 1 2 2 Site

unauthorised access of Supervisor Supervisor

exclusion zone - Men working above signs displayed at work areas

- Public entering area - Hard barricading off entry points to incomplete

walkways with information tag visible

- Ref – Boom lift SWMS

WMS: STRUCTURAL STEEL Page 3 of 7

WORK METHOD STATEMENT STRUCTURAL STEEL

HIGH RISK ACTIVITY: OPERATING A BOOM LIFT

JOB STEP POTENTIAL HAZARDS RISK SCORE CONTROLS RESIDUAL PERSON

(Before Control RISK RESPONSIBLE

Measures) (After Control

Measures)

L C R L C R

Site Delineation - Alert other trades to work

(Continued) - Visual awareness by all workers

- Erect barricades and restrict unauthorized access.

- Erect signage

Steel Erection - Personal injury 3 4 12 - Maintain good housekeeping procedures and 2 1 2 Work Team

- Slips & falls/Sprains & practices

Strains - Wear PPE correctly and correct fitting clothing

- Manual handling injuries - Store materials, tools and equipment properly

- Sprains, Strains, Trips, - Use correct manual handling practices and

Falls techniques

- Rotating Equipment - Use correct materials handling procedures

- Pinch points - Supervisors to monitor and ensure compliance

- Beware of rotating equipment

- Ref-Manual Handling SWMS

- Ref Working at Heights SWMS

- Unsecure structure 3 4 12 - Inspect area to be removed and look for items that 2 1 2 Work Team

- Falling objects may require supporting when other sections are

- Crushing/hit by object removed

- Equipment damage - Suitably prop any items that may be reliant of item

that is not connected

- Use only qualified riggers to connect loads and direct

loads

- Stay well clear of item when removing final

connection

- Never leave steel in an unsafe manner

(Unsecured/hanging at end of shift)

Oxy Acetylene Cutting 4 4 16 - Ensure that area is inspected for flammables and 2 1 2 Work Team

- Fire cleared before commencing

WMS: STRUCTURAL STEEL Page 4 of 7

WORK METHOD STATEMENT STRUCTURAL STEEL

HIGH RISK ACTIVITY: OPERATING A BOOM LIFT

JOB STEP POTENTIAL HAZARDS RISK SCORE CONTROLS RESIDUAL PERSON

(Before Control RISK RESPONSIBLE

Measures) (After Control

Measures)

L C R L C R

Steel Erection (Continued) - Burns - Ensure that correct P.P.E is worn when using oxy/Act

- Eye injury kit

- Explosion - Have spotter with appropriate fire extinguishers/hose

availability

- Ensure that Oxy/Act kit has been inspected before

using

Steel Erection Operating High Risk 4 4 16 - Inspect area where plant is to operate for stable 2 1 2 Work Team

Equipment ground conditions (No underground services, soft

- Falling from heights spots, trenchers or excavations)

- Hit by falling object - Ensure that the area is barricaded off, and all persons

- Hit by moving plant are aware of plant movement

- Crushed - Ensure that the appropriate P.P.E is worn in each

- Plant toppling over piece of plant

- Electrocution - Inspect area to operate plant for crush points before

moving, ensure that anyone working in that area is

aware of your movement

- Use spotter in confined areas to negate being hit or

crushed

- Do not allow anyone to work or operate below you

when working above, ensure that signage and

barricades are around area before commencing

- Ensure that plant has been inspected before

commencing works

- Is the equipment suitably for the task being

performed?

- Are the operators licensed and competent?

WMS: STRUCTURAL STEEL Page 5 of 7

WORK METHOD STATEMENT STRUCTURAL STEEL

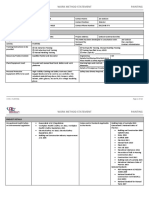

RISK MATRIX

CONSEQUENCES

LIKELIHOOD

INSIGNIFICANT (1) MINOR (2) MODERATE (3) MAJOR (4) CATASTROPHIC (5)

RARE (1) Low (1) Low (2) Low (3) Moderate (4) Moderate (4)

UNLIKELY (2) Low (2) Moderate (4) Moderate (6) Moderate (8) High (10)

POSSIBLE (3) Low (3) Moderate (6) Moderate (9) High (12) High (15)

LIKELY (4) Moderate (4) Moderate (8) High (12) Catastrophic (16) Catastrophic (20)

ALMOST CERTAIN (5) Moderate (5) High (10) High (15) Catastrophic (20) Catastrophic (25)

Catastrophic (16+) Then Work is unable to proceed. Seek other methods (Significant)

High (10 – 15) Then Permission from High Level Management for work to proceed (Significant)

If the residual risk is

Moderate (4 – 9) Then Permission from Worker in Charge for work to proceed (Insignificant)

Low (1 – 3) Then Work able to proceed (Insignificant)

1. Eliminate 2. Substitute 3. Isolate 4. Redesign 5. Administrative 6. PPE (Last Resort)

Substitute with a less

Redesign equipment or Introduce administrative

Eliminate the hazard hazardous material, Isolate the hazard Use appropriate PPE

work process controls

process or equipment

C= Consequence L= Likelihood

5= Catastrophic = Fatality, permanent disability, long term widespread 5= Almost Certain = It is almost certain that the risk will occur in most

impacts, huge financial loss circumstances

4= Major = Permanent disability or extensive injuries, medium to long term 4= Likely = The risk is likely to occur in most circumstances

widespread impact, major financial loss

3= Moderate = Lost time injury, reversible medium term local impact, high 3= Possible = There is uncertainty that the risk could occur

financial loss

2= Minor = Medical treatment, reversible short – medium term impact to local 2= Unlikely = The risk could occur at some time but there is confidence that it

area, medium financial loss will not

1= Insignificant = First aid, limited impact to minimal area, low financial loss 1= Rare = The impact/risk may occur only in exceptional circumstances

WMS: STRUCTURAL STEEL Page 6 of 7

WORK METHOD STATEMENT STRUCTURAL STEEL

I HAVE BEEN CONSULTED AND I ASSISTED IN DEVELOPPING THE WORK METHOS STATEMENTS THAT APPLY TO MY WORK ACTIVITIES.

I WILL COMPLY WITH ITS SAFE WORK PRACTICE.

PRINT NAMES POSITION/TRADE SIGNATURE DATE

JOE GEDOUN DIRECTOR/SITE MANAGER 16 October 2017

MATTHEW CARROLL SITE SUPERVISOR 16 October 2017

BOYD TURNER SITE SUPERVISOR 16 October 2017

CRAIG PENSINI SITE SUPERVISOR 16 October 2017

MONITORING AND REVIEWING OF WMS USE AND EFFECTIVENESS

NAME SIGNATURE DATE

STACY JACOBSEN 16 October 2017

WMS: STRUCTURAL STEEL Page 7 of 7

You might also like

- WMS Air ConditioningDocument23 pagesWMS Air Conditioningriyadigeng19gmailcomNo ratings yet

- Work Method Statement Tiling: Organisation DetailsDocument7 pagesWork Method Statement Tiling: Organisation DetailsKamagara Roland AndrewNo ratings yet

- Work Method Statement Plumbing: Organisation DetailsDocument12 pagesWork Method Statement Plumbing: Organisation DetailsShrikant BudholiaNo ratings yet

- Sample SWMS SP003 - Margate Parade Boardwalk Concrete WorkDocument10 pagesSample SWMS SP003 - Margate Parade Boardwalk Concrete WorkHaytham S. AtiaNo ratings yet

- Safe Demolition Method Statement & Risk AssessmentsDocument27 pagesSafe Demolition Method Statement & Risk Assessmentsmohamedamine.zemouriNo ratings yet

- Job Safety Analysis WorksheetDocument14 pagesJob Safety Analysis WorksheetCherry Betonio100% (2)

- 3.2 Method - Statement - For - Construction - of - Civil - WorksDocument23 pages3.2 Method - Statement - For - Construction - of - Civil - WorksJoseph EgonaNo ratings yet

- JSA For Erection & Dismantling of ScaffoldingDocument4 pagesJSA For Erection & Dismantling of ScaffoldingNoe AranelNo ratings yet

- Project Safety ChecklistDocument4 pagesProject Safety ChecklistAejaz Mujawar100% (1)

- Health, Safety, & Environment Manual: General Safety Requirement For Sub Structure Works (Foundation)Document4 pagesHealth, Safety, & Environment Manual: General Safety Requirement For Sub Structure Works (Foundation)rizal azizanNo ratings yet

- Piling Safety PlanDocument8 pagesPiling Safety PlanBalogun Isaac100% (1)

- JSA Formet New Structural Steel ErectionDocument11 pagesJSA Formet New Structural Steel Erectionsakthi venkatNo ratings yet

- Authorized Personnel Only PDFDocument1 pageAuthorized Personnel Only PDFsubhanmusadiq100% (1)

- Complete Office Fitout SWMSDocument30 pagesComplete Office Fitout SWMSPonraj MNo ratings yet

- Risk Assessment - Pull Out TestDocument12 pagesRisk Assessment - Pull Out TestMohsin MohdNo ratings yet

- 9 Method Statement For Floor TilesDocument10 pages9 Method Statement For Floor Tilesirfan khanNo ratings yet

- Method Statement For Construction - Designing Buildings Wiki PDFDocument5 pagesMethod Statement For Construction - Designing Buildings Wiki PDFKareemAdelNo ratings yet

- Job Safety Analysis WorksheetDocument4 pagesJob Safety Analysis WorksheetSAHIL SHARMANo ratings yet

- Ref: Section / Dept: Civil Activity: Risk Assessment For False CeilingDocument1 pageRef: Section / Dept: Civil Activity: Risk Assessment For False CeilingJack P100% (2)

- JSA For Erection Modification QSTECDocument7 pagesJSA For Erection Modification QSTECMohamed NouzerNo ratings yet

- SRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578Document9 pagesSRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578kkalvi100% (1)

- Part-A: Jsa Date: 23.11.16 Work Permit No: HW-: Civil Works Inside The Tank DykeDocument4 pagesPart-A: Jsa Date: 23.11.16 Work Permit No: HW-: Civil Works Inside The Tank DykevivekaramanaNo ratings yet

- Tower CarneDocument2 pagesTower CarnenabeelNo ratings yet

- Method Statement For Foundation InstallationDocument5 pagesMethod Statement For Foundation InstallationFrancis GonzalesNo ratings yet

- Safety Method StatementDocument14 pagesSafety Method StatementnayakyaNo ratings yet

- Method Statement: Emergency Contact DetailsDocument9 pagesMethod Statement: Emergency Contact DetailsShazwaniNo ratings yet

- 6.0 Method Statement and Risk AssessmentsDocument11 pages6.0 Method Statement and Risk Assessmentskumar sNo ratings yet

- Method Statement for Pile and Pile Cap Treatment WorksDocument11 pagesMethod Statement for Pile and Pile Cap Treatment Workssalman khanNo ratings yet

- Job Safety Analysis: Manual ExcavationDocument2 pagesJob Safety Analysis: Manual Excavationfdfddf dfsdfNo ratings yet

- EARTHWORKS SAFETYDocument4 pagesEARTHWORKS SAFETYsatti100% (2)

- Plumber - Drainer SWMSDocument12 pagesPlumber - Drainer SWMSallen2912100% (1)

- Method Statements 02 - Work at HeightDocument10 pagesMethod Statements 02 - Work at HeightMathewNo ratings yet

- Ehv SWP Form Scaffolding RemovalDocument2 pagesEhv SWP Form Scaffolding RemovalSn AhsanNo ratings yet

- SWP Brick LayingDocument3 pagesSWP Brick LayingHanis MuhamadNo ratings yet

- Contract Worker Welfare Management Plan - Short Duration TEMPLATEDocument16 pagesContract Worker Welfare Management Plan - Short Duration TEMPLATEMandhanNo ratings yet

- Demolition 4 PDFDocument19 pagesDemolition 4 PDFazrulNo ratings yet

- Hand Tool Risk AssessmentDocument1 pageHand Tool Risk AssessmentSijo RajanNo ratings yet

- SS JSP - 007 Excavation Work Using EquipmentDocument6 pagesSS JSP - 007 Excavation Work Using EquipmentFarhat SetharNo ratings yet

- Site Specific Safety PlanDocument4 pagesSite Specific Safety Planapi-315681725No ratings yet

- Risk AssessmentDocument3 pagesRisk AssessmentAkinbami Olorunnifemi100% (1)

- HSE-RA-025 Erecting, Dismantling and Maintanance of Tower Crane - Rev 0Document16 pagesHSE-RA-025 Erecting, Dismantling and Maintanance of Tower Crane - Rev 0عمروNo ratings yet

- Checklist Site and Security Fencing SchoolsDocument2 pagesChecklist Site and Security Fencing Schoolsakshay aryaNo ratings yet

- Formwork Safety Manual Section 3Document1 pageFormwork Safety Manual Section 3Rickesh Nunkoo100% (1)

- Ironbark: Safe Work Method Statement No. WMS-570 Task: Work Practice - Epoxy FlooringDocument12 pagesIronbark: Safe Work Method Statement No. WMS-570 Task: Work Practice - Epoxy Flooringklp_kedarpNo ratings yet

- Demolition Method Statement SummaryDocument86 pagesDemolition Method Statement SummaryEngr Nissar KakarNo ratings yet

- PM 01 Hira For Excavation of Boiler FoundationDocument3 pagesPM 01 Hira For Excavation of Boiler FoundationSyed Shariq Hassan100% (1)

- Jha - For Manhole ConstructionDocument2 pagesJha - For Manhole ConstructionChinedu AchilikeNo ratings yet

- Work Method Statement For Sub Structure Works: (Pile Cap)Document9 pagesWork Method Statement For Sub Structure Works: (Pile Cap)AlbawaviNo ratings yet

- Excavation Safety ChecklistDocument1 pageExcavation Safety ChecklistJoy BD0% (1)

- Job Hazard Analysis Worksheet: M-BCW-000DS0-GH00-JHA-000019Document13 pagesJob Hazard Analysis Worksheet: M-BCW-000DS0-GH00-JHA-000019Al Mughsar CompanyNo ratings yet

- MS 02 Earthwork Construction Method StatementDocument32 pagesMS 02 Earthwork Construction Method StatementAbdullah Al MarufNo ratings yet

- 007 MS - Kerb & Interlocking Tiles InstallationDocument3 pages007 MS - Kerb & Interlocking Tiles InstallationAnonymous iI88LtNo ratings yet

- Health and Safety T-NETDocument229 pagesHealth and Safety T-NETPieter HerbstNo ratings yet

- Tower Crane Work Permit ChecklistDocument1 pageTower Crane Work Permit Checklistfaisal nadeemNo ratings yet

- 10-F20 Fuel Driven Equipment InspectionDocument3 pages10-F20 Fuel Driven Equipment InspectionSn AhsanNo ratings yet

- JSA Template 5 - Plumbing and Wastewater System InspectionsDocument13 pagesJSA Template 5 - Plumbing and Wastewater System InspectionsSayed Darwish100% (2)

- SWMS Mobilisation of Blocks For MLT TEST RKDocument14 pagesSWMS Mobilisation of Blocks For MLT TEST RKrakeshkhanna78100% (1)

- Working at Heights Checklist1112222333Document1 pageWorking at Heights Checklist1112222333Shojib khan100% (2)

- WMS RoofingDocument10 pagesWMS RoofingAddis Mekuria100% (1)

- WMS Painting PDFDocument10 pagesWMS Painting PDFCamlockNo ratings yet

- Plan - Front Gate & Fencing: Inside OutsideDocument1 pagePlan - Front Gate & Fencing: Inside OutsideconcretemadNo ratings yet

- 01-List of DrawingDocument1 page01-List of DrawingconcretemadNo ratings yet

- Petty Cash Claim With GSTDocument1 pagePetty Cash Claim With GSTconcretemadNo ratings yet

- GM SK01Document10 pagesGM SK01concretemadNo ratings yet

- IsoDocument1 pageIsoconcretemadNo ratings yet

- TD140809pyc Crane BeamDocument2 pagesTD140809pyc Crane BeamconcretemadNo ratings yet

- Architect's instructions for 37-story apartment construction projectDocument2 pagesArchitect's instructions for 37-story apartment construction projectconcretemadNo ratings yet

- HAVroof 8Document1 pageHAVroof 8concretemadNo ratings yet

- 2Nd Floor - 6Th Floor Car Park 28 Nos/ Floor Total 140 Nos MP 7 NosDocument1 page2Nd Floor - 6Th Floor Car Park 28 Nos/ Floor Total 140 Nos MP 7 NosconcretemadNo ratings yet

- PDF 20x1429415461Document2 pagesPDF 20x1429415461concretemadNo ratings yet

- 50x Wood Stake Silt Fence DetailsDocument1 page50x Wood Stake Silt Fence DetailsconcretemadNo ratings yet

- Set Calculation - 150mm X 150mm RC PileDocument1 pageSet Calculation - 150mm X 150mm RC Pileconcretemad100% (1)

- Job Information: Engineer Checked ApprovedDocument6 pagesJob Information: Engineer Checked ApprovedconcretemadNo ratings yet

- BIM Coordinator Contract AECOM SingaporeDocument3 pagesBIM Coordinator Contract AECOM SingaporeconcretemadNo ratings yet

- PS 17 Free Fall Concrete PDFDocument1 pagePS 17 Free Fall Concrete PDFconcretemad100% (1)

- PS 17 Free Fall ConcreteDocument11 pagesPS 17 Free Fall ConcreteconcretemadNo ratings yet

- Design of Piles To EC2 and EC 7position Paper Nov11Document3 pagesDesign of Piles To EC2 and EC 7position Paper Nov11concretemadNo ratings yet

- Petty Cash Claim With GSTDocument1 pagePetty Cash Claim With GSTconcretemadNo ratings yet

- Properties of Soils AppendixDocument5 pagesProperties of Soils Appendixpinkuru100% (1)

- Design of Piles To EC2 and EC 7 (Position Paper) - Nov11Document2 pagesDesign of Piles To EC2 and EC 7 (Position Paper) - Nov11Namburu SomanadhNo ratings yet

- TennsDocument8 pagesTennsconcretemadNo ratings yet

- Petrol ClaimDocument1 pagePetrol ClaimconcretemadNo ratings yet

- Materials-Supply Stainless-Steel OrnamentalDocument5 pagesMaterials-Supply Stainless-Steel OrnamentalconcretemadNo ratings yet

- RoadDocument1 pageRoadconcretemadNo ratings yet

- Materials-Supply Stainless-Steel OrnamentalDocument5 pagesMaterials-Supply Stainless-Steel OrnamentalconcretemadNo ratings yet

- D E 1 - CHS: Calculation SheetDocument2 pagesD E 1 - CHS: Calculation SheetajayaghimireNo ratings yet

- Erection Method StatementDocument32 pagesErection Method StatementDilxan Fdo100% (4)

- GCN 012001 EngDocument15 pagesGCN 012001 EngconcretemadNo ratings yet

- Example 13Document9 pagesExample 13droates100% (1)

- Employment Assigment 3Document11 pagesEmployment Assigment 3ninaNo ratings yet

- The Assam Factories Rules, 1950 - 0Document167 pagesThe Assam Factories Rules, 1950 - 0সৌগত চৌধুৰীNo ratings yet

- SDS-Saati Remove ER2Document2 pagesSDS-Saati Remove ER2Liz CNo ratings yet

- Portfolio in Swine123Document9 pagesPortfolio in Swine123Felmarie OloyNo ratings yet

- Osh Profil Indonesia 18 7 2018Document66 pagesOsh Profil Indonesia 18 7 2018Erni Wiliyani ZMNo ratings yet

- FDS Aro Insecticida Rastreros 12.02.18Document12 pagesFDS Aro Insecticida Rastreros 12.02.18Ella Yurley RiañoNo ratings yet

- Safety and Health of StudentsDocument3 pagesSafety and Health of StudentsChong Yi ChengNo ratings yet

- Labour Hire Candidate Induction Manual 2Document31 pagesLabour Hire Candidate Induction Manual 2ncx9zqx8ftNo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingDocument14 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingmahmoudNo ratings yet

- Simulated BusinessDocument20 pagesSimulated BusinessTatiana GMNo ratings yet

- Manual HaloilaDocument248 pagesManual HaloilaVlad ChioreanNo ratings yet

- The International Institute of Welding (IIW), Its Potential Positive Influence in The World and Some National Models For Technology InnovationDocument13 pagesThe International Institute of Welding (IIW), Its Potential Positive Influence in The World and Some National Models For Technology InnovationMahmoud ElemamNo ratings yet

- Understanding Technological Responses of Industrial Firms To Environmental Problems: Implications For Government PolicyDocument16 pagesUnderstanding Technological Responses of Industrial Firms To Environmental Problems: Implications For Government PolicyMuiz SaddozaiNo ratings yet

- Hse Igi PracticaleDocument33 pagesHse Igi PracticaleAamirFarhanNo ratings yet

- 302 1006 003 Make Up750ml MEK United StatesDocument8 pages302 1006 003 Make Up750ml MEK United StatesLeonor Virginia GalindezNo ratings yet

- MSDS - Hydol HawDocument6 pagesMSDS - Hydol HawMeldi HidayatNo ratings yet

- CBC Security Services NC IIDocument64 pagesCBC Security Services NC IILee Sy LemNo ratings yet

- Hot Weather Heat Stress ProcedureDocument6 pagesHot Weather Heat Stress ProcedureJay-Jay JapsNo ratings yet

- A Study On Satisfaction of Female Workforce Regarding Their Safety at Workplace in Manufacturing SectorDocument7 pagesA Study On Satisfaction of Female Workforce Regarding Their Safety at Workplace in Manufacturing SectorInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Safety Issues in RetailDocument12 pagesSafety Issues in RetailpntsrmNo ratings yet

- Safety Data Sheet for Foam-Brite Coil CleanerDocument8 pagesSafety Data Sheet for Foam-Brite Coil CleanerFreddy FloresNo ratings yet

- Safety Data Sheet Highlights Key HazardsDocument8 pagesSafety Data Sheet Highlights Key HazardsVanessa BellidoNo ratings yet

- Toolbox Talk Series (Construction) : TOPIC: DustsDocument2 pagesToolbox Talk Series (Construction) : TOPIC: DustsHassanNo ratings yet

- Ar Clpi 2019Document176 pagesAr Clpi 2019Nauvan RistiyantoNo ratings yet

- Health AssessmentDocument37 pagesHealth Assessmentgr8_nurseNo ratings yet

- Manual HandlingDocument27 pagesManual HandlingAtinzz ChrizNo ratings yet

- Housing and HealthDocument11 pagesHousing and Healthapi-612975585No ratings yet

- Safety Data Sheet: Section 1. Identification of The Substance/mixture and of The Company/undertakingDocument9 pagesSafety Data Sheet: Section 1. Identification of The Substance/mixture and of The Company/undertakingdaniel ruizNo ratings yet

- TopyDocument64 pagesTopyChristiano Calijorne de BarrosNo ratings yet

- Food Safety Culture Program: Business AssuranceDocument20 pagesFood Safety Culture Program: Business AssuranceLisa April YantiNo ratings yet