Professional Documents

Culture Documents

Traction Control System Topic Seminar Paper

Uploaded by

Amar KeniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Traction Control System Topic Seminar Paper

Uploaded by

Amar KeniCopyright:

Available Formats

TRACTION CONTROL SYSTEMS

TABLE OF CONTENTS:

Sl.No. Title Page No.

1. Abstract 02

2. Introduction 03

3. History 04

4. Literature survey 05

5. Block diagram of traction control system (TRAC) 05

6. Working of traction control system 06

7. Case studies 07

8. Scope 08

9. Summary of review 09

10. TRAC system components of Toyota supra mark IV 10

11. TRAC wheel speed control 12

12. Benefits of traction control 13

13. Applications 14

14. Reference 15

P.E.S. College of Engineering 1

TRACTION CONTROL SYSTEMS

A TOPIC SEMINAR ON

“TRACTION CONTROL SYSTEMS”

By,

Vijay S

(USN – 4PS07ME093)

Department of Mechanical Engg,

P.E.S.C.E. Mandya.

ABSTRACT:

Car accidents dominate the transportation industry in regards to the number of

deaths that occur on the road, accounting for 94 percent. With over half a million car

wrecks every year, safety aspects, such as traction control, are being constantly developed

to keep drivers safer. By understanding modern-day safety features, drivers can stay well-

informed of potential aftermarket options for their vehicles to keep them safe. Traction

Control Systems is the modern day solution to the problems such as unnecessary skids

power loss due to less traction and railway track traction control. Whilst the old methods

such as limited slip differentials are getting inefficient to handle the critical driving

situations, need for a more advanced traction control system arises and henceforth comes

into picture the Electronic Traction Control System or the TRAC System.

This paper puts light to the modern Traction Control system basics, working,

benefits and applications while appreciating the history of the traction control systems

and present world utilizations.

P.E.S. College of Engineering 2

TRACTION CONTROL SYSTEMS

INTRODUCTION:

Traction refers to the maximum frictional force that can be produced between

surfaces without slipping. In auto mobiles traction is responsible for the movement of

vehicle. In the design of wheeled or tracked vehicles, high traction between wheel and

ground is more desirable than low traction, as it allows for more energetic acceleration

without wheel slippage.

Traction control is a technology designed to help your vehicle maintain traction,

no matter how slippery the road surface. Technically, it is a mechanical, hydraulic, or

electric system that maintains or controls traction to any wheels driven by the engine.

Unlike mechanical traction control systems of the past such as limited slip differentials,

today’s systems are nearly all computer-controlled as they actively watch wheel slip. An

option formerly reserved for performance, you can find traction control on all types of

vehicles today.

The purpose of the Traction Control System is to prevent wheel spin from

occurring due to acceleration. The maximum torque that can be transmitted to the wheels

is determined by the coefficient of friction generated between the road and the tires. If

torque exceeds that level, the wheels are likely to spin. Conditions for Traction operation

may include slippery road surfaces, acceleration while cornering and hard acceleration.

The basic idea behind the need of a traction control system is the difference

between the slips of different wheels or an apparent loss of road grip that may result in

loss of steering control over the vehicle which leads to slipping of the vehicle and loss of

power which results in uncontrolled cruising. Difference in slip may occur due to turning

of a vehicle or differently varying road conditions for different wheels. And thus need to

be controlled for a safer way to cruise.

P.E.S. College of Engineering 3

TRACTION CONTROL SYSTEMS

HISTORY:

Traction has always been the Achilles Heel of any vehicle. A perfectly capable car

or truck becomes completely useless when stuck in sand, mud, or snow. Early in the

development of the modern motor vehicle, engineers realized that 4-wheel drive (4WD)

was one answer. By sending engine power to all four wheels, at least one wheel would

have enough grip to pull the vehicle through. It was a brilliant discovery, but 4WD meant

that the vehicle would have to carry extra weight, complexity, and suffer the increased

fuel consumption associated with the 4WD drive train, even when it was not in use.

Traction control system uses a form of technology designed for aircraft in the

1950s called anti-lock brakes, or ABS. Aircraft engineers developed a system of

mechanical sensors to measure and detect when a wheel was skidding and hydraulically

release the braking force on that wheel. With an ABS system, an aircraft could apply

brake with maximum stopping power without skidding, regardless of weather conditions.

With further development, automotive engineers realized they could “reverse” the

operation of the ABS to build an effective traction control system using the same sensors.

One hundred years after the development of the automobile, microcomputer

technology has finally solved the traction puzzle. In 1987, the earliest innovators of

automotive vehicles, Mercedes-Benz and BMW, introduced their first traction control

systems. Traction Control was first introduced on the 1994 Turbo Supra and expanded to

include the six cylinder Camry and Avalon models in 1997.

Recently in the motorsport sector traction control system is given a red flag by

International Automobile Federation as it banned use of traction control in races effective

from 2008. Apart from that when it comes to performance and safety, Traction control

system dominates the world automobile sector.

P.E.S. College of Engineering 4

TRACTION CONTROL SYSTEMS

LITERATURE SURVEY:

BLOCK DIAGRAM OF TRACTION CONTROL SYSTEM (TRAC):

Fig 1

P.E.S. College of Engineering 5

TRACTION CONTROL SYSTEMS

WORKING OF TRACTION CONTROL SYSTEM:

A simple input output process block diagram is given in figure 1 and various

inputs are shown on the left side. The process control unit is represented in the middle

part if the figure. Right side blocks of the diagram shows the various controlled outputs

for the TRAC system.

The main inputs for a TRAC system are wheel speed sensors, battery level sensor,

TRAC OFF switch, stop light switch, and the throttle position sensor. These inputs give

speed signal, remaining battery signal, OFF signal, stop signal and throttle level signal

respectively.

The processing part consists of an Anti-lock Braking System (ABS) or a TRAC

Electronic Control Unit (TRAC ECU) and an Engine Control Modulator (ECM). The

TRAC ECU will have an interconnection with ECM in order to communicate to the

engine throttle position control. These processing units process and analyze the input

signals and take necessary output actions if required.

The controlled outputs of a TRAC system are solenoids actuator, pump motor

actuator, slip indicator light, TRAC OFF light, ABS warning light, injectors control, and

solenoid valve actuator.

The control action can consist of one or more actions such as reducing or suppress

the spark to one or more cylinders, reducing fuel supply to one or more cylinders, brake

one or more wheels, close the throttle where vehicle is fitted with ECM controlled

throttle, and the boost control solenoid can be actuated to reduce boost and therefore

engine power. The controlled action of the one or more of the above outputs can help in

traction control of the vehicle resulting in a slip proof cruising of the vehicle irrespective

of the external weather conditions.

P.E.S. College of Engineering 6

TRACTION CONTROL SYSTEMS

CASE STUDIES:

1. The predecessor of modern electronic traction control systems can be found in

high-torque, high-power rear-wheel drive cars as a limited slip differential.

Limited slip differential is a purely mechanical system that transfers a relatively

small amount of power to the non-slipping wheel, but it still allows some wheel

spin to occur.

2. In 1971 the Buick division of GM introduced MaxTrac, which used an early

computer system to detect rear wheel spin and modulate engine power to those

wheels to provide the most traction. A Buick-exclusive at the time, it was an

option on all full-size models, including the Riviera, Estate Wagon, Electra 225,

Centurion, and popular LeSabre family sedan.

3. Traction control for a production motorcycle was first available with the Honda

ST1100 in 1992. By 2009, traction control was an option for several models

offered by BMW and Ducati, and the model year 2010 Kawasaki Concours 14

(1400GTR).

4. Mitsubishi's modern Active Skid and Traction Control (ASTC) system which was

developed to help the driver maintain the intended path through a corner, an

onboard computer monitored several vehicle operating parameters through the use

of various sensors.

5. In the design of wheeled or tracked vehicles, high traction between wheel and

ground is more desirable than low traction, as it allows for more energetic

acceleration including cornering and braking without wheel slippage. One notable

exception is in the motorsport technique of drifting, in which rear-wheel traction

is purposely lost during high speed cornering.

P.E.S. College of Engineering 7

TRACTION CONTROL SYSTEMS

SCOPE:

Spinning the tires not only makes the car harder to drive, but it also causes higher

tire temps and excessive tire wear. Lifting off the throttle or counter steering to correct for

this 5% mistake, not only upsets the rhythm, it slows the car down. Typically, if a driver

makes a 5% mistake with the throttle, he/she has to correct 20-25% to fix it. But if the tire

slip is detected within one cylinder worth of crank rotation, as the Davis Technologies

systems do, then a small reduction in power can reduce or stop the tire slip.

The Non Self-Learning systems, such as Traction Maintenance System (TMS),

periodically compare the rate of acceleration of the crankshaft to an Adjustable Fixed

Rate (AFR), known as Threshold. If the Engine RPM rate of change is in excess of that

Threshold, then a correction is made; therefore, reducing the slip.

Basically, the TRAC system looks for spikes in RPM that are caused by wheel

slip. If these spikes are large enough, then a correction is made, reducing the slip. By

adjusting the Threshold, the driver can tune the system to the desired "feel".

Self-Learning systems, such as our TMS-750-SL, TMS-5500-SL, and TMS-9500-

SL series, which were introduced by Davis Technologies, can compare the rate of

acceleration of the crankshaft to a calculated threshold value that is constantly updated

based on the average of the previous measurements. This update occurs on every

crankshaft revolution.

Through this very advanced control process, the system constantly accounts for

track conditions, tire condition, even driving style to constantly update the internal

settings. These settings are updated as many as 200 times a second to keep the unit

calibrated to exactly the right settings regardless of changing conditions. This allows the

P.E.S. College of Engineering 8

TRACTION CONTROL SYSTEMS

system to adjust to the correct settings even if one corner has more grip than another or

one grooves to another.

The user does have an adjustment referred to as “Mode” that sets the overall

sensitivity of the system to make a correction based the extent of the tire slip. By

adjusting the Mode, the driver can tune the system to the desired TRAC control level.

The speed and learning capabilities of these systems is what makes the best

traction control on the market today. Allowing you to focus on chassis set-up, and not be

distracted by constantly having to adjust your traction control settings, as with systems

that work on a percentage of slip between the front and rear wheels.

SUMMERY OF REVIEW:

Traction control helps limit tire slip in acceleration on slippery surfaces. Powerful

rear-drive cars from the sixties often had a primitive form of traction control called a

limited slip differential helping to reduce, but not eliminate wheel spin. While limited-slip

rear axles are still in use in many front- and rear-drive vehicles today, the device can't

completely eliminate wheel slip. Hence, a more sophisticated system was needed.

Enter electronic traction control. In modern vehicles, traction-control systems

utilize the same wheel-speed sensors employed by the antilock braking system. These

sensors measure differences in rotational speed to determine if the wheels that are

receiving power have lost traction. When the traction-control system determines that one

wheel is spinning more quickly than the others, it automatically applies brake to that

wheel to reduce its speed and lessen wheel slip. In most cases, individual wheel braking is

enough to control wheel slip. Therefore for drivers who routinely drive in snowy and icy

conditions, traction control is a must-have safety feature.

P.E.S. College of Engineering 9

TRACTION CONTROL SYSTEMS

TRAC SYSTEM COMPONENTS OF TOYOTA SUPRA MARK IV:

Fig 2

P.E.S. College of Engineering 10

TRACTION CONTROL SYSTEMS

The Toyota Supra is a sports car that was produced by Toyota Motor Company

from 1979 to 2002. It introduced TRAC system in model “Supra Mark IV” in the year

1994. It was most notable is the separate TRAC actuator and ABS actuator in 1993 till

1995. Engine torque is controlled via a sub-throttle actuator which controls the sub-throttle

ahead of the valve in the throttle body.

The TRAC System reduces engine torque and rear wheel speed as necessary to

bring the vehicle under control. The ABS ECU, TRAC ECU and ECM all work together

to provide traction control. ABS speed sensors are monitored by the TRAC ECU which in

turn controls a sub-throttle plate and applies the rear brakes. The ECM also retards engine

timing while the ABS modulates pressure at the rear brakes.

The supra TRAC system is represented in figure 2 of previous page. The TRAC

OFF switch is located on the instrument panel above the center console. It allows the

driver to activate or deactivate the TRAC system when the switch is depressed. The

system defaults to ON when the ignition switch is cycled.

The Sub-Throttle Actuator uses a step motor located between the main throttle

valve and air cleaner. It is fitted on the throttle body and controls the position of the sub-

throttle valve based on commands made by the TRAC ECU thus controlling the engine

output.

Sub-Throttle Position sensor is fitted to the sub-throttle valve shaft. It converts the

sub-throttle valve opening angle to a voltage signal and sends this signal to the TRAC

ECU via the ECM (Engine ECU). The sensor is built and operates in the same way as the

main Throttle Position Sensor.

Apart from the above explained components all the remaining operational

components work in the same way that of explanation to the block diagram of TRAC

system.

P.E.S. College of Engineering 11

TRACTION CONTROL SYSTEMS

TRAC WHEEL SPEED CONTROL:

Fig 3

Figure 3 shows a graph of wheel speed control against time taken to control. It

is basically representing the accuracy of the TRAC system for a particular wheel speed

control range.

When the accelerator pedal is depressed the main throttle opens resulting in

generation of more torque. If the TRAC system identifies excessive torque than required

causing one or more wheels to spin, then it applies brake to those wheels in small amount.

This braking action is intermittent till the wheel speed is reduced to the desired range for

safe cruising.

We can observe the highs and lows in the graph representing increased wheel

speed and TRAC wheel speed controlling action respectively. Finally it comes to the

required speed range and TRAC system stops controlling action and goes back to

monitoring state.

P.E.S. College of Engineering 12

TRACTION CONTROL SYSTEMS

BENEFITS OF TRACTION CONTROL:

Traction control systems bring overall improvement in the braking system of the

car. Here are a few of the benefits:

1. Traction control brake systems are helpful in avoiding accidents over low-traction

road surfaces.

2. The system assists in maintaining control over the car during sudden twists and

sharp turns on the road.

3. Slippage of the wheels during aggressive braking is prevented avoiding accidents.

4. A reduction in stopping distances after the brakes are applied can help in traffic.

5. TRAC system maintains directional control after breaking and reduces skidding.

6. Traction control is beneficial when roads are wet and icy as it helps in accelerate

from a stop.

7. Traction control is helpful when you're driving a powerful car as it regulates the

power to the tires, keeping the car on the path you set.

8. Wheels cannot lock up suddenly as the grooving is avoided by ABS system

control.

9. In case of huge truck applications TRAC system can help in accelerating as well

as stopping efficiently.

10. When accelerating, it gives you more traction because when you accelerate, more

weight shifts towards the rear.

11. By applying pressure to the slipping wheel, power is sent to the drive wheel with

the most gripping.

P.E.S. College of Engineering 13

TRACTION CONTROL SYSTEMS

APPLICATIONS:

There are many sectors in which Traction control system finds itself useful.

Here are few practical applications of TRAC System:

1. In road cars: Traction control has traditionally been a safety feature in high-

performance cars, which would otherwise need very sensitive throttle input to

keep them from spinning the driven wheels when accelerating, especially in wet,

icy or snowy conditions. In recent years, traction control systems have become

widely available in non-performance cars, minivans, and light trucks.

2. In race cars: Traction control is used as a performance enhancement, allowing

maximum traction under acceleration without wheel spin. When accelerating out

of turn, it keeps the tires at the optimum slip ratio.

3. In motorcycles: Traction control for a production motorcycle was first available

with the Honda ST1100 in 1992. By 2009, traction control was an option for

several models offered by BMW and Ducati, and the model year 2010 Kawasaki

Concours.

4. In off road vehicles: Traction control is used instead or in addition to the

mechanical limited slip differential. It is often implemented with an electronic

limited slip differential as well as other computerized control of the engine and

transmission. Generally used in railway track traction control systems.

5. Traction control is not just used for improving acceleration under slippery

conditions. It can also help a driver to corner more safely. If too much throttle is

applied during cornering, the drive wheels will lose traction and slide sideways.

This will be avoided by TRAC system and helps the driver in cornering.

P.E.S. College of Engineering 14

TRACTION CONTROL SYSTEMS

REFERENCE:

1. “Mechanical Wear Fundamentals and Testing” – Dr. Raymond Bayer, CRC Press.

2. “Theory of ground vehicles” - Prof. Jo Yung Wong, Carleton University, Canada.

3. “Traction Control and other electronic trickery” – Prof. Andrew Trevitt, California

State University.

4. “How stuff works - TRAC System” - Davison technologies, U.S.A.

5. "Work-Related Roadway Crashes - Challenges and Opportunities for Prevention"

- Stephanie G. et al. The National Institute for Occupational Safety and Health.

6. “AUTOSHOP 101” - Kevin Sullivan, Washington Post journalist.

P.E.S. College of Engineering 15

You might also like

- Improving VehicleDocument25 pagesImproving VehicleArun Kumar0% (1)

- Traction Control SystemsDocument20 pagesTraction Control SystemsVijay Shivakumar100% (4)

- Motorcycle Traction Control System ExplainedDocument33 pagesMotorcycle Traction Control System ExplainedMahaManthraNo ratings yet

- Report of Intelligent Braking SystemDocument29 pagesReport of Intelligent Braking SystemHarsh Gaming100% (3)

- Intelligent Braking System Using MicrocontrollerDocument6 pagesIntelligent Braking System Using MicrocontrollerJyotsanaTrivedi100% (1)

- ABS PresentationDocument17 pagesABS PresentationRahul PatilNo ratings yet

- Project Report Intelligent Breaking System 2Document30 pagesProject Report Intelligent Breaking System 2sagar89% (9)

- Intelligent Braking System Literature ReviewDocument39 pagesIntelligent Braking System Literature ReviewRaj WagdariNo ratings yet

- Intelligent Braking System Using MicrocontrollerDocument6 pagesIntelligent Braking System Using Microcontrollermukesh100% (1)

- Electronic Brake Force DistributionDocument17 pagesElectronic Brake Force Distributionvikas suryawanshi67% (3)

- Electronic Stability ProgrammeDocument11 pagesElectronic Stability Programmen_amarsinh9938100% (3)

- Sensotronic Brake ControlDocument23 pagesSensotronic Brake Controlsai ramanaNo ratings yet

- Electronic Brake Force Distribution Optimizes BrakingDocument26 pagesElectronic Brake Force Distribution Optimizes Brakingvikas suryawanshi50% (4)

- Automatic Braking System for VehiclesDocument82 pagesAutomatic Braking System for Vehiclesbalabooks100% (1)

- Literature Review of Steering SystemDocument2 pagesLiterature Review of Steering SystemGirish Mujawar100% (1)

- Traction CONTROLDocument18 pagesTraction CONTROLkiransideasNo ratings yet

- Anti Lock Braking SystemDocument22 pagesAnti Lock Braking SystemAbhay Yadav0% (2)

- Button Operated Electromagnetic Gear ChangerDocument64 pagesButton Operated Electromagnetic Gear ChangermkkfakesNo ratings yet

- Active Suspension SystemDocument18 pagesActive Suspension Systemvishnu Murali50% (2)

- Research Seminar on Air Suspension SystemsDocument15 pagesResearch Seminar on Air Suspension SystemsParth SawantNo ratings yet

- Traction ControlDocument15 pagesTraction Controllahari kuditala100% (1)

- Electro-Magnetic Breaking-Black BookDocument48 pagesElectro-Magnetic Breaking-Black BookAnjali BiramaneNo ratings yet

- SBC Seminar on Sensotronic Brake ControlDocument16 pagesSBC Seminar on Sensotronic Brake ControlAnand Kesarkar100% (1)

- Intelligent Braking System-Vehicle ModelDocument21 pagesIntelligent Braking System-Vehicle ModelVimal C Vijayan100% (1)

- 4.accident Avoiding System For Cutting MachineDocument5 pages4.accident Avoiding System For Cutting MachineIyappanNo ratings yet

- Automatic Air SuspentionDocument18 pagesAutomatic Air Suspentionashu047No ratings yet

- Project Report On Hydraulic Disc BrakesDocument55 pagesProject Report On Hydraulic Disc BrakesNithinReddy78% (40)

- Unit 1 Me8091 Automobile EngineeringDocument16 pagesUnit 1 Me8091 Automobile EngineeringRakeshkumarceg100% (3)

- Modern Brake SystemDocument24 pagesModern Brake Systemfadhilah91No ratings yet

- ABSDocument18 pagesABSRizan Saop79% (14)

- Automotive Chassis Control Q&ADocument14 pagesAutomotive Chassis Control Q&ANandakumar BasavarajNo ratings yet

- 8.0 Brake by Wire Ja505Document16 pages8.0 Brake by Wire Ja505Nareesh RajNo ratings yet

- Sensotronic Brake Control System Accelerating New TechDocument9 pagesSensotronic Brake Control System Accelerating New TechAnand KesarkarNo ratings yet

- Suspension Control SystemsDocument39 pagesSuspension Control SystemsKRISHNAPRIYANo ratings yet

- Internship ReportDocument37 pagesInternship ReportLemi Chala Beyene0% (1)

- Abuki Anti Lock Braking SystemDocument20 pagesAbuki Anti Lock Braking SystemAbubaker MuzayinNo ratings yet

- Four Wheel Steering System Full Seminar ReportDocument19 pagesFour Wheel Steering System Full Seminar ReportYashwanth Raj50% (6)

- Mech Sensotronic Brake Control ReportDocument25 pagesMech Sensotronic Brake Control ReportArmin PalalicNo ratings yet

- Four-Wheel Steering ReportDocument21 pagesFour-Wheel Steering ReportMuralee Dharan PillaiNo ratings yet

- A Seminar-Report: Topic Air Brake System of Indian RailwaysDocument9 pagesA Seminar-Report: Topic Air Brake System of Indian RailwaysVineet Yadav100% (1)

- Automobile Engineering NotesDocument120 pagesAutomobile Engineering Notesakshay2992No ratings yet

- Vishwakarma Institute of Technology: A Seminar Report OnDocument17 pagesVishwakarma Institute of Technology: A Seminar Report OnAmir RNo ratings yet

- Regenerative Braking SystemDocument15 pagesRegenerative Braking SystemVinay KumarNo ratings yet

- ABS Seminar ReportDocument27 pagesABS Seminar ReportPrem Shankar Singh29% (7)

- CNC Report1Document55 pagesCNC Report1coolguy02088775% (4)

- Fabrication of Automatic Side Stand Braking Mechanism For Two WheelerDocument28 pagesFabrication of Automatic Side Stand Braking Mechanism For Two Wheelergnana muruganNo ratings yet

- Unit I:: Design of Vehicle Body For SafetyDocument47 pagesUnit I:: Design of Vehicle Body For Safetyduraisvce75% (8)

- Electronic Ignition SystemDocument13 pagesElectronic Ignition SystemRahul Rai100% (8)

- Electromagnetic Braking System ExplainedDocument28 pagesElectromagnetic Braking System ExplainedTanvi Khurana83% (6)

- Steer-by-wire tech removes mechanical linksDocument12 pagesSteer-by-wire tech removes mechanical linksTarun Gupta50% (2)

- Anti-Lock Braking SystemDocument32 pagesAnti-Lock Braking SystemShehryar KhanNo ratings yet

- Flywheel Energy Storage System: Bachelor of TechnologyDocument13 pagesFlywheel Energy Storage System: Bachelor of Technologymadhu kotlaNo ratings yet

- Air Braking System in Indian RailwayDocument22 pagesAir Braking System in Indian RailwayClassic Printers100% (1)

- Sensors in Engine Management SystemsDocument19 pagesSensors in Engine Management SystemsRohit RajNo ratings yet

- Traction Control SystemDocument1 pageTraction Control SystemMeghana ChennaNo ratings yet

- "Traction Control Systems": Seminar OnDocument7 pages"Traction Control Systems": Seminar OnAmar KeniNo ratings yet

- Traction Control Systems Seminar ReportDocument17 pagesTraction Control Systems Seminar ReportMubashir HussainNo ratings yet

- Adhwaresh Poster Traction ControlDocument1 pageAdhwaresh Poster Traction ControlAdhwareshBharadwajNo ratings yet

- Toaz - Info Traction Control Seminar PRDocument33 pagesToaz - Info Traction Control Seminar PRDHANUSH B MNo ratings yet

- Mitsubushi's Torque Vectoring TechnologyDocument8 pagesMitsubushi's Torque Vectoring TechnologyVaisakh N NairNo ratings yet

- Highway Horizontal Alignment DesignDocument76 pagesHighway Horizontal Alignment DesignUsama AliNo ratings yet

- BRC PDFDocument111 pagesBRC PDFCarlos Tito AmésquitaNo ratings yet

- VoloDocument2 pagesVoloLION KINGNo ratings yet

- Bykea On-Demand Ride Hailing and Parcel DeliveryDocument11 pagesBykea On-Demand Ride Hailing and Parcel DeliveryClassic VinesNo ratings yet

- Supplier RelationshipsDocument9 pagesSupplier RelationshipsArun Sfrh100% (1)

- Dost Steel Container PDFDocument2 pagesDost Steel Container PDFSyambabuNo ratings yet

- 2011 ACCatalogDocument132 pages2011 ACCatalogAgus Yulfizar50% (2)

- Submitted By: (Logistics and Shipping)Document24 pagesSubmitted By: (Logistics and Shipping)അന്തോണി നായർNo ratings yet

- Wiper Blades Products and ApplicationsDocument32 pagesWiper Blades Products and ApplicationsEndar T. PrakosoNo ratings yet

- Chap 1 IntroductionDocument80 pagesChap 1 IntroductionNick Seiff PatrickNo ratings yet

- Parking Policy DhakaDocument13 pagesParking Policy DhakaShahriazAlamNo ratings yet

- Tensar TX GeogridsDocument20 pagesTensar TX GeogridsNarendra Goud100% (1)

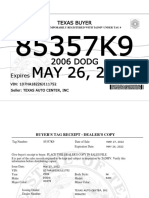

- Texas Dodge Ram Buyer ReceiptDocument3 pagesTexas Dodge Ram Buyer ReceiptCanojessyNo ratings yet

- Vortex Interaction and Breakdown Over Double-Delta WingsDocument8 pagesVortex Interaction and Breakdown Over Double-Delta WingsFHStallsNo ratings yet

- Eslam Ibrahim: SAP AMS Project Team Lead/ SAP SCM & PLM Senior Consultant - UAE Armed ForcesDocument5 pagesEslam Ibrahim: SAP AMS Project Team Lead/ SAP SCM & PLM Senior Consultant - UAE Armed ForcesM Akhtar MehtabNo ratings yet

- 2022-04-13 BMW X7 FLDocument20 pages2022-04-13 BMW X7 FLMarcelo CostaNo ratings yet

- REHS9597-19 Repair of Large Wheel Loader Lift Arms and LeversDocument26 pagesREHS9597-19 Repair of Large Wheel Loader Lift Arms and LeversCarlosNo ratings yet

- Placing Boom Pumping Unit Driven by Chassis 3 Axles: Truck-Mounted Concrete Boom PumpDocument2 pagesPlacing Boom Pumping Unit Driven by Chassis 3 Axles: Truck-Mounted Concrete Boom Pumpabo omrNo ratings yet

- Retirement Village Brandon Park Drive Development Plan Part 1Document5 pagesRetirement Village Brandon Park Drive Development Plan Part 1Property TwelveNo ratings yet

- Aerial Lift Safety PowerPointDocument28 pagesAerial Lift Safety PowerPointLal Kishan100% (1)

- USDA Guide to Developing a Food Defense PlanDocument15 pagesUSDA Guide to Developing a Food Defense PlannmmartinsaNo ratings yet

- ABS VOC - Template070210 GTDocument25 pagesABS VOC - Template070210 GT..No ratings yet

- Front Side Silver Paste 653G SDS - GENERAL - TEXANOL (English Version) V2.7 (PB)Document6 pagesFront Side Silver Paste 653G SDS - GENERAL - TEXANOL (English Version) V2.7 (PB)Desheng ChewNo ratings yet

- A Review of Battery Fires in Electric VehiclesDocument38 pagesA Review of Battery Fires in Electric VehiclesOleksandr Lazarenko100% (1)

- LJMB ChartDocument6 pagesLJMB ChartTemizel BoraNo ratings yet

- PARTS - EC M3040-M3540-M3550-M3560idnENPLR5Document40 pagesPARTS - EC M3040-M3540-M3550-M3560idnENPLR5Rômulo Baldotto RibeiroNo ratings yet

- Map Seminole County Country ClibDocument1 pageMap Seminole County Country ClibAnthonyNo ratings yet

- Document 1625498300Document21 pagesDocument 1625498300kerrycurchinNo ratings yet

- 1 s2.0 S0967070X23003049 MainDocument17 pages1 s2.0 S0967070X23003049 MainAmin AminiNo ratings yet

- Maharashtra Jeevan Pradhikaran Rate Analysis 2012 2013Document177 pagesMaharashtra Jeevan Pradhikaran Rate Analysis 2012 2013ulhas_nakasheNo ratings yet