Professional Documents

Culture Documents

2.11 FinalReport MFL-DMR-GEO EXAMPLE PDF

Uploaded by

saminasritnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2.11 FinalReport MFL-DMR-GEO EXAMPLE PDF

Uploaded by

saminasritnCopyright:

Available Formats

Final Report for

CLIENT

COUNTRY

on the GEO & MFL/DMR in-line inspection of the

10” PIPELINE

from START to END

Summary

The inspection of the 10” PIPELINE from START to END was executed on MONTH DAY, YEAR.

Internal metal loss: A total of 303 indications of internal metal loss are reported. The deepest

one with a depth of 36% (relative to the adjacent, unaffected pipe wall) is located at a

distance of 1651m, about 148m upstream the marker M5.

External metal loss: A total of 609 indications of external metal loss are reported. The two

deepest ones with a depth of 65%, already mentioned in the Preliminary Report, are located

at a distance of 77m and 856m, 189m downstream of marker M3.

Mill anomalies: There are 35 mill anomalies detected. The most significant ones are located at

15m and 345m with a contingency depth of 18%.

Girth weld anomalies: Three girth welds show irregularities. One of them is reported as

‘incomplete root’.

Geometric anomalies: There are 20 geometric anomalies reported. The deepest one is

reported with 1.8% reduction (relative to the outer diameter of the pipe) at 1604m, 195m

upstream of marker M5.

Inspection date: MONTH DAY, YEAR

Report date: MONTH DAY, YEAR

10” PIPELINE

Final Report

Content

1 Background 3

2 Results 3

2.1 Data quality & completeness 3

2.2 Metal loss 4

2.2.1 Internal metal loss 5

2.2.2 External metal loss 6

2.3 Interaction rules 8

2.4 Remaining Strength estimation 8

2.5 Other features 10

2.5.1 Mill anomalies 10

2.5.2 Girth weld anomalies 11

2.5.3 Geometric anomalies 12

2.6 Marker 12

2.7 Data deliverables 12

2.7.1 Raw data 12

2.7.2 Interpreted data 12

3 Pipeline Data 13

4 Inspection preparation & performance 13

4.1 Inspection task 13

4.2 Preparation of the pipeline 13

4.2.1 Inspection procedure 13

4.2.2 Cleaning and Gauging of the pipeline 14

4.3 High Resolution GEO Inspection 14

4.3.1 GEO tool applied 14

4.3.2 GEO tool settings 15

4.3.3 GEO tool performance 15

4.4 High Resolution MFL-Inspection 17

4.4.1 MFL tool applied 17

4.4.2 MFL tool settings 17

4.4.3 MFL tool performance 17

5 Attachments 19

6 Reference Specifications, Codes and Standards 19

7 Report Details 19

2.0 Hardcopy

1.0 Issue for client review

Vers. Description Written by Checked by Approved by Date

Report No.: Contract No.: Proposal No.:

Report Date: MM DD, YYYY page 2 of 19

10” PIPELINE

Final Report

1 Background

The 10” PIPELINE from START to END was built in 1968 and has never been inspected before.

2 Results

2.1 Data quality & completeness

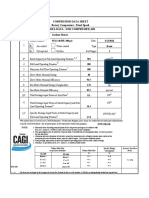

The inspection of the 10” PIPELINE from START to END was executed on MONTH DAY, YEAR.

The recorded sets of data are complete and of good quality. This allows an interpretation over

the entire length of the pipeline.

data Data

Type of data remarks

completeness quality

Axial distance

complete good all distance counts are aligned

record

Circumferential

complete good

position record

MFL 100% good

GEO 100% good

DMR 100% good

The zero point position of the distance count is set on the weld after the isolation valve at the

polyethylene unit.

Report Date: MM DD, YYYY page 3 of 19

10” PIPELINE

Final Report

2.2 Metal loss

The indications of metal loss are reported quantitatively if the depth is ≥10% of the adjacent,

unaffected pipe wall. The table below shows the total number of metal loss features detected

by depth classes.

internal external

depth total

in body of in body of

weld area weld area

pipe pipe

≥70% - - - - -

60% to <70% - - 7 - 7

50% to <60% - - 8 - 8

40% to <50% - - 12 1 13

30% to <40% 1 - 40 - 41

20% to <30% 5 2 162 1 170

10% to <20% 273 22 376 2 673

Total 279 24 605 4 912

Further there are 652 “minor indications” (MIIDs) reported. These show small but clearly

visible signals, where it becomes difficult or impossible to distinguish between metal loss, mill

defect, debris or other influences. Should any of those indications be metal loss, their depth

will not exceed 10%.

Report Date: MM DD, YYYY page 4 of 19

10” PIPELINE

Final Report

2.2.1 Internal metal loss

A total of 303 indications of internal metal loss are reported. The deepest one with a depth of

36% is located at a distance of 1651m, about 148m upstream the marker M5.

Fig. 1: Distribution of internal metal loss over the pipeline length

Fig. 2: Distribution of internal metal loss over the pipeline length and circumference

Fig. 1 & Fig. 2 show no accumulations of internal metal loss over the entire length and

circumference of the pipeline.

Report Date: MM DD, YYYY page 5 of 19

10” PIPELINE

Final Report

Fig. 3: Distribution of internal metal loss to closest girth weld and circumference

2.2.2 External metal loss

A total of 609 indications of external metal loss are reported. The two deepest ones with a

depth of 65%, already mentioned in the Preliminary Report, are located at a distance of 77m

and 856m, 189m downstream of marker M3.

Fig. 4: Distribution of external metal loss over the pipeline length

Report Date: MM DD, YYYY page 6 of 19

10” PIPELINE

Final Report

Fig. 5: Distribution of external metal loss over the pipeline length and circumference

Fig. 4 & Fig. 5 show an accumulation of external metal loss at a distance of 77m.

Fig. 6: Distribution of external metal loss to closest girth weld and circumference

Report Date: MM DD, YYYY page 7 of 19

10” PIPELINE

Final Report

2.3 Interaction rules

Interaction rules are applied to the individual anomalies. By default individual

anomalies are clustered by the ‘multiple of minimum extent’ following the interaction

rules [POF09]:

1. An anomaly shall never be clustered with another adjacent anomaly if the distance

(X/Y) is ≥6t (t: wall thickness). This is applicable for the axial and circumferential

direction.

2. Individual anomalies shall be clustered when the axial spacing between the

anomalies is less than the smallest anomaly length (X1) and the

circumferential spacing is less than the smallest anomaly width (Y1).

Fig. 7: Clustering method overview

Clustered features are reported with their accumulated length and width and their maximum

depth.

2.4 Remaining Strength estimation

In the Feature List included is an estimation of the Remaining Strength for dimensioned metal

loss features from the supplement to ANSI/ASME B31 code. The model “ASME B31G - 2009”

according to GESIP is applied within this calculation. Detailed information about the Remaining

Strength calculation can be found in Att. 3.

The applied parameters are:

term Parameter value unit remarks

measured maximum depth of

d mm from data interpretation

corroded area

measured longitudinal extent of

L mm from data interpretation

corroded area

D nominal outside diameter of the pipe 273.1 mm specified by operator

t nominal wall thickness of pipe 7.8 mm specified by operator

MAOP maximum operating pressure 20 bar specified by operator

Pld local design pressure 20 bar specified by operator

ERF estimated repair factor calculated value (result)

safe maximum pressure for corroded

Psafe calculated value (result)

area

SMYS specified minimum yield strength 245 MPa used for calculation

UTS ultimate tensile strength 415 MPa used for calculation

Report Date: MM DD, YYYY page 8 of 19

10” PIPELINE

Final Report

Fig. 8: Sentenced Plot

The ERF calculation was executed with Pld =MAOP=20bar. This represents a worst-case

scenario in which every indication in the pipeline results in an ERF of 1.

The target of 3P Services’ inspection is to supply data on metal loss features: location

(internal/external, axial and circumferential) as well as dimension (depth, length and width).

Development of integrity criteria out of this data is not part of 3P Services’ scope of work.

Elaboration of a repair strategy, setting new operating pressure levels etc. are part of what is

called “Fitness-For-Purpose” (FFP), which is not addressed in this report.

However, for practical reasons, some elementary calculations are made, using the interpreted

feature depth and length values. The calculations yield “Estimated Repair Factor” (ERF) and

Psafe numbers, which are based on formulae included in the standards outlined in the Att. 3.

Note that these figures may only be used for statistical purposes and give a general support

to estimate the condition of the pipeline. These values do not replace any aspect of a FFP

study.

Report Date: MM DD, YYYY page 9 of 19

10” PIPELINE

Final Report

2.5 Other features

The signals of these other features may be more or less typical, which introduces a degree of

uncertainty in characterization. If such uncertainties leave a risk that the identification may be

incorrect and the feature may involve metal loss instead, then this will be noted. As a

contingency for such a case, especially if potentially significant metal loss depth may be

present, a “contingency depth” is reported in the Feature List. It is shaded grey and only

applicable if our descriptions in the following paragraphs should be incorrect.

2.5.1 Mill anomalies

35 mill anomalies are detected, which probably arise during manufacturing process of the

pipeline, as for instance non-metallic inclusion, rollmark or possible lamination.

The most significant ones are located at 15m and 345m with a contingency depth of 18%.

Fig. 9: Distribution of mill anomalies over pipeline length and circumference

Report Date: MM DD, YYYY page 10 of 19

10” PIPELINE

Final Report

2.5.2 Girth weld anomalies

Three girth welds show irregularities which probably derive from the welding process, like e.g.

root penetration larger than usual.

One of them is reported as ‘incomplete root’. These anomalies are reported with length and

width as well as a severity category as following:

A -

(significant)

B -

(medium)

C 1

(minor)

total 1

Fig. 10: Distribution of girth weld anomalies over pipeline length and circumference

Report Date: MM DD, YYYY page 11 of 19

10” PIPELINE

Final Report

2.5.3 Geometric anomalies

There are 20 geometric anomalies reported. The deepest one is reported with 1.8% reduction

(relative to the outer diameter of the pipe [POF09][API1163]) at 1604m, 195m upstream of

marker M5. The remaining 19 are reported as minor dents with a reduction <1.5%.

Fig. 11: Distribution of possible geometric anomalies over pipeline length and circumference

2.6 Marker

In total five AGMs (Above Ground Marker) were placed on the pipeline. The locations of all of

them were defined by 3P Services. All of the marker were recorded. For detailed information

please refer to Att.7.

2.7 Data deliverables

2.7.1 Raw data

Attached to this report is the processed raw data together with a single-user license of the 3P

visualisation software (PipeAnalysis). It enables the Client to scroll through the pipeline,

enlarge sections of special interest, print out screen shots and dig sheets as required. This

software does not allow independent quantitative interpretations.

Raw data and software are stored on a USB stick. This further has an installation aid and a

user handbook.

2.7.2 Interpreted data

The main supporting document is the Pipe Book, which is attached to this report as an Excel

file. It includes tables containing all findings resulting from the pipeline inspection. This

document can be used by the Client to incorporate these results into its own pipeline

documentation system, e.g. GIS or other.

Throughout the Pipe Book abbreviations are used, mainly for feature type, identification and

classification. These follow the definitions as recommended by the “Pipeline Operator Forum”

[POF09]. Detailed information is placed as 1st page on each attachment.

Report Date: MM DD, YYYY page 12 of 19

10” PIPELINE

Final Report

3 Pipeline Data

Pipeline name 10" PIPELINE

Launcher location START

Receiver location END

Nominal diameter 10”

Outer diameter 273.1mm

Length ~1800m

Specified by operator

Wall thickness 7.8mm

Type of the pipe seamless

Pipe Grade API 5L / Gr. B

Min. bend radius ≥3D

Product oil

4 Inspection preparation & performance

4.1 Inspection task

Target of the inspection campaign was to determine metal loss in the pipeline to assess the

integrity of the pipeline.

4.2 Preparation of the pipeline

4.2.1 Inspection procedure

3P Services provided pig traps which were installed as temporary launcher and receiver on

site.

Fig. 12: Pig trap before installation as temporary launcher

Report Date: MM DD, YYYY page 13 of 19

10” PIPELINE

Final Report

4.2.2 Cleaning and Gauging of the pipeline

To be sure the pipeline is clean enough for the inspection and capable for the MFL tool a 3P

profile tool was applied MMM DD, YYYY.

Run no. #1

Tool function profile

multi module tool with gauge plate

Type

and transmitter

Manufacturer 3P Services

Gauge plate diameter 218mm / 141mm / 190mm

Run by 3P Services

Run date MMM DD, YYYY

Total run time [hh:mm] 00:42

Average tool speed ~0.71m/s

Propelled by water

Tool performance (wear/debris) normal wear / less debris

Gauge plate performance light deformation

Result OK for GEO

Fig. 13: Profile tool with gauge plates and transmitter after run

4.3 High Resolution GEO Inspection

4.3.1 GEO tool applied

The GEO tool is a tool developed by 3P Services for high resolution inspection of geometric

discontinuities such as dents, ovalities and other restrictions of the pipe bore. Details

regarding the GEO tool specification and general features of the measuring principle can be

found in Att. 1.

Report Date: MM DD, YYYY page 14 of 19

10” PIPELINE

Final Report

4.3.2 GEO tool settings

Type of tool GEO/DMR

Tool version 10” ATEX UNI GEO/DMR 3D Vers.9.8

Type of sensors GEO DMR [WallGuided]

No. of sensors 16 24

Sensor spacing on the circumference 52mm 33.1mm

Sampling frequency 400Hz

[per sensor]

Envisaged sampling distance 2.50mm

[per sensor]

No. of odometers 2

diameter of the odometer wheel 70mm

IP address 172.20.10.84

4.3.3 GEO tool performance

Run no. #2

Date of inspection MMM DD, YYYY

Launch time [local time] hh:mm

Receiving time [local time] hh:mm

Total run time [hh:mm] hh:mm

Measured total distance 1804m

Calculated average tool speed 0.69m/s

Maximum tool speed 1.83m/s at 16.12m

Propelled by water

Tool performance debris recovered

Result successful, OK for MFL

Fig. 14: GEO tool after run

Report Date: MM DD, YYYY page 15 of 19

10” PIPELINE

Final Report

Fig. 15: Speed profile of the GEO run

Fig. 16: Deviation chart of the internal measured minimum diameter of the pipeline

Report Date: MM DD, YYYY page 16 of 19

10” PIPELINE

Final Report

4.4 High Resolution MFL-Inspection

4.4.1 MFL tool applied

The tool is a high resolution MFL (magnetic flux leakage) system developed by 3P Services.

Details regarding the tool specification and general features of the measuring principle can be

found in Att. 1.

4.4.2 MFL tool settings

Type of tool MFL

Tool version 10” ATEX UNI MFL 3D Ves.10.3

Type of sensors MFL

No. of sensors 64

Sensor distance on the circumference 12mm

Sampling frequency [per sensor] 400Hz

Envisaged sampling distance [per 2.5mm

sensor]

No. of odometers 2

Diameter of odometers 70mm

IP addresses 172.20.10.91

4.4.3 MFL tool performance

Run no. #3

Date of inspection MMM DD, YYYY

Launch time [local time] hh:mm

Receiving time [local time] hh:mm

Total run time [hh:mm] hh:mm

Measured total distance 1814m

Calculated average tool speed 0.73m/s

Maximum tool speed 0.88m/s at 15.58m

Propelled by water

Tool performance good

Result successful

Report Date: MM DD, YYYY page 17 of 19

10” PIPELINE

Final Report

Fig. 17: MFL-tool after the run

Fig. 18: Speed profile of the MFL run

Report Date: MM DD, YYYY page 18 of 19

10” PIPELINE

Final Report

5 Attachments

1. Tool specifications & System properties

2. Preliminary Reports

3. Remaining Strength Calculations

4. Pipe Tally

5. Feature List

6. Installation List

7. Marker List

8. Tool Calibration Certificate

6 Reference Specifications, Codes and Standards

[POF09] Pipeline Operator Forum [POF] - Specifications and requirements for

intelligent pig inspection of pipelines, Version 2009

[API1163] API STD 1163 - In-Line Inspection Systems Qualification Standards

[GESIP 07.05] Groupe d'Étude de Sécurité des Industries Pétrolières et Chimiques

[GESIP] – Surveillance, Maintenance et Reparation des Canalisations

de Transport

7 Report Details

ReportNo.:

ProposalNo.:

ContractNo.:

JobProjectNo.:

Contacts

Project Coordinator:

Inspection team:

Author / Analyst:

Approver:

3P Services GmbH & Co. KG

Meitnerstr. 10-12 - 49835 Wietmarschen/Lohne - Germany

phone +49 5908 2656-0

www.3p-services.com

Report Date: MM DD, YYYY page 19 of 19

You might also like

- PA-CATTM Measures Metal Loss at Pipe Supports Using Phased ArrayDocument12 pagesPA-CATTM Measures Metal Loss at Pipe Supports Using Phased ArrayPetrNo ratings yet

- ECTDocument17 pagesECTvikramNo ratings yet

- IRISDocument67 pagesIRISArinze7No ratings yet

- IRTS NDT in Service Corrosion Mapping Procedure Revision 1Document11 pagesIRTS NDT in Service Corrosion Mapping Procedure Revision 1PeterNo ratings yet

- CN-11-Section 11 Teletest Functional Tests and Troubleshooting Rev0.1Document18 pagesCN-11-Section 11 Teletest Functional Tests and Troubleshooting Rev0.1Tĩnh Hồ TrungNo ratings yet

- Silverwing Scorpion2 Swift Robotic Tank Shell Inspection 1 01 PDFDocument4 pagesSilverwing Scorpion2 Swift Robotic Tank Shell Inspection 1 01 PDFBladimir OviedoNo ratings yet

- Ipc2022-87151 Advanced Non-Destructive Methods For Defect Characterization UnderDocument7 pagesIpc2022-87151 Advanced Non-Destructive Methods For Defect Characterization UnderOswaldo MontenegroNo ratings yet

- Al-Iris E-25a-02-003 PDFDocument12 pagesAl-Iris E-25a-02-003 PDFHao TranNo ratings yet

- CMAP Reporting - Operating ManualDocument46 pagesCMAP Reporting - Operating ManualJesus E ContrerasNo ratings yet

- Sims Tank Inspection SoftwareDocument4 pagesSims Tank Inspection SoftwareWilmer CarrascoNo ratings yet

- ANDT InspectionsDocument98 pagesANDT InspectionsHerris SimamoraNo ratings yet

- IRIS SetupDocument32 pagesIRIS SetupAqib AliNo ratings yet

- ACFM® & TSC Products OverviewDocument27 pagesACFM® & TSC Products OverviewStu SutcliffeNo ratings yet

- CN-5-Section 5 Introduction To The Teletest Software Rev0.1Document34 pagesCN-5-Section 5 Introduction To The Teletest Software Rev0.1Tĩnh Hồ TrungNo ratings yet

- Phased Array Probes Application MatrixDocument1 pagePhased Array Probes Application MatrixFethi BELOUISNo ratings yet

- Corrosion & Erosion: Inspection Solutions For Detection, Sizing & MonitoringDocument15 pagesCorrosion & Erosion: Inspection Solutions For Detection, Sizing & MonitoringMohd Azrul AzmanNo ratings yet

- Automated Robotic InspectionDocument6 pagesAutomated Robotic Inspectionprakush01975225403No ratings yet

- High Temperature Ultrasonic ScanningDocument7 pagesHigh Temperature Ultrasonic ScanningscribdmustaphaNo ratings yet

- Level IiiDocument3 pagesLevel IiiMangalraj MadasamyNo ratings yet

- IRTS Pulsed Eddy Current Testing Work ProcedureDocument10 pagesIRTS Pulsed Eddy Current Testing Work ProcedurePeterNo ratings yet

- Rms Auto Ut Corrosion Mapping PDFDocument6 pagesRms Auto Ut Corrosion Mapping PDFSangeeth Kavil PNo ratings yet

- IrisDocument16 pagesIrisvibinkumarsNo ratings yet

- Proc. For Radiographic Profile Thk. MeasurementDocument7 pagesProc. For Radiographic Profile Thk. MeasurementSergey KichenkoNo ratings yet

- NDT in Canada 2017 Olivier LavoieDocument20 pagesNDT in Canada 2017 Olivier LavoieChandrashekhar ThiramdasuNo ratings yet

- Omniscan Setup - Basic SetupDocument29 pagesOmniscan Setup - Basic SetupcarlosNo ratings yet

- Corrosion Mapping Solutions EddyfiDocument4 pagesCorrosion Mapping Solutions EddyfiTHIRU.SNo ratings yet

- Advances in Tube Testing 2008Document39 pagesAdvances in Tube Testing 2008AhmedA.HassanNo ratings yet

- Si EvertDocument4 pagesSi EvertLaxmikant TiwariNo ratings yet

- Advanced Inspection - Magnetic Flux Leakage (MFL) Tank InspectionDocument2 pagesAdvanced Inspection - Magnetic Flux Leakage (MFL) Tank InspectionVajid MadathilNo ratings yet

- Feritscope FMP30 Measurement of The Ferrite Content in Austenitic and Duplex SteelDocument8 pagesFeritscope FMP30 Measurement of The Ferrite Content in Austenitic and Duplex SteelBiju_PottayilNo ratings yet

- HTHA - Relatório SGS PDFDocument231 pagesHTHA - Relatório SGS PDFlgustavocoelhoNo ratings yet

- Technology - Magnetic Eddy Current MEC Inspection TechniqueDocument12 pagesTechnology - Magnetic Eddy Current MEC Inspection TechniqueCepi Sindang KamulanNo ratings yet

- Plant Integrity BookletDocument79 pagesPlant Integrity Bookletkihal zohirNo ratings yet

- ARTICLE - Remote Visual Inspection Basics (2010)Document3 pagesARTICLE - Remote Visual Inspection Basics (2010)Sangameswaran RamarajNo ratings yet

- HSE - Recommended Practice For MFLDocument108 pagesHSE - Recommended Practice For MFLMoisés MonteiroNo ratings yet

- Electromagnetic Acoustic Transducers (Emats) : Standard Guide ForDocument8 pagesElectromagnetic Acoustic Transducers (Emats) : Standard Guide ForEric GozzerNo ratings yet

- NDT ServicesDocument4 pagesNDT ServicesAdnan RanaNo ratings yet

- DLA Corrosion Probe en 201608 WebDocument2 pagesDLA Corrosion Probe en 201608 WebDennis ChaiNo ratings yet

- Pipescan MFL Pipe InspectionDocument4 pagesPipescan MFL Pipe InspectionRICARDO3454No ratings yet

- Phased Array Ultrasonic Techniques For Detection, Characterization and Sizing of High Temperature Hydrogen AttackDocument11 pagesPhased Array Ultrasonic Techniques For Detection, Characterization and Sizing of High Temperature Hydrogen AttackGetapo Ramin100% (1)

- MFL Tank Cleaning Requirements for InspectionDocument2 pagesMFL Tank Cleaning Requirements for Inspectioncal2_uniNo ratings yet

- Positive Material Identification (Pmi)Document2 pagesPositive Material Identification (Pmi)MurugadossRajendranNo ratings yet

- Fast, Reliable Pipe Scanner Detects CorrosionDocument4 pagesFast, Reliable Pipe Scanner Detects CorrosionJoseph MidouNo ratings yet

- Experienced NDT engineer CVDocument6 pagesExperienced NDT engineer CVTrung Tinh HoNo ratings yet

- 015 Emat Slofec TechniqueDocument9 pages015 Emat Slofec TechniquejasminneeNo ratings yet

- BPF-V-270 Test Separator-Cm-Pvir-Xxxxx-20Document32 pagesBPF-V-270 Test Separator-Cm-Pvir-Xxxxx-20Agung Prastyo WibowoNo ratings yet

- NDT and IRIS Status RCON SD 2015extractedDocument9 pagesNDT and IRIS Status RCON SD 2015extractedWIZKHALIFA100% (1)

- EMAT CatalogDocument4 pagesEMAT CatalogcanakyuzNo ratings yet

- 10 003591 01EN FlexoFORM User PDFDocument86 pages10 003591 01EN FlexoFORM User PDFSabino LaraNo ratings yet

- IRIS Parts - enDocument2 pagesIRIS Parts - enbenergy84No ratings yet

- Small Diameter Tube and Pipe Inspection With Phased Array PDFDocument7 pagesSmall Diameter Tube and Pipe Inspection With Phased Array PDFAlanka PrasadNo ratings yet

- 16" MFL-DMR Vers.15.15: ILI Tool Data SheetDocument3 pages16" MFL-DMR Vers.15.15: ILI Tool Data SheetJudo HardiantoNo ratings yet

- Info Sheet Iris Inspection of TubesDocument2 pagesInfo Sheet Iris Inspection of TubesCepi Sindang KamulanNo ratings yet

- Conventional and Phased Array UT Weld Application GuideDocument20 pagesConventional and Phased Array UT Weld Application Guidepokeboy19No ratings yet

- Instruction IRIS Tube Inspection EngDocument47 pagesInstruction IRIS Tube Inspection EngVasilyNo ratings yet

- ECT Inspection Technique: Setup and CalibrationDocument19 pagesECT Inspection Technique: Setup and CalibrationAbhishek DevarajNo ratings yet

- d01c25e978d2f79c771828530390SHIPPING CI PDocument1 paged01c25e978d2f79c771828530390SHIPPING CI PsaminasritnNo ratings yet

- STG2-40 100psi AirCooled 04 11 2016Document1 pageSTG2-40 100psi AirCooled 04 11 2016saminasritnNo ratings yet

- Pip 686aDocument8 pagesPip 686asaminasritn50% (2)

- ERFIFRANCE English Catalog PDFDocument111 pagesERFIFRANCE English Catalog PDFsaminasritnNo ratings yet

- Test Equipment 2 (Accbe) Answer KeyDocument1 pageTest Equipment 2 (Accbe) Answer KeysaminasritnNo ratings yet

- 336 AcDocument172 pages336 AcsaminasritnNo ratings yet

- 2.11 FinalReport MFL-DMR-GEO EXAMPLE PDFDocument19 pages2.11 FinalReport MFL-DMR-GEO EXAMPLE PDFsaminasritnNo ratings yet

- Drawer 75 MM Wall For 2940B Cabinet - 2940B-75: DescriptionDocument1 pageDrawer 75 MM Wall For 2940B Cabinet - 2940B-75: DescriptionsaminasritnNo ratings yet

- VCXT ™ Data Sheet: Debtor in PossessionDocument2 pagesVCXT ™ Data Sheet: Debtor in PossessionsaminasritnNo ratings yet

- Attachement E-Square Catalogue PDFDocument225 pagesAttachement E-Square Catalogue PDFsaminasritnNo ratings yet

- Understanding Major Accident HazardsDocument15 pagesUnderstanding Major Accident HazardssaminasritnNo ratings yet

- Natural Gas Knowledge Series - Laying Natural Gas PipelineDocument15 pagesNatural Gas Knowledge Series - Laying Natural Gas PipelineswordprincesNo ratings yet

- Problems With B16.5 and B16.47 Flange StandardsDocument1 pageProblems With B16.5 and B16.47 Flange StandardsManohar SeetharamNo ratings yet

- 6604 Issue 2 Testing of Insulating JointsDocument5 pages6604 Issue 2 Testing of Insulating Jointssaminasritn100% (1)

- GPT 1-9CasingSpacerManual OCT2013 LR en-NA 21Document2 pagesGPT 1-9CasingSpacerManual OCT2013 LR en-NA 21saminasritnNo ratings yet

- Paper20508 5121Document5 pagesPaper20508 5121saminasritnNo ratings yet

- Commissionning of Atlantic LNG Plant-PassingthebatonDocument12 pagesCommissionning of Atlantic LNG Plant-Passingthebatonsaminasritn100% (1)

- Energies 05 03892Document16 pagesEnergies 05 03892Daodu Olugbenga OlusegunNo ratings yet

- Integration of Major Liquefaction Units Within Existing Import TerminalsDocument8 pagesIntegration of Major Liquefaction Units Within Existing Import TerminalshortalemosNo ratings yet

- EE37 PPR ET 1919 0032 Rev 1 - Drying - Purge ProcedureDocument7 pagesEE37 PPR ET 1919 0032 Rev 1 - Drying - Purge ProceduresaminasritnNo ratings yet

- Offshore LNG Loading Problem SolvedDocument13 pagesOffshore LNG Loading Problem SolvedpriyoNo ratings yet

- Operation LNG TankDocument4 pagesOperation LNG TankpramodtryNo ratings yet

- PE Pipe Joining Procedures PDFDocument31 pagesPE Pipe Joining Procedures PDFymessaoudNo ratings yet

- Measuring Equipment Calibration Project InstructionsDocument3 pagesMeasuring Equipment Calibration Project InstructionssaminasritnNo ratings yet

- Typrical Piping TCCIDocument18 pagesTyprical Piping TCCIsaminasritnNo ratings yet

- Support Pipng TechnipDocument23 pagesSupport Pipng TechnipsaminasritnNo ratings yet

- G. Spare Parts ManagementDocument12 pagesG. Spare Parts ManagementVipul TikekarNo ratings yet

- Material Class ChevronDocument29 pagesMaterial Class ChevronsaminasritnNo ratings yet

- Corrosion Protection Under Insulation: PanoramaDocument4 pagesCorrosion Protection Under Insulation: PanoramasaminasritnNo ratings yet

- 5102024-00A Relay Kit Workboat 11 1 MEDocument2 pages5102024-00A Relay Kit Workboat 11 1 MEPatrickNo ratings yet

- How To Enable DHCP On MikroTik WinboxDocument2 pagesHow To Enable DHCP On MikroTik WinboxNikola DukicNo ratings yet

- Cambridge Assessment International Education: Computer Science 2210/13 October/November 2019Document14 pagesCambridge Assessment International Education: Computer Science 2210/13 October/November 2019Sarim JavedNo ratings yet

- History of The InternetDocument3 pagesHistory of The InternetAngelly V Velasco100% (1)

- Librosa - Audio and Music Signal Analysis in Python SCIPY 2015Document7 pagesLibrosa - Audio and Music Signal Analysis in Python SCIPY 2015Kate ZenNo ratings yet

- Graphing Polynomial FunctionsDocument30 pagesGraphing Polynomial FunctionsJean Aristonet Woods LeysonNo ratings yet

- ReceiptDocument2 pagesReceiptshaikh rehmanNo ratings yet

- محاضرة اختبار صلاحية تدريسDocument8 pagesمحاضرة اختبار صلاحية تدريسZiad Qais100% (1)

- Ece4009 - Wireless and Mobile Communication Review 2 Group Members Slot 1. 2. 3. TitleDocument10 pagesEce4009 - Wireless and Mobile Communication Review 2 Group Members Slot 1. 2. 3. TitledwijaNo ratings yet

- By 228-Damper DiodeDocument7 pagesBy 228-Damper DiodefrarainsNo ratings yet

- GSI Geological Survey Map PortalDocument2 pagesGSI Geological Survey Map PortalPraveen KumarNo ratings yet

- Hawk Eye TechnologyDocument14 pagesHawk Eye TechnologyDerrick MillerNo ratings yet

- Full Stack Java Developer ResumeDocument7 pagesFull Stack Java Developer Resumevitig2No ratings yet

- Daikin Inverter Air Cooled Screw ChillerDocument14 pagesDaikin Inverter Air Cooled Screw Chillerfiqrinovel100% (1)

- Thales Sophie LR-1Document15 pagesThales Sophie LR-1ashfaqNo ratings yet

- U2 Activity1 A-BDocument2 pagesU2 Activity1 A-BFELIX ROBERT VALENZUELANo ratings yet

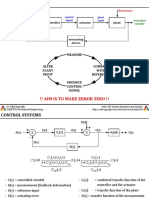

- CONTROL SYSTEMS: MINIMIZING ERRORSDocument11 pagesCONTROL SYSTEMS: MINIMIZING ERRORScapturemrahNo ratings yet

- Introduction To SageERPX31Document33 pagesIntroduction To SageERPX31Usman Khan100% (1)

- Real Estate Market Data Scraping and Analysis For Financial InvestmentsDocument67 pagesReal Estate Market Data Scraping and Analysis For Financial InvestmentsAgnaldo BenvenhoNo ratings yet

- Omnithreadlibrary SampleDocument85 pagesOmnithreadlibrary SamplePablo Ernesto Vigneaux WiltonNo ratings yet

- Custom Storage ClassesDocument2 pagesCustom Storage ClassesSameer KumthekarNo ratings yet

- E360 BrosurDocument6 pagesE360 BrosurPutra DalimaNo ratings yet

- The Best Web App To Convert JPG To PDFDocument1 pageThe Best Web App To Convert JPG To PDFJekly MoningkaNo ratings yet

- Software Project Management 4th Edition: Selection of An Appropriate Project ApproachDocument14 pagesSoftware Project Management 4th Edition: Selection of An Appropriate Project ApproachSudha KarNo ratings yet

- COMPARISON OF SORTING TECHNIQUES FOR DYNAMIC DATADocument40 pagesCOMPARISON OF SORTING TECHNIQUES FOR DYNAMIC DATAZubair AhmadNo ratings yet

- CHRMP Generative AI Sept 2023 1Document19 pagesCHRMP Generative AI Sept 2023 1shajmalikNo ratings yet

- GeorgeMagazine - February1997 - SurvivalGuideToTheFuture - Bill - Gates - Interview - CopieDocument18 pagesGeorgeMagazine - February1997 - SurvivalGuideToTheFuture - Bill - Gates - Interview - CopieYoBjj100% (3)

- Final MALIWALO CENTRAL ES BE-LCOP 2021-2022Document123 pagesFinal MALIWALO CENTRAL ES BE-LCOP 2021-2022Teng Sevilla0% (1)

- Dashboard Design LayoutDocument6 pagesDashboard Design Layoutluis anchayhua pradoNo ratings yet

- (FE) Hax GuiDocument5 pages(FE) Hax GuiSogeki LeeNo ratings yet